Page is loading ...

METRO®

SetupInstructions

ForSerialNos.720,000&Higher

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.Partnumbersnotshownareavailableonthedealer

extranet.

DealerPack

Part#

DescriptionQty.Use

323-4

Screw,HH3/8-16x3/4inch

8

3290-357

Nut,Whizlock3/8-16inch

8

Installingthefrontcasterwheels.

1-633023Stud,FuelTank2

322-3

Screw,HH5/16-18x3/4inch

2

3256-23

Washer,5/16inchSAE

4

1-805005

Washer,Lock5/16inchHeavy

2

1-633349

Spring,Compression

2

3296-47

Nut,Nyloc5/16-18inchThin

2

Installingthefueltank.

323-6

Screw,HH3/8-16x1inch

4

3296-39

Nut,Nyloc3/8-16inch

4

Installingthehandleassembly.

1-806003Hairpin,Cotter2InstallthePTOengagementlinkage.

1-808286

Pin,Clevis(PistolGripOnly)

2

1-806003

Hairpin,Cotter(PistolGripOnly)

2

322-9

Screw,HH5/16-18x13/4inch(ECS

Only)

2

3296-29

Nut,Nyloc5/16-18inch(ECSOnly)

2

Installingandadjustingthewheel

drivelinkages.

1-303287Tie,Cable2Connectingwireharness.

—

WarrantyRegistrationForm

1

103-2106

Key,ExmarkLogo

1

1-603511

Key,Standard

1

Filloutwarrantyregistrationformand

placekeysintoliteraturepack.

LiteraturePack

Part#

DescriptionQty.Use

—

Manual,Operator’s

1

—Manual,Parts1

Readbeforeoperatingthemachine.

—Manual,EngineOperator’s1

Forunitswith15hpKawasakiengines.

Readbeforeoperatingthemachine.

UncratingtheUnit

1.Leavingtheunitonthepallet,placetheupperhandle

assembly,thefueltank,andtheshifterleveratthe

rearofthemachine.Placethecastersatthefront

oftheunit.

2.Placealengthof4inchx4inch(10cmx10cm)

blockbetweenthefrontofthemowerdeckandthe

pallet.

©1997–2007—ExmarkMfg.Co.,Inc.

P .O.Box808

Beatrice,NE68310

PartNo.4500-279Rev.A

PrintedintheUSA.

AllRightsReserved

3.Removetheboltbagfromunderthemowerdeck

beltshield.

4.Refertothepartsmanualtohelpyouidentifyand

locatethepartsandtheirproperposition.

InstallingtheFrontCasterWheels

Installthecasterstothefrontofthedeckusingeight

3/8-16x3/4inchboltsandeight3/8inchwhizlock

nuts.Tightenthelowerfourboltsrst,thenthetopfour.

InstallingtheFuelTank

1.Applyretainingadhesive“Fel-ProProLockRetaining

IorRetainingII”or“LoctiteRC609or680”onthe

twothreadedstudsfromtheboltbagandinstallinto

thetwoleftholesunderneathfueltank.Installthe

fueltankontopofthefueltanksupportwiththe

studsgoingthroughtheslotsinthesupport.

2.Installtwo5/16x3/4inchscrewswitha5/16inch

SAEatwasherand5/16inchlockwasherintothe

threadedholesintherightsideofthefueltank.Do

notovertighten.

3.Placea5/16inchSAEatwasher,thenaspring,

overeachofthestudsandfastenwitha5/16inch

nylocnut.Tighten5/16inchnylocnutfullythen

backoffa1/2turn.Thisistoallowfornormal

fueltankexpansionandcontractionwithchangesin

temperatureandfuellevels.Donotovertighten.

4.Attachthefueltankhosetothetankttingand

securewiththeclampprovided.

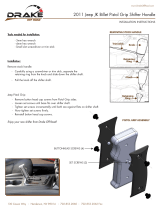

InstallingtheHandleAssembly

Positionthelowerendofthehandleassemblyonthe

outsideoftheupperrearsectionofthefueltankand

handlesupport.Installone3/8-16x1inchbolt(from

theoutsidein)intheupperholeoneachsideofthe

handle.Looselysecureeachscrewwitha3/8”nyloc

nut.Thehandlecannowbepivotedtoallowpositioning

inoneofthethreeholesallowingvariousadjustments

foroperatorcomfort(Figure1andFigure2).Oncea

properpositionisfound,installone3/8x1inchboltin

thebottommountingholesoneachsideofthehandle.

Secureeachboltwitha3/8inchnylocnut.Tightenall

hardware.

Figure1

1.Frontoftheunit

3.Upperhandle

2.Upperhandlemounting

tab

Note:Ifthemowerhasbeencompletelyassembled

andthehandlepositionischanged,itwillbenecessary

toreadjustthedriveandbrakelinkage.

Figure2

AdjustmentHolesareactuallyinthesideofthefueltank

support.

1.Upperhandle3.Adjustmentholes

2.Upperhole4.Fueltanksupport

AttachingtheThrottleCable

Routethethrottlecablealongtheleftsideoftheupper

handle,throughtheclip,underthefueltanksupport,

andpositionthecableonthefrontoftheengine.

Attachthrottlecabletoengine:

1.Positionthethrottlecontrollever(locatedonthe

console)inthefullthrottleposition.Youwillfeela

detentwhenthethrottleleverispushedtowardsthe

upperendoftheslot.

2

2.Attachtheinnerwireofthethrottlecabletothe

topholeinthethrottlecontrolleverasshownin

Figure3.

3.Loosentheclamp,placethecablebehindit,andpull

onthecabletomovethethrottlelinkagetothefull

throttleposition.Tightenthecableclampscrew .

Figure3

1.Throttlecontrollever

3.Clamp

2.Chokecable

4.Throttlecable

InstallthePTOEngagement

Linkage

1.Installthebladeengagementlinkagetothebellcrank

ontheLeftHandsideoftheenginedeck.

2.Insertrodthroughtheholefromtheoutsideand

fastenwithcotterhairpin.

InstallingandAdjustingtheShifter

Lever

1.Removethe3/8inchnylocnutandthespringdisc

washerfromthestudontopofthetransmission.

Installtheshifterleverthroughtheslotinthe

shifterleverplateandontothestudontopof

thetransmission.Besurethesquare-holewasher

remainsbetweentheleverandthetransmission.

Replacethespringdiscwasherandthenylocnut

(Figure4).Torquethe3/8inchnutto35ft-lb(47

N-m).

Figure4

1.Shifterlever

3.Transmission

2.Squareholedwasher

2.Shiftthelevertosecondgearandcheckthe

alignmentoftheleverintheslotoftheshifterplate.

Clearancebetweenthetopoftheleverandthetop

oftheslotshouldbeaboutequaltotheclearance

betweenbottomoftheleverandthebottomofthe

slot(Figure5).Ifitisnot,removetheleverandbend

itslightlytoadjust.DONOTbendtheleverwhile

itisattachedtothetransmission.Reinstallthelever

andtightenthehardware.

Figure5

1.Equaldistance

3.Shifterplate

2.Shifterlever

3.Shiftthelevertotheneutralposition.Thelever

shouldnotcontacttheleftedgeoftheupperslot.

Pushtheleverdown.Thelevershouldnotcontact

therightedgeofthebottomslot(Figure6).The

shifterplatecanbeadjustedsidetosidetoadjust

thepositionoftheleverrelativetotheslotinplate.

Loosenthetwoboltssecuringtheshifterplatetothe

shifterleverlegs.Adjustshifterplateandretighten

bolts.

3

Figure6

1.Shifterlever

3.Adjustmentslots

2.Equaldistance

InstallingandAdjustingtheWheel

DriveLinkages

ForPistolGripHandles:

1.Screwthethreadedendofthedrivelinkagesintothe

swivelsinthewheeldriveidlerarms.

2.Inserttheclevispinfromtheboltbagthroughthe

drivelinkage,theleverandtheslotintheneutral

lock/parkbrakelatches(Figure7).Maketheproper

adjustmentsbeforeaddingthehairpins.

Figure7

1.Drivelinkage

3.Neutrallock/parkbrake

latch

2.Clevispin

4.Drivelever

3.Adjustthedrivelinkagelengthbythreadingitinto

oroutoftheswiveluntilthereisa3/16inchto

1/4inch(4.7mmto6.4mm)clearancebetweenthe

linkageassemblyandthebottomoftheslotinthe

neutrallock/parkbrakelatch(Figure8).

Figure8

1.3/16inchto1/4inch(4.7mmto6.4mm)

2.Neutrallock/parkbrakelatch

3.Drivelinkage

Note:Theneutrallock/parkbrakelatchclearance

shouldbecheckedwherethereisaslightupward

forceplacedonthedriveleverstoremoveany

“slack”inthelinkage.

4.Aftertheclevispinhasbeeninserted,installthe

hairpinintotheholeontheclevispinbetweenthe

neutrallock/parkbrakelatchandthedrivelever

(Figure9).

Figure9

1.Drivelever

4.Neutrallock/parkbrake

latch

2.Clevispin

5.Hairpin

3.Drivelinkage

5.Repeattheprocedureonoppositesideofunit.

ForECSHandles:

1.Locatethedriveleverlinkageswhichhavethe

balljointandthejamnutsinstalledononeend.

Locatetwo5/16-18x13/4inchhexcapscrewsand

two5/16-18inchnylocnutsintheboltbag.

4

2.Threadthedriveleverlinkageintotheswivellocated

onthewheeldriveidlerarm.Threadthedrivelever

linkageinuntiltheatedgeofthedriveleveraligns

withthebottomoftherollernotchintheneutral

lock/parkbrakelatchwhenthe5/16-18x13/4

inchhexcapscrewisinsertedthroughtheholeinthe

driveleverandtheholeintheballjoint.

3.Securewiththe5/16-18inchnylocnut.Tighten

thenut.

4.Repeattheprocedurefortheotherside.See

Figure10andFigure11.

Figure10

RightSideofUnitShown

1.Wingnut

5.5/16-18x13/4inchhex

capscrew

2.Transmissionleverin

neutral

6.Driveleverlinkage

3.5/16-18inchnylocnut7.Swivel

4.Driveleversinneutral8.Brakerod

Figure11

1.Notchinneutrallock/parkbrakelatch

2.Drivelever

AdjustingtheBrakes

1.Adjusttheparkbrakebyrotatingthewingnutonthe

upperendofeachbrakerod.Tightenthewingnut

untilthebrakesengagewhenthedriveleversare

squeezedenoughtoallowtheneutrallock/park

brakelatchestobeplaceintothe“parkbrake”

position.SeeFigure12forPistolGripHandlesand

Figure13forECSHandles.

Figure12

1.Latchisinthedrive

position

6.Neutrallock

2.Rotateforwardforpark

brakeposition

7.Forward–releasedrive

lever

3.Rotatebackforneutral

lockposition

8.Neutral–holdinthis

position

4.Parkbrake9.Reverse–squeezedrive

lever

5.Fullspeedforward

Figure13

1.Driveleverindriveposition

2.Driveleverinneutralposition

3.Driveleverlockedinneutralposition

4.Driveleverlockedinparkposition

5

2.Checkthebrakeforcorrectadjustment:

A.Placethedriveleversinthe“park

brake”position.Themowershouldnot

moveforwardorbackward.Ifitdoes,tighten

thewingnuts.

B.Placethedriveleversinthe“neutrallock”

position.Themowershouldmoveforward

andbackwardfreely.Ifitdoesnot,loosenthe

wingnuts.

Note:Theneutrallock/parkbrakelatchesmustbe

abletobemovedintotheparkbrakeposition,ifnot,

thebrakelinkagesmustbeadjustedagain.

ConnectingWireHarness

1.Routethelong,unattachedwiringharnessleadup

thelefthandsideofthehandleandconnecttheag

terminals,inanyorder,totheoperatorpresence

controlswitchterminalsontheinsideofthecontrol

console.

2.Connecttheconnectorontheendoftheotherlead

tothekeyswitch.

3.Fastentheleadtothehandlewithtwosmallwireties,

fromboltbag,oneattheupperendofthehandle

nexttotheconsoleandoneattheverylowerendof

thehandlewhereitattachestothefueltanksupport.

OnECSunits:Fastenleadstothesmallholeinthe

channelundertheconsole.

InstallingtheMufer

Themufercomesinstalledontotheengineexhaust

manifoldbutrotatedrearwardtotinthecrate.

1.Loosentheclamp,rotatethemuferaheadand

securethebracketonthemufertothebracketon

theenginewiththehardwareprovided.

2.Tightentheclamp.

PositioningtheDischargeChute

Loosentwo5/16inchnylocnutsattachingdischarge

chute.Lowerthedischargechuteintoposition.

Retightennylocnutsuntilchuteissnugbutcanpivot

freely.

CheckingTirePressure

1.Checkthetirepressureinthedrivetires.Proper

inationfordrivetiresis12-16psi(83-110kPa).

2.Adjustifnecessary.

GreasingtheUnit

Note:Theunitisnotgreasedatthefactory.

LubricatettingswithNGLIgrade#2multi-purpose

gungrease.RefertothefollowingchartandFigure14

forttinglocationsandinitialpumps.

LubricationChart

Fitting

Locations

Initial

Pumps

NumberofPlacesService

Interval

32inch

Deck

36inch

Deck

48inch

Deck

1.Front

Caster

Wheel

Bearings

12222

Daily

2.Front

Caster

Pivots

2222

Daily

3.Drive

Wheels

18222

Daily

4.Drive

Wheel

IdlerArm

2222

Daily

5.Brake

Arm

2222

40hours

6.Trans-

mission

Output

Shaft

Coupler

2222

40hours

7.Mower

DeckIdler

Pivots

2111

40hours

Number4and7(IdlerArmPivots)Disassembleand

greaseonceamonthundera“NoLoad”condition.

Number6(TransmissionCoupler)Locatedbelowfuel

tanksupport.

6

Figure14

48inchDeckShownforReferenceOnly

ServicingtheEngine

RefertoEngineOwner’sManual.

FillingOuttheWarranty

RegistrationForm

Filloutwarrantyregistrationformandplacekeysinto

literaturepack.

7

/