Page is loading ...

September

1976

FORM:

OM-1512A

Effective

With

Serial

No.

HG053870

FLE

Copy

RETURN

TO

uL~E~

MODEL

WIRE

SIZE

SINGLE

SWINGARC

4770-3

STOCK

NO.

5280-3

STOCK

NO.

.030

&

.035

hard

078

102

.045

hard

078

103

.052

hard

003 364

1/16hard

078 104

MODEL

WIRE

SIZE

1/16

hard

1/16

cored

5/64

cored

3/32

cored

7/64

cored

1/8

cored

4770-2

STOCK

NO.

078

106

078

107

078

108

078

109

078

110

078

111

5280-2

STOCK

NO.

078

117

078

118

078

119

078

120

078

121

078

122

MODEL/STOCK

NO.

SER%AL/STYLE

NO.

DATE

PURCHASED

ADDITIONAL

COPY

PRICE

55

CENTS

OWNERS

MANUAL

MILLER

ELECTRIC

MFG.

CO.

APPLETON,

WISCONSIN,

USA

54911

078

113

078

114

003

365

078

115

NWSA

CODE

NO.

4579

U

S

%.

s_.

LIMITED

WARRANTY

EFFECTIVE:

NOVEMBER

1,

1976

This

warranty

supersedes

all

previous

MILLER

warranties

and

is

ex

cl~ive

with

no

other

guarantees

or

warranties

expressed

or

implied.

d

LIMITED

WARRANTYMiller

Electric

Mfg.

Co.,

Apple-

3.

All

welding

guns

and

feeder/guns

90

days

ton,

Wisconsin

warrants

to

Customer

that

all

new

and

unused

4.

All

other

Millermatic

Feeders

I

year

~

Equipment

furnished

by

Miller

is

free

from

defect

in

workman-

provided

that

the

user

so

notifies

Miller

in

writing

within

thirty

ship

and

material

as

of

the

time

and

place

of

delivery

by

Miller.

(30)

days

of

the

date

of

such

failure.

No

warranty

is

made

by

Miller

with

respect

to

engines,

trade

accessories

or

other

items

manufactured

by

others.

Such

engines,

trade

accessories

and

other items

are

sold

subject

to

the

warran-

ANY

EXPRESS

WARRANTY

NOT

PROVIDED

HEREIN

ties

of

their

respective

manufacturers,

if

any.

At

the

present

time,

AND

ANY

IMPLIED

WARRANTY,

GUARANTY

OR

REP-

the

manufacturers

warranty

on

the

Mag-Diesel

engine

on

DEL-

RESENTATION

AS

TO

PERFORMANCE,

AND

ANY

200

is

limited

to

six

months

and

on

all

other

engines

to

one

year.

REMEDY

FOR

BREACH

OF

CONTRACT

WHICH,

BUT

In

the

case

of

Millers

breach

of

warranty

or

any

other

duty

FOR

THIS

PROVISION,

MIGHT

ARISE

BY

IMPLICA

with

respect

to

the

quality

of

any

goods,

the

exclusive

remedies

TION,

OPERATION

OF

LAW,

CUSTOM

OF

TRADE

OR

therefor

shall

be,

at

Millers

option,

(1)

repair

or

(2)

replace-

COURSE

OF

DEALING,

INCLUDING

ANY

IMPLIED

ment

or,

where

authorized

in

writing

by

Miller

in

appropriate

WARRANTY

OF

MERCHANTABILITY

OR

OF

FITNESS

cases,

(3)

the

reasonable

cost

of

repair

or

replacement

at

an

FOR

PARTICULAR

PURPOSE,

WITH

RESPECT

TO

ANY

authorized

Miller

service

station

or

(4)

payment

of

or

credit

for

AND

ALL

EQUIPMENT

FURNISHED

BY

MILLER

IS

the

purchase

price

(less

reasonable

depreciation

based

upon

EXCLUDED

AND

DISCLAIMED

BY

MILLER.

actual

use)

upon

return

of the

goods

at

Customers

risk

and

ex

pense.

Upon

receipt

of

notice

of

apparent

defect

or

failure,

EXCEPT

AS

EXPRESSLY

PROVIDED

BY

MILLER

IN

¶

Miller

shall

instruct

the

claimant

on

the

warranty

claim

proce-

WRITING,

MILLER

PRODUCTS

ARE

INTENDED

FOR

dures

to

be

followed.

ULTIMATE

PURCHASE

BY

COMMERCIAL/INDUS

TRIAL

USERS

AND

FOR

OPERATION

BY

PERSONS

As

a

matter

of

general

policy

only,

Miller

may

honor

an

origi-

TRAINED

AND

EXPERIENCED

IN

THE

USE

AND

nal

users

warranty

claims

on

warranted

Equipment

in

the

event

MAINTENANCE

OF

WELDING

EQUIPMENT

AND

NOT

of

failure

resulting

from

a

defect

within

the

following

periods

FOR

CONSUMERS

OR

CONSUMER

USE.

MILLER

from

the

date

of

delivery

of

Equipment

to

the

original

user:

WARRANTIES

DO

NOT

EXTEND

TO,

AND

NO

RE-

1.

Arc

welders,

power

sources,

and

components

...

I

year

SELLER

IS

AUTHORIZED TO

EXTEND

MILLERS

WAR-

2.

Original

main

power

rectifiers

3

years

RANTIES

TO,

ANY

CONSUMER.

,J_

,,

J~

5, ,~r

,j~

5,

J~

5,

J~

5,

~

5,

Section

No.

SECTION

1

INTRODUCTION

TABLE

OF

CONTENTS

Page

No.

1

-1.

1

-

2.

1

-

3.

1

-

4.

2-1.

2

-

2.

2

-

3.

2

-

5.

2

-

6.

2

-

7.

2

-

8.

2

-

9.

2-10.

2-il.

2-12.

2-13.

2-14.

2-15.

2-16.

3-1.

3

-

2.

3

-

3.

3

-

4.

3~5

Pressure

Roll

Alignment

Installation

Of

Hub

And

Spindle

Assembly

Installation

Of

Wire

Reel

Installation

Of

Reel-Type

Wire

Installation

Of

Spool-Type

Wire

Adjustment

Of

Hub

Tension

Sheilding

Gas

Connections

Water

Connections

Weld

Cable

Connection

Contactor

Control

Connections

Gun

Switch

Receptacle

115

Volts

AC

Connections

2

2

2

2

3

3

3

3

3

3

3

3

3

3

3

3

4

4

4

4

4

4

4

5

General

Receiving-Handling

Description

Safety

SECTION

2

INSTALLATION

Location

Installation

Of

Electrode

Wire

Gun

Connector

Electrode

Wire

Inlet

&

Outlet

Guide

Installation

2

-

4.

Pressure

&

Feed

Roll

Installation

2-17.

Boom

Adjustments

SECTION

3

FUNCTION

OF

CONTROLS

Wire

Speed

Control

Circuit

Breaker

Purge

Switch

Inch-Advance

Switch

Burnback

Control

SECTION

4

SEQUENCE

OF

OPERATION

4

-

1.

Welding

Wire

Threading

4

-

2.

Gas

Metal-Arc

(GMAW)

Welding

4

-

3.

Shuttinci

Down

SECTION

5

TROUBLESHOOTING

SECTION

~

-

INTRODUCTION

Model

12

Foot

Boom

16

Foot

Boom

Motor

1/4

Horsepower.

D.C.

10,000

RPM

Control

Solid

State

Solid

State

Speed

Range

Boom

Turning

Radius

(Standard)

No.2

gear

70

to

500

1P.M.

LN0.

3

gear

100

to

750

l.P.M.

12

ft.

16

ft.

Swing

3600

0

n

Post

Mounting

Vertical

Lift

Horizontal

t

o

+700

Above

Maximum

Height

(With

4

Ft.

Post)

To

Top

Of

Boom

At

Tip

(+70

Position)

18

ft

~

23

ft

.

Counterbalance

(Patented)

Compression

spring

designed

to

hold

boom

at

any

angle

adjustable

pressure

(a

broken

spring

would

drop

weld

head

only

6

inches)

Adjustable

Burnback

Timer

3/8

to

3/4

sec.

3/8

to

3/4

sec.

Weight

(Pounds)

Net

170

Ship

230

Net

200

Ship

265

1-1.

GENERAL

Figure

1-1.

Specifications

This

manual

has

been

prepared

especially

for

use

in

familiar

izing

personnel

with

the

design,

installation,

operation,

main

tenance,

and

troubleshooting

of

this

equipment.

All

informa

tion

presented

herein

should

be

given

careful

consideration

to

assure

optimum

performance

of

this

equipment.

1

-2.

RECEIVING-HANDLING

Prior

to

installing

this

equipment,

clean

all

packing

material

from

around

the

unit

and

carefully

inspect

for

any

damage

that

may

have

occurred

during

shipment.

Any

claims

for

loss

or

damage

that

may

have

occurred

in

transit

must

be

filed

by

the

purchaser

with

the

carrier.

A

copy

of

the

bill

of

lading

and

freight

bill

will

be

furnished

by

the

carrier

on

request

if

occasion

to

file

claim

arises.

When

requesting

information

concerning

this

equipment,

it

is

essential

that

Model

Description

and/or

Stock

Number

and

Serial

(or

Style)

Numbers

of

the

equipment

be

supplied.

The

following

definitions

apply

to

CAUTION,

IMPORTANT,

and

NOTE

blocks

found

throughout

this

manual:

~this

heading.

installation,

opera~,

and

main

tenance

procedures

or

practices

will

be

found

that

if

not

carefully

followed

may

create

a

hazard

to

per-

sonnel.

U

FT~1

1

I

Under

this

heading,

installation,

operating,

and

main

tenance

procedures

or

practices

will

be

found

that

if

not

carefully

followed

may

result

in

damage

to

equip

ment.

This

control/feeder

is

of

the

Constant

wire

feed

speed

type

and

is

designed

to

be

used

in

conjunction

with

a

constant

potential

welding

power

source.

The

control/feeder

is

a

heavy-duty

wire

feeding

unit

combin

ing

both

the

wire

feeder

and

the

control.

It

contains

all

the

controls

and

equipment

needed

to

supply

welding

wire

and

shielding

gas

to

the

welding

gun.

I

NOTE

Under

this

heading,

explanatory

statements

will

be

found

that

need

special

emphasis

to

obtain

the

most

efficient

operation

of

the

equipment.

SECTION

2

-

INSTALLATION

2-1.

LOCATION

The

control/feeder

with

12

foot

boom

is

equipped

with

a

4

foot

long

by

2-1/2

inch

pipe

post

for

mounting

purposes.

The

control/feeder

with

16

foot

boom

is

equipped

with

a

4

foot

long

by

5

inch

pipe

post

for

mounting

purposes.

Ensure

that

the

item

to

which

the

unit

is

being

installed

is

of

sufficient

construction

to

permit

the

boom

to

be

pulled

completely

down

without

having

the

control/feeder

tip.

Also,

ensure

that

enough

space

is

available

to

permit

the

boom

to

swing

in

a

complete

circle.

NOTE

4.

Remove

pin

(1),

nut

(7),

washers

(6

&

12),

and

bolt(13)

from

the

boom.

Do

not

remove

safety

collar

(5)

until

instructed

to

do

so.

5.

Place

the

boom

base

plate

(14)

in

between

the

two

swivel

plates.

6.

Slide

washer

(12)

onto

bolt

(13)

and

insert

bolt

(13)

through

hole

(11).

Slide

washet

(6)

onto

bolt

(13)

and

install

nut

(7)

onto

bolt

(13).

Tighten

nut

(7)

then

back

off

nut

(7)

1/2

turn.

7.

Insert

pin

(1)

through

yoke

(4),

hole

(2),

and

install

cotter

pin

(3)

through

pin

(1).

If

an

optional

mounting

pedestal

was

purchased

with

the

control/feeder,

mounting

holes

are

provided

in

the

pedestal

for

attaching

the

control/feeder.

A.

Assembly

(Figure

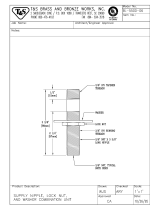

2-1)

1.

Uncrate

and

remove

all

packing

material

from

the

con

trol/feeder.

2.

Mount

pipe

post

(10)

to

the

desired

fixture.

3.

Place

bearing

(9)

on

top

of

post

(10)

and

insert

swivel

(8)

into

post

(10).

8.

Connect

the

welding

gun

to

the

drive

assembly

as

in

structed

in

Section

2

of

this

manual.

9.

Grasp

bar

(14)

and

pull

boom

down

slightly.

The

boom

should

be

pulled

down

only

far

enough

to

re

move

the

pressure

which

is

applied

to

the

safety

collar

(5).

10.

Remove

the

safety

collar

(5).

11.

The

boom

should

now

balance

in

any

position

from

horizontal

to

70

degrees

above

horizontal.

If

the

boom

does

not

balance

properly,

proceed

to

Section

2-16.

1

-

4.

SAFETY

1

-

3.

DESCRIPTION

I

I

U

OM-1512A

Page

1

TB-003

418-A

Figure

2-1.

Control/Feeder

Assembly

2-2.

INSTALLATION

OF

ELECTRODE

WIRE

GUN

CONNECTOR

(Figure

2-2)

Proceed

as

follows

to

install

the

Electrode

Wire

Gun

Connec

tor

into

the

drive

assembly

on

the

control/feeder:

1.

Loosen

the

gun

connector

securing

screw.

See

Figure

2-2

for

the

location

of

the

securing

screw.

2.

Insert

the

Electrode

Wire

Gun

Connector

fully

into

the

outlet

hole

with

the

flat

side

of

the

connector

facing

the

gun

connector

securing

screw.

3.

Rotate

the

Electrode

Wire

Gun

Connector

90

degrees

in

a

clockwise

direction.

4.

Tighten

the

gun

connector

securing

screw.

2-3.

ELECTRODE

WIRE

INLET

&

OUTLET

GUIDE

INSTALLATION

(Figure

2-2)

1.

Loosen

the

outlet

guide

securing

screw

(11).

2.

Install

the

Electrode

Wire

Gun

Connector

into

the

drive

assembly

as

instructed

in

Section

2-2.

3.

Insert

the

outlet

guide

(12)

flat

end

first

into

the

back

side

of

the

outlet

guide

hole

in

the

drive

assembly.

4.

Push

the

outlet

guide

(12)

into

the

outlet

guide

hole

until

the

outlet

guide

seats

against

the

Electrode

Wire

Gun

Con

nector,

or,

if

the

outlet

guide

is

equipped

with

a

flange,

until

the

flange

seats

against

the

drive

assembly.

5.

Tighten

the

outlet

guide

securing

screw

(11).

6.

Loosen

the

inlet

guide

securing

screw

(2).

7.

Insert

the

inlet

guide

(1)

point

fIrst

into

the

inlet

guide

hole

until

the

flange

on

the

inlet

guide

(1)

seats

against

the

drive

assembly.

8.

Tighten

the

inlet

guide

securing

screw

(2).

2-4.

PRESSURE

&

FEED

ROLL

INSTALLATION

(Fig

ure

2-2)

1.

Loosen

the

pressure

adjustment

knob

and

pivot

the

pres

sure

adjustment

assembly

off

the

pressure

roll

mounting

lever.

Swing

she

pressure

roll

mounting

lever

up.

2.

Remove

nut

(6).

lock

washer

(5),

and

flat

washer

(4)

from

the

feed

roll

shaft.

I

Prior

to

installing

I

the

NOTEJ

feed

roll,

ensure

that

the

sup-

.

I

plied

key

is

in

the

groo

ye

in

the

feed

roll

shaft.

3.

Slide

the

keyed

feed

roll

(3)

onto

the

feed

roll

shaft.

4.

Insert

flat

washer

(4)

and

lock

washer

(5)

onto

the

feed

roll

shaft

and

install

nut

(61

onto

the

feed

roll

shaft.

5.

Remove

bolt

17),

lock

washer

(8),

and

flat

washer

(9)

from

the

pressure

roll

mounting

lever.

6.

Slide

pressure

roll

110)

onto

the

shaft

on

the

pressure

roll

mounting

lever.

7.

Slide

lock

washer

(8)

and

flat

washer

(9)

onto

bolt

(7),

and

install

bolt

(7)

into

the

shaft

on

the

pressure

roll

mounting

lever.

8.

Lower

the

pressure

roll

mounting

lever

until

the

teeth

in

the

upper

and

lower

drive

rolls

mesh

together.

NOTE

The

pressure

adjustment

knob

will

have

to

be

adjusted

for

proper

tension

prior

to

operation

of

the

control/

feeder.

The

amount

of

pressure

will

vary

from

one

given

set

of

welding

conditions

to

another,

and

should

be

just

tight

enough

to

prevent

pressure

and

feed

roll

slippage

on

the

wire.

I~

-~

I

I

1

6

7

8

9

10

S

Pressure

Adjustment

Knob

9.

Pivot

the

pressure

adjustment

assembly

until

is

is

on

top

of

the

pressure

roll

mounting

lever,

and

tighten

the

knob

so

the

desired

amount

of

pressure.

2-

5.

PRESSURE

ROLL-ALIGNMENT

(Figure

2-3)

NOTE

TB-003

410

Figure

2-2.

Drive

Roll

&

Wire

Guide

Installation

The

pressure

and

drive

rolls

shown

in

Figure

2-3

are

the

only

type

of

rolls

that

require

this

type

of

adjust

ment.

Page

2

~___

Counter-

Proper

Clockwise

clockwise

Alignment

Rotation

of

Rotation

of

Adjustment

Adjustment

Nut

Required

Nut

Required

Figure

2-3.

Pressure

Roll

Alignment

TB-078

036-5

The

pressure

roll

mounting

lever,

which

holds

the

pressure

roll,

can

be

moved

on

a

horizontal

plane

to

facilitate

align

ment

of

the

groove

in

the

pressure

roll

with

respect

to

the

groove

in

the

feed

roll.

The

pressure

roll

should

be

checked

for

proper

alignment

whenever

erratic

wire

feed

is

noted,

or

whenever

the

pressure

and

feed

rolls

are

changed.

To

check

for

proper

alignment

of

the

pressure

roll,

remove

the

outlet

guide

and

look

into

the

outlet

guide

hole

in

the

drive

as

sembly.

Upon

viewing

the

groove

between

the

pressure

and

feed

rolls,

it

should

be

noted

that

the

outer

edges

of

the

grooves

on

the

pressure

and

feed

rolls

should

be

precisely

aligned.

Figure

2-3

shows

examples

of

proper

and

improper

alignment.

If

the

pressure

and

feed

rolls

are

not

in

alignment,

proceed

as

follows

to

adjust

the

pressure

roll:

1.

Loosen

the

pressure

adjustment

collar

and

pivot

it

off

the

pressure

roll

mounting

lever.

2.

Using

a

9/16

wrench,

loosen

the

outer

securing

bolt.

3.

Using

a

5/8

wrench,

rotate

the

adjustment

nut

as

re

quired.

Rotating

the

adjustment

nut

clockwise

will

move

the

pressure

roll

outward

and

counterclockwise

rotation

will

move

the

pressure

roll

inward.

4.

When

proper

alignment

is

achieved,

tighten

the

outer

securing

bolt

to

lock

the

pressure

roll

in

position.

5.

Pivot

the

pressure

adjustment

assembly

until

it is

on

top

of

the

pressure

roll

mounting

lever

and

tighten

the

collar

to

the

desired

amount

of

pressure.

2-6.

INSTALLATION

OF

HUB

AND

SPINDLE

AS

SEMBLY

(Figure

2-4)

Figure

2-4.

Hub

and

Spindle

Assembly

1.

Insert

spindle

support

shaft

(12)

into

the

hole

in

spindle

support

(13).

2.

Slide

washer

(14)

onto

spindle

support

shaft

(12)

and

secure

with

cotter

pin

(15).

3.

Slide

the

following

items

onto

the

spindle

support

shaft

(12)

in

order

given:

A.

Flat

Washer

(11)

B.

Flat

Washer

(10)

C.

Hub

(9)

D.

Flat

Washer

(8)

E,

Fiber

Washer

(7)

F.

Keyed

Washer

(6)

G.

Spring

(5)

H.

Flat

Washer

(4)

4.

Rotate

hex

nut

(3)

onto

support

shaft

(12).

Hex

nut

(3)

should

be

rotated

only

until

a

slight

drag

is

felt

while

turning

spindle

(9).

5.

Depress

both

spring-loaded

stops

(1)

on

the

retaining

ring

(2)

simultaneously,

and

slide

the

retaining

ring

(2)

into

the

proper

position

on

the

hub

(9).

2-

7.

INSTALLATION

OF

WIRE

REEL

(Figure

2-5)

1.

Depress

the

two

spring-loaded

stops

(7)

on

the

retaining

ring

(8),

and

slide

the

retaining

ring

(8)

off

the

hub

(2).

2.

Slide

the

wire

reel

(3)

onto

the

hub

(2).

Rotate

the

wire

reel

(3)

until

the

hub

guide

pin

(1)

is

seated

in

the

reel

(3).

3.

Place

the

retaining

ring

(8)

into

the

proper

position

on

the

hub

(2).

TC-007

886

Figure

2-5.

Reel,

Hub

&

Spindle

Assembly

12

3

7

8

TB-058

432-A

OM-1

512

Page

3

2-8.

INSTALLATION

OF

REEL-TYPE

WIRE

(Figure

2-5)(Optional

No.

3

Gear

Models)

1.

Loosen

the

four

wing

nuts

(5)

on

the

fingers

(4)

of

the

wire

reel

(3).

2.

Pull

the

four

fingers

(4)

out

until

they

can

be

rotated

toward

the

center

of

the

reel

(3).

3.

Install

the

wire

onto

the

reel

(3)

over

the

four

fingers

(4).

Ensure

that

the

wire

feeds

off

the

top

of

the

reel

(3).

(The

reel

(3)

turns

in

a

clockwise

direction.)

4.

Rotate

the

fingers

(4)

to

their

proper

position.

Tighten

the

four

wing

nuts

(5).

2-9.

INSTALLATION

OF

SPOOL-TYPE

WIRE

(Figure

2-5)

1.

Remove

the

retaining

ring

(8)

from

the

hub

(2).

2.

Slide

the

spool

of

wire

onto

the

hub

(2).

Ensure

that

the

wire

feeds

off

the

top

of

the

spool.

(The

spool

turns

in

a

clockwise

direction.)

3.

Rotate

the

spool

until

the

hub

guide

pin

(1)

is

properly

seated.

4.

Place

the

retaining

ring

(8)

into

proper

position

on

the

hub

(2).

2-10.

ADJUSTMENT

OF

HUB

TENSION

(Figure

2.4)

Check

the

hub

tension

by

slowly

pulling

the

wire

toward

the

feed

roll.

The

wire

should

unwind

freely,

but

the

hub

tension

should

be

sufficient

to

keep

the

wire

taut

and

prevent

back

lash

when

the

control/feeder

is

shut

off.

If

adjustment

is

required,

loosen

or

tighten

the

hex

nut

on

the

end

of

the

spindle

accordingly.

2-11.

SHIELDING

GAS

CONNECTIONS

A

hose

is

supplied

from

the

control

unit

for

making

con

nections

from

the

shielding

gas

source

to

the

control/feeder.

The

shielding

gas

which

is

fed

into

the

supplied

hose

will

be

supplied

to

the

shielding

gas

valve.

The

shielding

gas

hose

which

comes

from

the

gun

is

to

be

conntected

to

the

GAS

hose

which

protrudes

from

the

motor

end

of

the

boom.

2-12.

WATER

CONNECTIONS

(Optional)

This

unit

can

be

equipped

with

a

water

valve

so

allow

the

gun

to

be

liquid

cooled.

The

supplied

water

hoses

must

be

con

nected

to

the

proper

places

to

ensure

normal

operation.

(All

fittings

on

the

water

hoses

have

left-hand

threads.)

Connect

the

water

hose

from

the

bottom

of

the

control

box

to

the

water

(coolant)

supply.

Connect

the

water

hose

on

the

front

of

the

control

box

which

extends

through

the

boom

to

the

WATER

IN

hose

on

the

gun.

Connect

the

return

hose

from

the

gun

(WATER

OUT)

to

the

return

hose

that

extends

from

the

boom.

Connect

the

remaining

end

of

the

return

hose

to

a

drain.

2-13.

WELD

CABLE

CONNECTION

A

weld

cable

extends

out

of

the

back

end

of

the

boom

for

making

secondary

connections

to

the

welding

power

source.

The

end

of

the

weld

cable

is

equipped

with

a

1/2

inch

lug.

The

opposite

end

of

this

weld

cable

is

connected

to

a

bolt

on

the

drive

assembly.

The

bolt

on

the

drive

assembly

serves

as

a

junction

point

for

joining

together

the

weld

cable

from

the

welding

power

source

and

the

weld

cable

from

the

gun.

2-14.

CONTACTOR

CONTROL

CONNECTIONS

The

contactor

control

cable

has

two

leads

extending

from

it.

These

two

leads

are

so

be

connected

to

the

contactor

control

facility

on

the

welding

power

source.

IMPORTANT

The

contactor

control

circuitry

that

is

to

be

used

in

conjunction

with

this

control/feeder

must

be

of

the

type

that

operates

on

115

volts,

60

Hertz

power.

This

is

necessary

because

the

control/feeder

will

supply

115

volts

ac

through

the

contactor

control

cable

whenever

the

gun

switch

is

closed.

2-15.

GUN

SWITCH

RECEPTACLES

A

four-prong

receptacle

protrudes

out

of

the

motor

end

of

the

boom

for

connecting

the

gun

plug

to

the

control/feeder.

Ensure

that

the

securing

ring

on

the

gun

switch

plug

is

threaded

completely

onto

the

Gun

Switch

receptacle.

2-16.

115

VOLTS

AC

CONNECTIONS

The

control/feeder

will

be

electrically

hot

internally

and

ready

to

operate

as

soon

as

the

115

volts

ac

plug

is

connected

to

the

115

volts

ac

source.

The

115

volts

ac

input

power

cable

can

be

distinguished

from

the

contactor

control

cable

by

the

three-prong

plug

attached

to

the

end

of

the

115

volts

ac

cable.

The

115

volts

ac

cable

must

be

connected

to

an

outlet

which

is

capable

of

supplying

115

volts,

60

Hertz

electrical

power.

2-17.

BOOM

ADJUSTMENTS

(Figure

2-4)

A.

Weight

Lift

Adjustment

CAUTION

that

during

all

adjustment

procedures,

full

threads

on

the

adjustment

rod

are

maintained

through

the

yoke.

If

full

threads

are

not

maintained,

the

boom

may

suddenly

drop

down

and

cause

injury

to

person

nel

or

damage

to

equipment.

The

amount

of

weight

which

the

boom

can

retract

into

the

upright

position

when

released

can

be

varied

by

adjusting

the

jam

nut

and

adjustment

rod

located

at

the

base

of

the

boom.

If

a

heavier

gun

is

installed

on

the

end

of

the

boom

thereby

making

it

necessary

to

increase

the

amount

of

weight

that

the

boom

can

lift,

loosen

the

jam

nut

and

rotate

the

adjustment

rod

so

that

the

adjustment

rod

threads

into

the

yoke.

When

the

proper

adjustment

is

obtained,

tighten

the

jam

nut

against

the

base

of

the

yoke.

If

a

lighter

gun

is

installed

on

the

control/feeder,

rotate

the

adjustment

rod

so

that

the

adjustment

rod

threads

out

of

the

yoke.

B.

Locking

Knob

By

rotating

the

Locking

Knob

in

a

clockwise

direction,

the

boom

may

be

held

in

any

desired

position.

Rotating

the

Locking

Knob

in

a

counterclockwise

direction

will

permit

the

boom

to

free

travel.

TB-003

409-A

Locking

Knob

Adjustment

Rod

Figure

2-4.

Boom

Adjustments

Page

4

SECTION

3-

FUNCTION

OF

CONTROLS

3-

1.

WIRE

SPEED

CONTROL

(Figure

3-1)

The

WIRE

SPEED

control

provides

a

means

of

determining

the

rate

at

which

welding

wire

will

be

fed

into

the

weld.

Rotating

the

WIRE

SPEED

control

in

a

clockwise

direction

will

increase

the

rate

of

wire

feed.

When

the

WIRE

SPEED

control

is

set

at

0,

wire

will

feed

at

the

minimum

1PM;

when

set

at

10,

the

wire

will

feed

at

the

maximum

1PM.

3-

2.

CIRCUIT

BREAKER

(Figure

3-1)

A

Circuit

Breaker,

located

on

the front

panel

of

the

control/

feeder,

provides

protection

to

the

control/feeder

circuitry.

In

the

event

the

motor

should

be

placed

in

an

overloaded

con

dition,

the

breaker

would

trip

and

suspend

all

output.

Should

this

breaker

trip,

it

would

have

to

be

manually

depressed

to

reset.

3-3.

PURGE

SWITCH

(Figure

3-1)

The

PURGE

switch,

located

on

the

front

panel

of the

con

trol/feeder,

is

a

momentary

contact

switch.

This

switch

will

energize

the

shielding

gas

solenoid

and

purge

the

shielding

gas

line

of

the

gun.

It

also

allows

the

shielding

gas

regulator

to

be

adjusted

without

energizing

the

welding

circuit.

3..

4.

INCH-ADVANCE

SWITCH

(Figure

3-1)

The

INCH-ADVANCE

switch,

located

on

the

front

panel

of

the

control/feeder,

is

a

spring-actuated

toggle

switch.

When

actuated

it

completes

the

circuit

to

the

motor

without

having

to

depress

the

gun

switch.

This

switch

will

permit

inching

or

threading

of

the

wire

at

whatever

setting

the

WIRE

SPEED

control

is

at,

without

energizing

the

welding

power

source

contactor

or

the

gas

valve.

3-

5.

BURNBACK

CONTROL

(Figure

3-1)

The

BURNBACK

circuitry

in

this

control/feeder

provides

a

means

of

keeping

the

welding

wire

from

sticking

to

the

work-

piece

or

the

contact

tube

in

the

gun

after

the

gun

switch

is

released.

The

BURNBACK

capability

in

this

control/feeder

will,

depending

upon

the

setting

of the

BURNBACK

control,

keep

weld

current

present

on

the

welding

wire

from

1/4

to

3/4

of

a

second

after

the

wire

has

stopped

feeding.

This

delay

action

will

permit

the

welding

wire

to

burn

back

to

a

point

where

it

will

neither

stick

to

the

workpiece

nor

the

contact

tube.

If

the

welding

wire

sticks

to

the

contact

tube

in

the

gun

after

the

gun

switch

is

released,

rotate

the

BURNBACK

con

trol

to

a

setting

closer

to

the

0

(1/4

second)

position.

If

the

welding

wire

sticks

to

the

workpiece

after

the

gun

switch

is

released,

rotate

the

BURNBACK

control

to

a

setting

closerto

the

10

(3/4

second)

position.

SECTION

4

-

SEQUENCE

OF

OPERATION

4

1.

WELDING

WIRE

THREADING

1.

Install

the

wire

(reel-type

or

spool-type)

as

instructed

in

Sections

2-8

and

2-9.

NOTE

Ensure

that

the

pressure

roll

is

checked

for

proper

I

alignment

before

proceeding

with

the

welding

wire

threading

operation.

See

Section

2-5,

and

Figure

2-3.

2.

Cut

off

any

portion

of

the

free

end

of

the

welding

wire

which

is

not

straight.

3.

Route

the

welding

wire

through

the

wire

guide

tube

on

the

side

of

the

boom

up

to

the

drive

assembly.

4.

Lift

up

the

pressure

roll

mounting

lever.

5.

Install

the

Electrode

Wire

Gun

Connector

as

instructed

in

Section

2-2.

6.

Feed

the

wire

through

the

inlet

guide

and

on

into

the

outlet

guide.

Feed

approximately

4

inches

of

wire

into

the outlet

guide.

7.

Secure

the

pressure

roll

mounting

lever.

8.

Tighten

the

pressure

adjustment

knob

for

the

approxi

mate

amount

of

pressure

desired

on

the

pressure

and

feed

rolls.

Precise

adjustment

of

the

pressure

adjust

ment

assembly

will

have

to

be

made when

welding

commences.

9.

Connect

the

115

volts

ac

plug

from

the

control/feeder

into

a

115

volts,

60

Hertz

source.

10.

Connect

the

Switch

Control

plug

from

the

gun

into

the

Gun

Switch

receptacle

on

the

boom.

11.

Lay

the

gun

cable

out

straight.

12.

Depress

the

ADVANCE

switch

until

the electrode

wire

extends

approximately

one

inch

out

of

the

gun

tip.

4-2.

GAS

METAL-ARC

(GMAW)

WELDING

~sU1ts]~j

I

Prior

to

welding,

it is

imperative

that

proper

protective

clothing

(welding

coat

and

gloves)

and

eye

protection

(glasses

and/or

welding

helmet)

be

put

on.

Failure

to

comply

may

result

in

serious

or

permanent

bodily

damage.

1.

Make

all

necessary

connections

as

instructed

in

Section

2

of

this

manual.

2.

Rotate

the

WIRE

SPEED

control

to

the

desired

setting.

3.

Rotate

the

BURNBACK

control

to

the

desired

setting.

4.

Turn

on

the

shielding

gas

supply

and

press

the

PURGE

switch

for

10

seconds.

CAUTION

I

The

welding

wire

and

all

metal

parts

i~actwit~it

are

energized

while

welding.

Do

not

touch

the

welding

wire

or

any

metal

part

making

contact

with

it.

5.

Depress

the

trigger

on

the

gun.

Gas

will

start

to

flow

and

wire

will

start

to

feed

if

drive

roll

pressure

is

properly

adjusted

to

prevent

slippage.

If

wire

slippage

is

noticed,

tighten

the

pressure

~djustment

collar

1/2

turn

clockwise.

Repeat

until

slippage

stops.

Do

not

tighten

pressure

ad

justment

collar

too

much.

4-3.

SHUTTING

DOWN

1.

Turn

off

the

shielding

gas

at

the

source.

2.

Remove

the

115

volts

ac

plug

from

the

source.

3.

Turn

off

all

associated

equipment.

Circuit

Breaker

Purge

Switch

Figure

3-1.

Control

Location

TA-003

408-A

OM-1512

Page

5

CAUTION

If

welding

is

performed

in

a

confined~failureto

turn

off

the

shielding

gas

supply

could

result

in

a

buildup

of

shielding

gas

fumes,

thereby

endangering

personnel

reentering

the

welding

area

SECTION

5

-

TROUBLESHOOTING

The

following

chart

is

designed

to

diagnose

and

provide

remedies

for

some

of

the

common

troubles

that

may

develop

in

this

control/feeder.

It

is

assumed

that

proper

installation

has

been

made,

according

to

Section

2 of

this

manual,

and

that

the

control/feeder

has

been

functioning

properly

until

this

trouble

developed.

Use

this

chart

in

conjunction

with

the

Circuit

diagram

while

performing

troubleshooting

procedures.

If

the

trouble

is

not

remedied

after

performing

these

procedures,

the

nearest

Factory

Authorized

Service

Station

should

be

contacted.

In

all

cases

of

equipment

malfunction,

the

manufacturers

recommendations

should

be

strictly

followed.

TROUBLE

PROBABLE

CAUSE

REMEDY

Depressing

gun

switch

will

not

energize

control/feeder.

Electrode

wire

is

not

energized

and

shielding

gas

does

not

flow.

Circuit

breaker

(CB1)

tripped.

Reset

circuit

breaker.

Plug

from

Gun

Switch

(PLG4)

is

not

secure

in

Gun

Switch

receptacle

(R

C4)

on

control/feeder.

Insert

plug

(PLG4)

fully

into

Gun

Switch

receptacle

(RC4)

and

tighten.

Plug

from

Gun

Switch

not

secure

in

cable

receptacle

(RC3).

Ensure

that

plug

is

secure

in

cable

receptacle

(RC3).

115

vac

input

plug

(PLG1)

is

not

secure

in

receptacle,

Insert

plug

(P

LG

1)

fully

into

115

vac

receptacle.

Wire

feeds,

shielding

gas

flows,

but

electrode

wire

is

not

energized.

Contactor

Control

cable

leads

not

secure

on

contactor

plug

terminals.

Secure

leads

to

plug

terminals.

Defect

in

welding

power

source.

See

troubleshooting

section

in

welding

power

source

instruction

manual.

Wire

feeds

erratically.

Pressure

on

pressure

and

drive

rolls

is

insufficient.

Rotate

pressure

adjustment

knob

clockwise

in

1/4

turn

increments

until

wire

slippage

stops.

Pressure

roll

alignment

incorrect.

Ensure

that

proper

alignment

is

achieved.

See

Section

2-5

and

Figure

2-3.

Pressure

and

drive

rolls

are

too

large

for

wire

size

being

used.

Change

to

proper

size

pressure

and

drive

roll.

Worn

pressure

and

drive

rolls.

Replace

pressure

and

drive

rolls.

See

Section

2-4.

Dirt

in

pressure

and

drive

roll

grooves.

Clean

pressure

and

drive

rolls.

Motor

is

inoperative.

Worn

brushes.

Replace

motor

brushes.

Motor

plug

(PLG2)

not

secure

in

receptacle

(RC2).

Tighten

motor

plug

(PLG2).

Motor

plug

(PLG5)

not

secure

in

receptacle

(R

CS).

Tighten

plug

(PLG5)

in

receptacle

{RC5).

.

Page

6

Figure

5-1.

Circuit

Diagram

OM-1512

Page

7

September

1976

FORM:

OM-1512A

Effective

With

Serial

No.

HG053870

SINGLE

SWINGARC

MODEL

WIRE

SIZE

47

70-3

STOCK

NO.

5280-3

STOCK

NO.

.030

&

.035

hard

.045

hard

.052

hard

1/1

6hard

MODEL

WIRE

SIZE

1/16

hard

1/16

cored

5/64

cored

3/32

cored

7/64

cored

1/8

cored

078

102

078

103

003

364

078

104

47

70-2

STOCK

NO.

078

106

078

107

078

108

078

109

078

110

078

111

078

113

078

114

003

365

078

115

5280-2

STOCK

NO.

078

117

078

118

078

119

078

120

078

121

078

122

MODEL/STOCK

NO.

SERIAL/STYLE

NO.

DATE

PURCHASED

PARTS

LIST

MILLER

ELECTRIC

MFG.

CO.

APPLETON,

WISCONSIN,

USA

54911

NWSA

CODE

NO.

4579

V.,.

U,,

Fig

4

Figure

A

Main

Assemby

TD.003

193

19

6

-~Fig

E

3~

Fig

B

30

29

28

OM-1512

Page

1

Quantity

Model

Item

Dia.

Factory

Single

Single

No.

Mkgs.

Part

No.

Description

12

Ft.

16

Ft.

Figure

A

Main

Assembly

1

075 074

CABLE,

interconnecting

-

motor/control

(consisting

of)

1

1

075

075

CABLE,

interconnecting

-

motor/control

(consisting

of)

1

2

RC5

073265

.

RECEPTACLE,6socketg7-3101A-20-17S

1

1

3

039

734

.

CLAMP,

cable

AN-3057-1

2

2

2

4

073

139

.

CORD,

portable

No.

16/6

conductor

(order

by

foot)

15 ft

19

ft.

5

PLG2

073

264

.

PLUG,

6pm

97-3106A-20-17P

1

1

077

650

.

TUBING,

vinyl

No.

7

x

3/4

12

12

6

079

202

HOSE,

gas

(consisting

of)

1

6

079

204

HOSE,

gas

(consisting

of)

1

7

010

604

.

ADAPTER,

brass

-

gas

1/4-18

NPT

5/8-18

female

1

1

8

079

196

.

COUPLING,

brass

-

female

3/16

ID

hose

x

1/4

NPT

1

1

9

604

550

.

HOSE,

whippet

3/16

x

1

(order

by

foot)

16

ft

19

ft.

10

073839

.FERRULE

2 2

11

010

606

.

NUT,

brass

-

swivel

5/8-18

right

hand

1

1

12

056

851

.

NIPPLE,

brass

-

hose

3/16

1

1

13

075

325

CONTROL

BOX

(See

Fig.

C

Page

5)

1

1

14

074

976

CABLE,

trigger

(consisting

of)

1

14

074

977

CABLE,

trigger

(consisting

of)

1

15

600

340

.

CORD,

portable

No.

16/2

conductor

(order

by

foot)

15

ft

20

ft.

16

073

331

.

CLAMP,

cable

97-3057-10-6

2

2

17

PLG4

073

329

.

PLUG,

4

pin

97-3106A-18-4P

1

1

18

RC3

073

441

.

RECEPTACLE,

4

socket

MS-3101A-18-4S

1

1

077 650

.

TUBING,

vinyl

No.

7

x

3/4

4

4

19

078

992

CORD,

power

No.

2

gear

or

19

074

983

CORD,

power

No.

3

gear

(consisting

of)

1

19

078

993

CORD,

power

No.

2

gear

or

19

074

986

CORD,

power

No.

3

gear

(consisting

of)

1

20

077

455

.

TERMINAL,

ring

tongue

1/2

stud

3/0

wire

(No.

2

gear)

or

20

600

734

.

TERMINAL,

ring

tongue

1/2

stud

2/0

wire

(No.

3

gear)

1

1

21

600

323

.

CABLE,

weld

-

copper

stranded

3/0

(No.

2

gear)

or

21

600

322

.

CABLE,

weld

-

copper

stranded

2/0

(No.

3

gear)

27

ft

30

ft.

22

600

742

.

TERMINAL,

ring

tongue

3/8

stud

3/0

wire

(No.

2

gear)

or

22

600

732

.

TERMINAL,

ring

rongue

3/8

stud

2/0

wire

(No.

3

gear)

1

1

23

Figure

E

BOOM

(See

Page

9)

1

1

24

t079

214

BASE,

support

-

boom

(18

inch

base)

1

24

t079

216

BASE,

support

-

boom

(24

inch

base)

1

25

601

865

NUT,

steel

-

hex

full

1/4-20

4

4

26

602

207

WASHER,

lock

-

steel

split

1/4

4

4

601

926

SCREW,

cap

-

steel

hex

hd

1/4-20

x

5/8

(attaching

control

box)

4

4

27

601

967

SCREW,

cap

-

steel

hex

hd

3/8-16

x

1-1/2

3

3

28

602

224

WASHER,

lock

-

steel

split

3/8

3

3

29

010

910

WASHER,

flat

-

steel

SAE

3/8

3

3

30

075

150

WASHER,

nylon

-

shoulder

.622

x

1

x

3/8

3

3

31

074772

INSULATOR

1

1

32

078

143

MOTOR

&

DRIVE

ASSEMBLY,

No.

2

gear

or

32

078

144

MOTOR

&

DRIVE

ASSEMBLY,

No.

3

gear

(See

Fig.

B

Page

3)

1 1

073329

PLUG,4pin97-3106A-18-4P

1 1

073

331

CLAMP,

cable

1

1

tOptional

Equipment

BE

SURE

TO

PROVIDE

STOCK,

MODEL,

AND

SERIAL

NUMBERS

WHEN

ORDERING

REPLACEMENT

PARTS.

OM-1512

Page

2

71

72

73

74

75

76

77

78

79

80

81

82

83

075

31

5

073

308

074

780

073

307

074

771

074

781

073

597

073

581

073

583

073

598

077

214

073

595

*073

591

Item

Factory

No.

Part

No.

Description

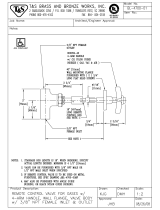

Figure

B

Motor

&

Drive

Assembly

(See

Fig.

A

Page

2

Item

32)

Quantity

Model

No.

21

No.

3

MOTOR,

drive

(consisting

of)

1

1

BEARING,

ball

1

1

SHAFT,

idler

gear

1

1

RING,

retaining

-

external

2

2

GEAR,

spur

-

steel

40

pitch

43

tooth

1

1

STUD,

steel

12-28

x

1-314

3

3

BEARING,

ball

1

1

.FIELDASSEMBLY

1

1

.ARMATURE

1

1

SPRING,

brushholder

2 2

HOLDER,

brush

2

2

CAP,

brushholder

2 2

BRUSH,

contact

2

2

71

114

11590

117

116

Figure

B

Motor

&

Drive

Assembly

TD-039

159

Page

3

*

Recommended

Spare

Parts

BE

SURE

TO

PROVIDE

STOCK,

MODEL,

AND

SERIAL

NUMBERS

WHEN

ORDERING

REPLACEMENT

PARTS.

Item

Factory

No.

Part

No.

Figure

B

Description

Motor

&

Drive

Assembly

(See

Fig.

A

Page

2

Item

32)

(Contd)

Quantity

Model

No.

21

No.

3

84

073596

.BEARING,baIl

1

1

85

073

593

.

WASHER,

spring

1

1

86

073

296

.

CLAMP,

cable~

amphenol

97-3057-12-6

1

1

87

073

264

073

703

.

PLUG,

amphenol

97-3106A-20-17P

GASKET,

motor

1

1

1

1

88

074

768

GEAR,

drive

1

1

89

073268

BEARING,ball

3

3

90

010 910

WASHER,

flat

-

steel

SAE

3/8

7

7

91

602

221

WASHER,

lock

-

steel

internal

tooth

3/8

2

2

92

074 902

LEVER,

mounting

-

pressure

gear

1

1

94

604

538

WASHER,

flat-

steel

SAE

5/16

1

1

95

602

211

WASHER,

lock

-

steel

split

5/16

1

1

96

601

948

SCREW,

cap-

steel

hex

hd

5/16-18

x

1 1

1

97

074811

BUSHING,

9/16-18x

1-13/32

with

3/8

hole

1

1

98

605

209

SCREW,

cap

-

steel

hex

hd

3/8-16x

2-1/4

1

1

99

073356

KNOB

1 1

100

073

303

SPRING,

compression

1

1

101

074

783

ARM,

adjustment

-

pressure

(consisting

of)

1 1

102

076647

.FASTENER,pin

1

1

103

076

682

.

BLOCK,

pressure

stud

1

1

104

010324

.PIN,spring3/16x

1/2

1

1

105

074

778

SHAFT,

drive

1

1

106

056 068

KEY,

steel

1/8

x

1/8

x

1/2

1

1

107

073

309

SEAL,

oil

-

drive

shaft

1

1

108

073

240

RING,

retaining

-

external

4

4

109

074

858

TUBING,

steel

7/8

OD

x

19/32

ID

x

.303

1

1

110

602

247

WASHER,

flat

-

steel

SAE

1/2

1

1

111

602

216

WASHER,

lock

-

steel

split

1/2

..

.

1

1

112

601

881

NUT,

steel-hex

jam

1/2-20

1 1

113

602

177

SCREW,

set

-

steel

socket

hd

1/4-20

x

1/4

2 2

114

601

967

SCREW,cap-steel

hex

hd

3/8-16x

1-1/2

5 5

115

602

224

WASHER,

lock

-

steel

split

anti link

positive

3/8

5

5

116

078

880

SCREW,

cap

-

steel

socket

hd

5/16-18

x

1-1/2

1

1

117

079

375

HOUSING,

adapter-

gun/feeder

1

1

118

078

881

SCREW,

cap-brass

hex

hd

3/8-16

x

2-1/2

1

1

119

078

882

WASHER,

lock

-

brass

split

3/8

1

1

120

078

751

WASHER,

flat

-

bronze

3/8

1

1

121

078

687

WASHER,

lock

-

steel

split

No.

12

3

3

122

078

858

NUT,

steel

-

hex

full

12-28

3

3

123

075

229

HOUSING,

drive

(consisting

of)

1

1

124

073334

.HELICOIL

1

1

125

075

150

WASHER,

nylon

-

shoulder

.622

x

1

x

3/8

3

3

126

074

772

INSULATOR

1 1

127

078 879

SCREW,

machine

-

steel

truss

phillips

hd

10-24

x

1/2

12

12

128

074

775

COVER,

bearing

2

2

,~

129

073

306

RING,

retaining

-

internal

3

130

073302

BEARING,ball

1

131

073

300

RING,

retaining

-

internal

1

132

074

827

GEAR,

helical

-

bronze

12

pitch

30

tooth

double

thread

No.

2

1

132

074

828

GEAR,

helical

-

bronze

12

pitch

30

tooth

triple

head

No.

3

1

133

134

076

871

074

822

PIN,

spring

3/16

x

1-1/2

GEAR,

miter

No.

2

1

1

1

134

074

823

GEAR,

miter

No.

3

1

135

078

672

PIN,

spring

3/16

x

7/8

1

1

136

073

304

GASKET,

cover

-

housing

drive

1

1

137

074

777

COVER,

housing

-

drive

1

1

3

OM-1512

Page

4

Item

Dia.

Factory

006

750

CB1

073676

R22

*073

361

S2,3

073362

R23

073562

075

308

073

756

TR1

030112

075

369

R25

030617

075

364

073

483

078

035

010

116

007

709

007

708

R18,19

074154

605

742

Ti

073630

075

117

2

4

2

2

4

1

No.

Mkgs.

Part

No.

Description

Quantity

Figu

re

C

075

325

Control

Box

(See

Fig.

A

Page

2

Item

13)

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

PANEL,

front

(attaching

hardware

C

&

P)

CIRCUIT

BREAKER,

manual

reset

7

amp

POTENTIOMETER,

carbon

1

turn

2

watt

55K

ohm

SWITCH,

toggle

SPDT

10

amp

250

volts

ac

POTENTIOMETER,

carbon

1

turn

2

watt

10K

ohm

CIRCUIT

CARD

ASSEMBLY

(attaching

hardware

A,

D

&

J)

(See

Fig.

Ci

Page

7)

SPACER,

hex

1/2

x

5/8

x

6-32

thread

(attaching

hardware

A

&

J)

THYRECTOR,

protector

-

surge

(attaching

hardware

K

&

N)

BASE

RESISTOR,

WW

adj

25

watt

2000

ohm

(attaching

hardware

A,

J

&

M)

COVER

(attaching

hardware

E,

G,

K

&

N)

RETAINER,

screw

FASTENER,

screw

GROMMET,

rubber

3/8

ID

x

1/2

mounting

hole

1/16

groove

BRACKET,

mounting

-

resistor

(attaching

hardware

E,

K

&

N)

SHIELD,

resistor

(attaching

hardware

G)

RESISTOR,

WW

fixed

100

watt

1.6

ohm

BRACKET,

mounting

-

resistor

(attaching

hardware

A,

J

&

M)

TRANSFORMER,

filament

26

volts

CT

115