NOT A WALKWAY

NOT A WALKWAY

C

L

A

S

S

C

E

R

T

I

F

I

ED

T

O

C

A

N

/CS

A

C

2

2

.

2

N

O

.

247

C

O

N

F

O

R

MS

T

O

A

N

S

I

/

U

L

-

3

2

5

V

E

H

I

C

U

L

A

R

G

A

TE

O

P

E

R

A

T

O

R

H

P

5

3

38

2

M

O

D

E

L

S

E

R

I

A

L

V

O

L

T

SP

H

A

S

E

A

MP

S

6

0

H

z

M

A

X

G

A

T

E

L

O

A

D

Do

o

r

K

i

n

g

,

I

n

c

.

,

I

n

g

l

e

w

o

od

,

C

A

M

OV

I

N

G

A

RM

c

an

ca

us

e

v

e

hi

cl

e

d

am

a

g

e

,

s

er

i

o

us

i

n

j

ur

y

o

r

de

a

th

.

S

TA

Y

C

L

EA

R

o

f

a

r

m

a

t

al

l

t

i

m

e

s

.

NO

:

Pedes

t

r

i

a

ns

Bi

c

y

c

l

e

s

M

o

t

or

cy

c

les

WA

R

NI

NG

Mo

vi

n

g

G

a

te

C

a

n

C

a

u

se

Ser

i

o

u

s In

j

u

r

y

o

r

D

e

a

th

KEEP

C

L

EAR

!

G

at

e

ma

y

mo

ve

a

t

a

n

y

t

i

me

w

i

t

h

o

u

t

p

ri

o

r

w

a

rn

i

n

g

.

D

o

n

o

t

l

e

t

ch

i

l

d

re

n

o

p

e

ra

te

t

he

g

a

t

e

o

r

p

l

a

y

i

n

t

h

e

g

a

te

a

re

a

.

T

h

i

s

e

n

tra

n

ce

i

s

f

o

r

vehi

cl

e

s

o

n

l

y.

Pe

d

e

st

ri

a

n

s

mu

st

u

se se

p

a

ra

t

e

e

n

t

ra

n

ce.

M

OV

I

N

G

A

R

M

c

a

n

ca

u

se

v

e

h

ic

l

e

d

a

ma

g

e

,

se

r

iou

s

i

nj

u

r

y

o

r

d

e

a

t

h.

S

T

A

Y

C

L

EA

R

o

f

a

r

m

a

t

a

ll

tim

e

s

.

N

O:

P

e

d

e

s

t

r

ia

n

s

Bi

c

yc

l

e

s

Mo

to

r

c

y

c

le

s

WA

R

N

IN

G

THIS PRODUCT IS TO BE INSTALLED AND SERVICED BY A TRAINED GATE/DOOR SYSTEMS TECHNICIAN ONLY.

Visit

www.doorking.com/dealer-locator

to find a professional installing and servicing dealer in your area.

Used with 1601 Barrier Gate Operator

WITHOUT Convenience Open,

WITH Manual Release

to Enhance Vehicular Traffic

Control Management

Installation Manual

1620 Lane Barrier Add-On

1620 Lane Barrier Add-On

1620 Lane Barrier Add-On

1620 Lane Barrier Add-On

Surface Mount Vehicular Lane Barrier Accessory

Copyright 2020 DoorKing

®

, Inc. All rights reserved.

The 1620 lane barrier is not a stand-alone product. It must

be used with a 1601 Barrier Gate Operator (sold separately).

The 1620 is not crash rated. It is intended to provide a more

formidable barrier in conjunction with a standard barrier

arm operator system. The 1620 is ideally used to control

passenger vehicles and light-duty trucks.

IMPORTANT: Installation of Traffic

Light, Photocell and Octagon

Arm with Reverse/LED Edge is

REQUIRED.

Use this manual for circuit board 1601-010 Revision W or higher.

1620-065-G-8-20

1620 Models

Table of Contents

Secondary Barrier Arm

1601 Barrier Operator

(sold separately)

Lane Width

IMPORTANT: Secondary barrier arm is a

fixed distance for each lane width model.

9 ft Lane - P/N 1620-080

2 - 3ft Arm Channel Sections

1 - 2ft Arm Channel Section

2 - End Caps

Secondary Barrier Arm 9ft Assembly

30 Counterweights (1620-050)

10 ft Lane - P/N 1620-081

3 - 3ft Arm Channel Sections

2 - End Caps

Secondary Barrier Arm 10ft Assembly

32 Counterweights (1620-052)

12 ft Lane - P/N 1620-083

3

- 3ft Arm Channel Sections

1 - 2ft Arm Channel Section

2 - End Caps

Secondary Barrier Arm 12ft Assembly

32 Counterweights (1620-054)

14 ft Lane - P/N 1620-085

3

- 3ft Arm Channel Sections

2 - 2ft Arm Channel Sections

2 - End Caps

Secondary Barrier Arm 14ft Assembly

34 Counterweights (1620-058)

1

2

3-4

5

6

7

8

9

10

11

12

DoorKing Safety for Lane Barrier

Safety and Traffic Management for Lane Barrier System

Layout

Entry Lane Only In-Ground Loop Options

Install Traffic Light (Required)

Install Octagon Arm

Install Photocell (Required)

Opening Operation (Green Lights)

Closing Operation (Red Lights)

Manual Release Operation

Operator Factory Wiring and ALL REQUIRED Components Wiring

Arm Channel Section

End

Cap

One-Way Traffic Direction ONLY!

IMPORTANT: Installation of Octagon Arm with Reverse/LED Edge, Traffic Light and Photocell is REQUIRED.

Octagon Arm with

Reverse/LED Edge

Photocell

Traffic

Light

1

1620-065-G-8-20

Moving Gate Can Cause

Serious Injury or Death

KEEP CLEAR! Gate may move at any time

without prior warning.

Do not let children operate the gate or play

in the gate area.

This entrance is for vehicles only.

Pedestrians must use separate entrance.

DoorKing Safety for Lane Barrier

NOT A WALKWAY

WA

LKWAY

C

L

A

S

S

C

E

R

T

I

F

I

E

D

T

O

C

A

N

/

C

S

A

C

2

2

.

2

N

O

.

2

4

7

C

ON

F

O

R

M

S

T

O

A

N

S

I

/

U

L

-

3

2

5

VE

H

I

C

U

L

A

R

G

A

T

E

O

P

E

R

A

T

O

R

H

P

5

3

3

8

2

M

O

D

E

L

S

E

R

I

A

L

V

O

L

T

S

P

H

A

S

E

A

M

P

S

6

0

Hz

M

A

X

G

A

T

E

L

O

A

D

D

o

o

r

K

i

n

g

,

I

n

c

.

,

I

n

g

l

e

w

o

o

d

,

C

A

MO

V

I

N

G

A

R

M

c

a

n

c

a

u

s

e

v

e

h

i

c

l

e

d

a

m

a

g

e

,

s

e

r

i

o

u

s

i

n

j

u

ry

o

r

d

e

a

t

h

.

S

T

AY

C

L

EAR

o

f

a

r

m

a

t

a

l

l

t

i

m

e

s

.

N

O

:

P

ed

e

s

tr

ia

n

s

B

i

c

y

c

l

e

s

M

o

t

o

r

c

y

c

l

e

s

WA

RNI

NG

Mo

vi

n

g

Ga

te

Ca

n

Ca

u

se

S

e

riou

s In

ju

ry

o

r

Dea

th

K

E

E

P

CLE

A

R!

G

ate

ma

y

mo

ve

a

t

a

n

y

ti

me

w

i

th

o

u

t p

r

i

o

r

wa

r

n

i

n

g

.

D

o

n

ot

l

e

t c

hi

l

d

r

e

n

o

p

e

rate

the

g

a

te

o

r

p

l

a

y

i

n

th

e

g

a

te

a

re

a.

T

h

i

s

e

n

tr

a

nce

i

s fo

r

veh

i

c

l

e

s

o

nly

.

P

ede

str

i

a

n

s

mu

s

t use

s

ep

a

r

ate

en

tr

a

n

ce.

IMPORTANT: A lane barrier gate operator installed WITHOUT any

external safety sensors CANNOT sense a person under the raised

arm and can strike them while the arm is lowering.

This scenario is VERY DANGEROUS and MUST NEVER OCCUR!!

When the photo beam gets

interrupted by a pedestrian, a

lowering arm will reverse and raise.

Photo Sensor

• DKS Lane Barrier System is NOT crash rated. It is intended to provide a formidable barrier to help

prevent passenger vehicles and light-duty trucks from driving through a controlled traffic lane.

• Lane barrier MUST have reverse/LED edge on arm, traffic light and photoelectric cell functioning or

remove lane barrier from service until repairs have been made.

• Make sure all warning signs are on operator and arm. They MUST be easily visible.

• Do not install the operator in such a way that the arms moves within 16 inches of a rigid object

or 10 feet from high voltage power wires with arm in the raised position.

• Speed limit through barrier area is 5 MPH. Install speed bumps, warning signs and hazard stripes

where visible in the area of the lane barrier gate, failure to do so may result in injury, damage to

operator and vehicle.

• Users should be familiar with proper use of operator, these include; hardware operation, reversing

functions and testing, reversing loops, inherent reversing system, electric edges, photoelectric cells

related external devices and possible hazards.

• Keep adults, children and objects away from operator and HAZARD ZONES.

•

Automotive ONE-WAY traffic only - No bicycles or motorcycles.

Pedestrians MUST be provided with separate access.

• All electrical connections should be made in accordance with local electrical codes.

• Security features should be installed to avoid unauthorized use.

• Controls intended for user activation must be located at least six feet (6') away from any moving

part of the barrier gate and where the user is prevented from reaching over, under or around the lane

barrier gate to operate the controls. Emergency access controls only accessible by authorized

personnel (e.g., fire, police, EMS) may be placed at any location in the line-of-sight of the lane barrier

gate.

• When manually operating the gate operator arms, the user MUST make sure that the gate area is

clear BEFORE operating the controls. Any activity in the traffic lane should be monitored to ensure a

safe operation when opening or closing the lane barrier gate. The motion of the barrier arms must be

directly observable by the person operating the lane barrier. While barrier arms are in motion

NO pedestrian and NO vehicle shall be in the immediate vicinity of the lane barrier area.

• When removing the operator from service, move the arms to the full open

position and shut off power at the service panel.

• Operators and components should be properly installed and

maintained following the recommended service schedule,

test the operator monthly. Keep all debris out of arm

channel and from operator housing vents and off of

arms. Contact your service dealer for any

maintenance or repairs.

• Vehicular lane barrier gate operator can produce high

levels of force, it is important that you are aware and

eliminate possible HAZARDS; Pinch Points, Entrapment

Areas, Overhead Power Wires, Absence of Controlled

Pedestrian Access, Traffic Backup.

OT

N

2

1620-065-G-8-20

Safety and Traffic Management for Lane Barrier System

NOT A WALKWAY

A

WALKWAY

C

L

A

S

S

C

E

R

T

I

F

I

E

D

T

O

C

A

N

/

C

S

A

C

2

2

.

2

N

O

.

2

4

7

C

O

N

F

O

R

M

S

T

O

A

N

S

I

/

U

L

-

3

2

5

V

E

H

I

C

U

L

A

R

G

A

T

E

O

PE

R

A

T

O

R

H

P

5

3

3

8

2

M

O

D

E

L

S

E

R

I

A

L

V

O

L

T

S

P

H

A

S

E

A

M

P

S

6

0

H

z

M

A

X

G

A

T

E

L

O

A

D

D

o

o

r

K

i

n

g

,

I

n

c

.

,

I

n

g

l

e

w

o

o

d

,

C

A

M

O

V

IN

G

A

R

M

c

a

n

c

aus

e

v

e

h

i

c

l

e

d

a

m

age

,

s

e

r

i

o

u

s

i

nj

u

r

y

o

r

d

e

at

h.

S

T

A

Y

CL

E

A

R

of

ar

m

a

t

a

l

l

t

i

m

es

.

N

O:

P

e

des

t

r

ia

n

s

B

i

c

y

c

l

e

s

M

o

t

o

r

c

y

c

l

e

s

W

ARNI

NG

M

o

v

i

n

g

G

a

te

C

an

Ca

us

e

S

er

i

o

us

Inj

u

r

y

or Deat

h

K

EE

P

C

LE

A

R

!

Ga

t

e

m

a

y

m

o

v

e

a

t

a

n

y

t

i

m

e

w

i

t

h

o

u

t

p

r

i

o

r

w

a

r

n

i

ng

.

D

o

n

o

t

l

e

t

c

h

il

d

r

e

n

o

p

e

ra

t

e

t

h

e

g

a

t

e

o

r

play

in

t

he

g

a

t

e

a

r

ea

.

T

h

i

s

e

nt

ra

nc

e

i

s

f

o

r

v

e

hic

l

e

s

o

n

l

y

.

P

e

d

e

s

t

r

ia

n

s

m

u

s

t

u

s

e

s

e

pa

r

a

t

e

en

t

r

an

c

e

.

Non-Contact Sensor: (photocell) Minimizes

the potential of the arms lowering on

vehicular or other traffic that loops cannot

sense. Located directly under arm.

Contact Sensor: (reverse edge)

Minimizes the potential of the arms

lowering on vehicular or other traffic

that loops cannot sense.

Located directly on arm.

Traffic

Red/Green

Light:

Helps control

traffic.

Arm Red/Green LED Lights:

Helps with arm’s visibility and

position. Helps control traffic.

Separate

Pedestrian

Entrance: Located so

pedestrians CANNOT

come in contact with the

lane barrier system.

In-Ground Loop: Loop minimizes the

potential of the arms closing when a

vehicle is present. Number and

placement of loop(s) is dependent on

the application.

Warning Signs: Permanently mounted on

operator and arm and easily visible.

Hazard Stripes: NO stopping or standing

“Hazard Stripes”. Permanently painted

WHITE on pavement on both sides of arm.

Pedestrian Alert Warning:

“NOT A WALKWAY” pavement marking

facing both directions, permanently

painted WHITE on pavement.

Vehicular lane barrier gate operator can produce high levels of force. It is important that

you are aware and eliminate possible HAZARDS; Pinch Points, Entrapment Areas,

Overhead Power Wires, Absence of Controlled Pedestrian Access, and Traffic Management.

ONE-WAY

Traffic Direction

ONLY

Entrance

Pedestrians MUST be provided with separate access.

3

1620-065-G-8-20

Secondary

Arm Rod

TOP

Adjustment

Ball Joint Fixture

Traffic Direction

One-Way Traffic Direction ONLY!

Secondary Arm

Assembly

Secondary Arm Assembly

Secondary arm

bracket bolted

to hub.

Secondary Arm Rod

Secondary Barrier Arm (Up Position)

Arm Channel Section

2 ft or 3 ft

End

Cap

1601 Octagon Arm

1601 Barrier

Operator

Support Post Assembly

Support Post Assembly

Lane Width

Varies depending on 1620 Model selected.

12”

12”

36”

6”

6”

6”

6”

6”

6”

1”

1”

6”

6”

6”

6”

Use 3000 psi

reinforced concrete. It MUST be flat.

DO NOT install directly on asphalt.

Secondary Barrier Arm Counterweight Assembly

Same number of counterweights

MUST be on each side of plate.

9 ft Lane: Use 30 counterweights (15 on each side)

10 ft Lane: Use 32 counterweights (16 on each side)

12 ft Lane: Use 32 counterweights (16 on each side)

14 ft Lane: Use 34 counterweights (17 on each side)

Photo Beam

Note: Allow an extra 6

inches of concrete

around all structures min.

IMPORTANT: Secondary barrier arm is a fixed distance for each lane width model

and this will determine the specific placement of the support post assemblies.

Connect secondary arm bracket and rod assembly on

opposite side of 1601’s octagon arm as shown.

Adjust arm position using ball joint fixtures so arm lays

completely in channel when down (see next page).

Plate

Counterweight

Counterweight

Cover

39.5”

CLASS

CERTIFIED TO

CAN/CSA C22.2 NO. 247

CONFORMS TO

ANSI/UL-325

VEHICULAR GATE OPERATOR

HP

53382

MODEL

SERIAL

VOLTS PHASE

AMPS 60 Hz

MAX GATE LOAD

DoorKing, Inc., Inglewood, CA

MOVING ARM

can

cause vehicle damage,

serious injury or death.

STAY CLEAR

of arm

at all times.

NO:

Pedestrians

Bicycles

Motorcycles

WARNING

Moving Gate Can Cause

Serious Injury or Death

KEEP CLEAR! Gate may move at any time

without prior warning.

Do not let children operate the gate or play

in the gate area.

This entrance is for vehicles only.

Pedestrians must use separate entrance.

Arm DOWN

Arm

UP

90°

Approx. 60°

Counterweight

Assembly

Secondary Arm

in UP position.

Ball Joint Fixtures

Test hub UP and DOWN

position before installing

secondary arm bracket.

H

ub

Secondar

y

Arm

Bracket

Traffic

Light

34.5”

14.74”

7.76”

Layout

Drawings NOT to scale.

Adjustment

Secondary

Arm Rod

BOTTOM

Ball Joint Fixture

Counterweig

ht

s

Secon

dar

y Arm in

DOWN position

.

Secondary

Arm

in

UP

position.

IMPORTANT: Installation of Octagon Arm with Reverse/LED Edge, Traffic Light and Photocell is REQUIRED.

4

1620-065-G-8-20

Layout

Octagon Arm Down

Reverse/LED Edge

CLASS

CERTIFIED TO

CAN/CSA C22.2 NO. 247

CONFORMS TO

ANSI/UL-325

VEHICULAR GATE OPERATOR

HP

53382

MODEL

SERIAL

VOLTS PHASE

AMPS 60 Hz

MAX GATE LOAD

DoorKing, Inc., Inglewood, CA

MOVING ARM

can

cause vehicle damage,

serious injury or death.

STAY CLEAR

of arm

at all times.

NO:

Pedestrians

Bicycles

Motorcycles

WARNING

Moving Gate Can Cause

Serious Injury or Death

KEEP CLEAR! Gate may move at any time

without prior warning.

Do not let children operate the gate or play

in the gate area.

This entrance is for vehicles only.

Pedestrians must use separate entrance.

Wire Mesh

Conduit

Wire Mesh

Arm Channel

Arm Down

Secondary Arm

See previous page.

Secondary Arm Rod

Secondary Barrier Arm (Up Position)

6”

Min

33.5”

6”

Use 3000 psi reinforced concrete. It MUST be flat.

DO NOT install directly on asphalt.

Note: Can be installed on existing concrete roadway (no asphalt).

Install arm channel

sections so arm is

centered in channel.

Sleeve

Anchor

Sleeve

Anchor

Photocell Beam

3/4

1/2

Secure stop posts to the concrete

using 3/4” x 3” minimum,

1” x 3” maximum

sleeve anchors

(not supplied).

Secure arm channels to the

concrete using 1/2” x 3” sleeve

anchors minimum (not supplied).

Cut off excess threads flush

with top of nut on the

sleeve anchors that will

come in contact with tires.

Drawings NOT to scale.

Counterweight

Assembly

(see previous page)

Wire Mesh

Arm Channel

Arm Up

Secondary Barrier

Arm Positions

Counterweight

Assembly

6” Min

MOVING ARM

can

cause vehicle damage,

serious injury or death.

STAY CLEAR

of arm

at all times.

NO:

Pedestrians

Bicycles

Motorcycles

WARNING

Stop Post Stop Post

5

1620-065-G-8-20

Arming Loop

for Access Control Device

(Optional)

OR

Ticket Eject Loop

for Ticket Spitter (Required)

9409

Entry Lane Only In-Ground Loop Options

Before attempting to connect any wiring to the operator, be sure that the

circuit breaker in the electrical panel is in the OFF position. Permanent wiring

must be installed to the operator as required by local electrical codes. It is

recommended that a licensed electrical contractor perform this work.

Loop detector wiring shown is for DoorKing model 9409 Dual Channel

plug-In loop detector only.

If using other loop detectors refer to their Loop Information Manual for

installation instructions, loops/preformed loops and wiring diagrams.

All inputs to the main terminal are NORMALLY OPEN.

Dual Channel

REVERSE

SENSITIVITY

TIME

DELAY

SW 1

SW 2

POWER

1

ON

2 3 4 5 6 7 81

ON

2 3 4 5 6 7 8

NC NO

UP

LOOP

DOWN

LOOP

123456 789 10 11 12 13 14

1601-010

Access

Control

Device

OR

Ticket

Spitter

Com

NO

Com

NO

A

A

If the ARMING LOOP is

not used, then a single

channel loop detector

can be used (9410) in the down loop port.

Connect the down loop to loop 1 on this

detector. Connect the access control device

directly to main terminal 6 and 14.

Arming Loop Note: The arming loop only allows the access control device to function when a vehicle is on the

loop, otherwise it will not function. This prevents pedestrians from gaining access through the vehicular gate.

Timer Note: The timer can be used with a down loop. When timer is ON with a down loop, it will start countdown

when the arm has fully raised. Activation of the down loop will cancel timer countdown. Useful when an access

control device OR ticket spitter has been activated but vehicle does not move forward to activate the down loop.

The arm will remain UP. Timer will time out and lower the arm without the down loop being activated.

Switch 4 is ON.

Switch 7 is OFF (Timer). The arm

will rotate down after the vehicle

clears the down loop.

See timer note below.

Switch 5 is ON. The lowering arm

will instantly reverse when photo

sensor gets blocked.

SW 1

1

ON

2 3 4 5 6 7 8

SW 2

1

ON

2 3 4 5 6 7 8

Main Terminal

Type of wiring to be used on ALL external devices:

A) Type CL2, CL2P, CL2R, or CL2X.

B) Other cable with equivalent or better electrical,

mechanical, and flammability ratings.

Down Loop

1 Ft. Minimum Distance

12 Ft.

NOT A WALKWAY

NOT A WALKWAY

DoorKing offers a free “Loop and

Loop-Detectors Information

Manual” PDF located at

DoorKing's web site for more

information. www.doorking.com

Photo

Sensor

See page 8.

Reverse

Typical DIP-Switch Settings

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Low Voltage Common

Reverse Input

UP Input

Down

Loop

Port

DIP

Switches

6

1620-065-G-8-20

Support

Post

Bracket

Bracket

Cover

U-Bolt

Clamp

Access Door

U-Bo

lt

Clam

p

Route

6 ft cable

through

hole

.

Elbow

Support Post

Use existing

cir

cuit boar

d

bracket bolts

to mount

support post

bracket.

Drill 7/8” hole

centered where

elbow touches

operator housing

(Approximatel

y 18” down

from th

e top of operator

).

Secure 3/4” conduit nipple

in drilled hole with conduit nut.

Route traffic light

cable through

support post.

Install Traffic Light (REQUIRED)

Assemble Support Post Mount Support Post on OPPOSITE Side of Access Door Wire Light to Operator

1 2

3

REVERSE

SENSITIVITY

TIME

DELAY

POWER

1

ON

2 3 4 5 6 7 81

ON

2 3 4 5 6 7 8

NCNO

UP

LOOP

DOWN

LOOP

1234567891011121314

SW 1

SW 2

ON

OFF

AC POWER

AUTO

DOWN

UP

Conduit

Nipple

Traffic Light Terminal

Red

Traffic

Light

Cable

Traffic Light

Cable

Green

Black

Black

(+)

Keep wire clear of all moving parts.

NONCC

Mo

ving

G

a

te

Can

Ca

u

se

Se

ri

ous

In

j

ury or De

a

th

K

E

E

P

C

LEA

R

! Ga

t

e

m

ay

m

o

v

e

at any

t

im

e

w

it

h

ou

t

pri

o

r

w

arn

in

g

.

D

o not

le

t c

h

ild

re

n

o

pe

ra

t

e

t

h

e

ga

te or p

la

y

in

t

h

e

gate are

a.

T

h

is

en

tra

nc

e is

for v

e

h

ic

les

o

n

ly.

P

e

d

e

s

t

ria

n

s

m

us

t

u

s

e

s

e

p

a

ra

te en

t

ra

nce

.

Conduit

Nipple

Existing

Bracket

Bolts

Existing

Bracket

Bolts

1601 operator WITH

convenience open

CANNOT be USED.

C - Common - White Wire

NC - Close - Red Wire

NO - Open - GREEN Wire

Arm Relay Contacts

1601-010

White (-)

to Common

12

VD

C

Approx 18”

Make sure traffic light

stays clear of raising arm.

Arm Down

Arm Up

2” conduit nut to secure elbow.

Use 2” conduit

nuts to secure

traffic light

to support post.

Traffic Light

Top View

2” Elbow

Support Post

WhiteRed/Brown

Wiring Note: See page 12 for complete wiring.

7

1620-065-G-8-20

Slide Reverse Edge on Arm

Drawings NOT to scale.

Install Octagon Arm

1

2

REVERSE

SENSITIVITY

TIME

DELAY

POWER

1

ON

2 3 4 5 6 7 81

ON

2 3 4 5 6 7 8

NCNO

UP

LOOP

DOWN

LOOP

12345678 10111213

SW 1

SW 2

ON

OFF

AC POWER

AUTO

DOWN

UP

NONCC

Red+

Black-

Power

Transformer

(1601-345)

T

ransformer Plug

C - Common - WHITE Wire

NC - Close - ORANGE Wire

NO - Open - GREEN Wire

Keep wire

harness

clear of

all moving

parts.

Arm Relay Contacts

Terminal 9 - Yellow Reverse Edge

Terminal 14 - Yellow Reverse Edge

Cable

Grip

Cable

Gr

ip

Cabl

e

Grip

Knock-Out

Knock-Out

Far Side

Option

Near Side

Option

Use bottom hole on arm bracket to secure cable grip.

Plug in reverse edge.

Wire Harnes

s Secured

to Top of Cabinet for

FAR

si

de option

Included Adhesive

Zip Ties

Use supplied adhesive

zip tie to secure harness

to bottom of bracket.

IMPORTANT: Choose which side of

the operator the arm is mounted on,

remove knock-out and run wire

harness accordingly as shown.

Test hub UP and DOWN position

before installing arm bracket.

Allow arm to protrude

about 1” past the end

of arm bracket. Make

sure arm cover fits

over arm.

Arm Bracket

Hub

Reverse Edge

Octagon

Arm

Install End Cap

Install Wire Harness

Install Arm & Reverse Edge (REQUIRED)

Wiring

Push a screwdriver

through the hole in the

bottom of cap to release

spring while pushing cap

on. Keep pushing cap on

until a “CLICK” is heard,

locking it in place.

1601 operator WITH

convenience open

CANNOT be USED.

Install Arm Cover

IMPORTANT: Wire harness MUST

remain clear of the rotating arm and

the arm cover to avoid wire chaffing.

3

Tip: Liquid soap will

help reverse edge

slide on easier.

Wiring Note: See page 12 for complete wiring.

1601-010

IMPORTANT: Allow slack in the

wire harness between the cable

grips of at least 13” or more

for the rotating arm.

IMPORTANT: Allow slack in the wire harness between the

cable grips of at least 13” or more for the rotating arm.

914

12 VDC

8

1620-065-G-8-20

S6 AC10-25V

DC12-30V

Power Relay

NO NC COM

NOT A WALKWAY

NOT A WALKWAY

REVERSE

SENSITIVITY

SW 2

POWER

2

3 4 5 6 7 8

NC NO

DOWN

LOOP

12345 6789 10 11 12 13 14

1601

Main Terminal

C

L

A

S

S

C

E

R

T

IF

IE

D

T

O

CA

N

/C

S

A

C2

2

.

2

N

O

.

2

4

7

C

O

N

F

O

R

M

S

T

O

A

N

S

I/U

L

-

3

2

5

V

E

HICU

L

AR

G

A

T

E

O

P

E

RAT

O

R

H

P

5

3

3

8

2

M

O

D

E

L

SER

IA

L

V

O

LT

S

P

H

ASE

A

M

PS

6

0

H

z

M

A

X

G

A

T

E

L

O

AD

D

o

o

r

K

i

n

g

,

I

n

c

.

,

I

ng

l

e

w

o

o

d

,

C

A

MO

VI

N

G

AR

M

c

a

n

cau

se

v

e

h

i

cl

e

d

a

ma

g

e

,

se

r

i

o

u

s

i

n

j

u

ry

o

r

d

e

a

t

h

.

STAY

CL

EA

R

o

f

a

r

m

a

t

a

l

l

t

i

me

s.

N

O

:

P

ed

es

t

r

i

an

s

B

i

cy

cl

es

Mo

t

or

c

yc

l

e

s

WARNING

M

ov

ing Gat

e Ca

n Cause

Serious Inj

ury or Death

K

E

E

P

C

L

EA

R

! G

a

te

m

ay

m

o

v

e a

t a

n

y

ti

m

e

w

it

ho

u

t

p

ri

o

r

w

a

rn

in

g

.

D

o

n

o

t le

t

c

h

ild

ren

o

pe

r

a

te th

e

g

a

te

o

r

p

l

a

y

in

th

e

g

a

te

a

re

a

.

T

h

is

en

t

r

a

n

c

e

i

s

fo

r

v

e

h

ic

le

s

o

n

ly

.

Ped

e

s

tri

a

n

s

m

u

s

t

u

s

e

s

e

p

a

r

a

te en

tr

an

c

e

.

M

OVING

A

RM

c

a

n

c

a

u

s

e

v

e

h

i

c

l

e

d

a

m

a

g

e

,

s

e

ri

o

u

s

i

n

j

u

r

y

o

r

d

e

a

t

h

.

ST

A

Y

CL

E

AR

o

f

a

rm

a

t

a

l

l

t

i

m

e

s

.

NO:

P

e

d

e

s

t

r

i

a

n

s

B

i

c

y

c

l

e

s

M

o

t

o

rc

yc

l

e

s

WA

R

N

I

N

G

Install Photocell (REQUIRED)

Mount photocell directly below the octagon arm as shown, mounting brackets not supplied.

Type of wiring to be used on ALL external devices:

A) Type CL2, CL2P, CL2R, or CL2X.

B) Other cable with equivalent or better electrical,

mechanical, and flammability ratings.

Low Voltage Common

Reverse Input

24 VAC - 250 mA max

DoorKing Retro-Reflective

Photocell (P/N 8080-057)

Relay (NO)

Power

If using other photocells refer

to the manufacturer’s manual

for wiring installation.

Reflector

SW 2, Switch 5 is ON. The lowering

arm will instantly reverse when

photocell gets blocked.

SW 2

1

ON

2 3 4 5 6 7 8

DIP-Switch

1601-010

Photocell

Make sure photocell mounting bracket

(not supplied) does not interfere with

the internal components.

S6 AC10-25V

DC12-30V

NO NC COM

Beam Sensors

After photocell has been mounted,

spring mounted beam sensors can

be precisely adjusted “Fine tuned”

using the 3 screws to help keep the

GREEN LED ON if necessary.

Green LED

Terminal #5 Note:

Exceeding 250 mA

of power from this

terminal may cause

the circuit board

transformer to

overheat, causing

intermittent

problems.

Position reflector directly across from

mounted and wired photocell. Green LED

on photocell will remain lit when reflector

is in correct position. Permanently mount

reflector making sure LED remains lit.

“Fine Tune” photocell alignment if necessary, see above.

Fine Tune Photocell

Wiring Note: See page 12 for complete wiring.

9

1620-065-G-8-20

NOT A WALKWAY

NOT A WALKWAY

ONE-WAY

Traffic Direction

ONLY

C

L

AS

S

CE

R

T

I

F

I

E

D

T

O

C

A

N

/

C

S

A

C

2

2

.

2

N

O

.

2

4

7

C

O

N

F

O

R

M

S

T

O

AN

S

I

/

U

L

-

3

2

5

VE

HI

C

UL

A

R

GA

T

E

OP

E

RAT

O

R

H

P

5

3

3

8

2

M

O

D

E

L

S

E

R

I

A

L

V

O

LT

S

P

H

AS

E

A

M

P

S

6

0

H

z

M

AX

G

A

T

E

L

O

A

D

D

o

o

r

K

in

g

,

In

c

.

,

In

gl

e

w

oo

d

,

C

A

M

O

VIN

G

AR

M

ca

n

cau

se

ve

h

i

cl

e

d

a

m

a

g

e

,

ser

i

o

u

s

i

n

j

u

ry

o

r

d

e

a

t

h

.

ST

A

Y CL

E

AR

o

f

a

rm

a

t

a

l

l

t

i

m

e

s.

N

O

:

P

e

d

e

st

r

i

a

n

s

B

i

c

y

cl

e

s

M

o

t

o

r

c

yc

l

e

s

W

A

RN

I

N

G

Mo

vi

n

g

G

a

t

e

C

a

n

C

a

u

se

Serio

us I

n

j

u

ry

o

r

D

ea

t

h

KE

EP

C

L

EA

R

! Gat

e

ma

y

mo

v

e

a

t a

n

y

t

ime

w

i

tho

ut

p

ri

o

r

w

a

r

n

ing

.

D

o

n

o

t

l

e

t

c

hild

r

e

n

op

e

ra

te

the

g

a

te

o

r

p

l

a

y

i

n

th

e

ga

te

a

r

e

a

.

This

e

n

tra

n

c

e

i

s

f

or

v

e

h

i

c

le

s

o

n

ly

.

Pe

d

e

s

tr

i

an

s

mus

t

u

s

e

s

e

pa

r

ate e

n

tr

a

n

ce

.

Opening

Traffic Light turns GREEN

Arm

RAISES and

LEDs turn GREEN

Secondary barrier

arm LOWERS

Opening Operation (Green Lights)

This occurs after access control device has approved entry.

10

1620-065-G-8-20

NOT A WALKWAY

NOT A WALKWAY

ONE-WAY

Traffic Direction

ONLY

C

L

A

S

S

CE

R

T

I

F

I

E

D

T

O

C

A

N

/

C

SA

C

2

2

.

2

N

O

.

2

4

7

C

O

N

FO

R

M

S

T

O

A

N

S

I/U

L

-

3

2

5

V

E

HI

C

UL

A

R

G

A

T

E

OP

ER

A

T

OR

H

P

5

3

3

8

2

M

O

D

E

L

S

E

R

I

AL

V

O

L

T

SP

H

A

S

E

AM

P

S

6

0

H

z

M

AX

G

A

T

E

LO

A

D

D

o

o

r

K

ing

,

I

n

c

.

,

I

n

g

l

e

w

o

o

d

,

C

A

MO

VIN

G

A

R

M

ca

n

ca

u

se

veh

i

cl

e

d

a

ma

g

e

,

s

e

r

i

o

u

s i

n

j

u

ry

o

r

de

a

t

h

.

ST

AY

CL

E

AR

o

f

a

r

m

a

t

a

l

l

t

i

m

e

s.

N

O

:

P

e

d

es

t

ri

an

s

B

i

c

y

cl

es

M

o

t

or

c

y

cl

e

s

WA

RNING

M

oving Gat

e Ca

n Caus

e

Serious Inj

u

ry or Death

KE

EP

C

L

E

A

R

!

G

a

te

ma

y

mo

v

e a

t

a

n

y

time

w

it

h

ou

t

p

ri

o

r

w

a

rn

in

g

.

D

o n

o

t le

t

c

h

il

d

r

e

n

o

p

e

r

at

e

th

e

g

a

te

o

r

p

l

a

y

in

th

e

g

a

te

a

re

a

.

This

e

n

t

ra

n

c

e i

s

for

v

e

h

ic

les

o

n

ly

.

Ped

e

s

tri

a

ns

mu

s

t

u

s

e

s

e

p

a

r

ate en

tr

a

n

c

e

.

Closing

M

OVING AR

M

c

a

n

c

a

u

s

e

v

e

h

i

c

l

e

d

a

m

a

g

e

,

s

e

ri

o

u

s

i

n

j

u

r

y

o

r

d

e

a

t

h

.

ST

AY

CL

E

AR

o

f

a

rm

a

t

a

l

l

t

i

m

e

s

.

NO:

P

e

d

e

s

t

ri

a

n

s

B

i

cy

c

l

e

s

M

o

t

o

rc

y

c

l

e

s

WA

R

N

I

N

G

Traffic Light turns RED

Arm LOWERS and

LEDs turn RED

Secondary barrier

arm RAISES

This occurs after vehicle has exited lane barrier area.

947G

HT4

Closing Operation (Red Lights)

11

1620-065-G-8-20

Manual Release Operation

Interlock

Assembly

Door

C

L

A

S

S

C

E

RT

I

F

I

E

D

T

O

C

A

N

/

C

S

A

C

2

2

.

2

NO.

2

4

7

C

O

NF

O

RMS

T

O

A

N

S

I

/

U

L

-

3

25

V

E

H

I

C

U

L

A

R

G

A

T

E

O

P

E

R

A

T

O

R

HP

5

3

3

8

2

MO

D

E

L

S

E

R

IA

L

V

OL

T

S

P

HA

S

E

A

MP

S

6

0

H

z

MA

X

GA

T

E

L

O

A

D

D

o

or

K

i

ng,

I

nc

.

,

I

ngl

ew

ood,

C

A

MOV

I

NG ARM

c

an

c

aus

e

v

ehi

cle damage,

s

er

io

us inju

r

y or

death.

ST

AY

C

L

E

AR

of ar

m

at al

l

time

s.

NO:

P

edestr

ians

B

ic

ycles

M

o

tor

cy

c

le

s

WARN

I

NG

Moving Gate Can Cause

Serious Injury or De

a

th

K

EEP

CLEAR

!

G

ate m

ay mo

ve

a

t

any

t

im

e

wi

thout prior warning.

Do not

l

et

chil

dren operat

e

th

e

g

ate or

pla

y

in t

he gate area.

This entra

n

c

e

is fo

r

vehi

c

les

on

ly

.

P

e

de

strians mu

s

t

u

se se

parate en

t

rance

.

1

2

4

-

3

+

Access Door

Crank Tool

Storage

1. Unlock and remove access door.

2. Remove crank tool from inside access door.

3. Flip interlock assembly door up, power will be disabled from operator.

4. Insert crank tool into motor pulley as shown.

5. Rotate crank tool to manually move operator arms up or down.

12

1620-065-G-8-20

S6 AC10-25V

DC12-30V

Power Relay

NO NC COM

Chassis

Ground

Operator Factory Wiring and ALL REQUIRED Components Wiring

Down Limit

Magnet

(White Dot)

AC Power UP/Auto/Down

115 VAC Convenience

Open Outlets

Manual Release

Assembly

115 VAC

NEU HOT

Power

Neutral

Purple

Black

Black

Black

Black

Black

Blue

Com

Red

Ground

Up Limit

Magnet

REVERSE

SENSITIVITY

TIME

DELAY

POWER

1

ON

2 3 4 5 6 7 81

ON

2 3 4 5 6 7 8

NC NO

CNCNO

UP

LOOP

DOWN

LOOP

12345 6789 10 11 12 13 14

1601-010

White

White White

Yellow

White

Orange

Ground

1601

1/2 HP

115 VAC

Single Phase

Motor

Interlock

Cut-Off Switch

Com

N.O.

1601

Access Door

C

rank

Tool

Stora

g

e

Factory/Dealer installed manual release

assembly MUST be on the 1601 operator.

Magnetic

Limit Sensor

12 VDC

Traffi

c

L

ight

12 VDC

Reverse/

L

ED

Octagon

Arm

Terminal 14 - Yellow Reverse Edge

Terminal 9 - Yellow Reverse Edge

NO - Open - GREEN Wire (Green LED)

Black Wire (+)

Black

Wire (-)

RED Wire (+)

NO - Open - GREEN Wire

NC - Close - ORANGE Wire (Red LED)

NC - Close - RED Wire

C - Common - WHITE Wire

C - Common - WHITE Wire (-)

+-

Traffic Light

Terminal

Traffic

Light

Cable

Black

Red/

Brown

Green

Red

White

White

Reverse Input

24 VAC - 250 mA max

Factory/Dealer Installed

Manual Release

Type of wiring to be used on ALL external devices:

A) Type CL2, CL2P, CL2R, or CL2X.

B) Other cable with equivalent or better electrical,

mechanical, and flammability ratings.

DoorKing Retro-Reflective

Photocell (P/N 8080-057)

+-

Reverse Edge/LED Lights Octagon Arm

Arm Relay

Contacts

Wire

Harness

(1601-345)

Terminal #5 Note:

Exceeding 250 mA

of power from this

terminal may cause

the circuit board

transformer to

overheat, causing

intermittent

problems.

THIS PRODUCT IS TO BE INSTALLED AND SERVICED BY A TRAINED GATE/DOOR SYSTEMS TECHNICIAN ONLY.

Visit

www.doorking.com/dealer-locator

to find a professional installing and servicing dealer in your area.

Used with 1601 Barrier Gate Operator

WITHOUT Convenience Open

to Enhance Traffic Control

Management

Use this manual for circuit board 1601-010 Revision W or higher.

Installation Manual

1620 Lane Barrier Add-On

1620 Lane Barrier Add-On

1620 Lane Barrier Add-On

1620 Lane Barrier Add-On

Surface Mount Lane Barrier Accessory

www.doorking.com

DoorKing, Inc.

120 S. Glasgow Avenue

Inglewood, California 90301

U.S.A.

Phone: 310-645-0023

Fax: 310-641-1586

1620-065-G-8-20

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

DKS 1620-085 Installation guide

- Type

- Installation guide

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

Other documents

-

Plasti Dip 11360-6 Operating instructions

Plasti Dip 11360-6 Operating instructions

-

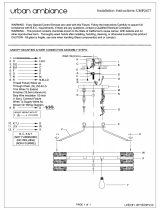

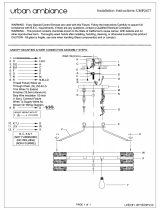

urban ambiance UHP2477 Installation guide

urban ambiance UHP2477 Installation guide

-

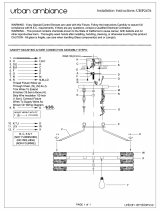

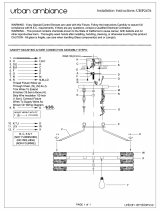

urban ambiance UHP2476 Installation guide

urban ambiance UHP2476 Installation guide

-

Udirc UD1601 1/16 High Performance 4wd Racing Car User manual

Udirc UD1601 1/16 High Performance 4wd Racing Car User manual

-

Chamberlain LiftMaster BAR Owner's manual

-

Raco 167TS Specification

-

BEA Matrix Wire Harness User guide

-

Sylvania 0021141 Datasheet

-

HySecurity StrongArmPark DC Quick Start Steps

-

Selby Hardware 54.X22402S Operating instructions

Selby Hardware 54.X22402S Operating instructions