Page is loading ...

Instruction

Manual

Direct Measuring

Mold Cavity Pressure

Sensors with ø4 mm

Sensor Front

with Machinable Front

Type 6157BA...,

6157BB...,

6177AA...

with Chrome-Plated

Front or Diaphragm

Type 6157BC...,

6157BD...,

6177AC...,

6167A...

6157B

_

002-391e-03.10

Instruction

Manual

Direct Measuring

Mold Cavity Pressure

Sensors with ø4 mm

Sensor Front

Type 6157BA...,

6157BB...,

6177AA...,

6157BC...,

6157BD...,

6177AC..., 6167A...

6157B_002-391e-03.10

Direct Measuring

Mold Cavity Pressure

Sensors with ø4 mm

Sensor Front

with Machinable Front

Type 6157BA...,

6157BB...,

6177AA...

with Chrome-Plated Front

or Diaphragm

Type 6157BC...,

6157BD...,

6177AC...,

6167A...

Foreword

6157B_002-391e-03.10 Page 1

Foreword

We thank you for choosing a Kistler quality product

distinguished by technical innovation, precision and long

life. Please take the time to thoroughly read this instruction

manual. It will help you with the installation, maintenance,

and use of this product.

Information in this document is subject to change without

notice. Kistler reserves the right to change or improve its

products and make changes in the content without obliga-

tion to notify any person or organization of such changes

or improvements.

To the extent permitted by law Kistler does not accept any

liability if this instruction manual is not followed or

products other than those listed under Accessories are

used.

© 2010 Kistler Group. All rights reserved. Except as

expressly provided herein, no part of this manual may be

reproduced for any purpose without the express prior

written consent of Kistler Group.

Kistler Group

Eulachstrasse 22

8408 Winterthur

Switzerland

Tel. +41 52 224 11 11

Fax +41 52 224 14 14

www.kistler.com

Direct Measuring Cavity Pressure Sensors, Types 6157Bx..., 6177Ax..., 6167A…

Page 2 6157B_002-391e-03.10

Content

1. General Information....................................................................................................................... 4

2. Important Hole Conditions ............................................................................................................ 5

3. Holes for Sensors ........................................................................................................................... 6

3.1 Hole for Unmachined Sensors............................................................................................ 6

3.1.1 Hole for Sensor with Mounting Nut Type 6457................................................................. 7

3.1.2 Hole for Sensor with Spacer Sleeve Type 6459 .................................................................. 7

3.2 Hole for Contour-Adapted Sensors.................................................................................... 7

3.2.1 Hole Seat with Rotation Protection.................................................................................... 8

3.2.2 Machining the sensor shoulder .......................................................................................... 8

3.2.3 Adapting the Sensor Front to Cavity Contour.................................................................... 9

3.3 Sensors with Chrome-Plated Front .................................................................................. 10

4. Cable Installation and Connectors ...............................................................................................11

4.1 Single-Wire Cables .......................................................................................................... 11

4.1.1 Single-Wire Clamping Connector Type 1839 and Mounting Plate................................... 12

4.1.2 Multichannel Single-Wire Connector Types 1708A... and 1710A... ................................. 12

4.1.2.1 Recess for 4-Channel Connector Type 1708A... .............................................................. 12

4.1.2.2 Recess for 8-Channel Connector Type 1710A... .............................................................. 13

4.2 Coaxial Cable...................................................................................................................13

5. Sensor Installation ....................................................................................................................... 14

5.1 Sensor Installation with Mounting Nut Type 6457........................................................... 14

5.2 Sensor Installation with Spacer Sleeve Type 6459 ............................................................ 15

5.2.1 Machining the Spacer Sleeve ........................................................................................... 15

5.2.2 Mounting Spacer Sleeve and Support Plate ..................................................................... 15

6. Cable and Connector ................................................................................................................... 16

6.1 Single-Wire Technique..................................................................................................... 16

6.1.1 Cut and Grip Technique................................................................................................... 17

6.1.2 Connector Installation...................................................................................................... 17

6.1.2.1 Installing Connector Type 1839....................................................................................... 17

6.1.2.2 Installation for Multichannel Connector Types 1708A0 and 1710A0............................... 18

6.2 Coaxial Technique ........................................................................................................... 19

6.2.1 Installing Coaxial Cable.................................................................................................... 19

7. Identification Plate....................................................................................................................... 20

8. Function Test ............................................................................................................................... 21

8.1 Insulation Testing ............................................................................................................ 21

8.2 Testing the Sensor Function............................................................................................. 22

9. Servicing and Repairs................................................................................................................... 23

9.1 Insulation Testing ............................................................................................................ 23

9.2 Testing the Sensor Function............................................................................................. 24

9.3 Sensor Removal ............................................................................................................... 24

Content

6157B_002-391e-03.10 Page 3

9.4 Single-Wire Repairs ..........................................................................................................25

9.5 Repairs at Kistler...............................................................................................................25

9.6 Disposal Instructions for Electrical and Electronic Equipment ............................................25

10. Measuring Chains.........................................................................................................................26

10.1 Machine-Integrated Mold-Cavity Pressure Monitoring.....................................................26

10.2 Mold Cavity Pressure Monitoring with External Kistler Instruments..................................27

Total Pages 27

Direct Measuring Cavity Pressure Sensors, Types 6157Bx..., 6177Ax..., 6167A…

Page 4 6157B_002-391e-03.10

1. General Information

Sensor diameter ø4 mm must not be machined

Sensor front must be clean and without notches

Use only recommended mounting tool

Do not pull the sensor out of the hole by pulling on the

cable.

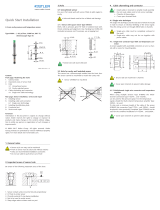

Fig. 1: Cavity pressure sensor Type 6157BA...

Fig. 2: Dimensions Type 6157BA...

Important Hole Conditions

6157B_002-391e-03.10 Page 5

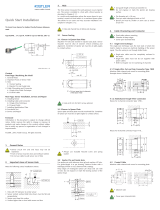

2. Important Hole Conditions

The measuring hole can influence the function and life of

the sensor. Inaccurate holes can lead to measuring errors

due to the inclusion of transverse forces acting on the

sensor.

Thus attention must be given to the following criteria:

Fig. 3: Important characteristics of the measuring hole

1. Contact surface right-angled and flat

2. Sensor center-aligned by the H7 hole

3. Chamfer prevents damage to the O-ring during moun-

ting

4. No centering hole; the sensor shoulder must not touch

the wall

5. Sharp edge reduces impressions on the molding

Direct Measuring Cavity Pressure Sensors, Types 6157Bx..., 6177Ax..., 6167A…

Page 6 6157B_002-391e-03.10

3. Holes for Sensors

The sensor is mounted front flush in the measuring hole in

the cavity wall. The pressure in the cavity is transferred via

the sensor front directly onto the piezoelectric measuring

element, which produces a proportional charge. The measu-

ring signals are converted to a voltage in the amplifier and

amplified to a standardized voltage signal, which is used to

record the pressure curve.

The sensor front can be machined on sensors which are not

chrome plated, so that the front will fit flush in the cavity

wall.

The sensor front of chrome-plated or diaphragm sen-

sors must not be machined (see section 3.3).

Clean hole and thread of metal particles and debris.

Accessory set Type 1300A81 is provided for machining

the sensor front.

3.1 Hole for Unmachined Sensors

For pressure measurements in flat parts and in those parts

with a flat cavity wall, the sensor is mounted without

machining in a hole at right-angles to the cavity wall. After

mounting, the sensor front must come flush with the cavity

wall and, for this purpose, the hole is adapted to the sensor

dimension of the front measuring body.

Holes for Sensors

6157B_002-391e-03.10 Page 7

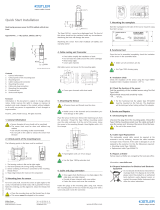

3.1.1 Hole for Sensor with Mounting Nut Type 6457

Use EDM (Electrical discharge machining), mill or grind H7

hole in hardened tool steel. Check centering and positional

alignment. Clean thread free of metal particles and debris.

Fig. 4: Sensor hole for fitting mounting nut; mounting nut

3.1.2 Hole for Sensor with Spacer Sleeve Type 6459

Use EDM, mill or grind H7 hole in hardened tool steel.

Check centering and positional alignment.

Fig. 5: Sensor hole for mounting with spacer sleeve; spacer

sleeve

3.2 Hole for Contour-Adapted Sensors

This concerns sensor Types 6157BA..., 6157BB... and

6177AA... .

With an oblique cavity wall or one with a oblique structure

or in free-form surfaces, the sensor can be adapted to the

contour.

The sensor front can be machined within certain limits. For

this purpose and in every case, the sensor must be secured

Direct Measuring Cavity Pressure Sensors, Types 6157Bx..., 6177Ax..., 6167A…

Page 8 6157B_002-391e-03.10

against rotation before machining by machining the sensor

shoulder on one side. The sensor hole is then adapted and

the sensor front machined either directly or in the mounted

position.

The sensor front of Types 6157BC..., 6157BD...,

6177AC and 6167A... must not be machined.

3.2.1 Hole Seat with Rotation Protection

Use EDM or mill the hole with rotation protection in the

hole seat using the hole dimensions as above

Section 3.1.1: Hole for sensor with mounting nut Type

6457 or

Section 3.1.2: Hole for sensor with spacer sleeve Type

6459

The hole dimensions indicated above are adapted accor-

ding to the following drawing in the area of the hole seat.

Fig. 6: Hole seat for rotation protection

Take care with the radius at the transition to the

"land". If necessary, a chamfer will need to be machi-

ned on the sensor shoulder.

The thread in the hole for the mounting nut must be

clean and free of metal particles and debris.

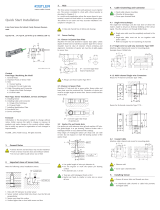

3.2.2 Machining the sensor shoulder

To prevent the sensor from rotating, the ø7 mm sensor

shoulder is machined on one side. The dimension for the

machined part is shown in Fig. 7. A face grinder is suitable

for the machining. If necessary, a free-hand grinder can also

be used to produce this surface. With manual grinding of

the sensor shoulder, no more than 0,6 mm must be

Holes for Sensors

6157B_002-391e-03.10 Page 9

removed from one side, so that the shoulder dimension at

the machined diameter is about 6,4 mm.

During machining the sensor should be clamped at the

ø5 mm connector end.

Fig. 7: Machine sensor shoulder on one side

The sensor must not be clamped or held at the front

end with the ø4 mm diameter.

The centering diameter ø4 mm and the sensor contact

shoulder must under no circumstances be machined.

Do not machine off the serial and type numbers.

3.2.3 Adapting the Sensor Front to Cavity Contour

This applies to sensor Types 6157BA..., 6157BB... and

6177AA... .

The front of the sensor can be machined with a radius or

slanted surface, also when mounted in the mold. When

eroding a cavity contour that has an installed sensor,

ensure that no liquid enters the connector. Seal the rear

sensor body with silicone sealant. The end of the cable

should always be secured outside the erosion bath.

After machining the sensor front, remove the sensor and

dry it. Tool Type 1315A can be used for the removal.

Clean and dry the hole.

Fig. 8: Sensor front dimension for radii; sensor front di-

mensions for surfaces

Use extraction tool Type 1315A.

Direct Measuring Cavity Pressure Sensors, Types 6157Bx..., 6177Ax..., 6167A…

Page 10 6157B_002-391e-03.10

3.3 Sensors with Chrome-Plated Front

This applies to sensor Types 6157BC..., 6157BD...,

6177AC... and 6167A... .

Chrome-plated sensors must not be machined.

Machining the sensor front will damage the chrome

layer and ruin the sensor. All liability and claims under

warranty become void in the case of a sensor whose

front has been machined.

Fig. 9: Chrome-plated sensors and sensors with a dia-

phragm cannot be machined

The chrome-plated front triples the life of the sensor in the

injection molding of glass-reinforced or fiber-reinforced

plastics. The front region of the sensor tip is chrome plated

for this purpose up to the O-ring and has the same dimen-

sions as the unplated sensor.

The sensor hole is thus the same as in Section 3.1 "Hole

for unmachined sensors". When installing the chrome

plated sensor, the hole depth L = 8 mm must be adapted

accurately to the length of the sensor adapter sleeve. The

sensor front must come flush with the cavity wall and must

not protrude. Here compliance is required with the dimen-

sional tolerance in the dimensional drawing on Page 4.

Cable Installation and Connectors

6157B_002-391e-03.10 Page 11

4. Cable Installation and Connectors

The cables for piezoelectric sensors must be well insulated.

Cables and connectors must be installed with good

protection to prevent cable damage during installation and

in operation. Moisture and dirt in the area of the connector

must be prevented in order to ensure optimum function.

Recommendations for cable installation:

Install cables with sufficient slack to ensure they are not

under strain.

Secure cables in the channel with putty/mastic to simplify

mold mounting.

Do not install cables around hot runner cartridges or in

hot runner holes.

Radii at transitions and corners in the cable channel and

holes prevent cable damage.

Cover open channels.

4.1 Single-Wire Cables

With the single-wire method, electrical shielding is pro-

vided by the injection mold. Thus the cable must be

integrated in the mold body and never be installed outside

the mold. In the case of an open channel, a cover plate

must be provided. All contact surfaces and threads for the

connectors must in addition be uncoated, clean and free of

grease.

The single-wire cable must on no account be installed toge-

ther with other electrical cables such as the power supply for

hot runner systems in the cable hole.

Electrical shielding is mandatory: install single-wire ca-

ble completely in the mold and cover open channels.

To prevent interference signals, never install single-

wire cables together with power cables.

To ensure effective insulation, contact surfaces and

threads must be clean and dry.

Direct Measuring Cavity Pressure Sensors, Types 6157Bx..., 6177Ax..., 6167A…

Page 12 6157B_002-391e-03.10

4.1.1 Single-Wire Clamping Connector Type 1839 and Mounting Plate

Mill a recess for the mounting plate. Contact surfaces and

threads must be clean and free of grease. Provide radii at

transitions and corners in the cable channel or hole, so as

to prevent cable damage during assembly and in

operation.

Example showing installation in a hole.

Fig. 10: Hole and recess for connector Type 1839

4.1.2 Multichannel Single-Wire Connector Types 1708A... and 1710A...

Mill a recess for the multichannel connector. Contact

surfaces and threads must be clean and free from grease.

Provide radii at transitions and corners in the cable channel or

hole, so as to prevent cable damage during assembly and

in operation.

4.1.2.1 Recess for 4-Channel Connector Type 1708A...

Wherever possible, position the cable channel or cable hole

in the middle of the recess to simplify connection of the

sensors. When space is limited, the cable entry can be

located as required, in which a side entry at the level of the

base may be used.

Fig. 11: Recess for multichannel connector Type 1708A0

Cable Installation and Connectors

6157B_002-391e-03.10 Page 13

4.1.2.2 Recess for 8-Channel Connector Type 1710A...

Wherever possible, position the cable channel or cable hole in the

middle of the recess to simplify connection of the sensors. When

space is limited, the cable entry can be located as required, in

which a side entry at the level of the base may be used.

Fig. 12: Recess for multichannel connector Type 1710A0

4.2 Coaxial Cable

Coaxial cable must be installed in holes and channels well

protected against mechanical damage.

Mill a recess for the mounting plate. Provide channels for

radii at transitions and corners in the cable channel or hole, so

as to prevent cable damage during assembly and in ope-

ration.

Attention should be given to larger radii at the transitions

when using high-temperature sensor Types 6157BB... and

6157BD....

Fig. 13: Channel and recess for coaxial connector

Note radii.

If possible, cover open channels.

Direct Measuring Cavity Pressure Sensors, Types 6157Bx..., 6177Ax..., 6167A…

Page 14 6157B_002-391e-03.10

5. Sensor Installation

First install the sensor, then the cable and finally the

connector. This sequence is particularly important when

installing single-wire sensors, in which the cable in the

mold is cut to the required length.

All sensor holes and threads must be clean.

Radii in the channel and at transitions prevent cable

damage.

5.1 Sensor Installation with Mounting Nut Type 6457

Insert the sensor into the hole with a slight rotary move-

ment. Tool Type 1315A is suitable for deep holes and is

screwed onto the M5 thread at the back of the sensor.

Install the mounting nut with the tubular socket wrench

Type 1383, taking care not to twist the single-wire cable.

Carefully tighten the mounting nut but do not overtighten

it. Allow a clearance of 0,01 ... 0,03 mm so that the sensor

is not pressed against the seat.

Fig. 14: Installation with mounting nut

With single-wire cables, ensure that the cable is

neither twisted nor pulls on the sensor.

Do not preload the sensor; allow a clearance of 0,01

... 0,03 mm.

Install the sensor with extraction tool Type 1315A.

Secure mounting nut with tubular socket wrench Type

1383.

Sensor Installation

6157B_002-391e-03.10 Page 15

5.2 Sensor Installation with Spacer Sleeve Type 6459

Insert the sensor into the hole with a slight rotary

movement. Tool Type 1315A is suitable for deep holes and

is screwed onto the M5 thread at the back of the sensor.

Allow a clearance of 0,01 ... 0,03 mm so that the sensor is

not pressed against the seat.

5.2.1 Machining the Spacer Sleeve

Cut the spacer sleeve to a length which is approx. 2 ... 3

mm longer than the mounting dimension. Then insert the

sensor with the spacer sleeve into the hole and measure

the protruding dimension. Now grind the sleeve to size so

as to ensure 0,01 ... 0,03 mm clearance.

The machined end must be flat and right-angled.

Do not preload the sensor; allow a clearance of 0,01

... 0,03 mm

With multi-cavity applications, the spacer sleeves

should be numbered and assigned to the individual

sensors.

5.2.2 Mounting Spacer Sleeve and Support Plate

Insert the machined spacer sleeve and check before

assembly that it is not protruding. Allow a clearance of

0,01 ... 0,03 mm so that the sensor is not pressed against

the seat.

Fig. 15: Installing the spacer sleeve

Before assembly check that the spacer sleeve is not

protruding.

Direct Measuring Cavity Pressure Sensors, Types 6157Bx..., 6177Ax..., 6167A…

Page 16 6157B_002-391e-03.10

6. Cable and Connector

The most frequent sensor failures are caused by damage to

the cable during installation. It is essential to allow suffi-

cient slack when installing the cable and the connector.

Edges and transitions should thereby be provided with radii

and a sufficient length of cable installed to ensure that it is

not under strain.

To prevent any possible damage to the cable during instal-

lation in the mold, it is advisable to cover open channels or

to secure the cable with mastic.

Good insulation is important for low-noise signal trans-

mission. Caps must be placed over open connectors.

Remove sharp edges in the cable hole and the chan-

nel; provide radii

Secure the cap on the mold and cover the connector

Provide open channels with a cover plate

6.1 Single-Wire Technique

The patented single-wire technique simplifies installation of

the pressure sensors, which affects both the installation of

the cable and the cable length as well as the connector

connection. With the single-wire sensor, the charge is fed

from the sensor through a single wire. Shielding, which

normally in a coaxial cable is provided by metallic braiding

in the cable sheath, is provided in the single-wire technique

by the mold steel. Thus the single-wire cable must always

be installed in the mold and covered in open channels.

Connection to the connector is made via cut-and-grip

contact, which is connected after sensor and cable

installation. Tightening the knurled nut clamps the cable, in

which the cable insulation is pierced and an electrical

contact made.

Cable and Connector

6157B_002-391e-03.10 Page 17

6.1.1 Cut and Grip Technique

Cut the sensor cable to the required length but do not strip

off the insulation. To simplify mold servicing, cut the cable

to an adequate length. Slacken the connector at the

knurled nut but do not separate it. Ensure that the

insulation is not stripped from the cable and the first 10

mm are not kinked. Insert the cable as far as it will go and

tighten it by hand. Check the connection by pulling on it

gently.

Fig. 16: Connection to connector Type 1839; connection to

multichannel connector

Do not cut the cable too short.

Do not strip insulation from the cable.

6.1.2 Connector Installation

When installing the single-wire connector, good contact

must be ensured between the mold and the mounting

plate or connector plate of the multichannel connector.

This contact is important for electrical shielding of the

sensor. Without shielding, the cable will also carry electrical

interference signals.

When installation is in an open channel, this must be

closed off with a plate to ensure effective shielding.

Tapped holes provide good electrical contact and must be

clean and free of grease. Secure the cable loop of the cap

when installing the mounting plate. The cap must also

remain inserted when sensors are not connected. The

short-circuit pin in the cap prevents crosstalk on sensors

making measurements.

6.1.2.1 Installing Connector Type 1839

Attach the connector to the mounting plate and insert in

the hole. Secure the mounting plate with three screws,

while in the same process also installing the cap cable and

fitting the cap.

/