Page is loading ...

0600-0021-0000 Rev E Made in the U.S.A.

July 2005 $15.00

Supersedes: 0600-0021-0000 Rev D

User’s Manual

User Levels:

• New User ....................................................... go to page 1.1

• Experienced User .......................................... go to page 2.1

• Expert User .................................................... go to page 2.1

Installers:

• Installation ...................................................... go to page 2.1

• Wiring .............................................................go to page 3.1

1241 Bundy Blvd., P.O. Box 5580, Winona, Minnesota USA 55987-5580

Phone: (507) 454-5300, Fax: (507) 452-4507 http://www.watlow.com

Registered Company

Winona, Minnesota USA

ISO 9001

TOTAL

3 Year Warranty

CUSTOMER

SATISFACTION

Series 97

Safety Information

We use note, caution and warning symbols throughout this book to draw your

attention to important operational and safety information.

A “NOTE” marks a short message in the margin to alert you to an important

detail.

A “CAUTION” safety alert appears with information that is important for pro-

tecting your equipment and performance. Be especially careful to read and fol-

low all cautions that apply to your application.

A “WARNING” safety alert appears with information that is important for pro-

tecting you, others and equipment from damage. Pay very close attention to all

warnings that apply to your application.

The safety alert symbol,

ç

, (an exclamation point in a triangle) precedes a

general CAUTION or WARNING statement.

The electrical hazard symbol,

Ó

, (a lightning bolt in a triangle) precedes an

electric shock hazard CAUTION or WARNING safety statement.

Technical Assistance

If you encounter a problem with your Watlow controller, see the Trouble-

shooting Table in the Appendix and review all of your configuration informa-

tion to verify that your selections are consistent with your application: inputs;

outputs; alarms; limits; etc. If the problem persists after checking the above,

you can get technical assistance from your local Watlow representative, or by

dialing (507) 454-5300.

An applications engineer will discuss your application with you.

Please have the following information available when calling:

• Complete model number • All configuration information

• User’s Manual • Diagnostic menu readings

Your Feedback

Your comments or suggestions on this manual are welcome. Please send them

to: Technical Writer, Watlow Winona, 1241 Bundy Blvd., P.O. Box 5580,

Winona, MN 55987-5580; phone: (507) 454-5300; fax: (507) 452-4507. The

Series 97 User’s Manual is copyrighted by Watlow Winona, Inc., © July 2005,

with all rights reserved. (2194)

NOTE:

Details of a “Note”

appear here in the

narrow margin on the

outside of each

page.

CAUTION:

Details of a

“Caution” appear

here in the narrow

margin on the out-

side of each page.

WARNING:

Details of a

“Warning” appear

here in the narrow

margin on the out-

side of each page.

Chapter 1: Overview . . . . . . . . . . . . . . . . . . . . . . .1.1

Chapter 2: Installation . . . . . . . . . . . . . . . . . . . . . .2.1

Chapter 3: Wiring . . . . . . . . . . . . . . . . . . . . . . . . . .3.1

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . .3.3

Sensor Installation Guidelines . . . . . . . . . . . .3.3

Wiring Example . . . . . . . . . . . . . . . . . . . . . . .3.4

Wiring Notes . . . . . . . . . . . . . . . . . . . . . . . . .3.5

Input 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.6

Input 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.6

Output 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.7

Output 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.8

Output 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.9

Output 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.10

Chapter 4: Software Navigation . . . . . . . . . . . . . . .4.1

Keys and Displays . . . . . . . . . . . . . . . . . . . . .4.2

Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . .4.3

Software Map . . . . . . . . . . . . . . . . . . . . . . . . .4.4

Task Charts . . . . . . . . . . . . . . . . . . . . . . . . . . 4.6

Chapter 5: Features. . . . . . . . . . . . . . . . . . . . . . . . 5.1

Limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.2

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.3

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.8

Communications . . . . . . . . . . . . . . . . . . . . . .5.11

Chapter 6: Parameters . . . . . . . . . . . . . . . . . . . . . 6.1

Home Page . . . . . . . . . . . . . . . . . . . . . . . . . .6.3

Operations Page . . . . . . . . . . . . . . . . . . . . . . 6.4

Setup Page . . . . . . . . . . . . . . . . . . . . . . . . . . 6.7

Factory Page . . . . . . . . . . . . . . . . . . . . . . . . . 6.17

Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A.1

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . A.2

Modbus™ RTU . . . . . . . . . . . . . . . . . . . . . . . A.4

Calibrating the Series 97 . . . . . . . . . . . . . . . . A.11

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . A.14

Specifications . . . . . . . . . . . . . . . . . . . . . . . . A.18

Ordering Information . . . . . . . . . . . . . . . . . . . A.20

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A.21

Prompt Index . . . . . . . . . . . . . . . . . . . . . . . . . A.23

Declaration of Conformity. . . . . . . . . . . . . . . . A.24

Parameter setup order . . . . . . . . . . . . . . . . . . A.25

Fold out Software Map. . . . . . . . . . . . . A.25 - A.26

Warranty and Returns . . . . . . . . . . . . back cover

Figures and Tables

Inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . .1.1

Multiple panel cutout dimensions . . . . . . . . . . . . . .2.1

Installing the controller . . . . . . . . . . . . . . . . . . . . . .2.2a

Gap dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . .2.2b

Removing the controller . . . . . . . . . . . . . . . . . . . . .2.3

Isolation blocks . . . . . . . . . . . . . . . . . . . . . . . . . . .3.2

Power wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.3

Wiring example . . . . . . . . . . . . . . . . . . . . . . . . . . .3.4

Wiring notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.5

Input 1 Wiring

Thermocouple . . . . . . . . . . . . . . . . . . . . . . . .3.6a

RTD (2- or 3-Wire) 100Ω platinum . . . . . . . . .3.6b

Input 2 Wiring

Digital Event . . . . . . . . . . . . . . . . . . . . . . . . . .3.6c

Output 1 Limit Output Wiring

AC Outputs . . . . . . . . . . . . . . . . . . . . . . . . . .3.7a

Output 2 Alarm Output Wiring

AC Outputs . . . . . . . . . . . . . . . . . . . . . . . . . .3.8a

Switched DC, Open Collector . . . . . . . . . . . . . . . . .3.8b

Output 3 Alarm Wiring

AC Outputs . . . . . . . . . . . . . . . . . . . . . . . . . .3.9

Output 4 wiring

AC Outputs . . . . . . . . . . . . . . . . . . . . . . . . . .3.10a

Communications and Retransmit . . . . . . . . . .3.10b

EIA-232 to EIA-435 Conversion . . . . . . . . . . . . . . .3.11a

EIA-232 to EIA-485 Converter . . . . . . . . . . . .3.11b

Keys and displays . . . . . . . . . . . . . . . . . . . . . . . . .4.2

Navigating the Series 97 . . . . . . . . . . . . . . . . . . . .4.3

Software Map . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.4

Calibration offset . . . . . . . . . . . . . . . . . . . . . . . . . .5.3

Filtered and unfiltered input signals . . . . . . . . . . . .5.4

Sensor ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.5

Event inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.6

Retransmitting a remote set point . . . . . . . . . . . . . .5.7

Alarm settings . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.8

Alarm latching . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.9

Alarm silencing . . . . . . . . . . . . . . . . . . . . . . . . . . .5.10

Parameter setup order . . . . . . . . . . . . . . . . . . . . . .6.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .inside back cover

T

Series 97

Table of Contents

TOTAL

3 Year Warranty

CUSTOMER

SATISFACTION

About Watlow Winona

Watlow Winona is a division of Watlow Electric Mfg. Co., St. Louis, Missouri, a

manufacturer of industrial electric heating products, since 1922. Watlow begins

with a full set of specifications and completes an industrial product that is

manufactured totally in-house, in the U.S.A.. Watlow products include electric

heaters, sensors, controllers and switching devices. The Winona operation has

been designing solid state electronic control devices since 1962, and has earned

the reputation as an excellent supplier to original equipment manufacturers.

These OEMs depend upon Watlow Winona to provide compatibly engineered

controls which they can incorporate into their products with confidence. Watlow

Winona resides in a 100,000 square foot marketing, engineering and

manufacturing facility in Winona, Minnesota.

ii ■ Table of Contents Watlow Series 97

Chapter One

Overview

Introduction

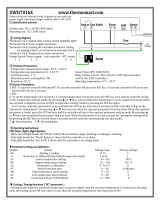

Watlow’s Series 97 is a microprocessor-based controller with a single input, second auxiliary

input and four outputs. Input 1 is used to measure temperature from a thermocouple or

RTD sensor. Input 2 can be utilized as a remote reset switch or a hardware lockout switch.

With up to four outputs, the controller is versatile in handling applications that require a

high/low limit, alarms, retransmit and communications. The controller is so user friendly it

can be set up to display safety and limit messages created by the end user to meet the exact

application need.

The Series 97 limit controller is added to thermal applications to limit over-temperature

conditions. The Series 97 controller provides safety assurance against instances where a

high temperature runaway condition could occur from a shorted input sensor or an output

device that could fail in a closed position.

The Series 97 is recommended for any application where thermal runaway could result in

large product scrap costs, affect operator safety, cause damage to equipment, or create a fire

hazard.

The Series 97 is manufactured by ISO 9001-registered Watlow Winona and reliably backed

by a three-year warranty.

Figure 1.1 — Series 97 inputs and outputs.

Input 1

Process

Input 2

Remote Reset or

Hardware Lockout

Output 1

Limit Relay

Output 2

Alarm

Output 3

Alarm

Output 4

Alarm, Analog or

Communications

234

LIMIT 97

1

RESET

Watlow Series 97 Overview ■ 1.1

1

Setup Steps

The controller must be equipped for communications,

(97_ _ - _ _ _ U - _ _ _ _ or 97_ _ - _ _ _ R - _ _ _ _).

See Chapter Five, Chapter Six and the Appendix.

4

Set up communications.

Chapter Four explains the keys, displays and software

navigation.

Chapter Five explains features, such as alarms and con-

trol methods.

Chapter Six lists parameter descriptions, ranges,

Modbus numbers and other information.

3

Configure the controller for

your application.

See Chapter Three.

2

Wire the controller.

See Chapter Two.

1

Install the controller.

How to do itWhat to do

1.2 ■ Overview Watlow Series 97

Chapter Two

Installation

Figure 2.1 - Series 97 multiple panel cutout dimensions.

NOTE: Measurements between panel cutouts are the minimum recommended.

For rapid mounting, use Greenlee 1/16 DIN punch, die, draw stud, part number 60287.

Panel Cutout

Panel

Thickness

0.06" to 0.38"

(1.5 to 9.7 mm)

1.77" to 1.79"

(44.96mm to 45.47mm)

1.77" to 1.79"

(44.96mm

to 45.47mm)

0.540"

(13.72mm)

Minimum

0.310"

(7.874mm)

2.050"

2.050"

234

LIMIT 97

1

RESET

Watlow Series 97 Installation ■ 2.1

2

Installing the Series 97 Controller

Installing and mounting requires access to the back of the panel.

1. Make the panel cutout using the tear-out mounting template found on the previous

page, or the dimensions found in this chapter.

2. Check to see that the gasket is properly seated into the gasket channel on the front

bezel and that it is not twisted. Make sure that the rounded surface of the gasket is the

surface that is exposed from the gasket channel, as this is the surface that will mate to

the panel surface. Insert the controller into the panel cutout.

3. With the controller inserted into the panel cutout, take the retention collar and slide it

over the controller, making certain that the two locating holes in the retention collar are

visible from the rear of the controller, with one hole pointing up and one pointing down.

Then, take the mounting collar and slide it over the controller, making certain that one

cantilever is pointing up and one is pointing down also. With one hand holding the con-

troller and the other hand using a #2 Phillips screw driver, tighten the two screws in

the mounting collar until the gap between the bezel and panel surface is .025” maxi-

mum. See figure below. Make sure that you cannot move the controller back and forth in

the cutout. If you can, you do not have a proper seal.

Figure 2.2a - Installing the controller. Figure 2.2b - Series 97 gap dimensions.

ç

CAUTION: Follow the installation procedure exactly to guarantee a proper NEMA 4X seal. Make sure the gasket between

the panel and the rim of the case is not twisted and is seated properly. Failure to do so could result in damage to equip-

ment.

NOTE: Be careful not to over-tighten the screws. This may cause the mounting cover to fail. Over-tightening occurs when

the front bezel is touching the customer’s front panel.

.025" Maximum gap

Customer's Front Panel

Front Bezel

Mounting Collar

Retention Collar

.325"

(8.6 mm)

3.875"

(98.4 mm)

2.2 ■ Installation Watlow Series 97

Watlow Series 97 Installation ■ 2.3

Removing the Series 97 Controller

1 Hold the controller with one hand while using the other hand to loosen the screws with

a #2 Phillips screwdriver until the end of the screw is flush or past the end of the can-

tilevers, see the figure below.

2. After the screws have been loosened, hold the controller with one hand while squeezing

the two screws together with the other hand. Then simply slide the mounting collar off

the controller.

Figure 2.3 - Removing the controller.

2.4 ■ Installation Watlow Series 97

Notes

Chapter Three

Wiring

Power Wiring . . . . . . . . . . . . . . . . . . . . . .3.3

Sensor Installation Guidelines . . . . . . . . .3.3

Wiring Example . . . . . . . . . . . . . . . . . . . .3.4

Wiring Notes . . . . . . . . . . . . . . . . . . . . . .3.5

Input 1 . . . . . . . . . . . . . . . . . . . . . . . . . . .3.6

Input 2 . . . . . . . . . . . . . . . . . . . . . . . . . . .3.6

Output 1 Limit Output Wiring . . . . . . . . . .3.7

Output 2 Alarm Output Wiring . . . . . . . . .3.8

Output 3 Alarm Wiring . . . . . . . . . . . . . . .3.9

Output 4 . . . . . . . . . . . . . . . . . . . . . . . . .3.10

EIA Conversions . . . . . . . . . . . . . . . . . . .3.11

Watlow Series 97 Wiring ■ 3.1

3

3.2 ■ Wiring Watlow Series 97

∫

WARNING:

To avoid potential

electric shock, use

National Electric Code

(NEC) safety practices

when wiring and

connecting this unit to a

power source and to

electrical sensors or

peripheral devices.

Failure to do so could

result in injury or death.

Wiring the Series 97

Wiring options depend on the model number. Check the terminal

designation stickers on either side of the controller and compare

your model number to those shown here and with the model

number breakdown on the inside back cover of this manual.

NOTE: Using the Diagnostics Menu (Factory Page) check

Output 1 Hardware through Output 4 Hardware, [Oty1]

through [Oty4]. See Chapter Six for information about the

menu and range of settings for each output. These outputs may

differ from those listed for the model number on the controller

and described in this manual, indicating a customized hardware

setup.

Input-to-output Isolation

The Series 97 uses optical and transformer isolation between the

analog inputs and the controller outputs, including the

communications interface. This isolation provides a barrier to

prevent ground loops when using grounded sensors and/or

peripheral equipment.

Here is a breakdown of the isolation barriers:

• Analog inputs 1 and 2 are grouped together.

• Outputs 1 through 4 are grouped together. This does not

apply to Output 4 when it is configured for communications.

• If Output 4 is configured for communications, it is isolated

from the the other inputs and outputs.

Figure 3.2 — Isolation blocks.

Input 1

Input 2

Output 1

Output 2

Output 3

Output 4 (unless Output 4 is used for communications)

Output 4 (if Output 4 is used for communications)

Isolation Blocks

There are no electrical connections between these blocks.

INPUT

OUTPUT

COMMUNICATIONS

Watlow Series 97 Wiring ■ 3.3

Power Wiring

100 to 240VÅ (ac), nominal (85 to 264 actual) 97 A _ - _ _ _ _ - _ _ _ _

24 to 28V‡ (ac/dc), nominal (21 to 30 actual) 97 B _ - _ _ _ _ - _ _ _ _

Figure 3.3 - Power wiring.

Sensor Installation Guidelines

Thermocouple inputs: Extension wire for thermocouples must

be of the same alloy as the thermocouple to limit errors.

When using a voltage input for the digital event on Input 2, use

an ungrounded thermocouple on Input 1. If a grounded

thermocouple is required, the signal to input 2 must be isolated

to prevent possible ground loops.

RTD input: Each 1Ω of lead wire resistance can cause a +2°F

error when using a two-wire RTD. A three-wire RTD sensor

overcomes this problem. All three wires must have the same

electrical resistance (i.e., same gauge, same length, multi-

stranded or solid, same metal).

10

8

1

2

3

4

5

6

7

13 14 15

11

12

16 17 18

19 20 21

Fuse

L2

L1

-

9

8

9

+

ç

CAUTION:

If high voltage is applied

to a low-voltage unit,

irreversible damage will

occur.

ç∫

WARNING:

To avoid damage to

property and equipment,

and/or injury of loss of

life, use National Electric

Code (NEC) standard

wiring practices to install

and operate the Series

97. Failure to do so could

result in such damage,

and/or injury or death.

ç

CAUTION:

Maintain isolation

between input 1 and

input 2 to prevent a

ground loop. A ground

loop may cause incorrect

readings, dashes across

the upper display or the

display of error codes.

Failure to follow this

guideline could result in

damage to equipment.

3.4 ■ Wiring Watlow Series 97

Wiring Example

Figure 3.4 - System wiring example.

1

120VÅ (ac)

L1

L2

2

7

6

4

5

1 2

1

2

(+)

(-)

3

13

21

14

15

16

17

2

1CR

18

high-temperature light

1

2

3

4

8

9

10

11

12

R

19

1

8

(+) (-)

1 CR-1

9

10

2

15 13

67

9 8

5

6

7

Series 96

96A0 - CAAA - 00RR

Temperature Controller

Series 97

97A1-DDAA-00RR

Limit Controller

13

14

15

16

6

98

1

3

7

(+)

(-)

Heater

DIN-a-mite

DA10-24C0-0000

21

3

4

11 12

1

17

56

20

96AO-CAAA-OORR

rear view

6 (-)

7 (+)

8

15 (+)

13 (-)

L1

L2

120VÅ (ac)

fuse

97A1-DDAA-00RR

Limit Controller

process sensor

limit sensor

optional

normally open

momentary switch

high limit

mechanical

contactor

7 (+)

6 (-)

high

temperature

light

coil

9

Heater

DIN-a-mite

DA10-24C0-0000

21

10

8

1

2

3

4

5

6

7

13 14 15

11

12

16 17 18

19 20 21

9

10

8

1

2

3

4

5

6

7

13 14 15

11

12

16 17 18

19 20 21

9

1

3

14 15

17

9

16

34

6

5

(-)

(+)

∫ç

WARNING:

To avoid potential

electric shock and

damage to property and

equipment, use National

Electric Code (NEC)

safety practices when

wiring and connecting

this unit to a power

source and to electrical

sensors or peripheral

devices. Failure to do so

could result in injury or

death.

ç

WARNING:

Install high or low

temperature limit control

protection in systems

where an over

temperature fault

condition could present a

fire hazard or other

hazard. Failure to install

temperature limit control

protection where a

potential hazard exists

could result in damage to

equipment, property and

injury to personnel.

Watlow Series 97 Wiring ■ 3.5

Wiring Notes

Sketch in your application on this page or a copy of it. See the

wiring example in this chapter.

Figure 3.5 - Wiring notes.

L1 L2

power

98

∫ç

WARNING:

To avoid damage to

property and equipment,

and/or injury of loss of

life, use National Electric

Code (NEC) standard

wiring practices to

install and operate the

Series 97. Failure to do

so could result in such

damage, and/or injury or

death.

3.6 ■ Wiring Watlow Series 97

Input 1 Wiring

Figure 3.6a – Thermocouple

Available on all units

Impedance: 20MΩ

Figure 3.6b – RTD (2- or 3-Wire) 100Ω Platinum

Available on all units

Input 2 Wiring

Figure 3.6c – Digital Event

97 _ 1 - _ _ _ _ - _ _ _ _

Voltage input

3-36VÎ (dc) Event Input High State

0-2VÎ (dc) Event Input Low State

Contact closure

0-2kΩ Event Input Low State

> 23kΩ Event Input High State

10

8

1

2

3

4

5

6

7

13 14 15

11

12

16 17 18

19 20 21

9

3

1

+

-

2.67kΩ

EVENT +

3

EVENT

-

1

20kΩ

100Ω

+5V

1

2

3

4

5

6

7

1

5

6

7

S1

S2

S3

3-wire

1

2

3

4

5

6

7

6

7

S1

S3

5

2-wire

jumper 5 to 6

10

8

1

2

3

4

5

6

7

13 14 15

11

12

16 17 18

19 20 21

9

- 6

+7

NOTE:

Successful installation

requires five steps:

• Choose the controller’s

hardware configuration

and model number

(Appendix);

• Choose a sensor

(Chapters 3 and 6, and

Appendix);

• Install the controller

(Chapter 2);

• Wire the controller

(Chapter 3) and

• Configure the controller

(Chapters 4, 5 and 6).

ç

WARNING:

To avoid damage to

property and equipment,

and/or injury of loss of

life, use National Electric

Code (NEC) standard

wiring practices to

install and operate the

Series 97. Failure to do

so could result in such

damage, and/or injury or

death.

ç

CAUTION:

Maintain isolation

between input 1 and

input 2 to prevent a

ground loop. A ground

loop may cause incorrect

readings, dashes across

the upper display or the

display of error codes.

Failure to follow this

guideline could result in

damage to equipment

and product.

Watlow Series 97 Wiring ■ 3.7

Output 1 Limit Output Wiring

Figure 3.7a – AC Outputs

•Electromechanical Relay without

contact suppression

97 _ _ - D _ _ _ - _ _ _ _

Form C, 2 amps, off-state

impedance: 31MΩ

10

8

1

2

3

4

5

6

7

13 14 15

11

12

16 17 18

19 20 21

9

External

Load

1514

COM. N.O.

L2

L1

(13 used for

D outputs only)

13

N.C.

customer-supplied

Quencharc

NOTE:

Successful installation

requires five steps:

• Choose the controller’s

hardware configuration

and model number

(Appendix);

• Choose a sensor

(Chapters 3 and 6, and

Appendix);

• Install the controller

(Chapter 2);

• Wire the controller

(Chapter 3) and

• Configure the controller

(Chapters 4, 5 and 6).

ç

WARNING:

To avoid damage to

property and equipment,

and/or injury of loss of

life, use National Electric

Code (NEC) standard

wiring practices to

install and operate the

Series 97. Failure to do

so could result in such

damage, and/or injury or

death.

NOTE:

Switching inductive loads

(relay coils, solenoids,

etc.) with the mechanical

relay, switched dc or

solid-state relay output

options requires use of

an R.C. suppressor.

Watlow carries the R.C.

suppressor Quencharc

brand name, which is a

trademark of ITW Pakron.

Watlow Part No. 0804-

0147-0000.

3.8 ■ Wiring Watlow Series 97

Output 2 Alarm Output Wiring

Figure 3.8a – AC Outputs

•Electromechanical relay without contact suppression

97 _ _ - _ D _ _ _ - _ _ _ _

Form C, 2 amps, off-state

impedance: 31MΩ

•Solid-state relay without

contact suppression

97 _ _ - _ K _ _ - _ _ _ _

0.5 amps, off-state

impedance: 31MΩ

Figure 3.8b – Switched DC, Open Collector

97 _ _ - _ C _ _ - _ _ _ _

Switched DC

configuration:

Maximum voltage:

28VÎ (dc)

Maximum current:

30mA

Open collector configuration:

Maximum voltage: 42VÎ (dc)

Maximum current: 200 mA

+VÎ (dc)

Internal Circuitry

16

18

17

22 to 28VÎ (dc)

10

8

1

2

3

4

5

6

7

13 14 15

11

12

16 17 18

19 20 21

9

+ 16 17 18 -

External

Load

COM.

Switched DC

10

8

1

2

3

4

5

6

7

13 14 15

11

12

16 17 18

19 20 21

9

External

Load

COM. N.C.

L2

L1

16 17 18 (18 used for

D outputs only)

N.O.

customer-supplied

Quencharc

NOTE:

Successful installation

requires five steps:

• Choose the controller’s

hardware configuration

and model number

(Appendix);

• Choose a sensor

(Chapters 3 and 6, and

Appendix);

• Install the controller

(Chapter 2);

• Wire the controller

(Chapter 3) and

• Configure the controller

(Chapters 4, 5 and 6).

NOTE:

Switching inductive loads

(relay coils, solenoids,

etc.) with the mechanical

relay, switched dc or

solid-state relay output

options requires use of

an R.C. suppressor.

Watlow carries the R.C.

suppressor Quencharc

brand name, which is a

trademark of ITW Pakron.

Watlow Part No. 0804-

0147-0000.

ç

WARNING:

To avoid damage to

property and equipment,

and/or injury of loss of

life, use National Electric

Code (NEC) standard

wiring practices to

install and operate the

Series 97. Failure to do

so could result in such

damage, and/or injury or

death.

Watlow Series 97 Wiring ■ 3.9

Output 3 Alarm Wiring

Figure 3.9 – AC Outputs

Electromechanical Relay without Contact Suppression

97 _ _ - _ _ D_ - _ _ _ _

Form C, 2 amps, off-state impedance: 31MΩ

10

8

1

2

3

4

5

6

7

13 14 15

11

12

16 17 18

19 20 21

9

External

Load

L2

L1

11

10

N.C.

N.O.

12

COM.

customer-supplied

Quencharc

NOTE:

Successful installation

requires five steps:

• Choose the controller’s

hardware configuration

and model number

(Appendix);

• Choose a sensor

(Chapters 3 and 6, and

Appendix);

• Install the controller

(Chapter 2);

• Wire the controller

(Chapter 3) and

• Configure the controller

(Chapters 4, 5 and 6).

NOTE:

Switching inductive loads

(relay coils, solenoids,

etc.) with the mechanical

relay, switched dc or

solid-state relay output

options requires use of

an R.C. suppressor.

Watlow carries the R.C.

suppressor Quencharc

brand name, which is a

trademark of ITW Pakron.

Watlow Part No. 0804-

0147-0000.

ç

WARNING:

To avoid damage to

property and equipment,

and/or injury of loss of

life, use National Electric

Code (NEC) standard

wiring practices to

install and operate the

Series 97. Failure to do

so could result in such

damage, and/or injury or

death.

3.10 ■ Wiring Watlow Series 97

Output 4 Wiring

Figure 3.10a – AC Outputs

Electromechanical Relay without Contact Suppression

97 _ _ - _ _ _ D - _ _ _ _

Form C, 2 amps, off-state impedance: 31MΩ

Figure 3.10b – Communications and Retransmit Option

EIA/TIA-232 EIA/TIA-485 Retransmit Option

97 _ _ - _ _ _ R - _ _ _ _ 97 _ _ - _ _ _ U - _ _ _ _ 97_ _ - _ _ _ M - _ _ _ _

10

8

1

2

3

4

5

6

7

13 14 15

11

12

16 17 18

19 20 21

9

19 20 21

V out COM. I out

10

8

1

2

3

4

5

6

7

13 14 15

11

12

16 17 18

19 20 21

9

19 20 21

T-/R- COM. T+/R+

10

8

1

2

3

4

5

6

7

13 14 15

11

12

16 17 18

19 20 21

9

19 20 21

T out COM. R in

10

8

1

2

3

4

5

6

7

13 14 15

11

12

16 17 18

19 20 21

9

External

Load

COM. N.C.

L2

L1

19 20 21

N.O.

customer-supplied

Quencharc

NOTE:

Successful installation

requires five steps:

• Choose the controller’s

hardware configuration

and model number

(Appendix);

• Choose a sensor

(Chapters 3 and 6, and

Appendix);

• Install the controller

(Chapter 2);

• Wire the controller

(Chapter 3) and

• Configure the controller

(Chapters 4, 5 and 6).

NOTE:

Switching inductive loads

(relay coils, solenoids,

etc.) with the mechanical

relay, switched dc or

solid-state relay output

options requires use of

an R.C. suppressor.

Watlow carries the R.C.

suppressor Quencharc

brand name, which is a

trademark of ITW Pakron.

Watlow Part No. 0804-

0147-0000.

ç

WARNING:

To avoid damage to

property and equipment,

and/or injury of loss of

life, use National Electric

Code (NEC) standard

wiring practices to

install and operate the

Series 97. Failure to do

so could result in such

damage, and/or injury or

death.

NOTE: For more information about communicating with Watlow controllers, go to www.watlow.com and download the Data

Communications Reference: Electronic User’s Manual. It is located under Literature, User’s Manuals, English and search

on data communications reference.

/