Page is loading ...

Z-DeckTM

Truck Leveler

Owners Manual

This Manual Covers Dock Lifts Built After Serial Numbers:

C78604 and up

PRINTED IN U.S.A.

RITE-HITE PRINT SHOP

PUBLICATION NO. 1241

MAY 2014

MADE IN U.S.A.

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

2 Pub. No. 1241 - May 2014

NOTES

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

Pub. No. 1241 - May 2014 3

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

PRODUCT SPECIFIC WARRANTY . . . . . . . . . . . . . . . . . . . . . . .3

NOTICE TO USER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SAFTY WARNINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

OWNER RESPONSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . .6

GENERAL FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

INSTALLATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . .9

OPERATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . 12

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

TROUBLESHOOTING AND ADJUSTMENTS. . . . . . . . . . . . . . . . . . . 14

HYDRAULIC SCHEMATICS . . . . . . . . . . . . . . . . . . . . . . . . . 15

ELECTRICAL SCHEMATIC . . . . . . . . . . . . . . . . . . . . . . . . . . 16

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

STANDARD WARRANTY . . . . . . . . . . . . . . . . . . . . . BACK COVER

NOTICE TO USER

Your local RITE-HITE® representative provides a Planned Maintenance Program (P.M.P.) which can be tted to your

specic operation. Call your local representative or the RITE-HITE® Corporation at 414-355-2600.

The RITE-HITE® products in this manual are covered by one or more of the following U.S. patents: 5,546,623; 5,553,987;

5,582,498; 5,664,930; 5,702,223; 5,762,459 (RE: 37,570); 5,882,167; 6,065,172; 6,070,283; 6,085,375; 6,089,544;

6,092,970; 6,106,212; 6,116,839; 6,190,109; 6,276,016; 6,311,352; 6,318,947; 6,322,310; 6,360,394; 6,368,043;

6,431,819; 6,488,464; 6,499,169; 6,505,713; 6,520,472; 6,524,053; 6,634,049; 6,726,432; 6,773,221; 6,832,403;

6,880,301; 7,032,267; 7,062,814; 7,134,159; 7,213,285; 7,216,391; 7,363,670; 7,380,305; 7,503,089; 7,533,431;

7,546,655; 7,584,517; 7,681,271; 7,823,239; 7,841,823; 7,877,831; 7,914,042; 8,006,811; 8,065,770; 8,141,189;

8,191,194; 8,286,757; 8,287,223; 8,303,235; 8,307,956; 8,443,474; 8,464,384; 8,464,846; 8,465,245 and pending U.S

and foreign patent applications. RITE-HITE®, LEVEL-RITE®, THINMANTM, SAFE-T-LIP®, HYDRACHEK®, WHEEL-LOKTM,

DOK-LOK®, DUAL-DOK®, SAFE-T-STRUTTM, DOK-COMMANDER®, JUMBOTM, HYDRA-RITETM, SAFE-T-GATE®, and

SMOOTH TRANSITION DOK SYSTEMTM, are trademarks of RITE-HITE® Corporation.

IMPORTANT

Read and understand contents of this manual prior to installation or operation of this equipment.

For best results, have this product serviced by your authorized RITE-HITE® representative.

PRODUCT SPECIFIC WARRANTY

RITE-HITE® warrants the Z-DeckTM Truck Leveler for one-year parts and labor from date of shipment in accordance with

Rite-Hite’s Standard Warranty Policy.

INTRODUCTION

The Z-DeckTM Truck Leveler is designed to provide a safer work place for workers in shipping and receiving dock areas.

The Z-DeckTM Truck Leveler is a hydraulic device that, when properly installed and operated provides safe and secure

access between truck and dock. The Z-DeckTM Truck Leveler is operated by pressing push buttons on an inside control

box.

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

4 Pub. No. 1241 - May 2014

SAFTY WARNINGS

FIGURE 1 - LOCKOUT/TAGOUT

LOCKOUT/TAGOUT PROCEDURES

The Occupational Safety and Health Administration requires that, in addition to posting safety warnings and barricading

the work area, the power supply has been locked in the OFF position or disconnected. It is mandatory that an approved

lockout device is utilized. An example of a lockout device is illustrated. The proper lockout procedure requires that the

person responsible for the repairs is the only person who has the ability to remove the lockout device.

In addition to the lockout device, it is also a requirement to tag the power control in a manner that will clearly note that

repairs are under way and state who is responsible for the lockout condition. Tagout devices have to be constructed and

printed so that exposure to weather conditions or wet and damp locations will not cause the tag to deteriorate or become

unreadable.

RITE-HITE® Corporation does not recommend any particular lockout device, but recommends the utilization of an

OSHA approved device (refer to OSHA regulation 1910.147). RITE-HITE® Corporation also recommends the review and

implementation of an entire safety program for the Control of Hazardous Energy (Lockout/Tagout). These regulations are

available through OSHA publication 3120.

This is the highest level statement. Failure to

follow the listed instructions will most likely result in

severe injury or death.

This is a statement of serious hazard. Failure

to follow the listed instructions could place the

individual at risk of serious injury or death.

The statements used with this level of

warning deal with a safe operating

procedure. If the procedure is ignored, the

possibility of personal injury may exist.

IMPORTANT is used to draw attention

to a procedure that needs to be followed to prevent

machine or property damage.

When working with electrical or electronic controls,

make sure that the power source has been locked

out and tagged according to OSHA regulations and

approved local electrical codes.

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

Pub. No. 1241 - May 2014 5

OTHER IMPORTANT SAFETY WARNINGS

• Beforestartinginstallationormaintenance,

check and follow the safety procedures of the

facility where the Z-DeckTM is being installed.

• Neverenteratruck/traileruntilitsbrakesare

set, air has been dumped from air ride

suspension (if applicable), and you have

visually inspected to be sure truck/trailer is

securely held in place by a vehicle restraint or

wheel chock per OSHA regulations.

• DONOToperatewithanyoneunderplatform

or in front of the lip.

• Keephands,limbsandloosehairclearof

equipment when operating the table. DO NOT

wear loose clothing or jewelry while operating

this equipment.

• Ifamalfunctiondoesoccur,alwayscallyour

authorized RITE-HITE® service representative

immediately.

• Postwarningsandbarricadesatdocklevel

and at drive level to indicate that work is

being done around and under the lift table.

• Inspectmonthlytoensurethatthereareno

broken or worn parts which could cause injury

to personnel or damage to the equipment.

• Lockout/Tagoutpowertothetrailerliftand

post warnings when work is being performed

on the dock lift.

• Makesurethattheliftingequipmentiscapable

of lifting 8,000lbs. or greater.

• Securelyattachliftinhchainstotheliftinglugs.

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

1. The owner should recognize the inherent danger of

the interface between dock and transport vehicle. The

owner should, therefore, train and instruct operators

in the safe use of dock equipment in accordance with

the information provided below. The manufacturer

shall publish, provide to the initial purchaser, and

make the following information readily available to

owners:

• Installationinstructions

• Recommendedinitialandperiodicinspections

procedures

• Maintenanceprocedures

• Operatinginstructions

• Descriptionsorspecicationsforreplaceableor

repairable parts

• Tablesidentifyingthegrade(slope)forall

variationsoflengthorcongurationofthedock

equipment.

• Informationidentifyingthemaximum

uncontrolled drop encountered upon sudden

removal of support while within the working range

of the equipment

Itshallbetheresponsibilityoftheownertoverifythat

the material listed in this section has been received

and that it is made available for the instruction

and training of personnel entrusted with the use or

maintenance of the dock equipment.

2. When a transport vehicle is parked at a loading

dock, it is important that the vehicle is relatively

perpendicular to the dock face and in close contact

with at least one of the dock bumpers.

3. Nameplates, cautions, instructions, and posted

warnings shall not be obscured from the view of

operating or maintenance personnel for whom such

warnings are intended.

4. Manufacturer’srecommendedperiodicmaintenance

and inspection procedures in effect at date of

shipment shall be followed, and written records of the

performance of these procedures should be kept.

5. As with any piece of machinery, dock equipment

requires routine maintenance, lubrication, and

adjustments.YourlocalRITE-HITE® representative

offersownerstheoptionofaPlannedMaintenance

Program(P.M.P.).Aspartofthisservice,yourlocal

RITE-HITE® representative will do all routine

maintenance, lubrication, and adjustments.

6. Dockequipmentthatisstructurallydamagedshall

be removed from service, inspected by a

manufacturer’sauthorizedrepresentative,and

repaired as needed before being placed back in

service.

7. The manufacturer shall make available

replacement nameplates, caution/instruction

labels, and operating/maintenance manuals upon

request of the owner. The owner shall see that all

nameplates, caution/instruction markings or labels

are in place and legible, and that the appropriate

operating/maintenance manuals are provided to

users.

8. Modicationsoralterationsofdockequipmentshall

be made only with written permission of the original

manufacturer. These changes shall also satisfy all

safety recommendations of the original equipment

manufacturer for the particular application of the dock

equipment.

9. When industrial trucks are driven on and off

transport vehicles during the loading and unloading

operation, the brakes on the transport vehicle shall

be applied and wheel chocks or a positive restraining

device shall be engaged.

10. Inselectingdockequipment,itisimportantto

consider not only present requirements but also

future plans or adverse environments.

6 Pub. No. 1241 - March 2009

OWNER RESPONSIBILITY

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

Pub. No. 1241 - May 2014 7

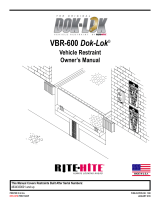

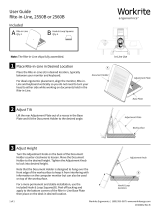

PLATFORM

The platform provides the lifting mechanism for the

truck/trailer. It is hinged at the front of the frame. The

platform is constructed of steel, with a non-slip coating

on the traction surfaces.

WHEEL GUIDES

The wheel guides are steel structures located in front of

the leveler platform and to the approach edges. These

guides assure the proper truck/trailer wheel alignment.

LIFTING LUGS

The lifting lugs are welded to the Z-DeckTM weldment.

These lugs are the attachment points when the unit is

lifted for installation or maintenance.

LIFTING CYLINDER AND MOUNTING PADS

The lifting cylinder is a single acting cylinder of

heavy-duty steel construction. When the power unit

is energized, the cylinder extends, lifting the platform.

When the power is removed, the unit holds position.

When the LOWER button is pressed, the platform’s

weight compresses the cylinder and returns the oil to

the reservoir, allowing the entire unit to lower to grade

level. Attached to each cylinder is a mounting pad.

When attached with the mounting bolts, the mounting

pads secure the cylinder rod end to the concrete

loading dock approach.

POWER UNIT

This assembly pumps hydraulic uid to the platform

lifting cylinders. The power unit consists of an electric

motor, a gear pump, a hydraulic uid reservoir, and

valving. The combination breather/ller cap. Hydraulic

uid can be added to the system by removing this cap

and pouring oil into the reservoir.

VELOCITY FUSE

In case of hose failure, the hydraulic truck leveler is

equipped with an emergency support system valve

called a velocity fuse. This valve is rigidly mounted to

the lifting cylinder hydraulic plumbing.

When an emergency drop occurs, the lift should be

inspected thoroughly by a RITE-HITE® representative.

If nothing has failed, normal operation can be resumed

by pressing the lift UP button to reset the velocity fuse.

DEBRIS GUARDS

The debris guards are located along both sides of

the Z-DeckTM Truck Leveler. These guards assist

in preventing debris from blowing underneath the

Z-DeckTM Truck Leveler.

CONTROL BOX ASSEMBLY

The control box for the Z-DeckTM Truck Leveler has two

buttons, RAISE and LOWER. It also includes a green

“Platform Fully Lowered” pilot light.

GENERAL FEATURES

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

8 Pub. No. 1241 - May 2014

DURING OPERATION PERSONNEL MUST STAY CLEAR OF SIDES OF TRUCK LEVELER AT ALL TIMES.

NEVER OPERATE THE TRUCK LEVELER WITHOUT A TRUCK/TRAILER PARKED IN POSITION.

NEVER RAISE TRUCK LEVELER UNTIL:

THE TRUCK/TRAILER BRAKES ARE SET

AIR HAS BEEN DUMPED FROM AIR RIDE SUSPENSION (IF APPLICABLE)

THE TRUCK/TRAILER HAS BEEN RESTRAINED VIA WHEEL CHOCKS OR OTHER MECHANICAL MEANS

NEVER BE UNDER THE PLATFORM OR SERVICE THE EQUIPMENT WITHOUT THE FOLLOWING:

INSERTING BOTH MAINTENANCE STRUTS AT REAR (DOCK END) OF SIDE TUBES

BARRICADING THE INSIDE AND OUTSIDE WORK AREAS.

FOLLOWING MAINTENANCE SUPPORT PROCEDURES AS SHOWN IN OWNERS MANUAL.

IF REPLACING A LIFTING CYLINDER IS REQUIRED, FOLLOW THE MAINTENANCE LIFTING PROCEDURE

AS OUTLINED IN THE OWNER'S MANUAL AND LIFT ONLY IN THE DESIGNATED SPOTS WITH

EQUIPMENT CAPABLE OF HANDLING 7,500 lb.

P/N LE 1498 REV. XX

Milwaukee, Wisconsin 53223

(800) 456-0600

PRODUCTS CORPORATION

R

TRUCK LEVELER

RAISE LOWER

PLATFORM

FULLY LOWERED

WHEN GREEN

LIGHT IS ON

IMPORTANT

ALWAYS PRESS AND HOLD THE LOWER BUTTON UNTIL

THE TRAILER IS FULLY LOWERED AND THE GREEN

“PLATFORM FULLY LOWERED” LIGHT IS ON

WARNING

WARNING

WHEN SERVICING OR REPAIRING THIS MACHINE, USER MUST LOCKOUT AND TAGOUT THE MACHINE.

COMPLY WITH OSHA 1910.147

Lifting

Lugs

Power Unit

Control Box

Wheel Guide

Wheel Guide

Lifting Lugs

Debris Guard

Debris Guard

Maintenance

Strut

Maintenance

Strut

Side Load

Brace

Side Load

Brace

Hinge Plate

Hinge Pin

Hinge Plate

Hinge Pin

Lifting Cylinder

Platform

FIGURE 2 - FEATURES

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

Pub. No. 1241 - May 2014 9

INSTALLATION INSTRUCTIONS

1. Inspect all equipment to ensure there has been no

freight damage and that all components have arrived.

NOTE: You should receive the following.

• Truck Leveler Deck (assembled with

hoses, cylinders and limit switch).

• Pallet with hydraulic power unit and control

box.

• Pallet with front base plates, wheel guides,

anchors, side load braces and side guards.

2. Review location to ensure it meets installation

needs. If there are any questions, contact RITE-HITE

Applications.

3. Review location of trench or other drains. Lifting

cylinders are located 78” from the bumper face and are

8” wide. Do not place cylinder pads directly over drains.

4. Locate the centerline of the dock. The truck leveler will

be centered on the dock position. See gure 3.

5. Place rear edge of truck leveler platform 32” off

BUMPER face. Make sure you compensate for thicker

bumper projections. See gure 4.

Example: 6” bumpers + 32” = 38” off dock face.

NOTE: Review restraint projection to ensure proper

clearances before setting truck leveler platform.

INSTALLATION INSTRUCTIONS

• Lockout/Tagoutpowertothetrailerlift

according to OSHA regulations and approved

local codes before welding on the truck leveler.

• Beforestartinginstallationormaintenance,

check and follow the safety procedures of the

facility where the Z-Deck is being installed.

• Makesurethattheliftingequipmentiscapable

of lifting 8,000lbs. or greater.

• Securelyattachliftingchainstotheliftinglugs.

A

A

CD

25'

Radius

25'

Radius

32”

C

D

BB

Dock Face

52-1/2"

C

L

52-1/2"

FIGURE 3 - DOCK CENTERLINE

32"

Off Bumper

Face

78" To Back Edge Of Base

85" To Front Of Base

FIGURE 4 - TRAILER LIFT POSITION

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

10 Pub. No. 1241 - May 2014

INSTALLATION INSTRUCTIONS - CONT.

52 1/2”52 1/2”

Centerline Of

Loading Dock

And Truck Leveler

Dock Face

32”

52 3/4” 52 3/4”

131 1/2”

105 1/2”

2”

Gap Between Deck

And Debris Guard

2”

Off

Bumper

Face

Dock Bumper

FIGURE 5 - PLATFORM POSITIONING

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

Pub. No. 1241 - May 2014 11

6. Square truck leveler platform. It is very important that

the truck leveler be square to the dock face.

7. Using lifting bar raise cylinder base plates and center

between structure channels.

8. Edge of cylinder plates must be 2” outside of lifting tube

and centered between channels.

9. If the dock is substantially canted from one side to

another, shim as required underneath base plates.

10. Bolt cylinder base plates to ground using (2ea.) 5/8” x

4” concrete anchors (Supplied).

11. Install front hinge plate weldments. Insert hingh pins

from inside of platform, so washer is on tire side of

hinge. Use washers and cotter pins supplied with pins.

12. Drill and epoxy anchor front hinge plates to the

approach in (14ea.) places with 3/4” x 6” anchors.

13 Install front wheel guides. See gure 6.

14. Install front debris guard at the back edge of the front

base plate and 2” off the side of the platform using 3/8”

stud anchors (Supplied). Align rear debris guard as

needed.

15. Install Side Load Braces at rear of platform. Review

dock side clearances if multiple units shall be installed

next to each other. Stagger placement of guards.

Each brace requires (4ea.) 5/8” x 4” concrete anchors

(Supplied).

16. Drill 3” diameter hole in wall and protect with PVC pipe

so hoses do not become damaged. Seal hole with

expandable foam after installation.

17. Place power unit inside building under control box. Bolt

down to keep from moving.

NOTE: Power unit must be protected via steel bollard

or other means to prevent damage.

18. Connect the two hydraulic hoses to the ttings on the

power unit.

NOTE: Power unit and hoses have been completely

lled and purged of air at the factory. Some leakage

may occur during connection of hoses; however there

is an adequate amount of uid in the reservoir tank in

case of minor spillage.

19. Locate and install the control boxes on wall adjacent

to the overhead door at approximately 48” above the

oor level. Secure control box to wall in accordance

with all local and national electrical codes. Nails are not

acceptable.

20. Connect control box to incoming power using Electrical

Schematics (shipped inside control boxes) and Wiring

Diagram.

NOTE: Fused disconnect must be provided within

sight of control box. This is the responsibility of the

electrician and the owner.

21. Installation complete. Test unit by following the

Operation Instructions in this manual.

INSTALLATION INSTRUCTIONS - CONT.

52 1/2”52 1/2”

Centerline Of

Loading Dock

And Truck Leveler

Dock Face

32”

52 3/4” 52 3/4”

131 1/2”

105 1/2”

2”

Gap Between Deck

And Debris Guard

2”

Off

Bumper

Face

Dock Bumper

FIGURE 6 - WHEEL GUIDE PLACEMENT

Top View

FIGURE 7 - SIDE LOAD BRACE PLACEMENT

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

12 Pub. No. 1241 - May 2014

OPERATING INSTRUCTIONS

1. No trailer at dock, inside green light is ON signaling the

truck leveler is completly lowered.

2. Restrain trailer via wheel chocks or mechanical means.

3. Open door.

4. Lift trailer bed to desired level by pressing and holding

the RAISE TRAILER pushbutton

5. Once loading is complete, store dock leveler.

6. Press and hold the LOWER TRAILER pushbutton until

unit is completely stored at grade level and the inside

green light is ON.

7. Close door.

8. Release trailer.

OPERATION INSTRUCTIONS

Read and obey these instructions to prevent

personal injury.

• DONOToperatetheliftuntiltruck/traileris

parked against the dock bumpers and the

truck/ trailer has been secured.

• ALWAYSsecureloadwhenusingthedocklift.

• NEVERenteratruck/traileruntilitsbrakes

are set, air has been dumped from the air

ride suspension (if applicable), and you have

visually inspected truck/trailer to ensure

truck/trailer is securely held in place

by a vehicle restraint or wheel chocks

per OSHA regulations.

• NEVERreleasethevehiclerestraintor

remove the wheel chocks until loading/

unloadingisnishedandthetruckdriverhas

been given permission to drive away from the

dock.

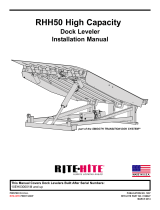

FIGURE 8 - TRAILER PARKED AT DOCK

DURING OPERATION PERSONNEL MUST STAY CLEAR OF SIDES OF TRUCK LEVELER AT ALL TIMES.

NEVER OPERATE THE TRUCK LEVELER WITHOUT A TRUCK/TRAILER PA RKED IN POSITION.

NEVER RAISE TRUCK LEVELER UNTIL:

THE TRUCK/TRAILER BRAKES ARE SET

AIR HAS BEEN DUMPED FROM AIR RIDE SUSPENSION (IF APPLICABLE)

THE TRUCK/TRAILER HAS BEEN RESTRAINED VIA WHEEL CHOCKS OR OTHER MECHANICAL MEANS

NEVER BE UNDER THE PLATFORM OR SERVICE THE EQUIPMENT WITHOUT THE FOLLOWING:

INSERTING BOTH MAINTENANCE STRUTS AT REAR (DOCK END) OF SIDE TUBES

BARRICADING THE INSIDE AND OUTSIDE WORK AREAS.

FOLLOWING MAINTENANCE SUPPORT PROCEDURES AS SHOWN IN OWNERS MANUAL.

IF REPLACING A LIFTING CYLINDER IS REQUIRED, FOLLOW THE MAINTENANCE LIFTING PROCEDURE

AS OUTLINED IN THE OWNER'S MANUAL AND LIFT ONLY IN THE DESIGNATED SPOTS WITH

EQUIPMENT CAPABLE OF HANDLING 7,500 lb.

P/N LE 1498 REV. XX

Milwaukee, Wisconsin 53223

(800) 456-0600

PRODUCTS CORPORATION

R

TRUCK LEVELER

RAISE LOWER

PLATFORM

FULLY LOWERED

WHEN GREEN

LIGHT IS ON

IMPORTANT

ALWAYS PRESS AND HOLD THE LOWER BUTTON UNTIL

THE TRAILER IS FULLY LOWERED AND THE GREEN

“PLATFORM FULLY LOWERED” LIGHT IS ON

WARNING

WARNING

WHEN SERVICING OR REPAIRING THIS MACHINE, USER MUST LOCKOUT AND TAGOUT THE MACHINE.

COMPLY WITH OSHA 1910.147

Truck leveler MUST BE stored in the completely

lowered position to avoid damage to the building and/

or equipment as new trailers back in to the dock.

FIGURE 9 - CONTROL BOX

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

Pub. No. 1241 - May 2014 13

SUGGESTED TRUCK LEVELER

MAINTENANCE

NOTE: Follow maintenance procedures below as

outlined. Include the specic steps for your

leveler model.

NOTE: Your local RITE-HITE® representative provides

a Planned Maintenance Program (P.M.P.)

which can be tted to your specic operation.

Call your local representative.

DAILY

1. During normal operation, inspect and report any

damaged parts or erratic operation. If there are any

broken or worn parts repair as needed.

2. Clean large debris or ice build-up from the dock area.

90 DAYS

1. Preform all Daily Maintenance.

2. Grease front hinge points.

3. Oil cylinder base pins.

4. Check uid level. If unit is low of uid, rell and inspect

hoses and ttings for damage or leaks.

5. Check condition of oil lter on the power unit by looking

at the lter manifold eye. If the eye is green, the lter is

good. If the eye is red, replace the lter.

6. Check to make sure that the debris guards are not

damaged or missing and inspect unit for any stuctural

damage.

7. Check the wheel guides for damage. Retorque any

loose mounting bolts.

8. Check UHMW wear pads on Side Load Braces.

MAINTENANCE

Post safety warnings and barricade work area,

at dock level and at ground level, to prevent

unauthorized use of the dock position.

Lockout/Tagout power to the trailer lift according to

OSHA regulations and approved local codes before

welding on the truck leveler.

Maintenance may be required more frequently at

loading docks exposed to harsh environments

(extreme climates, corrosive chemicals, frequency

of usage exceeding 8 trucks per day, ect.). Consult

RITE-HITE® if these conditions exist for accelerated

maintenance requirements.

All Pins -

Use SAE 30 Oil

UHMW Wear Pad UHMW Wear Pad

FIGURE 10 - LUBRICATION

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

14 Pub. No. 1241 - May 2014

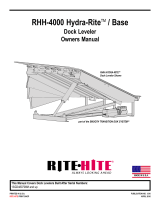

FLOW CONTROL ADJUSTMENT

Thisadjustmenttobeperformedbyaqualied

technician only. Refer to gure 5.

For adjustment, rst unlock the outside locknut.

(Adjustments should be made in 1/4 turn increments)

• To decrease platform fall speed turn adjustment screw

clockwise.

• To increase platform fall speed turn adjustment screw

counterclockwise.

NOTE: When making adjustments in extremely cold

temperatures (below freezing), run unit

several times to conrm that the velocity fuse

doesn’t lock-up with warmer oil.

TROUBLESHOOTING AND ADJUSTMENTS

Symptom Probable Cause Remedy

1. Platform does not lift. a. Excessive load. a. Remove load

b. Fuse and/or overload blown. b. Check fuse and/or overload reset.

c. Low oil level and/or oil leak. c. Check oil level. Check for leaks

that may have caused low oil level.

d. Defective pump. d. check system pressure. If pres

sure is too low may be worn out

pump. Replace if necessary.

e. Defective valve. e. Check valve block. Repair/Replace

if necessary.

f. Filter is clogged. f. Clean or replace suction lter.

2. Platform does not a. Oil Leak. a. Repair oil leaks.

maintain steady height. b. Defective check valve. b. Replace check valve.

c. Defective solenoid valve. c. Replace solenoid valve.

3. Platform locked in “UP” a. Velocity fuse locked up due to air. a. Cycle unit (5 to 10 times) until

position. velocity fuse no longer locks up.

b. Velocity fuse locks up due to b. See Adjustments.

valve adjustment.

(unit lowering to fast)

c. Bent safety stop bar. c. Replace safety stop bar.

Locknut

Adjustment

Screw

O-Ring

FIGURE 11 - FLOW CONTROL ADJUSTMENT

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

Pub. No. 1241 - May 2014 15

HYDRAULIC SCHEMATICS

POWER UNIT

MESH

FILTER

2100 PSI MAX

@5 GPM RELIEF VALVE

ADJUSTABLE

PRESURE

COMPENSATED FLOW

CONTROL

2-WAY 2-POSITION

SOLENOID VALVE

120V/1PH COILS

WITH MANUAL

OVERRIDE

PULL TO RELEASE

0-3000 PSI GLYCERIN GAGE AND SHUT OFF

WITH MANUAL 2 WAY SOLENOID OVERRIDE AND EXTRA TANK

LINE TEE PORT INSTALLED

5 HP- 1750 RPM - TEFC motor

4.11GPM 24 SECONDS TO FULL RAISE

2100 PSI ADJUSTABLE RELIEF

460V/230V -3PH

FLA 6.6 / 13.2 respectively

184 TC Frame

CHECK VALVE

PRESSURE

GAUGE

4" BORE x 2" ROD - 16" STROKE CYLINDERS

PORTS-SAE

#8 ORB

DRILL 3" DIAMETER HOLE IN BUILDING WALL

USE PVC SLEEVE TO PROTECT HOSES

FIGURE 12 - HYDRAULIC SCHEMATIC - STANDARD

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

16 Pub. No. 1241 - May 2014

ELECTRICAL SCHEMATIC

Copper Wire

75°C Minimum

NOTE:

FIELD SUPPLIED BRANCH CIRCUIT PROTECTION OF 25 AMP

MAXIMUM AND DISCONNECTING MEANS REQUIRED

TO MEET N.E.C. AND LOCAL CODES.

Copper Wire

75°C Minimum

102

L2

L3

L1

101

1L2 1L3

N

22

21

20

19

18

17

16

15

6

14

13

12

11

10

9

8

7

5

4

3

2

1

DEVICE LOCATED IN THE FIELD

TERMINAL IN CONTROL PANEL

INDICATES FIELD WIRING

LOCATION CODE:

(F)

LEVELER RELAY

119, 121

LEVELER STORED

RAISE MOTOR

102, 115

2L3

2L1

2L2

L2 L3

105

SPARE

107

108

109

110N

102

NLOWER VALVE

103

106

103A 104

FU1

FNQ-R1

M1

M1

CR1

5 9

MMP1

CR1

13 14

PL1

G

MMP1

RAISE

MOTOR

6.6 FLA

460/3

5

(F)

SV1

(F)

M1

CR1

8 12

LS2

(F)

T1

0.100KVA

240V

115V

FU2

FRN-R-1.25

LS1

(F)

PB2

LOWER

12 AWG

16 AWG (TYP. )

(F)

GND LUG

Minimum 10 AWG

75°C, Copper

12 AWG

HP

SET O.L. TO MOTOR

NAMEPLATE FLA

(FACTORY SET @ 6.6A)

H4

H3 H2

X2

X1

H1

NOTE:

REMOVE JUMPER IF LS1

(LOK UPPER TRAVEL) IS USED

SHOWN AT 240 VOLT 3PH

NEED STANDARD 480 VOLT 3 PHASE

FUSES AND TRANSFORMERS

SHOWN AT 240 VOLT 3PH

NEED STANDARD 480 VOLT 3 PHASE

FLA = 6.6 AMP AT 460 3

FLA = 13.2 AMP AT 230 3

240 VAC

60 HZ.

3 PH

15.7 FLA

PB1

RAISE

FIGURE 13 - ELECTRICAL SCHEMATIC - STANDARD

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

Pub. No. 1241 - May 2014 17

NOTES

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

18 Pub. No. 1241 - May 2014

REPLACEMENT PARTS

1

2

3

4

5

6

7

5

6

7

8

9,10

PLATFORM ASSEMBLY

Item Qty Description RH Part Number Leum Part Number

1 1 Platform Weldment Z-Deck 145523 LE 937

2 2 Side Load Brace 145524 LE 604

3 1 RH Side Back Debris Guard 145525 LE 609-2

3 LH Side Back Debris Guard (Not Shown) 145526 LE 609-1

4 1 RH Side Front Debris Guard 145527 LE 609-4

1 LH Side Front Debris Guard (Not Shown) 145528 LE 609-3

5 2 Hinge Pin 145529 LE 1328

6 2 Hinge Plate 145530 LE 325

7 2 Wheel Guide 102461 -

8 2 Maintenance Strut 145531 LE 1329

9 1 Limit Switch 102500 -

10 1 Limit Switch Mounting Bracket 145532 LE 610

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

Pub. No. 1241 - May 2014 19

7

1

2

9

10

6

10

6

2

Hydraulic Power Unit

5

3

12

11

14

12

11

15

15

8

8

13

“P” Port

“R” Port

Runs Through Platform

Structure Channel

4

HYDRAULIC REPLACEMENT PARTS

* Specify Hose Lenght If Greater Than 20 Feet.

Item Qty Description RH Part Number Leum Part Number

1 1 Hose Assy .50ID 150L 10FJS 6FJS 3000PSI 145511 LE 2856

2 2 Hose Assy .38ID 47L 6FJS 8FJS 90 DEG 3000PSI 145512 LE 2862

3 1 Hose Assy .38ID 125L 6-6FJS Elb 90 DEG 0 DEG 3000PSI 145513 LE 2859

4 1 Hose Assy .25ID 150L 4-4FJS 3000PSI 140898 LE 2863

5 1 Hose Assy .25ID 125L 4-4FJS Elb 90 DEG 0 DEG 3000PSI 145514 LE 2858

6 2 Hose Assy .25ID 35L 4-4FJS 3000PSI 145515 LE 2860

7 1 FTG ELB 90 10 MAORB 10MJ STL ZP 117646 LE 2855

8 2 Velocity Fuse 102493 -

9 1 FTG ELB 90 8MAORB 4MJ STL ZP 145516 LE 2864

10 2 FTG STRT 8MORB 4MJ STL ZP 140950 LE 2861

11 2 FTG Tee 6-6-6MJ STL ZP 55284 LE 2857

12 2 FTG Tee 4-4-4MJ STL ZP 16925 LE 2865

13 1 FTG Cap 6FJ STL ZP 103321 LE 2868

14 2 FTG Cap 4FJ STL ZP 118656 LE 2869

15 2 Hydraulic Cylinder 4 x 16 Z-Deck 141272 LE 1325

RITE-HITE® Z-DeckTM Truck Leveler Owners Manual

20 Pub. No. 1241 - May 2014

HYDRAULIC POWER UNIT REPLACEMENT PARTS

Item Qty Description RH Part Number Leum Part Number

1 1 Hydraulic Power Unit - Complete LE 1077

2 1 Wiring Harness - Hirschmann Connector 111729

3 1 Cartridge Valve - Directional 116789

1 Solenoid Valve w/manual adjust 103983

4 1 Coil Solenoid Hirschmann 104025

5 1 Gauge 103987

6 2 Manifold Assembly

7 1 Filter Element 116800

8 1 Relief Valve 116797

9 1 Pilot to Open Check Valve 116799

10 1 Breather Cap 116805

11 1 Drain Plug 116806

1

2

3

4

5

6

7

8

11

/