Table of Contents

Manual No. 016-5035-002 Rev. A i

Chapter 1 Important Safety Information............................................................................. 1

Instructions for Wire Routing .................................................................................................................................2

Chapter 2 Introduction............................................................................................................. 5

Preparing for Installation ..........................................................................................................................................5

Recommendations .................................................................................................................................................................6

Point of Reference .................................................................................................................................................................6

Kit Contents ...................................................................................................................................................................6

RS1/HDU Kits ................................................................................................................................................................6

Updates ...........................................................................................................................................................................6

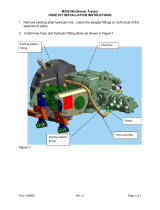

Chapter 3 Hydraulic System Installation............................................................................ 11

Install Fittings in the Steering Valve ..................................................................................................................12

Mount the Steering Valve .....................................................................................................................................13

Install the Left and Right Steering Hoses ........................................................................................................14

Install the Pressure and Tank Hoses .................................................................................................................17

Install the Load Sense Hoses ...............................................................................................................................19

Hydraulic Diagram ...................................................................................................................................................21

Chapter 4 Wheel Angle Sensor Installation ...................................................................... 23

Assemble the WAS ...................................................................................................................................................23

Install THE was ......................................................................................................................................................................23

Chapter 5 Cab Component Installation.............................................................................. 27

RS1 Installation ..........................................................................................................................................................27

Cab Component Installation ................................................................................................................................29

Install the Master Switch .......................................................................................................................................30

Install System Cables ...............................................................................................................................................31

HDU Cable ..............................................................................................................................................................................31

HDU Switch Cable ....................................................................................................................................................34

Valve Cable .................................................................................................................................................................35

RS1 Cable .....................................................................................................................................................................37

Routine Operation ...................................................................................................................................................39

System Diagrams ......................................................................................................................................................41

Appendix A Kits Lists ................................................................................................. 43

Kits ..................................................................................................................................................................................43