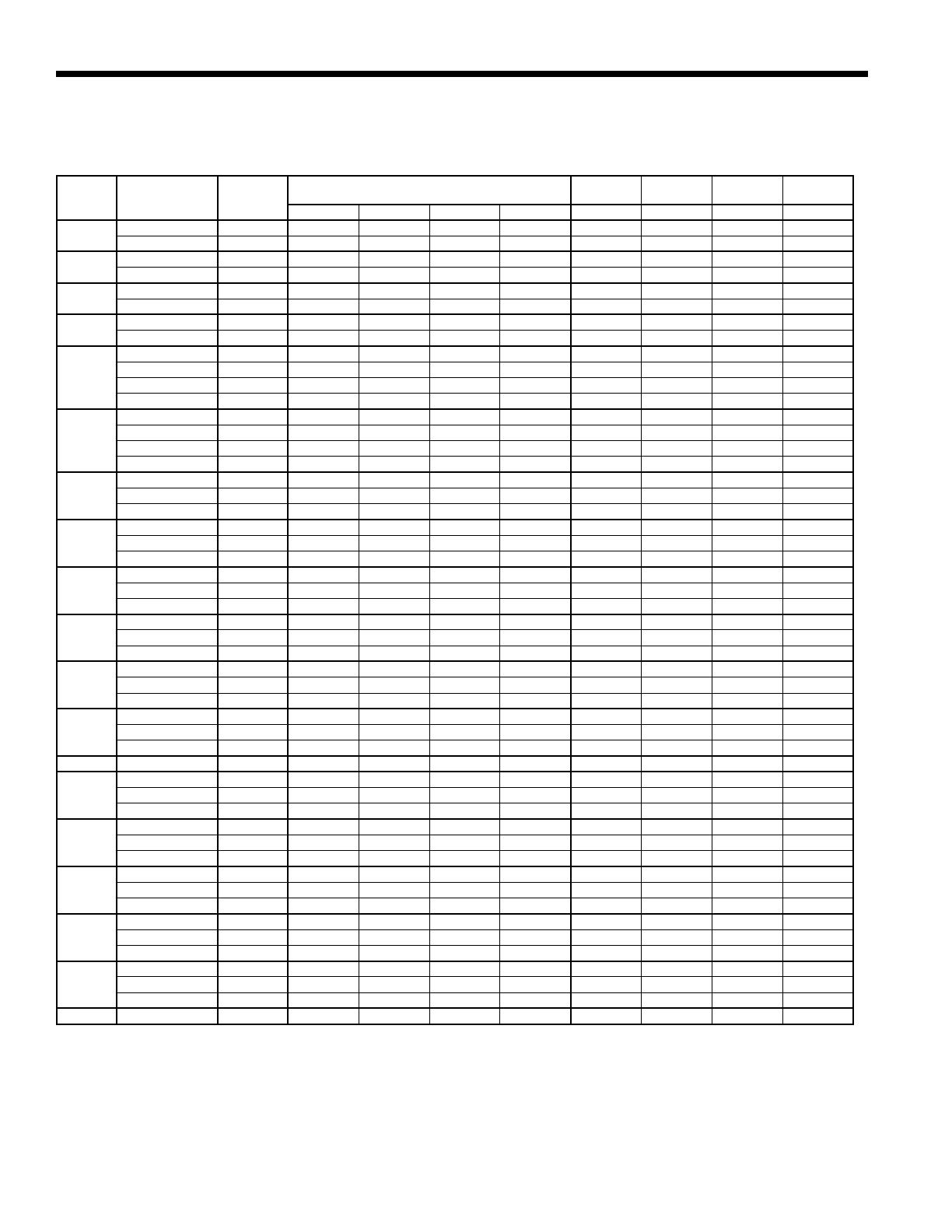

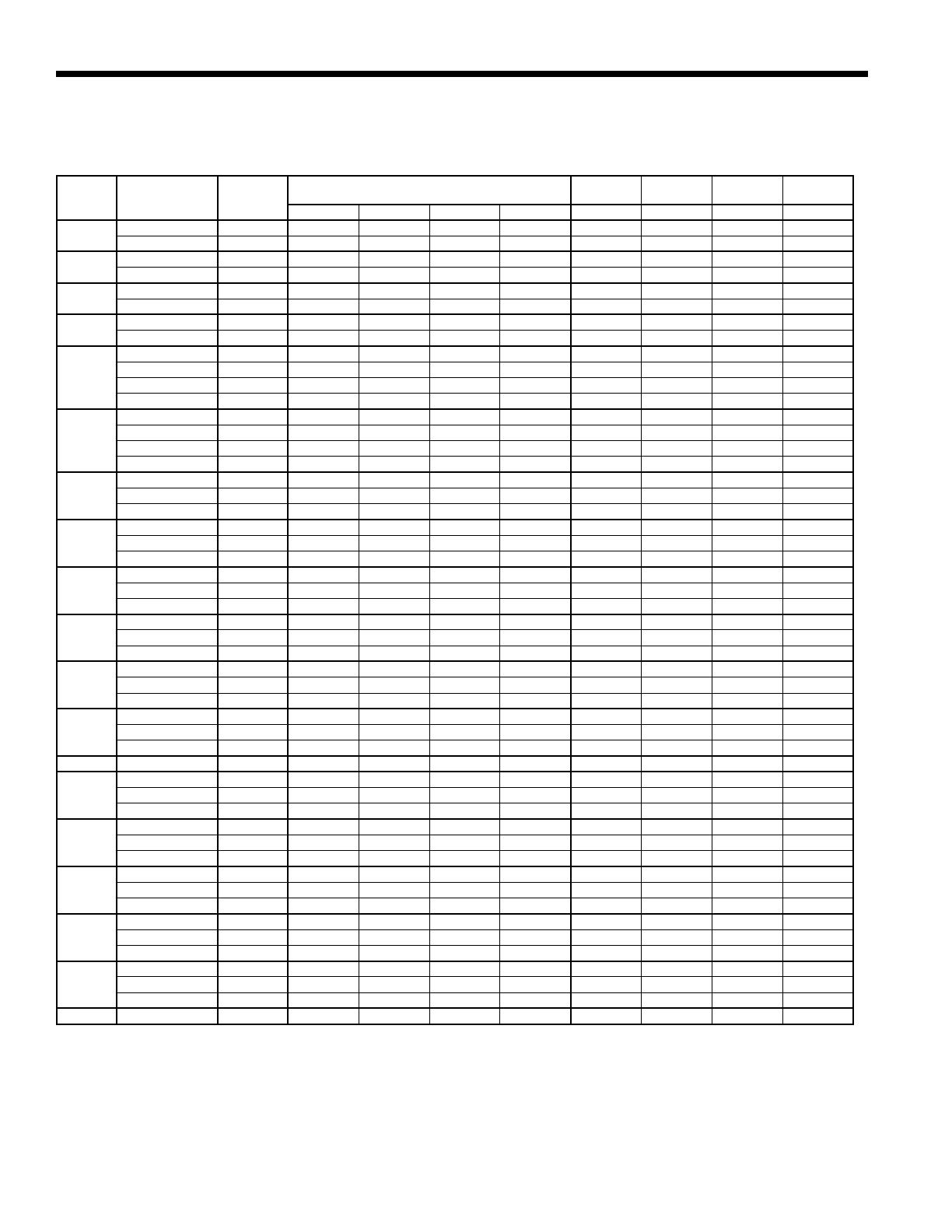

18

RJ SERIES INSTALLATION MANUAL

Electrical Data

ECMMotor

HACR circuit breaker in USA only

*With optional 1 HP ECM2 motor

**With optional GeoStart, only available on 208-230/60/1

Model

Rated

Voltage

Voltage

Min/Max

Compressor

Fan

Motor

Total

Unit

Min

Circ

Max

Fuse/

MCC RLA LRA LRA** FLA FLA Amp HACR

015

208-230/60/1 197/253 na 6.2 29.0 n/a 4.0 10.2 11.8 15

265/60/1 238/292 na 5.6 28.0 n/a 4.1 9.7 11.1 15

018

208-230/60/1 197/253 na 8.4 33.5 n/a 4.0 12.4 14.5 20

265/60/1 238/292 na 7.3 28.0 n/a 4.1 11.4 13.2 20

022

208-230/60/1 197/253 14.0 9.0 48.0 17.0 4.0 13.0 15.2 20

265/60/1 238/292 13.0 8.3 40.0 n/a 4.1 12.4 14.5 20

030

208-230/60/1 197/253 20.0 12.8 58.3 21.0 4.0 16.8 20.0 30

265/60/1 238/292 14.9 9.5 87.0 n/a 4.1 13.6 16.0 25

036

208-230/60/1 197/253 22.0 14.1 73.0 26.0 4.0 18.1 21.6 35

265/60/1 238/292 17.5 11.2 60.0 n/a 4.1 15.3 18.1 25

208-230/60/3 187/253 13.9 8.9 58.0 n/a 4.0 12.9 15.1 20

460/60/3 414/506 6.5 4.2 28.0 n/a 4.1 8.3 9.4 10

036*

208-230/60/1 197/253 22.0 14.1 73.0 26.0 7.0 21.1 24.6 35

265/60/1 238/292 17.5 11.2 60.0 n/a 6.9 18.1 20.9 30

208-230/60/3 187/253 13.9 8.9 58.0 n/a 7.0 15.9 18.1 25

460/60/3 414/506 6.5 4.2 28.0 n/a 6.9 11.1 12.2 15

042

208-230/60/1 197/253 26.0 16.6 79.0 28.0 4.0 20.6 24.8 40

208-230/60/3 187/253 16.3 10.4 73.0 n/a 4.0 14.4 17.0 25

460/60/3 414/506 9.0 5.8 38.0 n/a 4.1 9.9 11.3 15

042*

208-230/60/1 197/253 26.0 16.6 79.0 28.0 7.0 23.6 27.8 40

208-230/60/3 187/253 16.3 10.4 73.0 n/a 7.0 17.4 20.0 30

460/60/3 414/506 9.0 5.8 38.0 n/a 6.9 12.7 14.1 15

048

208-230/60/1 197/253 31.0 19.8 109.0 38.0 4.0 23.8 28.8 45

208-230/60/3 187/253 21.2 13.6 83.1 n/a 4.0 17.6 21.0 30

460/60/3 414/506 9.5 6.1 41.0 n/a 4.1 10.2 11.7 15

048*

208-230/60/1 197/253 31.0 19.8 109.0 38.0 7.0 26.8 31.8 50

208-230/60/3 187/253 21.2 13.6 83.1 n/a 7.0 20.6 24.0 35

460/60/3 414/506 9.5 6.1 41.0 n/a 6.9 13.0 14.5 20

060

208-230/60/1 197/253 41.2 26.4 134.0 47.0 7.0 33.4 40.0 60

208-230/60/3 187/253 24.9 15.9 110.0 n/a 7.0 22.9 26.9 40

460/60/3 414/506 12.1 7.7 52.0 n/a 6.9 14.6 16.6 20

070

208-230/60/1 197/253 47.0 30.1 158.0 55.0 7.0 37.1 44.6 70

208-230/60/3 187/253 32.0 20.5 155.0 n/a 7.0 27.5 32.6 50

460/60/3 414/506 15.0 9.6 75.0 n/a 6.9 16.5 18.9 25

026 208-230/60/1 197/253 16.0 10.2 52.0 18.0 4.0 14.2 16.8 25

038

208-230/60/1 197/253 26.0 16.6 82.0 29.0 4.0 20.6 24.8 40

208-230/60/3 187/253 17.4 11.1

58.0 n/a 4.0 15.1 17.9 25

460/60/3 414/506 7.0 4.5 29.0 n/a 4.1 8.6 9.7 10

038*

208-230/60/1 197/253 26.0 16.6 82.0 29.0 7.0 23.6 27.8 40

208-230/60/3 187/253 17.4 1

1.1 58.0 n/a 7.0 18.1 20.9 30

460/60/3 414/506 7.0 4.5 29.0 n/a 6.9 11.4 12.5 15

049

208-230/60/1 197/253 33.0 21.1 96.0 34.0 4.0 25.1 30.4 50

208-230/60/3 187/253 21.0 13.4 88.0 n/a 4.0 17.4 20.8 30

460/60/3 414/506 10.0 6.4 41.0 n/a 4.1 10.5 12.1 15

049*

208-230/60/1 197/253 33.0 21.1 96.0 34.0 7.0 28.1 33.4 50

208-230/60/3 187/253 21.0 13.4 88.0 n/a 7.0 20.4 23.8 35

460/60/3 414/506 10.0 6.4 41.0 n/a 6.9 13.3 14.9 20

064

208-230/60/1 197/253 40.0 25.6 118.0 41.0 7.0 32.6 39.0 60

208-230/60/3 187/253 27.5 17.6 123.0 n/a 7.0 24.6 29.0 45

460/60/3 414/506 14.0 9.0 62.0 n/a 6.9 15.9 18.1 25

072 208-230/60/1 197/253 42.5 27.2 150.0 53.0 7.0 34.2 41.0 60

5/6/09