s Engineering Guide

R

W

S

erie

s

iGid

RW Series

Commercial Reversible Chiller - 60 Hz

• 10-50 Tons

9LQWDJH'

Design Features

Factory Options

Accessories

Dim

ensional Data

Ph

ysical Data

Performance Data

En

g

ineerin

g

G

uide

S

peci

fi

cations

Form: 146.00-EG6A (0614)

Supersedes: 146.00-EG6A (0314)

R

W

S

ERIE

S

REVER

S

IBLE

C

HILLER

S

PE

C

IFI

C

ATI

O

N

C

ATAL

OG

T

able of Contents

N

o

m

e

n

c

l

a

t

u

r

e

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4

AHRI D

a

t

a

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

5

-

6

The RW

S

eries

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

7-

8

Inside the RW

S

eries

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

9

-1

1

C

ontrols

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

12-1

5

R

W

S

eries Application Notes

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

6

-1

7

Water

Q

ualit

y

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

7

S

election Process

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

8

T

y

pical Pipin

g

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

8

-1

9

Ph

y

sical Dimensions

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2

0

-2

1

V

i

b

r

a

ti

o

n I

so

l

a

t

o

r

s

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2

2

Ph

y

sical Data

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2

3

El

ec

tri

ca

l D

a

t

a

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

24

Anti

f

reeze

C

orrection

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2

5

R

e

f

erence

C

alculations

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2

6

Le

g

end and Notes

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2

6

Pressure Dro

p

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2

7

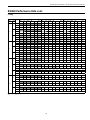

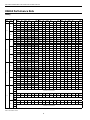

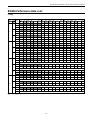

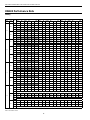

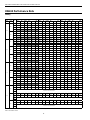

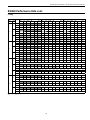

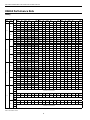

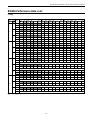

P

e

r

fo

rm

a

n

ce

D

a

t

a

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

2

8

-

37

Wirin

g

S

chematics

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

38

-

39

En

g

ineerin

g

G

uide

S

peci

f

ications

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4

0

-4

3

R

evision

G

uid

e

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4

5

4

R

W

S

ERIE

S

REVER

S

IBLE

C

HILLER

S

PE

C

IFI

C

ATI

O

N

C

ATAL

OG

M

odel Nomenclatur

e

All RW

S

eries product is

S

a

f

et

y

listed under UL1995 thru ETL and per

f

ormance tested in accordanc

e

with standard AHRI

/

I

SO

1

3

2

56

-2.

V

olta

g

e Availabilit

y

V

olta

ge

Mode

l

12

0

1

80

24

0

360

600

2

08

-2

30/60/3

•

•

•

•

N

/

A

4

60/60/3

••

••

••

•

•

5

7

5/60/3

•

•

•

•

•

380/60/3

••

N

/

A N

/

A

•

•

03/05/

14

Le

g

end

:

NA = N

o

t Av

a

il

ab

l

e

•

= Volta

g

e available in this siz

e

••

= Volta

g

e and so

f

t start available in this siz

e

RWXW 120 R 3 A E 8 N N

1-4 5-7 8 9 12 13 14

Model

RWXW – RW Series

Reversible Chiller

Unit Capacity (MBTUH)

120, 180, 240, 360, 600

Operation

R - Reversible

Voltage

3 – 208-230/60/3

4 – 460/60/3

5 – 575/60/3

8 – 380/60/3

Phase Protection

A – Non-Fused Disconnect, Phase Guard

B – Non-Fused Disconnect, IntelliStart®

C – Fused Disconnect, Phase Guard

D – Fused Disconnect, IntelliStart

Chassis

E – Enclosed

P – Enclosed with Pressure Gauges

Vintage

Non-Standard

Options

SS

- Standard

Future Option

N – Future Use

Future Option

N – Future Use

Controls

8 – FX10 without Communication,

with User Interface

9 – FX10 with Open N2 Communication

Card with User Interface

0 – FX10 with Lonworks Communication

Card with User Interface

3 – FX10 with BacNet Communication

Card with User Interface

Rev.: 14 February 2014D

SS

15-16

'

17

10 11

Notes:

See electrical availability table for detailed offering by voltage

5

R

W

S

ERIE

S

REVER

S

IBLE

C

HILLER

S

PE

C

IFI

C

ATI

O

N

C

ATAL

OG

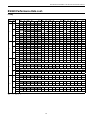

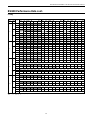

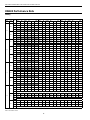

AHRI/ASHRAE/ISO 13256-2 Water-to-Water Ratings

g

E

n

g

lish

(

IP

)

Units

M

ode

l

Capacit

y

M

odulation

Flow Rat

e

Water Loo

p

Heat Pum

p

G

round Water Heat Pum

p

G

round Loo

p

Heat Pum

p

Coolin

g

E

ST 86°F

E

LT 53.

6

o

F

Heatin

g

E

ST 68°F

E

LT 10

4

o

F

Coolin

g

E

ST 59°F

E

LT 53.

6

o

F

Heatin

g

E

ST 50°F

E

LT 10

4

o

F

Coolin

g

Full EST 77°F

P

art EST 6

8

o

F

E

LT 53.

6

o

F

Heatin

g

Full EST 32°F

P

art ELT 4

1

o

F

E

LT 10

4

o

F

S

g

pm

Lg

p

m

Capacit

y

Btuh

E

ER

Btuh

/W

Capacit

y

Btuh

CO

P

Capacit

y

Btuh

E

ER

Btuh

/W

Capacit

y

Btuh

CO

P

Capacit

y

Btuh

E

ER

Btuh

/W

Capacit

y

Btuh

CO

P

120

Full 4

0

4

0

145,400 1

6

.

0

189,000 4.

5

161,400 22.

5

157,200

3

.

8

147,700 17.

3

118,800

3

.

0

P

ar

t

4

0

4

0

79,300 17.4 101,500

5

.

1

84,400 24.

1

84,600 4.4 82,900 22.

2

69,800

3

.

3

180

Full

60

60

201,300 1

5

.

9

263,700 4.

6

225,100 21.

5

217,000

3

.

9

208,300 17.

2

173,400

3

.

2

P

ar

t

60

60

105,500 17.

0

138,700

5

.

0

177,700 2

3

.

0

112,600 4.

2

115,400 2

0

.

5

100,900

3

.

5

2

40

Full

80

80

265,700 1

6

.

0

347,500 4.

7

306,900 2

3

.4 280,600

3

.

9

275,300 17.

9

219,400

3

.

3

P

ar

t

80

80

140,100 1

6

.

7

182,100

5

.

0

163,600 24.

6

141,400 4.

2

150,000 21.

6

115,800

3

.

5

3

60

Full 12

0

12

0

394,700 1

6

.

0

487,600 4.

3

452,300 22.

1

420,300 4.

0

410,200 17.

5

339,300

3

.

3

P

ar

t

12

0

12

0

206,000 1

6

.

9

256,000 4.

6

241,100 2

3

.

2

214,400 4.

3

223,200 21.

2

183,500

3

.

7

600

Full 2

00

2

00

602,000 1

5

.

2

798,000 4.

3

756,000 1

9

.

9

622,000 4.

0

633,000 1

6

.

5

533,100

3

.4

P

ar

t

2

00

2

00

313,300 1

6

.

1

419,000 4.

6

407,000 2

0

.

9

318,000 4.

3

376,000 1

9

.

6

303,900

3

.

7

3/5/

14

6

R

W

S

ERIE

S

REVER

S

IBLE

C

HILLER

S

PE

C

IFI

C

ATI

O

N

C

ATAL

OG

The per

f

ormance standard AHRI

/

A

S

HRAE

/

I

SO

13256-2 became e

ff

ective Januar

y

1, 2000. This new standard has three ma

j

or cate

g

ories:

Water Loop,

G

round Water, and

G

round Loop.

U

nit o

f

Measure: The

C

ooling

CO

P

The coolin

g

e

ff

icienc

y

is measured in EER

(

U

S

version measured in Btuh per Watt. The Metric version is measured in a coolin

g

CO

P

(

Watt per Watt

)

similar to the traditional

CO

P measurement.

P

ump Power

C

orrection

C

alculation

Within each model, onl

y

one water

f

low rate is speci

f

ied

f

or all three

g

roups and pumpin

g

Watts are calculated usin

g

the

f

ollowin

g

f

ormula. This additional power is added onto the existin

g

power consumption.

• Pump power correction =

(g

pm x 0.0631

)

x

(

Press Drop x 2990

)

/

30

0

Where

‘g

pm’ is water

f

low in

g

pm and

‘

Press Drop’ is the pressure drop throu

g

h the unit heat exchan

g

er at rated water

f

low in

f

eet o

f

head

.

ISO

C

apacit

y

and E

ff

icienc

y

C

alculation

s

The

f

ollowin

g

equations illustrate coolin

g

calculations

:

• I

SO

C

oolin

g

C

apacit

y

=

C

oolin

g

C

apacit

y

(

Btuh

)

x 3.41

2

• I

SO

EER E

ff

icienc

y

(

W

/

W

)

= I

SO

C

oolin

g

C

apacit

y

(

Btuh

)

x 3.412

/

[Power Input

(

Watts

)

+ Pump Power

C

orrection

(

Watt

)

]

The

f

ollowin

g

equations illustrate heatin

g

calculations

:

• I

SO

Heatin

g

C

apacit

y

= Heatin

g

C

apacit

y

(

Btuh

)

x 3.41

2

• I

SO

CO

P E

ff

icienc

y

(

W

/

W

)

= I

SO

Heatin

g

C

apacit

y

(

Btuh

)

x 3.412

/

[Power Input

(

Watts

)

+ Pump Power

C

orrection

(

Watt

)

]

T

est Conditions

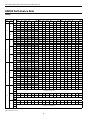

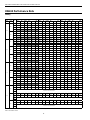

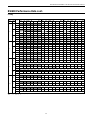

Performance Standard (AHRI/ISO/ASHRAE 13256-2)

()

7A=/6@7

! #$

E:6>

7A=/6@7

! #$

5E6>

7A=/6@7

! #$

5:6>

1]]ZW\U

:W_cWR3\bS`W\U7\R]]`AWRS4

AbO\RO`R@ObW\UBSab

:W_cWR3\bS`W\U6SOb3fQVO\US`4

>O`bZ]OR@ObW\UBSab

:W_cWR3\bS`W\U6SOb3fQVO\US`

4ZcWR4Z]e@ObS

6SObW\U

:W_cWR3\bS`W\U7\R]]`AWRS4

AbO\RO`R@ObW\UBSab

:W_cWR3\bS`W\U=cbR]]`aWRS6SOb3fQVO\US`4

>O`bZ]OR@ObW\UBSab

:W_cWR3\bS`W\U=cbR]]`aWRS6SOb3fQVO\US`

4ZcWR4Z]e@ObS

#!$

&$

&$

"

$&

$&

#!$

#'

#'

"

#

#

#!$

%%

$&

"

!

"

<=B3A(4Z]e`ObSWaa^SQWTWSRPgbVS[O\cTOQbc`S`

E:6>+EObS`:]]^6SOb>c[^)5E6>+5`]c\REObS`6SOb>c[^)

5:6>+5`]c\R:]]^6SOb>c[^

Conversions

Water Flow

(

lps

)

=

G

PM x 0.0631

Press Drop

(

Pascals

)

= Press Drop

(f

t hd

)

x 299

0

R

W

S

ERIE

S

REVER

S

IBLE

C

HILLER

S

PE

C

IFI

C

ATI

O

N

C

ATAL

OG

7

T

he R

W

Series

RWXW Features

D

ual scroll com

p

ressors

p

fo

r

eff

icienc

y

and reliabilit

y

H

H

ea

vy

gau

ge

i

nsulated sheet metal

c

abine

t

t

o

r

educe

no

i

se

Heav

y

g

au

g

e

ste

el

wel

ded

fra

me

to

re

duc

e

vi

b

r

a

ti

on

Small modular

desi

g

n

fo

r

app

lication

f

lexibili

ty

Hig

h efficie

ncy

b

razed

pl

ate heat

e

xchan

g

ers

fo

r

eff

icienc

y

and

c

ompact siz

e

Sta

inl

ess

st

eel

bi

-

dir

ect

ion

al

TXV

fo

r

p

recise superheat

con

tro

l

Full

y

insulated heat

e

xchan

ger

, r

efr

ige

rant

p

ipin

g

, and water lines

to

pre

vent condensation

at reduced

f

luid operatin

g

tem

per

atures

So

p

histicated

m

icro

p

rocessor

c

ontrol with r

obus

t

s

a

f

et

y

controls and

ad

v

a

n

ced

f

r

ee

z

e

de

t

ec

ti

o

n

Fork truck

p

ockets

fo

r

maneuverabilit

y

Factor

y

installed

f

used or non-fused

disconnec

t

t

o

i

so

l

a

t

e

e

lectrical suppl

y

Int

ern

al cla

ss

J

/

CC fusin

g

fo

r

p

rotection o

f

electrical

c

omponents

V

ibration absorbers

a

nd isolation loo

p

s

to miti

g

ate re

f

ri

g

erant

lea

k

s

due

t

o

vi

b

r

a

ti

on

Optional factor

y

i

nstalled

pr

essure

ga

u

ges

8

R

W

S

ERIE

S

REVER

S

IBLE

C

HILLER

S

PE

C

IFI

C

ATI

O

N

C

ATAL

OG

T

he RW Series cont

.

J

ohnson

C

ontrols is proud to announce the up

g

rade o

f

the RW

R

eversible

C

hiller

S

eries with premium e

ffi

cienc

y

, additional

s

a

f

et

y

f

eatures, improved serviceabilit

y

, in a compact

f

ootprint.

This product comes with new electrical

f

eatures such as a

l

ow volta

g

e emer

g

enc

y

stop button,

f

actor

y

mounted, internal

disconnect, and Intelli

S

tart. With internal,

fi

n

g

er-touch

f

usin

g

the RW

S

eries Reversible

C

hiller

S

eries is protected a

g

ainst

l

ar

g

e current

f

aults that ma

y

occur. The control panel was

desi

g

ned with the technician in mind b

y

dividin

g

hi

g

h and low

volta

g

e, a removable, hin

g

ed lockable service door, and plent

y

o

f

space

f

or installation and dia

g

nostics. Additional

f

eatures and

improvements are listed below

:

RW Series Reversible Chiller Hi

g

hli

g

hts

•

C

apacities ran

g

in

g

f

rom 120-600 MBtu

/

h outpu

t

•

C

omplete commercial volta

g

e selection o

f

208-230V

/

60Hz

/

3ph, 460

/

60

/

3, 575

/

60

/

3

•

O

versized brazed plate heat exchan

g

ers o

ff

er hi

g

h e

ffi

cienc

y

with industr

y

low waterside pressure dro

p

• True-dual brazed plate heat exchan

g

ers provide better part

l

oad e

ffi

ciencies compared to two sin

g

le-circuit evaporators

•

C

ompressor suction

/

dischar

g

e tubes come with braided

s

tainless steel vibration absorbers to dampen compressor

vibration on s

y

stem pipin

g

•

H

eav

y

g

au

g

e,

g

alvanized steel enclosure with hin

g

ed access

p

anels that can easil

y

be removed

f

or ease o

f

servic

e

• Fork pockets and li

f

tin

g

points in the

f

rame enable

maneuverabilit

y

f

or installation and shipmen

t

• Factor

y

installed pressure

/

temperature port externall

y

accessible

f

or improved serviceabilit

y

• Low-volta

g

e emer

g

enc

y

stop button disabl

e

c

ompressor operation

• Fin

g

er-touch sa

f

e power

f

uses provide circuit protection

• Primar

y

f

usin

g

to control trans

f

ormer to protect low volta

g

e

c

omponents

f

rom spikes in current

f

aul

t

•

R

u

gg

ed plu

g

assembl

y

wirin

g

harness provides a solid

y

et

s

erviceable connection

f

or control wirin

g

to the control panel.

•

S

hort circuit current ratin

g

up to 100kA with

f

used disconnect

and phase

g

uard optio

n

• Temperature setpoint control

Wide arra

y

o

f

standard

f

actor

y

installed options includin

g:

• Factor

y

mounted, internall

y

wired, rotar

y

-st

y

le,

no

n-

fused

d

i

sco

nn

ect

• 2 1

/

2” dial-t

y

pe re

f

ri

g

erant pressure

g

au

g

es

f

actor

y

mounted below the control panel aid the technician in

sy

stem dia

g

nostics

• FX10

C

ontrols with N2, LonWorks, BA

C

net,

or non-communicatin

g

• Intelli

S

tart reduces compressor in-rush current b

y

40

%

meanwhile reducin

g

mechanical shock on re

f

ri

g

erant

tubin

g

due to hi

g

h motor start-up torque

• Phase

g

uard monitor provides phase reversal, phase

imbalance, and loss o

f

phase protectio

n

9

R

W

S

ERIE

S

REVER

S

IBLE

C

HILLER

S

PE

C

IFI

C

ATI

O

N

C

ATAL

OG

Cabine

t

All unit

f

rames are constructed o

f

heav

y

g

au

g

e steel channel and

p

ainted with a corrosion resistant black, pol

y

ester, powder coat

p

aint. The optional sheet metal cabinets are constructed o

f

heav

y

g

au

g

e

g

alvanized sheet steel painted with white, pol

y

ester, powder

c

oat paint rated at more than a 1,000 hours salt spra

y

ratin

g

. The

f

rame includes

f

ork truck access pockets in two dimensions and

l

i

f

tin

g

points

f

or eas

y

maneuverin

g

durin

g

installation and servicin

g

.

Com

p

ressors

R

eversible chillers use hi

g

h e

ff

icienc

y

R-410A, hermeticall

y

s

ealed, scroll compressors that are mounted on rubber

g

rommets

f

or vibration isolation.

S

croll compressors provide hi

g

h e

ff

icienc

y

while providin

g

g

reater tolerance to liquid re

f

ri

g

erant enterin

g

the

s

uction port.

V

ibration Absorbers

Vibration absorbers are

f

actor

y

installed

on ever

y

compressor suction and

dischar

g

e tube to dampen the vibrations

introduced b

y

compressor on the

r

e

f

ri

g

erant pipin

g

. These absorbers are

c

onstructed

f

rom corru

g

ated copper

tubin

g

wrapped with stainless steel wire

braid to provide stren

g

th and

f

lexibilit

y

.

E

lectrical Bo

x

U

nit controls

f

eature quick connect

wirin

g

harnesses

f

or eas

y

servicin

g

.

S

eparate knockouts

f

or low volta

g

e,

and two

f

or power on two sides

allow eas

y

access to the control

box. A lar

g

e 75VA trans

f

ormer

assures adequate control's power

f

or accessories. Flexible

J

ohnson

C

ontrols FX10 microprocessor

c

ontrol is included,

f

eaturin

g

several

innovations.

S

ee

C

ontrols section

fo

r m

o

r

e

in

fo

rm

a

ti

o

n.

Water Connections

All water line connections are Victaulic

g

rooved nipples

f

or ease

o

f

installation with optional connection kits. Factor

y

installed

thermistors are used on all water lines and can be viewed throu

g

h

the microprocessor inter

f

ace tool. Pressure ports are also added at

the

f

actor

y

f

or eas

y

service access.

Inside the RW Series

T

hermostatic Ex

p

ansion Valv

e

All r

e

v

e

r

s

i

b

l

e

c

hill

e

r

s

u

tiliz

e

ba

l

a

n

ced

p

ort, bi-directional, thermostatic

e

xpansion valves

(

TXV

)

f

or re

f

ri

g

erant

meterin

g

. These valves have

s

tainless steel capillar

y

tube and

bulb

f

or improved robustness over

c

onventional copper sensin

g

capillar

y

l

in

es

. Th

e

v

a

lv

e

co

n

s

i

s

t

s

of

a

l

ase

r-

welded power-head,

f

or

g

ed brass

valve bod

y

and diaphra

g

m optimized

f

or R-410A applications.

This valve desi

g

n allows precise re

f

ri

g

erant

f

low in a wide ran

g

e o

f

e

nterin

g

water variation

g

eothermal s

y

stems.

Water-to-Refri

g

erant Heat Exchan

g

er

Lar

g

e oversized stainless steel

interlaced copper-brazed plate

water-to-re

f

ri

g

erant heat exchan

g

ers

p

rovide unparalleled e

ff

icienc

y

. The

h

eat exchan

g

ers have common

water circuits with isolated re

f

ri

g

erant

c

ircuits so that in part load operation,

the

f

ull mass o

f

the heat exchan

g

er

is utilized. All heat exchan

g

ers are

p

ressure rated to 450 psi water

s

ide and 650 psi re

f

ri

g

erant side. All

h

eat exchan

g

ers, water lines, and

s

uction lines are insulated to prevent

c

ondensation durin

g

low temperature

inlet water operation.

Strainers

All r

e

v

e

r

s

i

b

l

e

c

hill

e

r

s

s

h

a

ll h

a

v

e

a

f

i

e

l

d

-in

s

t

a

ll

ed

s

trainer either Y-t

y

pe or basket t

y

pe.

S

trainers

s

hould be made o

f

a suitable bod

y

such as brass

with

3

1

6

stainless steel screens with a minimum

o

f

60

mesh.

WARNING: Warrant

y

is void if

strainers are not used on the

e

nterin

g

side of the load and source

.

Service Connections and Serviceabilit

y

Two

S

chrader service ports are provided

f

or

e

ach circuit on ever

y

unit. The suction side

and dischar

g

e side ports are

f

or

f

ield char

g

in

g

and servicin

g

access. All valves are 7

/

16”

S

AE connections.

1

0

R

W

S

ERIE

S

REVER

S

IBLE

C

HILLER

S

PE

C

IFI

C

ATI

O

N

C

ATAL

OG

Flow Switch

A

f

low switch or equivalent must be installed on the evaporator

f

or

e

ach unit to be installed. I

f

the unit is to operate as both modes

(

heatin

g/

coolin

g)

, a

f

low switch is needed on both heat exchan

g

ers.

D

ifferential Pressure Switch

A di

ff

erential pressure switch can be used in place o

f

a

f

low switch.

The di

ff

erential switch must be capable o

f

pressure ran

g

e as

indicated in the pressure drop tables.

4

-Wa

y

Reversin

g

Valv

e

R

W units

f

eature a reliable all-brass pilot

operated re

f

ri

g

erant reversin

g

valve.

The reversin

g

valve operation is limited

to chan

g

e o

f

mode b

y

the control to

e

nhance reliabilit

y

.

V

ibration Isolation

U

nits are shipped with heav

y

dut

y

, durometer selected rubber

g

rommets to reduce sound that can be transmitted throu

g

h the

f

loor

via the

f

rame

(

see

g

rommets below

)

. For additional sound attenuation,

optional heav

y

dut

y

sprin

g

isolation can reduce sound levels b

y

3 dBA

(

see sprin

g

s below

)

can be purchased as an accessor

y

.

Cabine

t

All r

e

v

e

r

s

i

b

l

e

c

hill

e

r

f

r

a

m

es

a

r

e

co

n

s

tr

uc

t

ed

o

f

heav

y

g

au

g

e steel channel and painted

with corrosion resistant black, pol

y

ester,

p

ower coat paint. The

f

rame includes

f

ork

truck pockets and li

f

tin

g

points to assist

in maneuverabilit

y

o

f

the product durin

g

in

s

t

a

ll

a

ti

o

n. Th

e

r

e

v

e

r

s

i

b

l

e

c

hill

e

r

s

co

m

e

with

an enclosure that provides additional sound

attenuation, protection o

f

the electrical

and re

f

ri

g

eration s

y

stems, and makes the

p

roduct more aestheticall

y

pleasin

g

. The

e

nclosure is constructed o

f

heav

y

g

au

g

e

Inside the RW Series cont

.

G

rommets Standard

Heav

y

Dut

y

Mountin

g

Sprin

g

s Optional

I

S

-325-01

(

R120-360

)

I

S

-750-01

(

RW600

)

g

alvanized steel painted with

g

ra

y

textured, pol

y

ester, powder

c

oat paint rated at more than 1,000 hours salt spra

y

ratin

g

. The

e

nclosure includes heav

y

dut

y

hin

g

ed doors that can be easil

y

r

emoved

f

or improved serviceabilit

y

.

Control Panel

Re

v

e

r

s

i

b

l

e

c

hill

e

r

co

ntr

o

l

p

anel

f

eatures a heav

y

-

dut

y

, hin

g

ed service door

with

a

co

nv

e

ni

e

nt

use

r

inter

f

ace displa

y

f

or ease

of

se

rvi

ce

a

n

d

in

s

t

a

ll

a

ti

o

n.

The ke

y

ed service door

f

eatures a low volta

g

e

e

mer

g

enc

y

stop button

with an optional

f

actor

y

m

ou

nt

ed

d

i

sco

nn

ec

t

s

wit

c

h. Th

e

l

ef

t int

e

ri

o

r

of

the control panel

f

eatures

h

i

g

h volta

g

e components

suc

h

as

th

e

e

l

ec

tri

ca

l

disconnect,

f

uses, and

c

ompressor contactors.

The ri

g

ht interior o

f

the panel

f

eatures the FX10 main control

board, expansion board, control trans

f

ormer, and 24 VA

C

terminal

s

trip

f

or control wirin

g

. The control panel was desi

g

ned with the

technician in mind to provide convenient, clear wirin

g

with plent

y

o

f

workin

g

space.

E

lectrical Disconnec

t

A

f

actor

y

mounted, internall

y

wired, disconnect is available

to provide electrical isolation

f

rom hi

g

h volta

g

e suppl

y

at

the heat pump.

S

eparate

c

ircuit protection must be

f

ield

installed in the power wirin

g

and must compl

y

with National

Electric

C

ode

(

NE

C)

and

/

o

r l

oca

l

codes

. Di

sco

nn

ec

t

fea

t

u

r

es

in

c

l

ude

:

• Non-

f

used, rotar

y

d

i

sco

nn

ec

t wit

h

“

on

/

o

ff

” positio

n

• Door interlocked, external

p

istol handle keeps door

c

l

osed

wh

e

n

d

i

sco

nn

ect

i

s

“o

n

”

•

“

Lockout

/

Ta

g

out”

f

eature to

keep the unit

“

o

ff”

durin

g

servic

e

•

C

omplies with NE

C

Article 440-14

1

1

R

W

S

ERIE

S

REVER

S

IBLE

C

HILLER

S

PE

C

IFI

C

ATI

O

N

C

ATAL

OG

Short Circuit Current Ratin

g

An optional

f

actor

y

mounted,

f

used disconnect provides the

s

ame bene

f

its as the non-

f

used version

y

et increases the short

c

ircuit current ratin

g

,

SCC

R to compl

y

with buildin

g

s with a hi

g

h

available

f

ault current. Addin

g

the

f

used disconnect option ensures

the equipment will compl

y

with NE

C

Article 409.

S

eparate circuit

p

rotection must be

f

ield installed in the power wirin

g

and must

c

ompl

y

with National Electric

C

ode

(

NE

C)

and

/

or local codes.

Di

sco

nn

ec

t

fea

t

u

r

es

in

c

l

ude

:

• Increases

SCC

R to 1

00

kA

• Door interlocked, external pistol handle keeps door closed

wh

e

n

d

i

sco

nn

ec

t i

s

“o

n

”

•

“

Lockout

/

Ta

g

out”

f

eature to keep the unit

“

o

ff”

durin

g

servic

e

•

C

omplies with NE

C

Article 440-14

•

C

omplies with NE

C

Article 409

f

or

S

hort

C

ircui

t

C

urrent Ratin

g

E

mer

g

enc

y

Stop

R

eversible chillers

f

eature a low-volta

g

e,

twist-release emer

g

enc

y

stop button that is

wired to the emer

g

enc

y

shutdown input on

the FX1

0

main control board. This

f

eature

e

nables the technician to immediatel

y

stop

operation o

f

the heat pump without shuttin

g

o

ff

the hi

g

h volta

g

e suppl

y

.

IntelliStar

t

The optional Intelli

S

tart three-

p

hase so

f

t starter will reduce

the normal start current

(

LRA

)

b

y

40

%

. Usin

g

Intelli

S

tart also

p

rovides a substantial reduction in

vibration, reduces startup noise,

and improves the compressor's

s

tart behavior.

(

Available on

R

W120-240, 460

/

60

/

3 units onl

y)

P

hase Guard

Factor

y

mounted phase

g

uard device is available to protec

t

the compressor a

g

ainst loss o

f

phase, reverse rotation, or

p

hase imbalance.

Com

p

ressor Protection Modul

e

M

odel size 600 come with external compressor protection module

that provides additional motor protection such as reverse phase

detection and a pre-wire thermistor. All other models have internal

overload protection without reverse phase detection.

Inside the RW Series cont

.

Fuses

Re

v

e

r

s

i

b

l

e

c

hill

e

r

s

co

m

e

with

n

on-indicatin

g

C

UBEFuse

which is a

f

in

g

er-sa

f

e,

time-dela

y

, power

f

use with

a small

f

ootprint,

C

lass

J

ratin

g

, and have hi

g

h

f

ault interruptin

g

ratin

g

.

CU

BEFuse includes dual-

e

l

e

m

e

nt

fuse

co

n

s

tr

uc

ti

o

n

th

a

t

ca

n with

s

t

a

n

d

inr

us

h

c

urrent

y

et still allow low let-

throu

g

h currents durin

g

a

f

ault condition.

1

2

R

W

S

ERIE

S

REVER

S

IBLE

C

HILLER

S

PE

C

IFI

C

ATI

O

N

C

ATAL

OG

FX10 Microprocessor and BAS S

y

ste

m

Standard Features

• Anti

S

hort

Cy

cl

e

•

H

i

g

h Pressure Protectio

n

•L

o

w Pr

essu

r

e

Pr

o

t

ec

ti

on

•Fr

ee

z

e

D

e

t

ec

ti

on

• Loss o

f

C

har

g

e Detectio

n

•

R

andom

S

tar

t

• Displa

y

f

or dia

g

nostics

•

R

eset Lockout at disconnect or throu

g

h BA

S

• 1 Accessor

y

outputs

•

O

ptional BA

S

add-on controls

•

C

ompressor Lead

/

La

g

• Temperature setpoint control

D

DC O

p

eration & Connection

O

ther optional network protocol boards that can be added to the

FX1

0

are

:

•

J

ohnson

C

ontrol N

2

•L

o

nW

o

rk

s

•BA

C

ne

t

- M

S/

TP

@

19,200 Baud rat

e

- Limit devices to 30 on a sin

g

le trunk line.

Control and Safet

y

Feature Details

E

mer

g

enc

y

Shutdown

The emer

g

enc

y

shutdown mode can be activated b

y

a command

f

rom a

f

acilit

y

mana

g

ement s

y

stem or a closed contact on BI-2.

The de

f

ault state

f

or the emer

g

enc

y

shutdown data point is o

ff

.

When the emer

g

enc

y

shutdown mode is activated, all outputs will

be turned o

ff

immediatel

y

and will remain o

ff

until the emer

g

enc

y

s

hutdown mode is de-activated. The

fi

rst time the compressor

s

tarts a

f

ter the emer

g

enc

y

shutdown mode has been de-activated,

there will be a random start dela

y

present.

L

ockout Mod

e

Lockout mode can be activated b

y

an

y

o

f

the

f

ollowin

g

f

ault

s

i

g

nals: re

f

ri

g

erant s

y

stem hi

g

h pressure, re

f

ri

g

erant s

y

stem

l

ow pressure, heatin

g

f

reeze detection, coolin

g

f

reeze detection,

and compressor current sensor.

When an

y

valid

f

ault si

g

nal

r

emains continuousl

y

active

f

or the len

g

th o

f

its reco

g

nition dela

y

,

the controller will

g

o into

f

ault retr

y

mode, which will turn o

ff

both compressors. A

f

ter the compressor short c

y

cle dela

y

, the

c

ompressors will attempt to operate once a

g

ain. I

f

three consecutive

f

aults occur in 60 minutes, the unit will

g

o into lockout mode, turnin

g

o

ff

the compressor

(

s

)

, enablin

g

the alarm output until the controller

is reset. I

f

the control

f

aults due to the low pressure input bein

g

open durin

g

the pre-compressor startup check, the control will

g

o

into lockout mode immediatel

y

, disablin

g

the compressors

f

rom

s

tartin

g

and enablin

g

the alarm output. The lockout condition can be

r

eset b

y

powerin

g

down the controller, b

y

a command

f

rom the BA

S

,

or b

y

the holdin

g

the E

SC

and Return ke

y

s on the user inter

f

ace

f

or

5

seconds. N

O

TE:

S

ee freeze detection section for more detail.

Controls - FX10

M

ai

n

n

FX 10 Boa

rd

D

ispla

y

(

Medium User Interface - MUI

)

O

ne local displa

y

is standard on all units. Up to 2 displa

y

s, either 1

l

ocal and 1 remote, or 2 remote.

(

A 2-displa

y

con

fi

g

uration requires

identical displa

y

s.

)

Local displa

y

can be up to 3 meters from the

c

ontroller, power suppl

y

, and data communication. Remote displa

y

c

an be up to 300 meters

f

rom the controller. Remote displa

y

must

be independentl

y

powered with data communication done via 3

p

ole shielded cable.

Control Timin

g

& Fault Reco

g

nition Dela

y

s

Lead compressor

“O

N” dela

y

.........................................

90

seconds

M

inimum compressor

“O

N” tim

e

........................................

5

minutes

(

except

f

or

f

ault condition

)

S

hort c

y

cle dela

y

...............................................................

5

minutes

R

andom start dela

y

...................................................

0

-12

0

seconds

H

i

g

h pressure

f

aul

t

...........................................................

<

1

seco

n

d

Low pressure

f

aul

t

..........................................................

30

seconds

Fr

ee

z

e

de

t

ec

ti

o

n

fau

l

t

..................................................

0

-

30

seconds

Low pressure

f

ault b

y

pass

.................................................

2 min

u

t

es

1

3

R

W

S

ERIE

S

REVER

S

IBLE

C

HILLER

S

PE

C

IFI

C

ATI

O

N

C

ATAL

OG

Controls - FX10 cont

.

Reversible Chiller Advanced Freeze

D

etection S

y

ste

m

The reversible chiller source and load heat exchan

g

ers are

p

rotected b

y

a multi-sourced temperature lo

g

ic strate

gy

. The

temperature lo

g

ic is based upon the re

f

ri

g

erant temperature

s

ensed as the re

f

ri

g

erant is about to enter the heat exchan

g

er;

while enterin

g

and leavin

g

water temperatures are bein

g

used as

c

orrelatin

g

f

actors. The detection scheme is shown as basic and

advanced al

g

orithms.

Basic Freeze Detection O

p

eration: “Com

p

1 or Com

p

2

Freeze” Alar

m

This alarm can be tri

gg

ered b

y

one o

f

two detection schemes.

Hard Limit Freeze Detection

I

f

the re

f

ri

g

erant temperature drops below the

f

reeze detection

s

etpoint b

y

1.8

°

F, the associated compressor is locked out

immediatel

y

re

g

ardless o

f

an

y

other

f

actors and requires a

m

a

n

ua

l r

ese

t. NOTE: This Lockout

p

roduces a “Com

p

1 or

Comp 2 Freeze” error on the MUI displa

y.

Freeze Detection

The re

f

ri

g

erant temperature is compared to the

f

reeze detection

s

etpoint

(

15

°

F [anti

f

reeze] or 33

°

F [water]

f

ield selectable

)

, and

i

f

the temperature

f

alls below the setpoint

f

or 30 continuous

s

econds, the associated compressor will be halted. This

fu

n

c

ti

o

n

beco

m

es

e

n

ab

l

ed

af

t

e

r th

e

f

ir

s

t tw

o

min

u

t

es

of

c

ompressor operation. Three such events in 60 minutes will

tri

gg

er a compressor lockout that requires a manual reset.

NOTE: This Lockout

p

roduces a “Com

p

1 or Com

p

2

Freeze” error on the MUI displa

y.

In addition to the above:

Entering Water Temperature In

f

luence

I

f

the enterin

g

water temperature o

f

the evaporative heat

e

xchan

g

er is within 10

°

F o

f

the

f

reeze setpoint, the previousl

y

mentioned two minute dela

y

will be eliminated. This allows the

f

reeze detection to operate immediatel

y

when the compressor

s

tarts based on enterin

g

water temperature.

Leaving Water Temperature Influenc

e

I

f

the leavin

g

water temperature o

f

the evaporative heat

e

xchan

g

er is within 10

°

F o

f

the

f

reeze setpoint, the previousl

y

mentioned 30 second dela

y

will be

g

in to be proportionatel

y

r

educed, endin

g

at a 1 second dela

y

when the leavin

g

water

temperature is 1.5

°

F above the

f

reeze setpoint.

Dua

l

Circuite

d

Heat Exc

h

an

g

er Protectio

n

A low temperature condition on either re

f

ri

g

erant circuit will

p

revent the start o

f

both compressors. I

f

the low temperature

c

ondition exists

f

or 5 minutes when both compressors are

o

ff

, a lockout is tri

gg

ered

f

or both compressors. However,

i

f

f

or instance both compressors are operatin

g

and circuit

1 experiences a re

f

ri

g

erant temperature below the

f

reeze

detection setpoint such that compressor 1 is halted,

c

ompressor 2 will not be halted as a result.

Advanced Freeze Detection O

p

eration

:

“

Pre Freeze” Alar

m

P

redictive freeze condition detection

:

I

f

the re

f

ri

g

erant temperature is within 7.2

°

F o

f

the

f

reeze

detection setpoint, the predictive

f

reeze detection al

g

orithm is

e

nabled, and i

f

the lo

g

ic determines that a

f

reeze condition is

l

ikel

y

to happen based on current conditions, the compressor o

f

the involved re

f

ri

g

erant circuit is immediatel

y

stopped. Three

(

3

)

s

uch events in 60 minutes will tri

gg

er a compressor lockout that

requires a manual reset. In the absence o

f

such a condition,

the compressor is allowed to operate so that the re

f

ri

g

erant

temperature ma

y

eventuall

y

be at the threshold o

f

the

f

reeze

detection setpoint. NOTE: This Lockout

p

roduces a “Pre

Freeze” detection error on the MUI displa

y.

Capacit

y

Limitin

g

I

f

the leavin

g

water temperature drops to 1.8

°

F above the

f

reeze detection setpoint, the lead compressor is halted. When

the leavin

g

water temperature rises to 3.6

°

F above the

f

reeze

detection setpoint, it will be allowed to resume operation.

This limitin

g

is allowed to repeat inde

f

initel

y

with no lockout or

indication on the displa

y

.

I

f

the leavin

g

water temperature drops to the

f

reeze detection

s

etpoint, the la

g

compressor is halted. When the leavin

g

water

temperature rises to 1.8

°

F above the

f

reeze detection setpoint, it will

be allowed to resume operation. This limitin

g

is allowed to repeat

inde

f

initel

y

with no lockout or indication on the displa

y

.

Hi

g

h Pressur

e

The hi

g

h-pressure switch shall be a normall

y

closed

(

N

C)

switch

that monitors the s

y

stems re

f

ri

g

erant pressure. I

f

the input senses

the hi

g

h-pressure switch is open it must disable the compressor

output immediatel

y

and count the

f

ault. The compressor minimum

on time does not appl

y

i

f

the hi

g

h-pressure switch opens. The

c

ompressor will not restart until the compressor short c

y

cle time

dela

y

has been satis

f

ied.

L

ow Pressur

e

The low-pressure switch shall be a normall

y

closed

(

N

C)

switch

that monitors the s

y

stems re

f

ri

g

erant pressure. The input 15

s

econds be

f

ore compressor start up and then i

g

nored

f

or the

f

irst

2 minutes a

f

ter the compressor output

(

B

O

-2

)

is enabled. I

f

the

s

witch is open continuousl

y

f

or 30 seconds durin

g

compressor

14

R

W

S

ERIE

S

REVER

S

IBLE

C

HILLER

S

PE

C

IFI

C

ATI

O

N

C

ATAL

OG

Controls - FX10 cont

.

operation the compressor output

(

B

O

-2

)

will be disabled. The

c

ompressor will not restart until the compressor short c

y

cle time

dela

y

has been satis

f

ied.

A

larm Out

p

uts

The control has two alarm outputs, one

f

or each compressor circuit.

These 24VA

C

outputs are desi

g

nated as L

C

1

(

compressor 1

)

and

L

C

2

(

compressor2

)

on the low volta

g

e terminal board.

T

est Mod

e

B

y

holdin

g

the E

SC

and down arrow ke

y

s on the MUI

f

or 5 seconds

will put the control into test mode. In test mode the random start

dela

y

and the compressor

f

ixed on dela

y

time will both be shortened

to 5 seconds and the reversin

g

valve will be allowed to c

y

cle with

out shuttin

g

down the compressor. I

f

an MUI is connected to the

c

ontrol LED

8

will

f

lash and the words

“

Test Mode Enabled” will be

s

hown on the L

C

D displa

y

when the control is in test mode. Test

mode will be disabled a

f

ter a power c

y

cle, 30 minute timeout, or b

y

h

oldin

g

the E

SC

and Up arrow ke

y

s on the MUI.

Se

q

uence of O

p

eration

P

ower Fail Restar

t

When the controller is

f

irst powered up, the outputs will be

disabled

f

or a random start dela

y

. The dela

y

is provided to prevent

s

imultaneous startin

g

o

f

multiple heat pumps.

O

nce the timer

e

xpires, the controller will operate normall

y

.

Random Start Dela

y

This dela

y

will be used a

f

ter ever

y

power

f

ailure, as well as the

f

irst

time the compressor is started a

f

ter the control exits the unoccupied

mode or the emer

g

enc

y

shutdown mode. The dela

y

should not be

l

ess than 1 second and not lon

g

er than 120 seconds. I

f

the control is

in test mode the random start dela

y

will be shortened to 5 seconds.

L

ead Compressor Start Dela

y

Tim

e

The Lead

C

ompressor Fixed

O

n Dela

y

Time will ensure that

the lead compressor output is not enabled

f

or 90 seconds a

f

ter

the control receives a call to start the compressor. This dela

y

is

ad

j

ustable

f

rom 30 – 300 seconds over a BA

S

or a MUI. I

f

the

c

ontrol is in test mode the Lead

C

ompressor

S

tart Dela

y

Timer will

be shortened to

5

seconds.

L

a

g

Compressor Start Dela

y

Tim

e

The La

g

C

ompressor Fixed

O

n Dela

y

Time will ensure that the la

g

c

ompressor output is not enabled

f

or 90 seconds a

f

ter the control

r

eceives a call to start the compressor. This dela

y

is ad

j

ustable

f

rom

30

–

300

seconds over a BA

S

or a M

U

I. I

f

the control is in test

mode the La

g

C

ompressor

S

tart Dela

y

Timer will be shortened to

5

seconds.

Compressor Minimum On Dela

y

The compressor minimum on dela

y

will ensure that the compressor

output is enabled

f

or a minimum o

f

f

ive

(

5

)

minutes each time the

c

ompressor output is enabled. This will appl

y

in ever

y

instance

e

xcept in the event the hi

g

h pressure switch is tripped,

f

reeze

p

rotection, or emer

g

enc

y

shutdown then the compressor output will

be disable immediatel

y

.

Compressor Minimum Off Dela

y

Tim

e

The compressor minimum o

ff

time dela

y

will ensure that the

c

ompressor output will not be enabled

f

or a minimum o

f

f

ive

(

5

)

m

inutes a

f

ter it is disabled. This allows

f

or the s

y

stem re

f

ri

g

erant

p

ressures to equalize a

f

ter the compressor is disabled.

Compressor Lead/La

g

C

ompressor lead

/

la

g

is a standard part o

f

the FX10 control s

y

stem.

The unit is shipped

f

rom the

f

actor

y

with lead

/

la

g

enabled. Lead

/

la

g

c

an be activated throu

g

h the unit mounted user inter

f

ace.

Heatin

g

C

y

cl

e

The control will run the unit in heatin

g

mode when there is a

c

ommand on the

O/

B terminal on the terminal board.

Coolin

g

C

y

cl

e

The control will run the unit in coolin

g

mode when there is no

c

ommand on the

O/

B terminal on the terminal board.

M

UI Alarm Histor

y

Reportin

g

I

f

a

f

ault occurs the

f

ault will be recorded in histor

y

f

or displa

y

on

the medium user inter

f

ace in the Histor

y

Menu. Each

f

ault t

y

pe will

be displa

y

ed in the histor

y

menu with a number between 0 and 3.

A readin

g

o

f

3+ will mean that

f

ault has occurred more than three

times in the past. The histor

y

menu can be cleared with a power

cy

cle onl

y

. Alarm date and time are not included in the histor

y

.

1

5

R

W

S

ERIE

S

REVER

S

IBLE

C

HILLER

S

PE

C

IFI

C

ATI

O

N

C

ATAL

OG

Inputs and Outputs Confi

g

uration

Field Selectable O

p

tions

L

oad and Source Freeze Detection Set

p

oin

t

The

f

reeze detection setpoint input allows

y

ou to ad

j

ust the

f

reeze detection setpoint

f

or either the load or source sides o

f

the heat pump. When the

j

umper is installed on BI-5 the load

f

reeze detection setpoint is

f

actor

y

set

f

or 30

°

F. When the

j

umper

on BI-5 is removed the load

f

reeze detection setpoint will be

15

°

F. When the

j

umper is installed on BI-4 the source

f

reeze

detection setpoint is

f

actor

y

set

f

or 30

°

F. When the

j

umper on

BI-4 is removed the source

f

reeze detection setpoint will be 15

°

F.

NOTE: Pipin

g

circuit must be antifreeze protected to the set

l

evels or the warrant

y

will be voided

.

A

ccessor

y

Outpu

t

The Accessor

y

O

utput will be ener

g

ized 90 seconds prior to the

l

ead compressor output bein

g

ener

g

ized. When both compressor

outputs are turned o

ff

the accessor

y

output will be deactivated

immediatel

y

. This output is selectable

f

or normall

y

open or

n

ormall

y

closed operation throu

g

h the Medium User Inter

f

ace or

throu

g

h the Buildin

g

Automation

Sy

stem.

Controls - FX10 cont

.

Reversible Chiller Set

p

oint Control

This control so

f

tware is b

y

de

f

ault set to operate in

‘

Aquastat’

mode, which requires external setpoint lo

g

ic to

g

enerate the Y1

or Y2 call. The mode ma

y

be chan

g

ed to

‘S

etpoint’ b

y

use o

f

the

‘S

ettin

g

s’ menu in the MUI in the

‘