Page 12 Model 21 -CET-16 Service Manual

WARNING

INJURY AND EQUIPMENT DAMAGE could result from

improper lifting. The SteamCraft 5.1 weighs

approximately 135 pounds. Use enough workers with

experience lifting heavy equipment to place the

SteamCraft 5.1 on the counter.

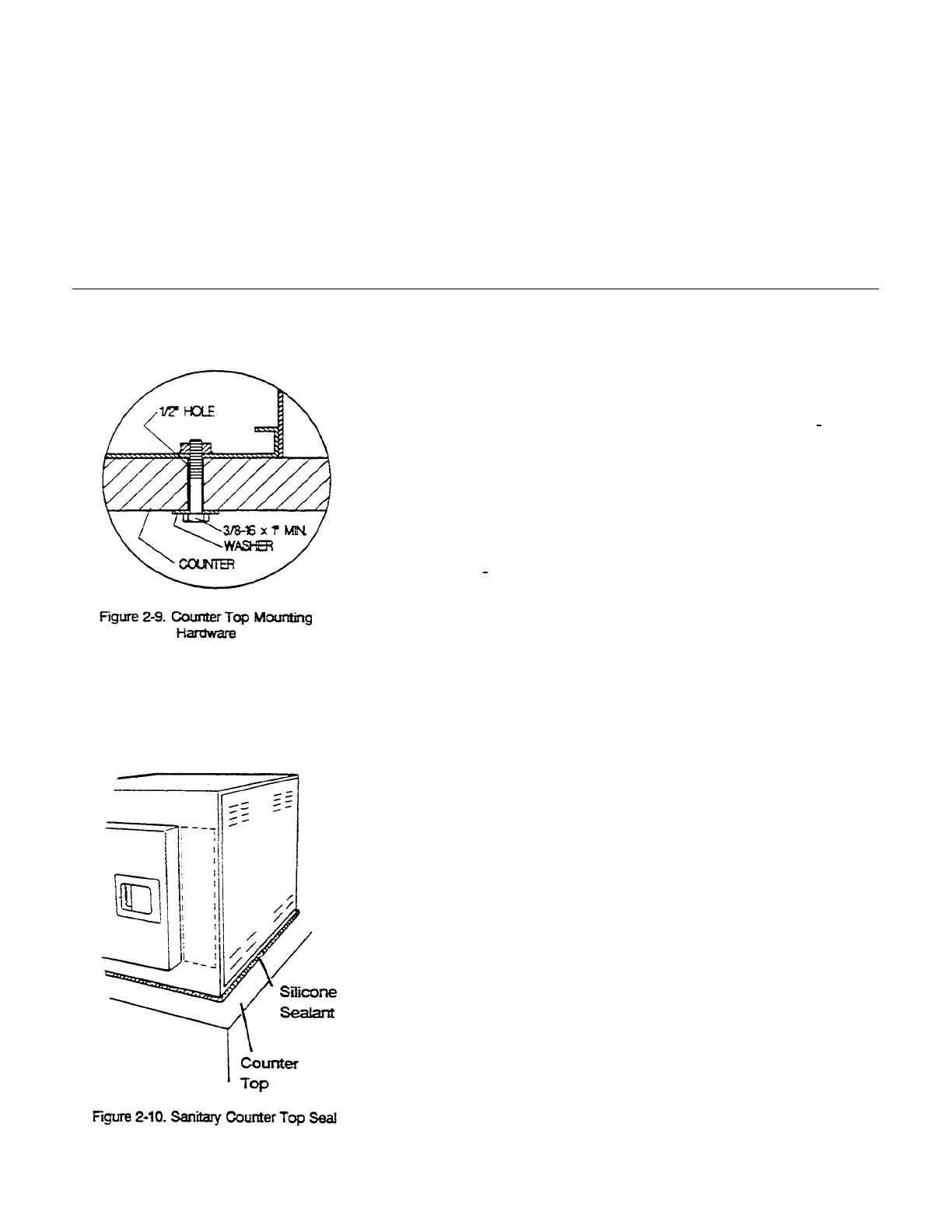

4. Lift the SteamCraft 5.1 into position on the counter and align the

steamer mounting holes with the counter mounting holes. The steamer

mounting holes are the holes with the 3/8"-16 weldnuts usually used to

mount the adjustable legs-

NOTE: If there is not enough clearance behind the steamer to install the

drain, electrical, and water lines; skip the remainder of this

procedure and go to page 14, Install the Free Air Vented Drain

Lines- After installing all necessary drain, electrical, and water

lines, proceed with step 5 of these instructions and mount the

steamer to the counter top.

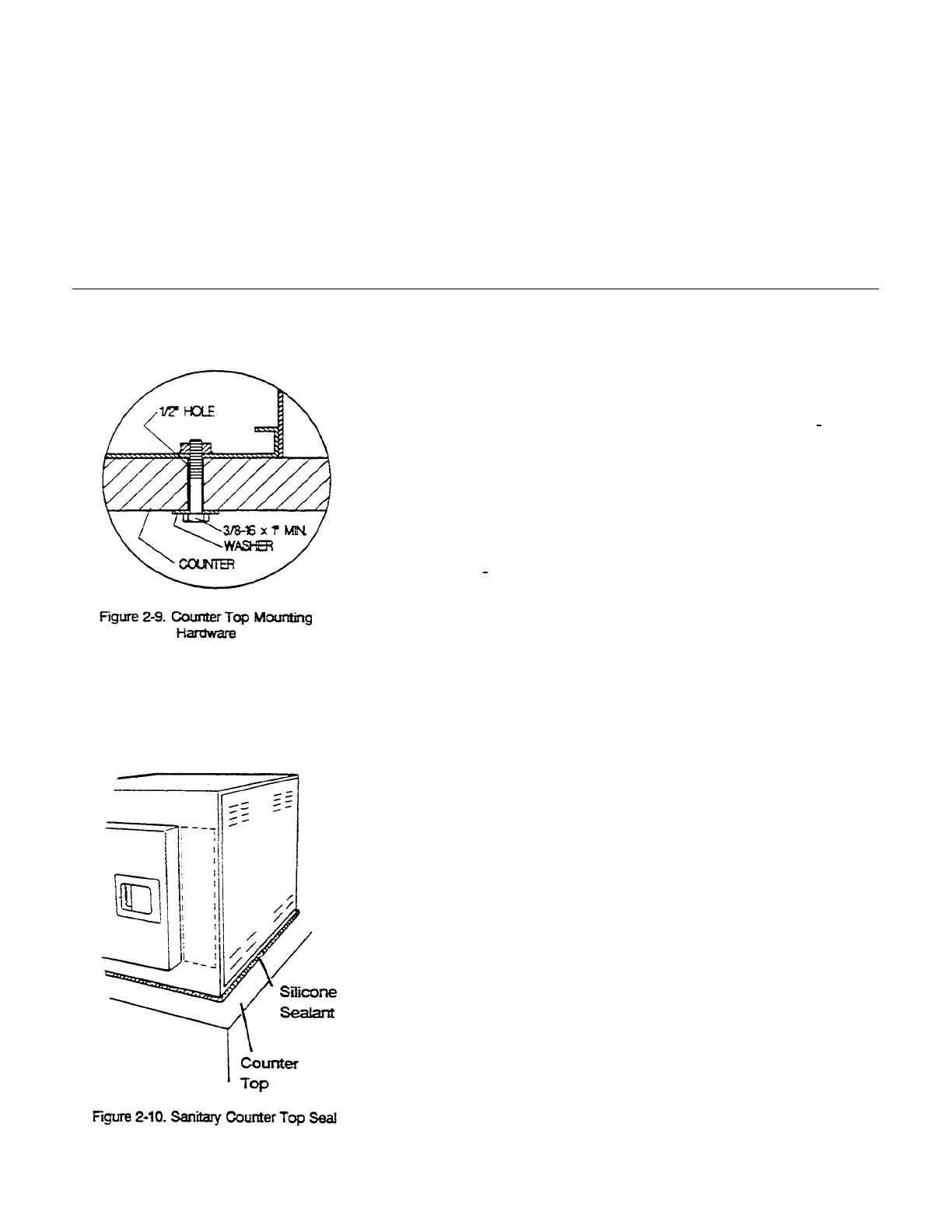

5. Install 3/8"-16 mounting screws and washers as shown in Figure 2-9.

The screws should be long enough to pass through the washer,

counter, shims, and weldnut without projecting more than 1/2 inch

above the weldnut. Thread the screws only a few turns into the

weldnuts, leaving enough play for leveling the unit and sealing the

mounting holes-

6- Do not shim at the highest corner (marked in step 2). Shim the other

three comers until the unit is level both front to back and side to side.

7. Inject enough silicone sealant into each mounting hole in the counter to

seal the hole as the hardware is tightened.

8. Tighten the mounting hardware enough to secure the unit in place but

not change the level. After hardware is tightened, verify that the

SteamCraft 5.1 is level front to back and side to side.

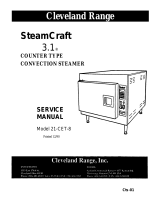

9. Seal the gap between the SteamCraft 5.1 and the counter top. Lay a

generous bead of silicone sealant under the entire perimeter of the

steamer bottom. See Figure 2-10.

10. Smooth the silicone seal into the crevice with finger or tool to provide a

cove seal.

11. After the SteamCraft 5.1 has been positioned and leveled, refer to page

14, and install the slide racks.

Stand Mounting and Leveling

The Cleveland Range ES-2130 Equipment Stand provides a stable, level

mounting base for the SteamCraft 5.1. In addition, the stand has a slide-

away work surface, and storage for five cafeteria trays. When mounting a

SteamCraft 5.1 on the ES-2130, first install and level the stand, then

surface mount the steamer to the top of the stand. Because the stand is

level and designed to support the SteamCraft 5.1 it is not necessary to

place shims or seals between the stand and steamer.