Page is loading ...

Page is loading ...

Baumer Electric AG

Hummelstrasse 17

8501 Frauenfeld / Switzerland

Phone +41 52 728 11 22 · Fax +41 52 728 11 44

sales.ch@baumer.com · www.baumer.com

Printed in Switzerland · 01.18

Version 03 · 81195324

Subject to modication in technic and design.

Errors and omissions excepted.

EN

Assembly instruction and

safety information

(Translation of original instruction)

BMMS K, BMMS M - Analog

Cable transducer with analog interface

1. Identicationofnotes

Note

Information for intended product use.

2. Technical data

Voltage supply 10...30 VDC (UL Class 2)

Consumption w/o load: typ. 50 mA (24 VDC)

R

ø

ø = 5.3 mm

R x ≥27 mm

R exible ≥55 mm

3. Intended use

The cable transducer is a precision measuring

device that is used to record linear positions and

speeds. It provides measuring values as electronic

output signals for the subsequently connected

device. It must not be used for any other purpose.

Unless this product is specially labeled, it may

not be used for operation in potentially explosive

environments.

Make sure by appropriate safety measures, that

in case of error or failure of the cable transducer,

no danger to persons or damage to the system or

operating facilities occurs. Do not directly connect

with on board supply system but with a DC/DC

converter which is released by automotive standar-

dization group.

4. Personnelqualication

Installation and assembly of this product may be performed

only by a person qualied in electronics and precision

mechanics.

5. Maintenance

The cable transducer is maintenance-free and must not

be opened up nor mechanically or electronically modied.

Opening up the cable transducer can lead to injury caused

by the spring.

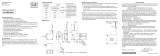

6. Recommended grounding concept

screen connection

7. Terminal assignment

See type designation: BMMS.xxxxx24

xx/xx00x

U/5/Y/7 = voltage output / V/Z = current output / W = current/voltage output

7.1 Cable

Non redundant Redundant

Colour U/5 V W Y/7 Z

white (wh) 0 V 0 V 0 V 0 V 0 V

brown (bn) +Vs +Vs +Vs +Vs 1 +Vs 1

green (gn) d.u. Iout Iout Uout 1 lout 1

yellow (ye) Uout d.u. Uout Uout 2 lout 2

grey (gy) Set Set Set Set 1 Set 1

pink (pk) DV/Status DV/Status DV/Status DV/Status1 DV/Status1

blue (bu) – – – Set 2 Set 2

red (rd) – – – DV/Status2 DV/Status2

black (bk) – – – 0 V 0 V

violet (vt) – – – +Vs 2 +Vs 2

Cable 6 x 0.14 mm

2

/ 10 x 0.14 mm

2

Screen: connected to housing.

7.2 Flange connector M12, 5-pin

Non redundant 1xM12 Redundant 2xM12

1)

Pin U/5 V W Y/Z Z

1 0 V 0 V 0 V 0 V 0 V

2 +Vs +Vs +Vs +Vs +Vs

3 d.u. Iout Iout Uout Iout

4 Uout d.u. Uout DV/Status DV/Status

5 Set Set Set Set Set

1

2

3

4

5

1) Terminal assignment for each M12 connector

7.3 Flange connector M12, 8-pin

Non redundant Redundant

Pin U/5 V W Y/7 Z

1 0 V 0 V 0 V 0 V 0 V

2 +Vs +Vs +Vs +Vs +Vs

3 d.u. Iout Iout Uout1 lout1

4 Uout d.u. Uout Uout2 lout2

5 Set Set Set Set1 Set1

6 DV/Status DV/Status DV/Status DV/Status1 DV/Status1

7 n.c. n.c. n.c. Set2 Set2

8 n.c. n.c. n.c. DV/Status2 DV/Status2

1

3

4

2

5

6

7

8

For customer-specic cable transducers please refer to product label and data sheet.

8. General informations

Protect cable transducer and measuring wire as far as

possible from water. Avoid mounting with measuring wire

outlet pointing upwards (especially in outdoor applications)

to reduce risk of water entry. Freezing water can lead to

damage. Drainage holes can be opened to allow water

to drain. Prefer mounting cable transducer with drainage

holes in low position.

>3°

>3°

<3°

Ensure pulling out of measuring wire in straight direction.

Maximum misalignment ≤3°. Use pulley to limit misalign-

ment. Do not loop measuring wire around objects or allow

them to touch measuring wire. Protect measuring wire

from dirt and damage.

Ensure free rotation of measuring wire xation to assure

optimum wire guiding.

Letting snap back of pulled out measuring wire can cause

injuries and damage of cable transducer.

10. Teach process

Activate teach process

Set “Set-input” on HIGH for 6 seconds and afterwards on

LOW level.

DV/Status output: Oscillates after 5 seconds.

Position1

Get cable transducer on position 1 intended for voltage

output 1 / current output 1. Set “Set-input” for 1 second on

HIGH level.

DV/Status output: Switches to HIGH level for 3 seconds

and ashes shortly.

Position2

Get cable transducer on position 2 intended for voltage

output 2/current output 2. Set “Set-input” for 1 second on

HIGH level.

DV/Status output: Switches to LOW level for 3 seconds

and oscillates afterwards.

If measuring range is exceeded or the limits are too close

to each other, the teaching process was not successful and

has to be repeated.

Set / restore default

Set „Set-input“ for 16 seconds to HIGH. DV/Status output:

Oscillates after 5 seconds. Note: The cable transducer hast

to be completely drawn in.

Behavior

U

m

Pos 2

Pos 1

Pos 2

Pos 1

Teach in direction - move in

Teach in direction - move out

11. Disposal

The cable transducer contains electronic components.

At its disposal, local environmental guidelines must be

followed.

9. Mounting

BMMS K

2.

1.

M4 DIN912 (3x)

max. 2.5 Nm

BMMS M

1.

2.

M6 DIN912 (3x)

max. 2.5 Nm

Fit cable transducer on a plain base to avoid excessive force on housing. Make sure that drainage holes are free. It is

recommended to use at washers.

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

/