OM-1581 Page 8

3-4. Internal Connections To Feeder

ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Turn OFF wire feeder and welding power source,

and disconnect input power before inspecting or

installing. Stop engine on welding generator.

The welding wire, drive rolls, drive assembly, and all

metal parts touching the welding wire are electrically

live when welding or feeding wire using gun trigger.

CYLINDERS can explode if damaged.

• Keep cylinders away from welding and other

electrical circuits.

• Never touch cylinder with welding electrode.

• Always secure cylinder to running gear, wall, or

other stationary support.

HIGH GAS PRESSURE can cause gun

gas valve to leak.

• Do not use gas pressure above 50 psi (345 kPa) or

mechanical gas valve in gun can leak.

OVERHEATING can damage gun parts.

• If using recirculating coolant system, do not make

connections from coolant system to water valve;

instead make connections directly from coolant

system to gun hoses.

INCORRECT COOLANT FLOWRATE

can damage gun parts.

• Maintain minimum 1 qt/min flowrate at all times.

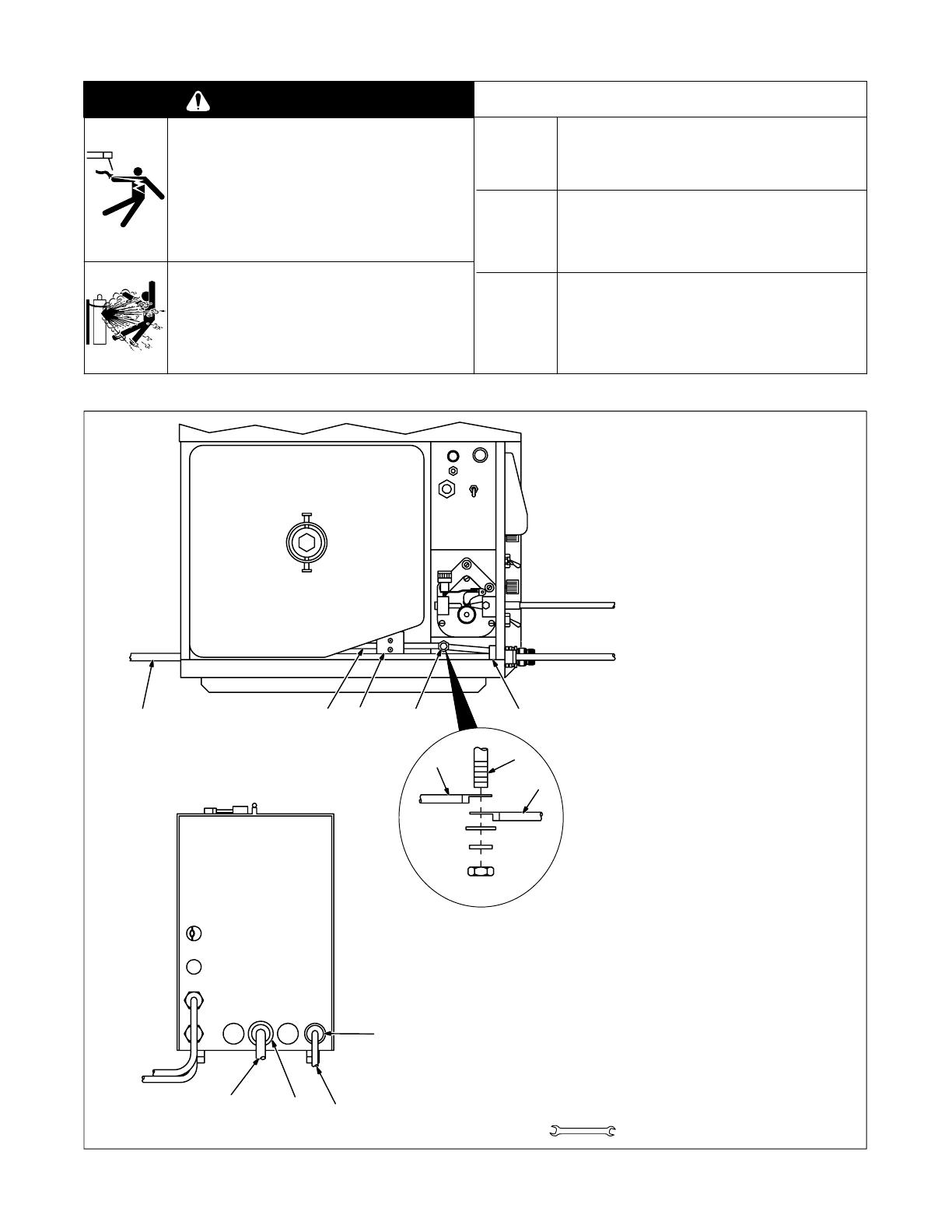

WARNING

wfwarn7.1* 9/91

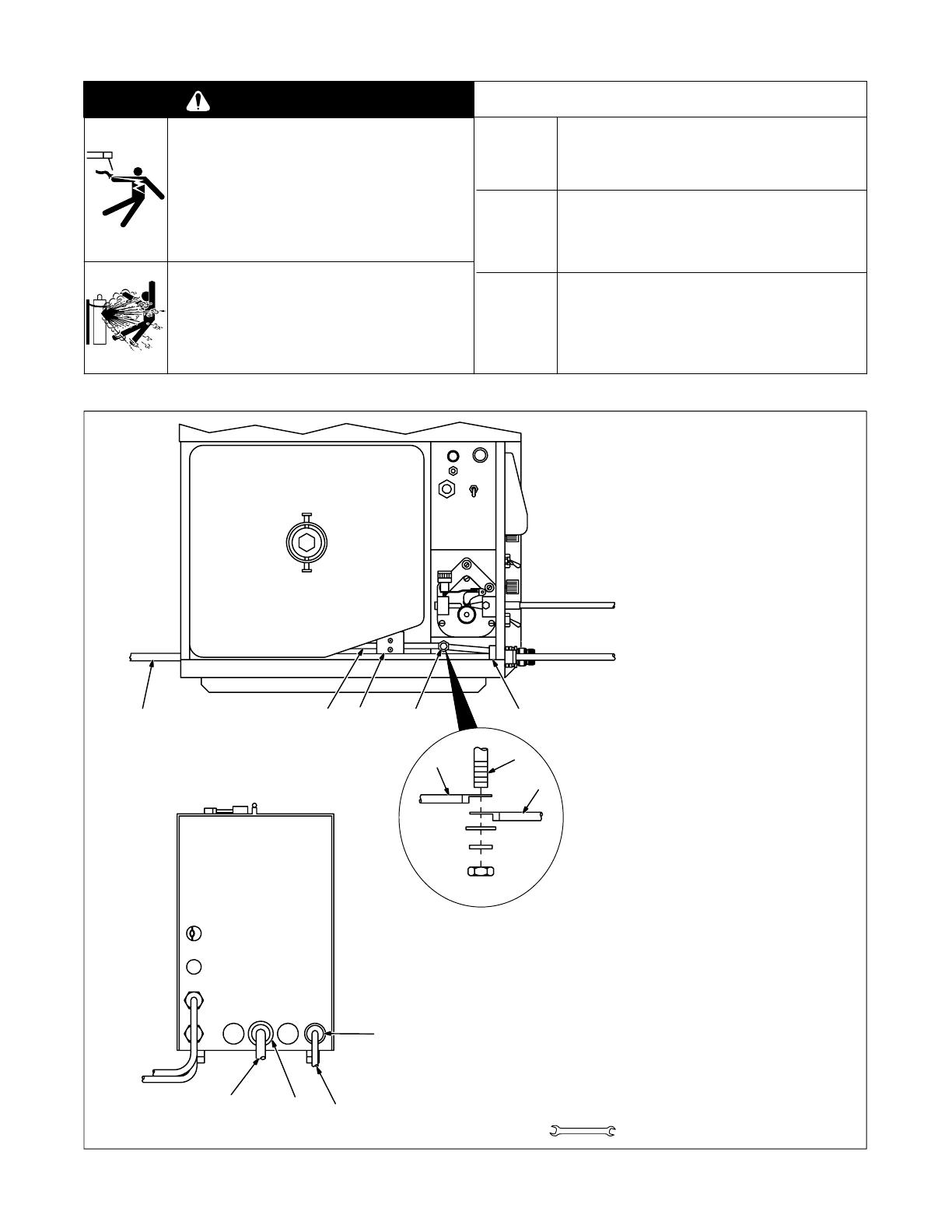

A. Air-Cooled Feeder Connections

1 Gas Hose Grommet

2 10 ft (3 m) Gas Hose

3 Rear Of Gas Fitting

Route one end of gas hose through

grommet, and connect hose to rear

of GAS fitting in feeder. Connect re-

maining end of hose to regulator/

flowmeter.

4 Weld Cable To Welding Power

Source

Select and prepare weld cable ac-

cording to welding power source

manual.

5 Weld Cable Grommet

6 Reed Switch

7 Weld Cable Terminal In Feeder

Route one end of weld cable through

grommet, through reed switch, and

connect to weld cable terminal in

feeder. Connect remaining end of

cable to positive (+) weld output ter-

minal on welding power source.

8 Gun Weld Cable

Be sure that terminal of welding pow-

er source weld cable is in direct con-

tact with terminal from gun weld

cable. Close and latch door.

Ref. ST-151 771

Tools Needed:

5/8 in, 1-1/8 in

Top View

4

7

8

Connect To

Positive (+) Weld

Output Terminal On

Welding Power Source

Connect To

Regulator/

Flowmeter

1

5

246 7 3

Rear Panel

Figure 3-8. Air-Cooled Feeder Connections