Page is loading ...

P.O. Box 309, Menomonee Falls, WI USA 53052-0309

800 BRADLEY (800 272 3539) +1 262 251 6000

bradleycorp.com

Installation

HDWP-INSTR-013 Rev. K; ECN 12-14-012

© 2014 Bradley

Page 1 of 21 10/1/2014

Bradmar

™

Restroom Partitions

Overhead Braced - Series 400

(includes No-Site style)

Table of Contents

Pre-Installation Information ....................2

Layout Dimensions for Brackets ................3

Mounting Brackets to Wall .....................4

Leveling Bolts to Pilaster ......................5

Brackets to Pilasters .......................5–6

Pilaster Shoes ..............................6

Mounting Panels and Pilasters ...............7–8

Headrail ...................................9

Hinges ................................10–14

Latch and Strike/Keeper ..................15–18

Stiffener Bracket............................19

Urinal Screens ..........................20–21

IMPORTANT

Read this installation manual completely to ensure proper installation, then file it with the owner

or maintenance department. Compliance and conformity to local codes and ordinances is the

responsibility of the installer.

Separate parts from packaging and make sure all parts are accounted for before discarding packag-

ing material. If any parts are missing, do not begin installation until you obtain the missing parts.

Leave the protective masking on until installation is complete. To prevent warping, always lay the

material flat. Do not lean the material against the wall or stack unevenly. Allow 24 hours for material

to adjust to site environment.

Use caution when drilling. Accuracy is important!

Partitions should be installed in a climate-controlled environment and shielded from direct sunlight.

Product warranties and parts information may also be found under ”Products” on our web site at

bradleycorp.com.

Installation

THIS

SIDE

UP

Packing List

•

•

•

•

For Standard Height

Doors and Panels Only

*HDWP-INSTR-013*

2

Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400 Installation

10/1/2014 Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012

Supplies Required:

Hardware Provided

#14-2" Button HD

Sheet Metal Screw

TORX-T27 Drive

FAST-P002

#14-¾" Button HD

Sheet Metal Screw

TORX-T27 Drive

FAST-P001

#14-16 Plastic

Anchor

FAST-T373

⁵⁄₁₆" x 1½"

HEX HD Lag

FAST-S008

#8-1" Flat HD

Sheet Metal Screw

Phillips Drive

FAST-P006

#10-24 x 2" Flat

HD Machine Screw

TORX-T25 Drive

FAST-S0027

Washer Flat

⁹⁄₃₂" x ⁵⁄₈"

P10-449

Example of Submittal Drawing

• Chalklineandpencil

• FlatbladeandPhillipsheadscrewdrivers

• Jigsaworhacksaw

• Circularsaw

• Twospringclamps

• ³⁄₃₂", ⁷⁄₆₄", ¹⁄₈", ⁵⁄₃₂", ¹³⁄₆₄", ⁷⁄₃₂"and¼"drillbits

• Powerdrillorscrewgunwithdrillbitextension

• Tapemeasureand4'level

• ⁵⁄₁₆"ceramictileandmasonrydrillbit

• Hammerdrill

• Spacer,14"(356mm)highandstrongenoughto

support the panel

#10-24 x ¾" Button HD

Barrel Nut

TORX-T27 Drive

FAST-P003

#10 x ¾" Flat HD

Sheet Metal Screw

TORX-T25 Drive

FAST-S0006

#6 x ¾"

Phillips Flat-Head

Sheet Metal Screw

FAST-P011

#10-¾" Button HD

Sheet Metal Screw

TORX-T25 Drive

FAST-P005

#10-24 x ¾" Button HD

Shoulder Screw

TORX-T27 Drive

FAST-P004

60½"(1537mm)

WalltoCenter

Line

61¼"

(1556mm)

to

Face

36"(914mm)

CentertoCenter

1"(25mm)

Gap

½"(13mm)

Gap

1"(25mm)

Gap

7"

(178mm)

26"

(660mm)

24"

(610mm)

19.5

4

4.5

5.5

1.5

58 ¾"

(1492mm)

58 ¾"

(1492mm)

36"

(914mm)

4"

(102mm)

#14-⁵⁄₈" Button HD

Sheet Metal Screw

TORX-T27 Drive

FAST-S0016

#10-⁵⁄₈" Button HD

Sheet Metal Screw

Torx-T27 Drive

FAST-S0019

3

Installation Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400

Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012 10/1/2014

*

*

*

*

*

*

*

*

*

Pilaster

PlumbLine

When installing the partition components, consult

the applicable Mills Partition submittal drawing

for compartment layout dimensions.

1a

Layout Dimensions - Stirrup Brackets (Optional)

Pilaster Shoe Centerline: Measure from

thebackwallforwardtothefaceofthe

compartment,subtract½"(13mm)and

markthislocationonthefloor(“A”).Mark

the same measurement on the opposite

endofyourlayout(“A1”)anddrawa

straightlineconnectingbothmarks.

FOR FREESTANDING (FS) PARTITION:

Refertosubmittaldrawingsanddetermine

the approximate location of the outside

panels.Establishdimensions“A”and“A1”

asexplainedabove.

A

Panel centerline: Measure the stall width across the

backwallandplaceamarkatthebaseoftherearwall

(“B”).Repeatthisstepforeachpanel,startingeach

measurementfromthelastpanelcenterline(“B1”).

B

Stirrup brackets:Drawaplumblineonallwalls

from each pilaster and panel centerline. From the

highestpointintheroom,measure20"(508mm),

41½"(1054mm)and63"(1600mm)fromthefloor

andplaceamarkonthepilaster/panelplumbline

("C").Thesemarksrepresenttheholecenterline

ofthestirrupbrackets.Usealeveltotransferthat

marktoallotherplumblines.

C

Panel

plumbline

63"

(1600mm)

41½"

(1054mm)

"A"

"B"

"B1"

"A1"

"C"

"C"

"C"

"C"

"C"

"C"

"C"

"C"

"C"

20"

(508mm)

C

L

C

L

C

L

C

L

C

L

C

L

C

L

C

L

C

L

C

L

Pilaster

PlumbLine

When installing the partition components,

consult the applicable Mills Partition submittal

drawing for compartment layout dimensions.

1

Layout Dimensions - Continuous Brackets (Standard)

Pilaster Shoe Centerline: Measure from

thebackwallforwardtothefaceofthe

compartment,subtract½"(13mm)and

markthislocationonthefloor(“A”).Mark

the same measurement on the opposite

endofyourlayout(“A1”)anddrawa

straightlineconnectingbothmarks.

FOR FREESTANDING (FS) PARTITION:

Refer to submittal drawings and

determine the approximate location of the

outside panels. Establish dimensions “A”

and “A1” as explained above.

A

Panel centerline: Measure the stall width across the

backwallandplaceamarkatthebaseoftherearwall

(“B”).Repeatthisstepforeachpanel,startingeach

measurementfromthelastpanelcenterline(“B1”).

B

Continuous brackets: Drawaplumblineonallwallsfromeach

pilaster and panel centerline. From the highest point in the room,

measure14½"(369mm)fromthefloorandplaceamarkonthe

pilaster/panelplumbline.Usealeveltotransferthatmarktoall

otherplumblines(“C”).

C

Panel

plumb

line

"C"

"C"

"C"

"A"

"B"

"B1"

"A1"

*

*

*

14½"(369mm)To

bottomofbracket

(highestpointin

floor)

4

Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400 Installation

10/1/2014 Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012

2a

Stirrup Brackets to Wall (Optional)

establishedlevelline

pilaster/panelplumbline

floor

C

L

Place the center of the stirrup

bracketateachestablished

levelline.Centerthebracket

opening on the pilaster/panel

plumbline.

A

Insert the plastic anchors

in all holes and secure the

bracketstothewallwiththe

#14 x 2" screws provided.

C

On end panel and pilaster applications, position the bracket

with the ear facing toward the inside of the stall.

Usingthebracketasa

template, mark the hole

locations on the wall.

Removethebracketand

drill a Ø ⁵⁄₁₆"hole(min.

2"[51mm]deep)ateach

hole location.

B

One-Eared

Bracket

Two-Eared

Bracket

2

Continuous Brackets to Wall (Standard)

establishedlevelline

pilaster/panel

plumbline

floor

C

L

Placethebottomofthe

continuousbracketatthe

establishedlevelline.Center

thebracketopeningonthe

pilaster/panelplumbline.

A

Insert the plastic

anchors in all holes

and secure the

bracketstothewall

with the #14 x 2"

screws provided.

C

On end panel and pilaster applications, position the bracket

with the ear facing toward the inside of the stall.

Usingthebracket

as a template, mark

the hole locations on

the wall. Remove the

bracketanddrilla

Ø ⁵⁄₁₆"hole(min.2"

[51mm]deep)ateach

hole location.

B

Brackets are used as templates but, since the hole patterns may

be different, the brackets may not be interchanged.

One-Eared

Bracket

Two-Eared

Bracket

5

Installation Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400

Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012 10/1/2014

3

Leveling bolts to Pilaster

Notch indicates

bottomofintegral

hinge pilaster

Notch indicates

bottomofintegral

hinge pilaster

Use leveling screw to adjust

height of pilaster

Use leveling screws to

adjust height of pilaster

Drill a Ø ¹³⁄₆₄" pilot hole,

1½"(38mm)deep.Hole

shouldbeapproximately

centered for pilasters 3"–16"

(76mm–406mm)wide.

A

Drill a Ø ¹³⁄₆₄"pilothole,1½"(38mm)

deep.Holeshouldbe2"(51mm)

off each end for the pilasters

18"–24"(457mm–610mm)wide.

A

4

Continuous Brackets to Pilaster (Standard)

Refer to the submittal drawing to locate the split

dimension and layout location of each marked pilaster.

Locate Brackets: Measure down from the top of the

pilaster and place a mark on the pilaster split centerline

atdimensionsat13½"(343mm)and67½"(1715mm).

Pilaster shown is for reference only. Actual pilaster

varies depending on application.

A

Securethebrackets.

For "H" Bracket:Usethebracketasa

template, drill a Ø ¼" holes through the

pilaster/panelandsecurethebracketto

the pilaster and panel with #10-24 x ¾"

barrelnutsand#10-24x¾"shoulder

screws provided.

For continuous bracket:Securethebracket

to the pilasters using the #14 x ¾" screws

provided.

C

Split

Split

13½"

(343mm)

67½"

(1715mm)

Placethecontinuousbracketbetweeneachestablished

levelline.Centerthebracketopeningonthepilaster

splitcenterline.Usingthebracketasatemplate,mark

theholelocationsonthepilaster.Removethebracket

and drill a Ø ⁷⁄₃₂ x¾"(19mm)deeppilotholeateach

location.

B

Brackets are used as templates but, since the hole patterns may

be different, the brackets may not be interchanged.

C

L

6

Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400 Installation

10/1/2014 Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012

4a

Stirrup Brackets to Pilaster (Optional)

Refer to the submittal drawing to locate the split

dimension and layout location of each marked pilaster.

Locate Brackets: Measure down from the top of the pilaster

and place a mark on the pilaster split centerline at dimension

"A","B"and"C"fortherespectivebracket(seetableatleft).

Pilaster shown is for reference only.

Actual pilaster varies depending on application.

A

Placethecenterofeachstirrupbracketateach

establishedlevelline.Centerthebracketopening

onthepanelplumbline.Usingthebracketas

a template, mark the hole locations on the

pilaster.RemovethebracketanddrillaØ⁷⁄₃₂" x

¾"(19mm)deeppilotholeateachlocation.

B

Split

Split

"A"

"B"

"C"

"U"

Bracket

"H"

Bracket

Dim. "A"

19"

(483mm)

13½"

(343mm)

Dim. "B"

40½"

(1029mm)

67½"

(1715mm)

Dim."C"

62"

(1575mm)

—

Securethestirrupbracketsto

the pilasters using the #14 x ¾"

screws provided.

Refer to step 4 for location and

attachmentof"H"bracket.

C

5

Pilaster Shoes

Thisviewisanexampleonly.Refertoyoursubmittaldrawingsforactualsizes.Layoutthe

pilasteranddoorwidthsonthepilastercenterline,leavingtheappropriategapbetween

the wall and pilaster. Place the corresponding shoe on the pilaster centerline, center the

shoebetweenthepilastermarks.Usingtheshoesasatemplate,marktheholelocations.

A

Insert plastic anchors

into the holes and fasten

the shoe to the anchors

using hardware provided.

C

Drill Ø ⁵⁄₁₆"holes(min2"

[51mm]deep)inthefloor

and make sure the holes

arefreeofdirtanddebris.

B

Install the shoes starting with the one closest to the wall

36"(914mm)

Door Opening

PilasterCenterline

24"(610mm)

4"

(102mm)

7"

(178mm)

1"(25mm)Gap

26"(660mm)

Door Opening

⁹⁄₃₂" x ⁵⁄₈" Flat Washer

#14 x 2" Screw

Stainless Steel Shoe

Plastic

Anchor

7

Installation Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400

Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012 10/1/2014

6

Panels and Pilasters with Continuous Brackets (Standard)

Pilasters located at walls should be mounted first. Start at one end and install a panel, then a pilaster.

Continue alternating until installation is complete. When installing in an alcove or in-corner alcove, use an "H"

bracket to secure the pilaster to the panel.

When installing pilasters at walls, the gaps range

from ½" to 1¼" (13mm to 32mm). Refer to your

submittal drawing for your gap sizes.

Check to make sure the pilasters are plumb and level to each other. The pilaster height can be adjusted with

the leveling screw that was placed at the bottom of the pilaster (see page 5 for attaching leveling bolt).

Refer to your submittal drawing and leave the appropriate

gaps. Standard gap is 1" (25mm) between the panel and

wall and ½" (13mm) between the panel and pilaster.

Usingthebracketasatemplate,drillؼ"

holes through the pilaster at each pilaster

brackethole.Securethepilastertothebracket

with#10-24x¾"barrelnutsand#10-24x¾"

shoulder screws provided.

Using the hole in the shoe as a template, drill a

Ø ¼" hole through the pilaster and secure the

shoetothepilasterwith#10-24x¾"barrelnuts

and #10-24 x ¾" shoulder screws provided.

Using the hole in the shoe as a template, drill a Ø ¼"

hole through the pilaster and secure the shoe to the

pilasterwith#10-24x¾"barrelnutsand#10-24x¾"

shoulder screws provided.

Set the pilaster into the shoe while at the

sametimeplacingintothewallbracket.

A

Place a panel on the spacer and insert the panel into

thewallbracket.

Set the pilaster into the shoe while at the same time

placingthebracketaroundthepanel.

A

B

Usingthebracketsasatemplate,drillؼ"holesthrough

thepanelateachpanelbrackethole.Securethepanelto

thebracketswith#10-24x¾"barrelnutsand#10-24x¾"

shoulder screws provided.

B

C

C

Spacer14"(356mm)

Aluminum heatsink

onbottomofpanel.

Pilasters at Wall Pilasters with Panels

8

Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400 Installation

10/1/2014 Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012

6a

Panels and Pilasters with Stirrup Brackets (Optional)

Pilasters located at walls should be mounted first. Start at one end and install a panel, then a pilaster.

Continue alternating until installation is complete. When installing in an alcove or in-corner alcove, use an "H"

bracket to secure the pilaster to the panel.

When installing pilasters at walls, the gaps range

from ½" to 1¼" (13mm to 32mm). Refer to your

submittal drawing for your gap sizes.

Check to make sure the pilasters are plumb and level to each other. The pilaster height can be adjusted with

the leveling screw that was placed at the bottom of the pilaster (see page 5 for attaching leveling bolt).

Refer to your submittal drawing and leave the appropriate

gaps. Standard gap is 1" (25mm) between the panel and

wall and ½" (13mm) between the panel and pilaster.

Usingthebracketsasatemplate,drillؼ"

holes through the pilaster at each pilaster

brackethole.Securethepilastertothebracket

with#10-24x¾"barrelnutsand#10-24x¾"

shoulder screws provided.

Using the hole in the shoe as a template, drill a

Ø ¼" hole through the pilaster and secure the

shoetothepilasterwith#10-24x¾"barrelnuts

and #10-24 x ¾" shoulder screws provided.

Using the hole in the shoe as a template, drill a Ø ¼"

hole through the pilaster and secure the shoe to the

pilasterwith#10-24x¾"barrelnutsand#10-24x¾"

shoulder screws provided.

Set the pilaster into the shoe while at the

sametimeplacingintothewallbrackets.

A

Place a panel on the spacer and insert the panel into

thewallbrackets.

Set the pilaster into the shoe while at the same time

placingthebracketsaroundthepanel.

A

B

Usingthebracketsasatemplate,drillؼ"holesthrough

thepanelateachpanelbrackethole.Securethepanelto

thebracketswith#10-24x¾"barrelnutsand#10-24x¾"

shoulder screws provided.

B

C

C

Spacer14"(356mm)

Aluminum heatsink

onbottomofpanel.

Pilasters at Wall Pilasters with Panels

9

Installation Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400

Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012 10/1/2014

Foropenendapplications,cuttheheadrailtotheappropriatelength(if

required).Attachthebrackettothewallatthecorrectheight(seestepB).

Attachanotherbrackettoapilasterwith#10x¾"screwsatthecorrect

height(seeviewbelow).Theheadrailshouldbelevelwithanyadjacent

headrailandshouldbelocateddirectlyoverthepanel.Positioneach

headrailontothebracketsandsecurewithrequiredfasteners(seeStepC).

Usingarubbermallet,installtheheadrailendcap.

E

7

Headrail

Make sure the pilasters are plumb and that the pilaster has been secured to the shoe. Leave the appropriate door opening

between the pilasters as shown on your submittal drawing.

Place headrail over the top of the pilasters

andslideittightintothemountingbracket.

Usethemountingbracketasatemplateand

drill a Ø ⁷⁄₃₂" hole through the headrail. Secure

theheadrailtothemountingbracketwiththe

#10 x ⁵⁄₈" screws provided.

C

Makesurethepilasterisplumbandthatthespacingbetweenthe

pilastersforthedoorsisthecorrectdimension.Onthebackofeach

pilaster(startingwiththefirstpilaster),drillaØ⁷⁄₃₂" hole through one

face of the headrail only.

Using this hole as a template, drill a Ø ¹⁄₈" pilot hole into the pilaster,

¾"(19mm)deep.Securetheheadrailtothebackofeachpilaster

with the #10 x ¾" screws provided.

D

Completed Headrail Assembly

The illustrations on this page show mounting hardware and fasteners for a generic application. Refer to your submittals

to determine your actual headrail configurations.

Some headrail sections may need to be cut to an appropriate size. Refer to your submittals for general headrail placement.

Place headrail over the top of each pilaster

located at the wall and slide it tight against

the side wall. Mark the outline of the headrail

on the wall and remove the headrail.

A

Wall

Placetheheadrailbracketontheoutlinemarkedonthewalland

markthelocationsofthemountingholes.Removebracketand

drill(2)Ø⁵⁄₁₆"holesataminimumof2"(51mm)deep.Priorto

securingtothewall,enlargethe(2)backmountingholesofthe

brackettoؼ".Securethebrackettothewallwiththe#14x2"

screws and plastic anchors provided.

B

Headrail configurations that come to an intersection should meet over pilaster (see completed headrail assembly view below).

10

Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400 Installation

10/1/2014 Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012

Aluminum Heatsink on

bottomofdoor

8

Integral Hinges (Standard)

Top and bottom pintles are pre-

lubricated for your convenience.

Do not remove lubricant.

Pilaster

Spring

3" Top

Pin

Door

Set

Screw

¾"

3"

3³⁄₈" Top

Pintle

3¼" Bottom

Pintle Assy.

¾"

(19mm)

Insert top pintle into the

bottomofthedoor.Besure

thepintlebottomsout(usethe

bottompintletopushthetop

pintleintothedoor).

A

Using a Ø ¹⁄₈"(3mm)drillbit,drillapilot

hole for the set screw into the center

ofthedooredge(approximately¾"

(19mm)downfromthetopofthedoor).

Besuretodrillatleast1½"(38mm)to

penetrate the top pin in the door.

Screw the set screw in flush with the

door'ssurface,thencheckforproper

door operation.

If the door is installed and pinned

correctly, the door will "raise" slightly

on the pintles as the door is opened.

F

Insertthebottompintleinto

thepilasterbottom.Position

thedoorontothebottom

pintleassemblyonthe

pilaster and swivel the door to

engage the pintles.

Insert the spring and the top

pin into the pilaster top.

Move the top of the door into

position while pushing the top

pin into the pilaster. Release

the top pin and force the pin

tobottomoutinthedoor.

C

D

Using a Ø ¹⁄₈"drillbit,drilla

pilot hole for the set screw into

the center of the door edge

(approximately¾"(19mm)up

fromthebottomofthedoor).

Be sure to drill at least 1½"

(38mm)topenetratethetop

pintle in the door. Screw the

set screw in flush with the

door'ssurface.

B

With the door "at rest"

position, drill a Ø ¹⁄₈" hole for

the set screw in the center

of the pilaster edge, down

3"(76mm)fromthecutout.

Be sure to drill at least 1½"

(38mm)topenetratethe

bottompintleassemblyinthe

pilaster.

Screw the set screw in flush

withthepilaster'ssurface.

Position the door at the desired

"at rest" position. Push down

on the door to make sure the

topandbottompintlesare

engaged properly.

E

Repeat steps A-F for all doors

G

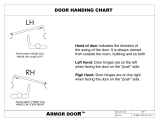

Before installing the hinges, make sure the door openings are the appropriate size, all pilasters are

plumb and secured to the shoe. Determine the door swing by facing the compartment from the outside.

Refer to your submittal drawings to determine each specific door swing for your application.

Right-hand

inswing

(RHI)

Left-hand

inswing

(LHI)

Right-hand

outswing

(RHO)

Left-hand

outswing

(LHO)

11

Installation Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400

Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012 10/1/2014

8a

Integral Hinges - No-Site (Standard)

Installing the heat sink after the doors are installed is difficult due to the limited space between the

bottom of the door and the floor. The heat sink should be installed prior to completing step "C".

Aluminum heatsink

onbottomofdoor

Pilaster

Spring

3" Top Pin

Lip

Lip

3"

(76mm)

3³⁄₈" Top Pintle

3¼" Bottom

PintleAssembly

Notch Feature

(foradjacent

doorstrike)

¾"

(19mm)

1¾"

(44mm)

½"

(13mm)

¾"

Drill first hole as shown. Attach and align

heatsinkwithsinglescrew(#6x¾"flat

headscrew).Useremainingheatsink

holes as a drilling template and fasten with

remaining screws

SameprocedureaslettersA–Fforstep8.Seebelowforinstructionsandnoteson

installingthealuminumheatsinkonbottomofdoorpriortostartinginstallation.

A

The "lip" will be on the outside of the stall for outswing doors and on the inside for inswing doors.

The heat sink should always be on the bottom.

Ø ⁷⁄₆₄ x ¾"

Deep

(allPilot

Holes)

12

Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400 Installation

10/1/2014 Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012

8b

Continuous Spring Loaded Piano Hinge (Optional)

Spacer14"(356mm)

abovefinishedfloor

Usea14"(356mm)spacer

to help support the weight of

the door.

(FOR ALUMINUM HINGE:

removesnap-onfaceplate)

Place the door on the spacer

and set the gap at the hinge

and latch side. Standard gap

is

³⁄₁₆"(5mm).

A

Centerthehingeintheopening

opposite the latch and top to

bottomondoor(approximately½"

[13mm] down from the top of the

door)

B

RepeatproceduresA-CforStainlessSteelHinges

and procedures A-D for Aluminum Hinges.

E

Using the hinge as a template, drill a Ø ¼"

holethroughthedooratthetopandbottom

hole. Secure the hinge to the door with the

#10-24 x ¾" shoulder screws and #10-24 x ¾"

barrelnutsprovided.

Ensure that the gap on the latch side is

consistentandrepeatprocedureConthe

pilaster side.

Then drill a Ø ¼" holes through the remaining

hinge holes on the door and pilaster. Secure

with the fasteners provided.

C

ALUMINUM HINGE ONLY, FOR STAINLESS STEEL

SKIP THIS STEP: Hold the snap-on faceplate squarely on

theleaf.Tapthefaceplatefirmlyusingasoftwoodblockto

protectthefinishfromhammerblows.Startatthetopand

work downward until the entire length of the faceplate is

firmly engage. Secure the faceplate with a #8 x 1" flat head

Phillips drive screw.

To adjust spring tension, use a torx screwdriver and turn

the torx head clockwise approximately one complete

revolution.Inserta1½"(38mm)longnailintothehole

through the hinge pin. The hinge pin has a hole in two

directionsallowingadjustmentstobemadeatevery¼turn.

Checktheswingofthedoor.Ifthedoordoesnotclosefast

enough, remove the temporary nail and turn the torx head

¼ turn.

When desired tension is reached, hold the torx head in

place, remove the nail and insert the roll pin. Tap the roll

pinintoplacewithanailsetuntil1/8"(3mm)remainsout

from the hinge.

D

Closed

Door View

Before installing the hinges, make sure the door openings are the appropriate size, all pilasters are

plumb, secured to the shoe and that the headrail is installed. Determine the door swing by facing the

compartment from the outside. Refer to your submittal drawings to determine each specific door swing

for your application.

Right-hand

inswing

(RHI)

Left-hand

inswing

(LHI)

Right-hand

outswing

(RHO)

Left-hand

outswing

(LHO)

Continuous Piano Hinge

Part # Prefix HDWP-S0209 Part # Prefix HDWP-S0208

Thepartnumberslistedareprefixesonlyand

are used to identify the appropriate door kit

basedonyourdoorswingasdeterminedabove.

Inswinging doors should have hinges mounted

on the inside of the stall while outswinging doors

should have hinges mounted on the outside of

the stall.

(lefthandin,righthandout,

knucklesfacingfront)

(righthandin,lefthandout,

knucklesfacingfront)

Door

side

Pilaster

side

Pilaster

side

Door

side

13

Installation Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400

Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012 10/1/2014

Top and

Bottom Insert

Female(2)

Bottom Insert

Malew/Cutoff

Cam&Spacer

(1)

Top Insert w/

CamMale(1)

Aluminium

Hinge Blank

(4)

Left In and Right Out Assembly

Top Hinge Set

Bottom Hinge Set

Insert

Correct

Incorrect

Hinge

Blank

Aluminum Hinge Blank

Reference

Mark

Reference

Mark

Top and

Bottom Insert

Female

Bottom Insert

Malew/Cutoff

Cam&Spacer

Top Insert w/

CamMale

Top Hinge Set

Bottom Hinge Set

Cam

Cutoff

Cam

Right In and Left Out Assembly

8c

Aluminum Wraparound Hinge (Optional)

Before installing the hinges, make sure the door openings are the appropriate size, all pilasters are

plumb, secured to the shoe and that the headrail is installed. Determine the door swing by facing the

compartment from the outside. Refer to your submittal drawings to determine each specific door swing

for your application.

Hinge blanks and inserts have reference marks

that are used in setting the hinge position. The

hinge contains the cam mechanism and the bottom

hinge has the cutoff cam with spacer.

Right-hand

inswing

(RHI)

Left-hand

inswing

(LHI)

Right-hand

outswing

(RHO)

Left-hand

outswing

(LHO)

Separate the hinge components and ensure all parts

are included as shown

A

Assembleinsertsintothehingeblanksmakingsurethe

insertcollarfitstightlyagainsteachofthehingeblanks.

D

Align the reference marks of the inserts and hinge

blanksasshown.

C

Findthehingeassemblythatcoincideswiththedoor

swing. Arrange the hinge sets as shown.

B

Pilaster Side

Pilaster Side

Pilaster Side

Pilaster Side

Door Side

Door Side

Door Side

Door Side

14

Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400 Installation

10/1/2014 Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012

Closed

Upper Blank

Top Hinge Set

#8 x 1"

Stainless

Steel Phillips

head screw

#8 x 1" Stainless

Steel Phillips head

screw

Cardboard

Spacer

#10-24 x¾"

Shoulder

Screw

Aluminum

Heat Sink

#10-24 x ¾"

Barrel Nut

Lower Blank

Bottom Hinge Set

#10-24 x ¾"

Shoulder

Screw

#10-24 x ¾"

Barrel Nut

Lower

Blank Top

Hinge Set

Upper Blank

Bottom

Hinge Set

2"(51mm)

2"

AlignCammedInsert

Reference Mark

AlignCammedInsert

Reference Mark

AlignCammedInsert

Reference Mark

30° Open

PositiveClosed

8c

Aluminum Wraparound Hinge (Optional)

Set the "at rest" position for the door

byadjustingthepositionofthetop

maleinsertinthehingeblank.

E

Ensure

Hinge set

is fully

engaged

Ensure hinge

set is fully

engaged to

cardboard

spacer

Aluminum

Heat Sink

Tape

Tape

Assemblethehingesetsonthe

door. Use tape to hold the hinge

sets together

H

Placetheupperblankofthetophingesetonthedoor2"(51mm)from

the top. Using the hinge as a template, drill a Ø ³⁄₃₂"x1"(25mm)deep

pilot hole into the edge of the door. Secure the hinge to the door with

a #8 x 1" stainless steel Phillips head screw. Then repeat the same

procedureforlowerblankofthebottomhingeset.

Usinga14"(356mm)spacer,

support the door in the opening.

Removetapeandcardboard

spacer from the hinge set

As the door is moved

intoplace,slipbothhinge

blanksonthepilaster.

AttachLowerblankof

the top hinge set to the

pilaster. Using the hinge as

a template, drill Ø ¼" holes

through the hinge set and

door. Secure with

#10-24 x ¾" shoulder

screws and #10-24 x ¾"

barrelnuts.

Then repeat the same

procedureforupperblank

ofthebottomhingeset.

F

I

L

J

K

Using the hinge as a template, drill

ؼ"holesthroughbothhinge

sets and the door. Secure with

#10-24 x ¾" shoulder screws and

#10-24x¾"barrelnuts.Place

thecardboardspaceronthemale

insert of the lower hinge set.

G

Make sure that the upper and

lower portions of each hinge

set are fully engaged.

15

Installation Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400

Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012 10/1/2014

9

Latch and Strike/Keeper for Inswing Doors

Local codes vary from state to state. Check your local

codes before installing the coat hook and door pulls.

D

C

Line up the center hole of the strike/keeper with the mark on

the pilaster. Using the strike/keeper as a template, drill Ø ¼"

holes through the pilaster. It is not necessary to remove the

strike/keeperbeforedrilling.Securethestrike/keepertothe

pilaster using hardware provided.

E

For32"-26"(813mm–914mm)ADAdoors,measure5½"

(140mm)fromthelatchedsideofthedoorand25¾"down

from the top of the door. Drill Ø ¼" hole through the face of

thedoor.Drillanidenticalhole,3½"(89mm)belowthehole

just drilled. Install one door pull to each side of the door with

the hardware provided.

Using the latch mounting holes as a template, drill a Ø ⁷⁄₃₂"

pilotholeintothedoor,¾"(19mm)deep.Securethelatchto

the door using hardware provided.

A

B

F

G

With the door in the closed position, set

the latch on the inside of the door so that

theslidebariscenteredintheslotonthe

strike/keeper. The leading edge of the

latchshouldbepositionedapproximately

³⁄₈"(10mm)fromthedooredge.

Install the coat hook in the upper corner on

the inside of the door on the latched side

atalocation3"(76mm)downfromthetop

and3"(76mm)infromtheside.Usingthe

coat hook as a template, drill two Ø ⁵⁄₃₂"

pilotholes(max.¾"[19mm]deep).Secure

the coat hook using hardware provided.

Repeat steps A-F for remaining doors.

The measurement from the top of the door to the

centerholeonthestrike/keeperis27½"(699mm).

Mark this measurement on the inside of the pilaster,

opposite the hinged side of the door.

25¾"

(654mm)

5½"

(140mm)

³⁄₈"

(10mm)

27½"

(699mm)

3½"(89mm)

Door

Latch

Pilaster

One Ear Door

Stop(Inswing)

Flat Door Stop

(Inswing)

#10-24 x ¾" Machine Screw

#14 x ¾" Screw

#10 x ¾"

Screw

3"(76mm)

3"(76mm)

CoatHook

(Inswing)

#14 x ¾" Screw

#14 x ¾" Flat Head Screw

#14 x ¾" Screw

#10-24 x 2" Machine Screw

Door Pull

Door Pull

Slide

Latch

Slide

Latch

FLAT DOOR

STOP

ONE EAR

DOOR STOP

Door Pull

DoorStop(Inswing)

#10-24 x ¾" Barrel Nut

#14 x ¾" Screw

#10-24 x 2"

Machine Screw

Slide

Latch

Door Pull w/

Countersink(addedfor

32"-36" inswing ADA

Doors)

#10-24 x ¾"

Shoulder Screw

DOOR STOP

Door Pull w/

Countersink(added

for 32"-36" inswing

ADADoors)

Door Pull w/

Countersink(added

for 32"-36" inswing

ADADoors)

16

Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400 Installation

10/1/2014 Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012

5½"

(140mm)

1"

(25mm)

27½"

(699mm)

3½"(89mm)

9a

Latch and Strike/Keeper for Outswing Doors

Local codes vary from state to state. Check your local

codes before installing the coat hook and door pulls.

D

C

Line up the center hole of the strike/keeper with the mark on

the pilaster. Using the strike/keeper as a template, drill Ø ¼"

holes through the pilaster. It is not necessary to remove the

strike/keeperbeforedrilling.Securethestrike/keepertothe

pilaster using hardware provided.

E

Measure5½"(140mm)fromthelatchedsideofthedoorand

25¾"(654mm)downfromthetopofthedoor.Drillaؼ"

hole through the face of the door. Drill an identical hole 3½"

(89mm)belowtheholejustdrilled.Installonedoorpulltoeach

side of the door with the hardware provided.

Using the latch mounting holes as a template, drill a Ø ⁷⁄₃₂"

pilotholeintothedoor,¾"(19mm)deep.Securethelatchto

the door using hardware provided.

A

B

G

F

H

With the door in the closed position, set the latch on the

insideofthedoorsothattheslidebariscenteredonthe

strike/keeper.Theleadingedgeofthelatchshouldbe

positioned approximately 1"(25mm)fromthedooredge.

Install the coat hook according to local codes.

Forsuggestedlocationseeimagebelow

Installthewallbumperinthelowercornerofthedoor

oppositethehingedsideatalocation3"(76mm)up

fromthebottomand3"(76mm)overfromtheside.

Using a Ø ⁵⁄₃₂"drillbit,drilltwoholes(max.¾"deep).

Securethewallbumperusingthehardwareprovided.

Repeat steps A-G for remaining doors.

The measurement from the top of the door to the

centerholeonthestrike/keeperis27½"(699mm).

Mark this measurement on the inside of the pilaster,

opposite the hinged side of the door.

25¾"

(654mm)

Door

Latch

Pilaster

One Ear Door

Stop(Outswing)

Flat Door Stop

(Outswing)

#14 x ¾" Screw

#14 x ¾"

Screw

#10 x ¾"

Screw

3"

3"

CoatHook

(Outswing)

Door

Pilaster

Wall Bumper

#14 x ¾" Screw

#14 x ¾" Flat Head Screw

#14 x ¾" Screw

Door Pull

Door Pull

Slide

Latch

Slide

Latch

FLAT DOOR

STOP

ONE EAR

DOOR STOP

Door Pull

DoorStop(Outswing)

#10-24 x ¾" Barrel Nut

#14 x ¾" Screw

#10-24 x 2"

Machine

Screw

Slide

Latch

Door Pull w/

Countersink

#10-24 x ¾"

Shoulder

Screw

DOOR STOP

36"

A.F.F.

#10-24 x ¾" Machine Screw

Door Pull w/

Countersink(added

for 32"-36" inswing

ADADoors)

Door Pull w/

Countersink(added

for 32"-36" inswing

ADADoors)

#10-24 x 2" Machine Screw

17

Installation Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400

Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012 10/1/2014

9b

Latch and Keeper for No-Site Inswing Doors

Local codes vary from state to state. Check your local

codes before installing the coat hook and door pulls.

C

Line up the top of the keeper with the mark on the pilaster.

Using the keeper as a template, drill Ø ⁷⁄₃₂"x¾"(19mm)

deep holes into the pilaster. It is not necessary to remove

thekeeperbeforedrilling.Securethekeepertothepilaster

using hardware provided.

E

For 32"-26" ADA doors, measure 5½" from the latched side

of the door and 25¾" down from the top of the door. Drill

a Ø ¼" hole through the face of the door. Drill an identical

hole,3½"belowtheholejustdrilled.Installonedoorpullto

each side of the door with the hardware provided.

D

Using the latch mounting holes as a template, drill a Ø ⁷⁄₃₂"

pilotholeintothedoor,¾"(19mm)deep.Securethelatchto

the door using hardware provided.

B

With the door in the closed position, mount the latch on

theinsideofthedoorsothatthecenteroftheslidebar

is27½"(699mm)fromthetopofthedoor.Theleading

edgeofthelatchshouldbepositionedapproximately

³⁄₈"(10mm)fromthedooredge"lip."Ifstainlesssteel

hardwareisused,thisdistanceshouldbe1¹⁄₈"(29mm).

F

For coat hook install see Step 9 letter F on page 15.

G

Repeat steps A-F for remaining doors.

A

The measurement from the top of the door to the top of the

keeper is 27⁹⁄₁₆"(700mm).Markthisontheinsideofthe

pilaster, opposite the hinged side of the door. The leading

edgeofthekeepershouldbelinedupwiththeedgeofthe

pilasternotch(approximately⁵⁄₈" [16mm] in from the edge

ofthepilaster).

#14 x ¾" Screw

#14 x ¾" Screw

#10-24 x 2"

Machine Screw

Door

Pull

Pilaster(Double

StrikeShown)

Door

Keeper

Lip

5½"

27½"

**³⁄₈"

27⁹ ⁄₁₆"

⁵⁄₈"

Door Pull w/

Countersink(added

for 32"-36" inswing

ADADoors)

Slide Latch

**If stainless steel hardware is used measurement should be ¹⁄₈"

18

Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400 Installation

10/1/2014 Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012

9c

Latch and Keeper for No-Site Outswing Doors

D

C

Line up the top of the keeper with he mark on the pilaster.

Using the keeper as a template, drill Ø ⁷⁄₃₂"x¾"(19mm)

deep holes into the pilaster. It is not necessary to remove

thekeeperbeforedrilling.Securethekeepertothe

pilaster using hardware provided.

E

Measure 5½" from the latched side of the door and 29¼" up

fromthebottomofthedoor.Drillaؼ"holethroughthe

faceofthedoor.Drillanidenticalhole,3½"belowthehole

just drilled. Install one door pull to each side of the door with

the hardware provided.

Using the latch mounting holes as a template, drill a Ø ⁷⁄₃₂"

pilotholeintothedoor,¾"(19mm)deep.Securethelatch

to the door using hardware provided.

A

B

G

F H

With the door in the closed position, mount the latch on the

insideofthedoorsothatthecenteroftheslidebaris27½"

(699mm)fromthetopofthedoor.Theleadingedgeofthe

latchshouldbepositionedapproximately¹⁄₈"(3mm)fromthe

"inside face" door edge.

Install the coat hook according to local codes. See

step 9a letter G on page 16 for suggested location.

Forwallbumperinstallseestep9aletterFonpage17.

Repeat steps A-G for remaining doors.

The measurement from the top of the door to the top of the

keeper is 27⁹⁄₁₆"(700mm).Markthisontheinsideofthe

pilaster, opposite the hinged side of the door. The leading

edgeofthekeepershouldbelinedupwiththeedgeofthe

pilasternotch(approximately⁵⁄₈" [16mm] in from the edge of

thepilaster).

#14 x ¾" Screw

#14 x ¾" Screw

#10-24 x 2"

Machine

Screw

Door Pull

Pilaster(DoubleStrike

Shown)

Door

Keeper

Lip

5½"

27½"

¹⁄₈"

27⁹⁄₁₆"

⁵⁄₈"

DoorPullw/Countersink

(addedfor32"-36"

inswingADADoors)

Slide Latch

Local codes vary from state to state. Check your local

codes before installing the coat hook and door pulls.

19

Installation Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400

Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012 10/1/2014

Positionstiffenerbracketonpilastersothe

bracketedgeis¼"fromtheintegralhingecutout

andcenteredtoptobottom.

A

Split at Door Hinge Split at Door Strike

10

Stiffener Bracket

A stiffener bracket is required for all pilasters 16" and larger.

B

Usingthebracketasaguide,drillaØ⁷⁄₃₂" x ¾" deep

pilot hole at each screw hole location.

The stiffener bracket is installed on the largest side of a pilaster split.

B

Usingthebracketasaguide,drillaØ⁷⁄₃₂" x ¾"

deep pilot hole at each screw hole location.

A

Positionstiffenerbracketonpilastersothebracket

edge is ¼" from the strike/keeper and centered top to

bottom.

Securebrackettopilasterusingthe#14x⁵⁄₈"

screws provided.

C

Securebrackettopilasterusingthe#14x⁵⁄₈"

screws provided.

C

For wrap around and continuous hinges, position the

bracket edge ¼" from the hinge edge.

¼" ¼"

¼"

20

Bradmar

™

Restroom Partitions, Floor-Mounted with Overhead Brace — Series 400 Installation

10/1/2014 Bradley • HDWP-INSTR-013 Rev. K; ECN 12-14-012

Before installing the urinal screen components,

determine the correct location for your application.

Brackets are used as templates but, since the hole patterns

may be different, the brackets may not be interchanged.

Drawaplumblineonallwalls

representing urinal screen

centers.Measure18½"(470mm)

upfor42"(1067mm)tallurinal

screensor21½"(546mm)upfor

48"(1219mm)tallurinalscreens

from the floor and place a mark

ontheplumbline.Usealevel

to transfer that mark to all other

plumblines.

A

Usingthebracketasatemplatemark

the hole locations on the wall. Remove

thebracketanddrillaØ⁵⁄₁₆" x min. 2"

(51mm)deepholeateachholelocation.

C

Placethebottomofthe

continuousbracketat

theestablishedlevelline.

Centerthebracketopening

ontheplumbline.

B

Drill Ø ¼" holes through the screen at

eachbrackethole. Secure the screen

tothebracketwith#10-24x¾"

barrelnutsand#10-24x¾"shoulder

screws provided.

F

18½"(470mm)for

42"(1067mm)tallscreens

or21½"(546mm)for

48"(1219mm)tallscreens

established

level line

urinalplumbline

floor

11

Urinal Screens with Continuous Brackets (Standard)

Placethebottomofeachurinalscreen

18"(457mm)upfromoor.Establisha1"

(25mm)gapbetweenthenishedwalland

urinal screen edge. A spacer may help

to support the weight of the screen and

establishtheappropriatedistances.

E

Insert the plastic

anchors in all holes

andsecurethebracket

with the #14 x 2"

screws provided.

D

/