3

A

Abbreviations . . . . . . . . . . . . . . . . . . .4

Access Covers

Floor . . . . . . . . . .222-223, 226-231

Parking Lot . . . . . . . . . . . . . . . .231

Wall . . . . . . . . . . . . . . . . . . 224-230

Acid-Resisting Floor Sinks

(See Floor Sinks)

Adapters

Hub . . . . . . . . . . . . . . . . . . 289-290

No-Hub . . . . . . . . . . . . . . . . . . . 288

Trap Primer . . . . . . . . . . . . . . . .288

Adjustable Floor Drains (See Drains)

Air Gaps . . . . . . . . . . . . . . . . . 290-291

Air Inlets . . . . . . . . . . . . . . . . . 291-292

Arresters, Water Hammer . . . . . . . .276

B

Backwater Valves

Ball Float . . . . . . . . . . . . . . . . . .260

Comb. Check & Gate . . . . . 260-261

Offset. . . . . . . . . . . . . . . . . 261-263

Pit Type . . . . . . . . . . . . . . . . . . .263

Straight-Through Pattern. . 260-261

Swing-Check . . . . . . . . . . . 260-264

Terminal . . . . . . . . . . . . . . . . . .264

Backwater Valve Drains . . . . . . . . .173

Bearing Pan

(Drain Receiver) . . . . . . . . . . 67-69

Butt Weld Outlet. . . . . . . . . . . 180-185

C

Can Wash Drain (See Drains)

Carriers, Closet

Adapter Types. . . . . . . . . . . . . . .19, 44

Adjustable Close . . . . . . . . . . . . . 38-43

Adjustable Horizontal . . . . . . . . . 20-25

Adjustable Vertical . . . . . . . . . . . 26-37

Floor-Mounted Back Outlet. . . . . . . . 14

Hub & Spigot. . . . . . . . . . .21-25, 27-39

Options, Illustrated . . . . . . . . . . . 10-17

Prison . . . . . . . . . . . . . . . . . . . . . 43-44

Wheelchair . . . . . . . . . . . . . . . . . . . .15

Wide Chase. . . . . . . . . . . . . . . . . 10-11

Carriers, Cooler Drinking Fountain

. . . . . . . . . . . . . . . . . .57-58, 60-61

Carriers, Lavatory

Corner Type . . . . . . . . . . . . . . . . . 58

Floor-Mount

Concealed Arms . . . . . . . . 48-49

Exposed Arms . . . . . . . 52-54, 63

Hanger Plate . . . . . . . . . . .56, 59

Options Illustrated. . . . . . . . . . . .47

Wall Mount

Concealed Arms . . . . . . . . 49-52

Exposed Arms . . . . . . . . . . 54-55

Hanger Plate . . . . . . . . . . . 61-62

Carriers, Sink

Floor-Mount

Exposed Arms . . . . . . . . . . 52-54

w/Hanger Plate . . . . . . . . . . . .63

Hanger Plate w/Adapter . . . . . 64

Hanger Plate w/Fitting. . . . . . . 65

Options, Illustrated . . . . . . . . . . . 47

Carriers, Urinal

Floor-Mount Hanger Plate . . . 57, 60

Wall-Mount Hanger Plate . . . 62-63

Cast Stainless Steel . . . . . . . . . 181-185

Cleanouts

Ferrules . . . . . . . . . . . . . . . . . . . 232

Plugs . . . . . . . . . . . . . . . . . . . . .221

Stainless Steel . . . . . . . . . . . . . .185

Trap Drains

w/Cleanouts . . . . . . 140, 173-177

Cleanout Access Covers

Floor . . . . . . . . . . . . . . . . . 226-230

Wall . . . . . . . . . . . . . . . . . . 224-230

Cleanouts, Adjustable. . . . . . . 212-221

Finished Areas . . . . . . 212, 214-221

Un nished Areas

. . . . . . . . . .212-213, 216-218, 220

Closet Fittings (See Closet Carriers)

Combination Drains . . . . . . . . 113-119

Composition Deck Drains . . . . . . . . . . .

. . . . . . . . . . . . . . . 93-95, 137, 179

Connections . . . . . . . . . . . . . . . . . .112

Hub Inside Caulk (X)

Gasket, JIFFEE-JOINT (Y)

No-Hub Spigot (Z)

Threaded (T)

D

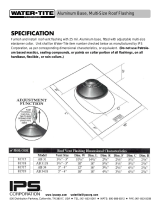

Deck Clamps, Roof Drain . . . . . . . . . 68

Deep Seal Trap Drains. . . . . . . . . . .286

Dental Sink Interceptors . . . . . . . . . 254

Distribution Unit . . . . . . . . . . . . . . .287

Drains

Adjustable w/Strainers

Cast Iron . . . . . . . . . . . . 141-154

Adjustable, Floor

Cast Iron

. . . .156-158, 161-162, 170, 172

Stainless Steel . . . . . . . . 181-184

Balcony . . . . . . . . . . . . . . . . . . . . 92

Blood . . . . . . . . . . . . . . . . . . . . . 159

Boiler Room. . . . . . . . . . . . . . . . 175

Can-Wash

Acid-Resisting . . . . . . . . . . . .210

Cast Iron . . . . . . . . . . . . . . . . 178

Combination/Cleanouts

. . . . . . . . . . . . . . . . . 140, 173-177

Dairy (See Floor Sinks)

Drip Drains. . . . . . . . . . . . . 144-145

Extended Rim . . . . . . 103-104, 144

Flushing Rim, C.I. . . . . . . . . . . .210

Funnel . . . . . . . . . . . . 144-145, 286

Gasoline, Volatile Liquid . . . . . . 174

Gutter, Roof. . . . . . . . . . . . . . 96-98

Isolation Deck, Roof. . . . . . . . . .108

IRMA, Roof . . . . . . . . . . . 81-82, 89

Key Lock, Floor . . . . . . . . . . . . . 157

LEVELEZE

®

Drains

Floor . . . . . . . . . . . . . . . 156-158

Roof. . . . . . . . . . . . . . . 79-80, 88

NON-CLOG . . 156-157, 160-162, 164

Over ow

Downspout Scupper . . . . 98-103

Fountain . . . . . . . . . . . . . . . .147

Roof. . . . . 79-80, 85-86, 103-104

Packing House. . . . . . 159, 172, 177

Parapet . . . . . . . . . . . . . . . . 98-100

Parking Deck, Roof . . . . . . . . 93-95

Pit, Cast Iron . . . . . . . . . . . . . . . 263

Planting Area. . . . . . . . . . . 108, 178

Promenade . . . . . . . . . . . . . . 87-92

Refrigerator (See Floor Sinks)

Roof (See Roof Drains)

Sill Drain . . . . . . . . . . . . . . . . 96-98

Slaughter House . . . . 159, 172, 177

Stainless Steel . . . . . . . . . . 181-185

Toilet Rooms . . . . . . . . . . . 139-149

Trench (See Trench Drains)

Drain Receiver, Roof . . . . . . . . . . 67-69

E

Electronic Grease Interceptors 240, 247

Grease/Oil Level Detectors. . . . .248

Expansion Joints, Roof . . . . . . . . . . 105

Extension Collars

Fixed, Floor . . . . . . . . . . . . . . . .121

Fixed, Roof. . . . . . . . . . . . . . . . . .69

LEVELEZE

®

Floor . . . . . . . . 156-158

LEVELEZE

®

Roof. . . . . 71, 79-80, 88

F

Finishes & Materials . . . . . . . . . . . . . .5

Fittings (See Carriers)

Fixed Air Gaps. . . . . . . . . . . . . 290-291

Fixed Supports (See Carriers)

Fixture Carriers (See Carriers)

Flashing Sleeves . . . . . . . . . . . 105-106

FLO-SEPTOR® Drains . . . . . . . 103-104

Floor Access Covers (See Cleanouts)

Floor Cleanouts (See Cleanouts)

Floor Drains (See Drains)

Floor Sinks

Acid-Resisting Cast Iron. . . 188-210

Stainless Steel

(See Josam Stainless Steel

Drainage Products Catalog)

Flow Control Roof Drains

(FLO-SET

®

) . . . . . . . . . . . . . . . . . . 107

Flow Control Fittings. . . . . . . . . . . .

237

Frames & Grates, Trench. . . . . 279-281

Fresh Air Inlets . . . . . . . . . . . . 291-292

Funnels . . . . . . . . . . . . . . . . . . 131-132

Funnel Drains . . . . . . . . . 144-145, 286

G

Gasket, JIFFEE-JOINT . . . . . . . . . . . . 66

Grates & Frames, Trench. . . . . 279-281

Grease Interceptors

Electronic. . . . . . . . . . . . . . . . . . 247

Enclosed . . . . . . . . . . . . . . 242-243

High Volume . . . . . . . . . . . . . . . 245

Low Boy. . . . . . . . . . . . . . . 244-245

Manual Clean

. . . . . . . . . .239, 241-242, 244-247

Recessed . . . . . . . . . . . . . . 242, 244

Semi-Automatic Draw-Off. .243-245

Grease Removal Device (GRD) . . . .240

Green Drains. . . . . . . . . . 109-112, 116

H

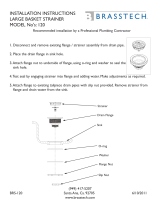

Hair Interceptors . . . . . . . . . . . . . . . 253

Hydrants

HYDRASAN

®

I (See Below)

Integral Back ow Preventer . . . 267

Non-Freeze . . . . . . . . . . . . . . . . 267

Parts List . . . . . . . . . . . . . . . . . . 268