TAMPER RESISTANCE

Intelligent programmable temperature sensors include a tamper-resistant ca-

pability that prevents their removal from the base without the use of a tool.

Refer to the base manual for details on making use of this capability.

BEFORE TESTING

Before testing, notify the proper authorities that the system is undergoing

maintenance, and will temporarily be out of service. Disable the system to

prevent unwanted alarms.

All sensors must be tested after installation and periodically thereafter. Test-

ing methods must satisfy the Authority Having Jurisdiction (AHJ). Sensors

offer maximum performance when tested and maintained in compliance with

NFPA 72.

The sensor can be self-tested or manually tested as described below.

SELF-TEST TESTING

A. Heat Test

The Notifier system with Self-Test temperature sensors can carry out a func-

tional test using the Self-Test function. It places enough energy into the therm-

istor to allow it to register heat and then measures the time it takes to cool

down after this heating cycle has been completed.

1. Use the associated app and gateway. (See Connected Life Safety Services

guides.

2. Initiate self-test from app. Wait at least 30 seconds before communicating

with the device; wait at least 90 seconds before moving or re-cycling.

3. Take appropriate action based on the outcome of the testing results. If

it has failed there may be an issue with the thermistor and the device

should be considered for cleaning or replacement.

NOTE: For safer testing the fire system can remain active while Self-Test is in

progress. The process will delay any alarm input signal from the SLC includ-

ing pull stations, input modules and other sensors (not undergoing Self-Test)

by a maximum of 30 seconds. Multiple loops and panels may be tested simul-

taneously.

B. Visual Inspection

This sensor contains a wireless beacon (only active during Self-Test process)

which is designed to communicate with the Honeywell Connected Life Safety

Services app in order to prove the successful completion of the visual inspec-

tion of any Self-Test sensor.

1. A range of Self-Test sensors can be placed into a beaconing mode from

the supporting app.

2. The App will display all selected Self-Test devices in range of your smart

phone and will place the device with the strongest signal at the top your

App display. The App will also provide details on the device address,

location and label. (For further details on the associated app and gateway

see Connected Life Safety Services guides).

3. Once the sensor is in beaconing range of your smart phone, you must

verify the completion of the visual inspection of the sensor via the App

(recording any remedial action required if necessary). Criteria for suc-

cessfully passing the visual inspections is available to review in the rel-

evant section of NFPA 72 guidance.

4. If the label of the self-test sensor is incorrect, you can update this on the

App (subject to holding the relevant user licence), which will upload it

to the system when you pair the device with the Connected Life Safety

Services gateway on completion of the visual inspection.

SELF-TEST TOKENS

If your license requires Self-Test tokens in order to activate the Self-Test pro-

cess, please refer to your Connected Life Safety Services guides in order to

purchase the required volume of tokens to complete testing on your project.

MANUAL TESTING

A. Test Magnet (Model No. M02-04 - optional)

1. Place the optional test magnet against the cover in the magnet test area,

as shown in Figure 3, to activate the test feature.

2. The LEDs should latch on within 10 seconds, indicating alarm and an-

nunciating the panel.

3. Reset the detector at the system control panel.

B. Direct Heat Method (Hair dryer of 1000 – 1500 watts)

1. From the side of the detector, direct the heat toward the sensor. Hold the

heat source about 6 inches (15 cm) away to prevent damage to the cover

during testing.

2. The LEDs on the detector should light when the temperature at the de-

tector reaches the alarm setpoint. If the LEDs fail to light, check the

power to the detector and the wiring in the detector base.

3. Reset the detector at the system control panel.

Detectors that fail these tests may need to be cleaned as described under

CLEANING and retested.

CLEANING

Before removing the detector, notify the proper authorities that the smoke

detector system is undergoing maintenance and will be temporarily out of

service.

Disable the zone or system undergoing maintenance to prevent unwanted

alarms.

1. Remove the sensor to be cleaned from the system.

2. Use a vacuum cleaner or compressed air to remove dust and debris from

the sensing area.

3. Reinstall the detector.

4. Test the detector as described in TESTING.

5. Reconnect disabled circuits.

6. Notify the proper authorities that the system is back on line.

FM CLASSIFICATION

RTI ratings are for installations which must comply with FM 3210.

135°F Fixed RTI: FAST

Rate of Rise/135°F Fixed RTI: V2-FAST

190°F Fixed RTI: QUICK

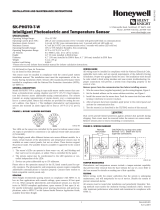

FIGURE 3. FEATURES OF THE HEAT DETECTOR

Magnet

Test

Marker

Base Alignment Notch

Magnet

Test

Marker

LED

Base

Notch

LED C2025-00

FIGURE 4. CLEANING THE HEAT DETECTOR

}

Access to

Sensing Area

C2026-00

Notifier® and FlashScan® are registered trademarks of Honeywell International, Inc.

DEVICE AND SYSTEM SECURITY

Before installing this product ensure that the

tamper seal on the packaging is present and

unbroken and the product has not been tampered

with since leaving the factory. Do not install this

product if there are any indications of tampering.

If there are any signs of tampering the product

should be returned to the point of purchase.

It is the responsibility of the system owner to

ensure that all system components, i.e. devices,

panels, wiring etc., are adequately protected to

avoid tampering of the system that could result

in information disclosure, spoofing, and integrity

violation.

FCC STATEMENT

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause undesired

operation.

WARNING: Do not make changes to the equipment. Changes or modifications not expressly approved

by the manufacturer could void the user’s authority to operate the equipment.

SUPPLEMENTAL INFORMATION

For Limitations of Fire Alarm Systems,

please go to:

http://www.systemsensor.com/

en-us/Documents/I56-1558.pdf

Limitations of

Fire Alarm Systems

2 I56-6784-000

©2021 Notifier. 1/6/2021