Page is loading ...

IN ORDER TO AVOID ELECTRIC SHOCK OR OTHER POSSIBLE INJURY:

• DO NOT USE THIS PRODUCT FOR HUMAN SAFETY APPLICATIONS.

IT WAS NOT DESIGNED, TESTED OR RECOMMENDED FOR THIS

USE.

• DO NOT USE THIS PRODUCT IN HAZARDOUS LOCATIONS (E.G.

EXPLOSIVE ATMOSPHERES). IT WAS NOT DESIGNED, TESTED OR

RECOMMENDED FOR THIS USE.

• ENSURE THE PRODUCT IS PROPERLY WIRED FOR THE

APPLICATION. REFER TO THE SPECIFICATIONS AND WIRING

DIAGRAMS IN THIS MANUAL.

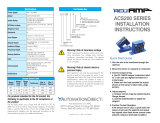

MODELS COVERED IN THIS MANUAL

Catalog Number Description

ECSNOASC Self-Powered, Solid Core, N.O., Adjustable Setpoint (1-150A), LED

ECSNOFSC Self-Powered, Solid Core, N.O., Fixed Setpoint (1.0A), No LED

ECSNCASC Self-Powered, Solid Core, N.C., Adjustable Setpoint (1-150A), LED

ECSNCFSC Self-Powered, Solid Core, N.C., Fixed Setpoint (1.0A), No LED

ECSNOASP Self-Powered, Split Core, N.O., Adjustable Setpoint (1.75-150A), LED

ECSNOFSP Self-Powered, Split Core, N.O., Fixed Setpoint (1.5A), No LED

ECSNCASP Self-Powered, Split Core, N.C., Adjustable Setpoint (1.75-150A), LED

ECSNCFSP Self-Powered, Split Core, N.C., Fixed Setpoint (1.5A), No LED

INTRODUCTION

The Cutler-Hammer

CurrentWatch™ ECS Series are

a family of self-powered, solid-

state current-operated switches

which trigger when the current

level sensed through the

aperture exceeds the adjusted

setpoint. The solid-state output contacts can

switch AC or DC, making the ECS Series well

suited for applications in automation systems.

Eaton’s current sensor family encompasses a broad range of products

for cost-effective monitoring, status, and predictive maintenance.

Downtime and costly repairs can be avoided by utilizing Eaton’s

products and technologies in your control systems.

Installation Instructions

CurrentWatch™ ECS Series Current Switch

AC Current Switch, Fixed or Adjustable Setpoint

INSTALLATION

Considerations for all ECS Series models…

• Run wire to be monitored through the aperture (opening) in the

switch body

• These switches can be located in the same environment as

motors, contactors, heaters, pull-boxes and other electrical

enclosures

• Mounting can be done in any position or hung directly on wires

with a wire tie

Considerations for split core versions (-SP suffi x)…

• To open the switch, press the tab inward (toward the body of the

switch) as shown below

• After placing the wire in the aperture, press the hinged portion

fi rmly downward until a click is heard and the tab pops out fully

• Keep the contact areas of split-core switches clean at all times

QUICK INSTALL GUIDE

The below steps can be followed to quickly install a CurrentWatch™

ECS Series switch.

1. Run the wire to be monitored through the aperture

2. Mount the switch

3. Connect output wiring

a. Use up to 14 AWG copper wires

b. Use caution not to exceed solid state output rating (see

specifi cation table on following page)

3. Adjust the setpoint

a. Use the potentiometer to adjust the setpoint

LED / OUTPUT STATUS TABLE

Monitored Amps

Output

Smart-LED

(If Present)N.C. N.O.

None or Minimum Closed Open Off

Below Trip Level Closed Open Slow (2 sec.)

Above Trip Level Open Closed Fast (0.5 sec.)

P51916 Rev 02

Effective: January 2008 Page 1

WARNING

Questions? Call our Sensor Application Engineers at (800) 426-9184.

To open:

Press tab inward

towards hinge

Important:

Keep contact areas clean

392500221

P51916 Rev 02

Effective: January 2008 Page 2

Questions? Call our Sensor Application Engineers at (800) 426-9184.

RANGES AND MAXIMUM AMPS

Housing

Style Setpoint Outputs

Maximum Input Amps

Continuous 6 sec. 1 sec.

Solid Core Fixed (1.0A) N.O. 250A 400A 1,000A

N.C. 150A 400A 1,000A

Adjustable (1-150A) N.O. 150A 400A 1,000A

N.C. 150A 400A 1,000A

Split Core Fixed (1.5A) N.O. 250A 400A 1,000A

N.C. 150A 400A 1,000A

Adjustable

(1.75-150A)

N.O. 150A 400A 1,000A

N.C. 150A 400A 1,000A

SETPOINT ADJUSTMENT

The CurrentWatch™ ECS Series setpoint is adjusted with a four-turn

potentiometer (for models ending -SP) or a fi fteen-turn potentiometer

(for models ending -SC). The pot is shipped factory set to the lowest

setpoint, fully clockwise. Turning the pot counter-clockwise will increase

the setpoint. The pot has a slip-clutch to prevent damage at either end

of its rotation. To determine where the adjustment is, turn the pot all the

way clockwise. This will return it to the minimum setpoint.

Important Setpoint Adjustment Notes

• Output contacts are solid-state. Check output status by applying

voltage to the contacts and reading the voltage drop across the

contacts. An Ohmmeter set on “continuity” will give misleading

results.

• It is recommended the setpoint be adjusted to allow for voltage

variations of 10 to 15 percent.

• Mounting can be done in any position or hung directly on wires

with a wire tie

Typical Adjustment Steps

1. Turn the pot to the minimum setpoint (four or fi fteen turns

clockwise).

2. Have normal operating current running through the switch. The

output should be tripped since the pot is at its minimum setpoint.

For units with an LED, it should be fl ashing fast (two to three times

per second).

3. Turn the pot counter-clockwise until the unit un-trips. This is

indicated by the slow fl ashing of the LED (once every two to three

seconds), or by changing of the output switch status.

4. Now turn the pot clockwise slowly until the unit trips again. It is

now set at the current level being monitored.

a. To set underload, turn the pot about 1/8 turn further clockwise

b. To set overload, turn the pot about 1/8 turn further counter-

clockwise

WIRING DIAGRAM

Connect control or monitoring wires to the sensor. Use up to

14 AWG copper wire and tighten terminals to 5 inch-pounds torque. Be

sure the output load does not exceed the switch rating.

CAUTION! Incandescent

lamps can have “cold

fi lament inrush” current

of up to ten times their

rated amperage. Use

caution when switching

lamps.

TROUBLESHOOTING

Problem Solution

Switch is

always tripped

The setpoint may be too low. Turn the pot counter-clockwise to

increase the setpoint.

The switch may have been overloaded and the contacts are

burned out. Check the output load, remembering to include inrush

on inductive loads (coils, motors, ballasts).

Switch will

not trip

The setpoint may be too high. Turn the pot clockwise to decrease

the setpoint.

On split core models, the core contact area may be dirty. Open the

switch and clean the contact area.

The monitored current may be below the minimum required. Loop

the monitored wire several times through the aperture until the

“sensed” current rises above the minimum. The sensed amps

equals “actual amps” multiplied by the “number of loops.” Count

loops on the inside of the aperture.

The switch may have been overloaded and the contacts are

burned out. Check the output load, remembering to include inrush

on inductive loads (coils, motors, ballasts).

SPECIFICATIONS

Solid Core Split Core

Power Supply Self Powered–No Power Supply Needed

Output Magnetically Isolated Solid-State Switch

Output Rating Normally Open Models: 0.15A, 240V AC/DC

Normally Closed Models: 0.20A, 135V AC/DC

Off-State Leakage < 10 µA

Response Time 120 ms

Adjustable Setpoint Range 1-150A 1.75-150A

Setpoint Adjustment 15-Turn Potentiometer 4-Turn Potentiometer

Fixed Setpoints 1.0A 1.5A

Hysteresis Approximately 5% of Setpoint

Overload Fixed Setpoint, N.O. Models: 6 sec. @ 500A; 1 sec. @ 1,000A

All Other Models: 6 sec. @ 400A; 1 sec. @ 1,000A

Isolation Voltage UL Listed to 1,270V AC, Tested to 5,000V AC

Frequency Range 6-100Hz

Sensing Aperture 0.74 in. (19mm) 0.85 in. (21.6mm)

Housing UL94 V0 Flammability Rated

Environmental Operating Temperature: -58 to +122° F (-50 to +50° C)

Humidity: 0-95% RH, Non-Condensing

Approvals UL and ULC Listed

CE Certifi ed

392500221

AC or DC

Power

AC or DC

Load

Monitored Wire

Current Switch

Use caution when

switching lamps

/