vacon 100 industrial

vacon 100 flow

ac drives

installation manual

ip00 drive modules

®

®

PREFACE

Document ID: DPD01665C

Date: 15.2.2016

ABOUT THIS MANUAL

This manual is copyright of Vacon Ltd. All Rights Reserved. The manual is subject to change

without prior notice.

ABOUT THE PRODUCT

This manual describes the Vacon 100 IP00 Drive Module. The drive has a power range of

75-800 kW, and a voltage range of 208-240 V, 380-500 V, or 525-690 V. The drive is available

in 4 different enclosure sizes: MR8, MR9, MR10 and MR12. The enclosure class of the drive is

IP00, and that is why the drive must be installed in a cabinet or other enclosure after

delivery.

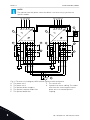

Fig. 1: Examples of the Vacon 100 IP00 drive module

PREFACE VACON · 3

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: [email protected]

VACON · 4

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

TABLE OF CONTENTS

Preface

About this manual 3

About the product 3

1 Approvals 7

2 Safety 9

2.1 The safety symbols used in the manual 9

2.2 Warning 9

2.3 Caution 10

2.4 Grounding and earth fault protection 11

2.5 Using an RCD or an RCM device 12

3 Receiving the delivery 13

3.1 Package label 13

3.2 Type designation code 14

3.3 The contents of the delivery 14

3.4 Removing the packaging and lifting the AC drive 15

3.4.1 Weight of the AC drive 15

3.4.2 Lifting the IP00 drive module 15

3.5 "Product modified" label 18

3.6 Disposal 19

4 Mounting dimensions 20

4.1 Dimensions of MR8, IP00 20

4.2 Dimensions of MR9, IP00 21

4.3 Dimensions of MR10 and MR12, IP00 22

5 Installation into cabinet 25

5.1 General information 25

5.1.1 General information about the installation, MR8-MR9 25

5.1.2 General information about the installation, MR10 26

5.1.3 General information about the installation, MR12 29

5.2 Mechanical installation 31

5.2.1 Installing the IP00 drive module into the cabinet 32

5.2.2 Cooling and free space around the AC drive 34

6 Power cabling 36

6.1 Cable dimensioning and selection 36

6.1.1 Cable and fuse sizes 36

6.1.2 Cable and fuse sizes, North America 43

6.2 Brake resistor cables 48

6.3 Preparing for the cable installation 50

6.4 Cable installation 51

6.4.1 Enclosure sizes MR8 and MR9 51

6.4.2 Enclosure sizes MR10 and MR12 55

TABLE OF CONTENTS VACON · 5

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: [email protected]

7 Control unit 64

7.1 Control unit components 64

7.2 Control unit cabling 65

7.2.1 Selection of the control cables 65

7.2.2 Control terminals and DIP switches 66

7.3 Fieldbus connection 70

7.3.1 Using fieldbus through an Ethernet cable 71

7.3.2 Using fieldbus through an RS485 cable 72

7.4 Installation of option boards 75

7.4.1 The installation procedure 76

7.5 Installation of a battery for the Real Time Clock (RTC) 77

7.6 Galvanic isolation barriers 77

8 Commissioning and additional instructions 79

8.1 Commissioning safety 79

8.2 Operation of the motor 80

8.2.1 Checks before starting the motor 80

8.3 Measuring the cable and motor insulation 80

8.4 Installation in an IT system 80

8.4.1 The EMC jumper in MR8 81

8.4.2 The EMC jumper in MR9 82

8.4.3 The EMC jumper in MR10 and MR12 83

8.5 Maintenance 86

8.5.1 Maintenance intervals 86

8.5.2 Replacing the fans of the AC drive 87

8.5.3 Downloading the software 91

9 Technical data, Vacon

®

100 95

9.1 AC drive power ratings 95

9.1.1 Mains voltage 208-240 V 95

9.1.2 Mains voltage 380-500 V 96

9.1.3 Mains voltage 525-690 V 97

9.1.4 Overload capability 97

9.1.5 Brake resistor ratings 98

9.2 Vacon

®

100 - technical data 102

10 Technical data, Vacon

®

100 FLOW 107

10.1 AC drive power ratings 107

10.1.1 Mains voltage 208-240 V 107

10.1.2 Mains voltage 380-500 V 108

10.1.3 Mains voltage 525-690 V 109

10.1.4 Overload capability 109

10.2 Vacon

®

100 FLOW - technical data 111

11 Technical data on control connections 116

11.1 Technical data on control connections 116

VACON · 6 TABLE OF CONTENTS

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

1 APPROVALS

Here are the approvals that have been granted to this Vacon product.

Find the EC Declaration of Conformity on the next page.

APPROVALS VACON · 7

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: [email protected]

1

EC DECLARATION OF CONFORMITY

We

Manufacturer’s name: Vacon Oyj

Manufacturer’s address: P.O. Box 25

Runsorintie 7

FIN-65381 Vaasa

Finland

hereby declare that the product

Product name: Vacon 100 AC drive

Model Designation: Wall-Mounted Drives:

Vacon 0100 3L 0003 2...0310 2

Vacon 0100 3L 0003 4...0310 4

Vacon 0100 3L 0003 5...0310 5

Vacon 0100 3L 0004 6...0208 6

Vacon 0100 3L 0007 7...0208 7

IP00 Drive Modules:

Vacon 0100 3L 0140 2...0310 2

Vacon 0100 3L 0140 5...1180 5

Vacon 0100 3L 0080 7...0820 7

Enclosed Drives:

Vacon 0100 3L 0140 5...1180 5

Vacon 0100 3L 0080 7...0820 7

has been designed and manufactured in accordance with the following

standards:

Safety: EN 61800-5-1: 2007

EN 60204-1: 2006 + A1: 2009 (as

relevant)

EMC: EN 61800-3: 2004 + A1: 2012

EN 61000-3-12: 2011

and conforms to the relevant safety provisions of the Low Voltage

Directive (2006/95/EC) and EMC Directive 2004/108/EC.

It is ensured through internal measures and quality control that the

product conforms at all times to the requirements of the current

Directive and the relevant standards.

In Vaasa, 11th of January, 2016

Vesa Laisi

President

The year the CE marking was affixed: 2009

VACON · 8 APPROVALS

1

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

2 SAFETY

2.1 THE SAFETY SYMBOLS USED IN THE MANUAL

This manual contains warnings and cautions, which are identified with safety symbols. The

warnings and cautions give important information on how to prevent injury and damage to

the equipment or your system.

Read the warnings and cautions carefully and obey their instructions.

Table 1: The safety symbols

The safety symbol Description

WARNING!

CAUTION!

HOT SURFACE!

2.2 WARNING

WARNING!

Do not touch the components of the power unit when the drive is connected to

mains. The components are live when the drive is connected to mains. A contact

with this voltage is very dangerous.

WARNING!

Do not touch the motor cable terminals U, V, W, the brake resistor terminals or the

DC terminals when the drive is connected to mains. These terminals are live when

the drive is connected to mains, also when the motor does not operate.

WARNING!

Do not touch the control terminals. They can have a dangerous voltage also when

the drive is disconnected from mains.

SAFETY VACON · 9

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: [email protected]

2

WARNING!

Before you do electrical work, make sure that there is no voltage in the

components of the drive.

WARNING!

To do work on the terminal connections of the drive, disconnect the drive from

mains and make sure that the motor has stopped. Wait 5 minutes before you open

the cabinet door or the cover of the drive. Then use a measuring device to make

sure that there is no voltage. The terminal connections and the components of the

drive are live 5 minutes after it is disconnected from mains and the motor has

stopped.

WARNING!

Before you connect the drive to mains, make sure that the front cover and the cable

cover of the drive are closed. The connections of the AC drive are live when the

drive is connected to mains.

WARNING!

Disconnect the motor from the drive if an accidental start can be dangerous. When

there is a power-up, a power break or a fault reset, the motor starts immediately if

the start signal is active, unless the pulse control for Start/Stop logic is selected. If

the parameters, the applications or the software change, the I/O functions

(including the start inputs) can change.

WARNING!

Wear protective gloves when you do mounting, cabling or maintenance operations.

There can be sharp edges in the AC drive that can cause cuts.

2.3 CAUTION

CAUTION!

Do not move the AC drive. Use a fixed installation to prevent damage to the drive.

CAUTION!

Do not make measurements when the AC drive is connected to mains. It can cause

damage to the drive.

CAUTION!

Make sure that there is reinforced protective ground connection. It is mandatory,

because the touch current of the AC drives is more than 3.5 mA AC (refer to EN

61800-5-1). See chapter 2.4 Grounding and earth fault protection.

CAUTION!

Do not use spare parts that are not from the manufacturer. Using other spare parts

can cause damage to the drive.

VACON · 10 SAFETY

2

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

CAUTION!

Do not touch the components on the circuit boards. Static voltage can cause

damage to these components.

CAUTION!

Make sure that the EMC level of the AC drive is correct for your mains. See chapter

8.4 Installation in an IT system. An incorrect EMC level can cause damage to the

drive.

CAUTION!

Prevent radio interference. The AC drive can cause radio interference in a domestic

environment.

NOTE!

If you activate the autoreset function, the motor starts automatically after an

automatic fault reset. See the Application Manual.

NOTE!

If you use the AC drive as a part of a machine, the machine manufacturer must

supply a mains disconnection device (refer to EN 60204-1).

2.4 GROUNDING AND EARTH FAULT PROTECTION

CAUTION!

The AC drive must always be grounded with a grounding conductor that is

connected to the grounding terminal that is identified with the symbol

. Not using

a grounding conductor can cause damage to the drive.

The touch current of the drive is more than 3.5 mA AC. The standard EN 61800-5-1 tells that

1 or more of these conditions for the protective circuit must be true.

The connection must be fixed.

a)

The protective grounding conductor must have a cross-sectional area of minimum 10

mm

2

Cu or 16 mm

2

Al. OR

b)

There must be an automatic disconnection of the mains, if the protective grounding

conductor breaks. See chapter 6 Power cabling. OR

c)

There must be a terminal for a second protective grounding conductor in the same

cross-sectional area as the first protective grounding conductor.

SAFETY VACON · 11

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: [email protected]

2

Table 2: Protective grounding conductor cross-section

Cross-sectional area of the phase conductors (S)

[mm

2

]

The minimum cross-sectional area of the protective

grounding conductor in question [mm

2

]

S ≤ 16 S

16 < S ≤ 35 16

35 < S S/2

The values of the table are valid only if the protective grounding conductor is made of the

same metal as the phase conductors. If this is not so, the cross-sectional area of the

protective grounding conductor must be determined in a manner that produces a

conductance equivalent to that which results from the application of this table.

The cross-sectional area of each protective grounding conductor that is not a part of the

mains cable or the cable enclosure, must be a minimum of:

•

2.5 mm

2

if there is mechanical protection, and

•

4 mm

2

if there is not mechanical protection. If you have cord-connected equipment,

make sure that the protective grounding conductor in the cord is the last conductor to be

interrupted, if the strain-relief mechanism breaks.

Obey the local regulations on the minimum size of the protective grounding conductor.

NOTE!

Because there are high capacitive currents in the AC drive, it is possible that the

fault current protective switches do not operate correctly.

CAUTION!

Do not do voltage withstand tests on the AC drive. The manufacturer has already

done the tests. Doing voltage withstand tests can cause damage to the drive.

2.5 USING AN RCD OR AN RCM DEVICE

The drive can cause a current in the protective grounding conductor. You can use a residual

current-operated protective (RCD) device, or a residual current-operated monitoring (RCM)

device to give protection against a direct or an indirect contact. Use a type B RCD or RCM

device on the mains side of the drive.

NOTE! You can download the English and French product manuals with applicable safety, warning and caution

information from

http://drives.danfoss.com/knowledge-center/technical-documentation/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit contenant l'en-

semble des informations de sécurité, avertissements et mises en garde applicables sur le site http://

drives.danfoss.com/knowledge-center/technical-documentation/.

VACON · 12 SAFETY

2

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

3 RECEIVING THE DELIVERY

Before a Vacon

®

AC drive is sent to the customer, the manufacturer makes many tests on

the drive. However, after you remove the packaging, examine the drive for transport

damages.

If the drive was damaged during the shipping, speak to the cargo insurance company or the

carrier.

To make sure that the contents of the delivery is correct and complete, compare the type

designation of the product to the type designation code. See Chapter 3.2 Type designation

code.

3.1 PACKAGE LABEL

To make sure that the delivery is correct, compare your order data to the data on the

package label. If the delivery does not agree with your order, speak to the vendor

immediately.

A B

C

H

I

D

F

G

E

VACON100-3L-0205-5+IP00

Fig. 2: The package label of Vacon AC drives

A. The batch ID

B. The order number of Vacon

C. The type designation code

D. The serial number

E. The mains voltage

F. The nominal output current

G. The IP class

H. The application code

I. The order number of the customer

RECEIVING THE DELIVERY VACON · 13

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: [email protected]

3

3.2 TYPE DESIGNATION CODE

The type designation code of Vacon is made of standard codes and option codes. Each part of

the type designation code agrees to the data in your order. The code can have this format, for

example:

VACON0100-3L-0385-5-FLOW+IP00

Table 3: The description of the parts in the type designation code

Code Description

VACON0100 The product family: VACON0100 = the Vacon 100 product family

3L Input/Function: 3L = A 3-phase input

0385 The drive rating in amperes. For example, 0385 = 385 A

5 The mains voltage:

2 = 208-240 V

5 = 380-500 V

7 = 525-690 V

FLOW The product:

(empty) = The Vacon 100 INDUSTRIAL AC drive

FLOW = The Vacon 100 FLOW AC drive

+IP00 The enclosure class of the AC drive is IP00.

3.3 THE CONTENTS OF THE DELIVERY

The contents of the delivery, MR8-MR9

•

The IP00 drive module with an integrated control unit

•

An accessories bag

•

Installation Manual, Application Manual and manuals for the options that you ordered

The contents of the delivery, MR10

•

The IP00 drive module with an integrated control unit

•

An accessories bag

•

The options module, if you ordered it with options

•

Installation Manual, Application Manual and manuals for the options that you ordered

The contents of the delivery, MR12

•

The IP00 drive module: 2 power units, 1 of them with an integrated control unit

•

An accessories bag

•

The options module, if you ordered it with options

•

A DC link cable

•

A set of optical fibre cables

•

Installation Manual, Application Manual and manuals for the options that you ordered

VACON · 14 RECEIVING THE DELIVERY

3

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

3.4 REMOVING THE PACKAGING AND LIFTING THE AC DRIVE

3.4.1 WEIGHT OF THE AC DRIVE

The weights of AC drives of different enclosure sizes are very different. It can be necessary

for you to use a lifting device to move the drive from its package.

Table 4: The weight of the AC drive, MR8-MR12

Enclosure size or item Weight [kg] Weight [lb]

MR8 IP00 drive module 62 137

MR9 IP00 drive module 104 228

MR10 IP00 drive module 205 452

MR10 IP00 drive module and the options module with the brake

chopper

252 556

MR10 IP00 drive module and the options module with the brake

chopper and the common mode filter

258 569

MR10 IP00 drive module and the options module with the brake

chopper, the common mode filter, and the du/dt filter

289 637

MR12 IP00 drive module 410 904

MR12 IP00 drive module and the options module with the brake

chopper

504 1111

MR12 IP00 drive module and the options module with the brake

chopper and the common mode filter

516 1138

MR12 IP00 drive module and the options module with the brake

chopper, the common mode filter, and the du/dt filter

578 1274

3.4.2 LIFTING THE IP00 DRIVE MODULE

The AC drive is delivered horizontally on a wooden pallet. Open the package only when you

install the drive. We do not recommend that you keep the drive in storage in the vertical

position.

LIFTING THE IP00 DRIVE MODULE, MR8 AND MR9

1 Remove the drive from the pallet where it was

bolted to.

2 Use a lifting device that is sufficiently strong for the

weight of the drive.

3 Put the lifting hooks symmetrically in a minimum of

2 holes.

RECEIVING THE DELIVERY VACON · 15

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: [email protected]

3

4 The maximum lifting angle is 45 degrees.

≤45º≤45º

VACON · 16 RECEIVING THE DELIVERY

3

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

LIFTING THE IP00 DRIVE MODULE, MR10 OR MR12 WITHOUT THE OPTIONS MODULE

1 Make sure that the support is attached to the

bottom of the drive. It gives the terminals

protection when you lift the drive or put it vertically

on the floor.

A

A

A. The support / fixing bracket

2 Lift the drive with a lifting device. Put the lifting

hooks in the holes on the top of the cabinet. The

maximum lifting angle is 60 degrees.

3 After the lifting, you can remove the support if

necessary. You can also use it as a fixing bracket.

LIFTING THE IP00 DRIVE MODULE, MR10 OR MR12 WITH AN OPTIONS MODULE

1 Remove the drive from the package.

2 Use a lifting device that is sufficiently strong for the

weight of the drive.

3 Put the lifting hooks in the holes on the top of the

cabinet.

RECEIVING THE DELIVERY VACON · 17

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: [email protected]

3

4 Lift the drive into a vertical position.

5 The maximum lifting angle is 60 degrees.

≤60º

3.5 "PRODUCT MODIFIED" LABEL

In the accessories bag, there is also a "product modified" label. The function of the label is to

tell the service personnel about the changes that are made in the AC drive. Attach the label

on the side of the AC drive to know where to find it. If you make changes in the AC drive, write

the change on the label.

Product modified

Date:

Date:

Date:

VACON · 18 RECEIVING THE DELIVERY

3

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

3.6 DISPOSAL

When the drive is at the end of its operation life, do not discard it as a part of municipal

waste. You can recycle the primary components of the drive. You must disassemble

some components before you can remove the different materials. Recycle the electrical

and electronic components as waste.

To make sure that the waste is recycled correctly, send the waste to a recycling centre.

You can also send the waste back to the manufacturer.

Obey the local and other applicable regulations.

RECEIVING THE DELIVERY VACON · 19

24-HOUR SUPPORT +358 (0)201 212 575 · EMAIL: [email protected]

3

4 MOUNTING DIMENSIONS

4.1 DIMENSIONS OF MR8, IP00

10

(0.37)

290 (11.42)

187 (7.34)

255 (10.04)

217 (8.54)

794 (31.26)

683 (26.89)

663 (26.10)

18

(0.71)

172 (6.75)

343 (13.50)

216 (8.49)

11

(0.43)

15

(0.59)

Ø9 (0.35)

Ø9

(0.35)

Ø22

(0.87)

Ø11 (0.43)

A

Fig. 3: The dimensions of the AC drive, MR8, [mm (in)]

A. An optional main connector cover for the

cabinet installation

VACON · 20 MOUNTING DIMENSIONS

4

TEL. +358 (0)201 2121 · FAX +358 (0)201 212 205

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

Vacon 100 IP00 Drives Installation guide

- Type

- Installation guide

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Vacon 100 Industrial Installation guide

-

Vacon 100 FLOW Installation guide

-

Vacon 100 FLOW Installation guide

-

Vacon 100 FLOW Installation guide

-

Vacon 100 FLOW Installation guide

-

Vacon 100 FLOW Installation guide

-

Vacon 100 FLOW Installation guide

-

Vacon 100 Industrial Installation guide

-

Vacon 100HVAC(old ctrl) Installation guide

-

Vacon 100 FLOW Installation guide

Other documents

-

Square D MMLK250 User manual

-

T & S Brass & Bronze Works B-0520-F1-05 Datasheet

T & S Brass & Bronze Works B-0520-F1-05 Datasheet

-

FLIR MR12 User manual

-

Danfoss VACON 100 FLOW User manual

-

Mackie Speaker MR8 User manual

-

Marson MR12 User manual

-

Hyundai N800A Installation guide

-

VEM VEMoDRIVE VSI 2.0 HD User manual

VEM VEMoDRIVE VSI 2.0 HD User manual

-

CrewPlex MR10-900 User guide

-

Hagerco 2-679-0650 - Emergency Door Release Installation guide