Page is loading ...

2006

600531

Axminster AW16BMST

Bench Morticer

Axminster Reference No: AW16BMST

User Manual

WHITE

AXMINSTER

W

www.axminster.co.uk

WHITE

AXMINSTER

W

Index of Contents...

Page No.

Safety Protection Symbols

SAFETY!!

!

The symbols shown on the cover of this

manual advise that you wear the correct

safety protection when using this machine.

E

y

e

P

r

o

t

e

c

t

i

o

n

S

a

f

e

t

y

H

e

l

m

e

t

P

r

o

t

e

c

t

i

v

e

G

l

o

v

e

s

S

a

f

e

t

y

F

o

o

t

w

e

a

r

R

e

s

p

i

r

a

t

o

r

S

a

f

e

t

y

V

i

s

o

r

R

e

a

d

M

a

n

u

a

l

T

w

o

M

a

n

A

s

s

e

m

b

l

y

E

a

r

D

e

f

e

n

d

e

r

s

D

u

s

t

M

a

s

k

Index of Contents...................................................................................................................02

Declaration of Conformity

………….………........……..………….......................................03

What’s in the Box………….………........……..…………......................................................... 04

General Instructions for 230v Machines...........................................................05-06

Specific Safety Instructions for Morticers..............................................................06

Initial Assembly.............................................................................................06-07-08

Specifications

….………........……..………….......................................................................08

Illustration and Parts Description.........................

..............................................09- 11-13

Parts Identification & Description......................................................................10-12

Setting up the Machine.................................................................................14-15-16

Maintenance............................................................................................................

17

Illustrated Parts Breakdown....................................................................................

18

Illustrated Parts Catalogue.....................................................................................

19

WHITE

AXMINSTER

W

03

Declaration of Conformity...

FREEPHONE 0800 371822

The undersigned, P. Seidel authorised

by Laizhou Tongtai Machinery Co., Ltd.

Chenggou Dongfeng Laizhou, Shandong 261437 P.R. China

declares that this product:

Morticer

MS3816

manufactured by Laizhou Tongtai Machinery Co. is in

compliance with the following standards or standardisation

documents in accordance with Council Directives

98/37/EC

Copied from CE Certificate

04

WHITE

AXMINSTER

W

What’s in the Box...

www.axminster.co.uk

Model Number: MS3816

1 No. 16mm Bench Morticer with Sliding Table

1 No. Operating Lever

1 No. Grip Sleeve for Operating Lever

2 No. Table Distance Stops rods with

ring collars and star knobs

1 No. Lateral Table Control Lever with knob

1 No. 12mm Hollow Chisel Set

1 No. Guarantee Card

1 No. Instruction Manual

Having unpacked your machine and its accessories, please check the contents against the

equipment list ”What’s in the box”, if there are any discrepancies, please contact Axminster

Power Tool Centre using the procedures laid down in the catalogue.

Please dispose of the packaging responsibly; much of the material is bio-degradable. The

machine and its accessories will arrive coated with heavy corrosion preventative grease and

greased wax paper. These may need to be cleaned from the machine, its components and

accessories prior to it being set up and commissioned. Use coal oil, paraffin or a proprietary

degreaser to remove the barrier grease.

Be warned, it will stain if you splash it on clothing etc.; wear overalls, coverall et al., rubber

gloves are also a good idea, as is eye protection if your cleaning process tends to be a little

bit enthusiastic. After cleaning, lightly coat the exposed metal surfaces of the machine with

a thin layer of light machine oil. N.B If you use paraffin/kerosene make sure you apply this

thin film sooner rather than later.

WHITE

AXMINSTER

W

05

General Instructions for 230v Machines...

The following suggestions will enable you to observe good working

practices, keep yourself and fellow workers safe and maintain your

tools and equipment in good working order.

Good Working Practices/Safety

General Advice

WARNING!!

!

KEEP TOOLS AND EQUIPMENT OUT

OF THE REACH OF YOUNG CHILDREN

Work Place/Environment

The machine is not designed for working outside, do not use when or where it is liable to get wet. If

the machine does get wet; dry it off as soon as possible, with a cloth or paper towel.

Do not use 230Va.c. powered machines anywhere within a site area that is flooded or puddled, and

do not trail extension cables across wet areas.

Keep the machines clean; it will enable you to more easily see any damage that may have occurred.

Clean the machine with a damp soapy cloth if needs be, do not use any solvents or cleaners, as

these may cause damage to any plastic parts or to the electrical components.

Keep the work area as well lit and uncluttered as is practical, this includes

personnel as well as material.

Under no circumstances should CHILDREN be allowed in work areas.

It is good practice to leave the machine unplugged until work is about to commence, also

make sure to unplug the machine when it is not in use, or unattended. Always disconnect

by pulling on the plug body and not the cable. Once you are ready to commence work,

remove any tools used in the setting operations (if any) and place safely out of the way.

Re-connect the machine.

Carry out a final check e.g. check the cutting tool, drill bit etc., is securely tightened in the

machine, check you have the correct speed and function set, check that the power cable

will not ‘snag’ etc.

Make sure you are comfortable before you start work, balanced, not reaching etc.,

If the work you are carrying out is liable to generate flying grit, dust or chips, wear the

appropriate safety clothing, goggles, gloves, masks etc., If the work operation appears to be

excessively noisy, wear ear-defenders. If you wear your hair in a long style, wearing a cap,

safety helmet, hairnet, even a sweatband, will minimise the possibility of your hair being

caught up in the rotating parts of the tool, likewise, consideration should be given to the

removal of rings and wristwatches, if these are liable to be a ‘snag’ hazard. Consideration

should also be given to non-slip footwear, etc.

!

!

06

WHITE

AXMINSTER

W

General Instructions for 230v Machines...

Do not work with cutting or boring tools of any description if you are tired,

your attention is wandering or you are being subjected to distraction. A deep cut, a

lost fingertip or worse; is not worth it!

Do not use this machine within the designated safety areas of flammable

liquid stores or in areas where there may be volatile gases. There are very

expensive, very specialised machines for working in these areas, THIS IS NOT ONE

OF THEM.

Check that cutters, drills etc., are the correct type and size, are undamaged and are kept

clean and sharp, this will maintain their operating performance and lessen the loading on

the machine.

Above all, OBSERVE…. make sure you know what is happening around you, and USE

YOUR COMMON SENSE.

!

!

Specific Safety Instructions for Morticers...

• Ensure that the morticer is firmly fixed to its base as the force exerted through the

operating handle could be enough to over-balance the machine.

• Ensure that the operating handle is returned to the upright position after cutting a mortise.

• Mortice chisels have very sharp ends, handle them with great care.

• Make sure that the timber is held firmly down against the table by using the table clamp.

This prevents the possibility of the timber being pulled upwards as the mortice chisel is

withdrawn from the hole.

Initial Assembly...

Please take some time to read the section entitled “Identification and Parts

Description” to identify the various parts of your machine so that you are familiar

with the terminology we will use to enable you to set up and operate your Morticer

safely and correctly.

1) Remove the morticer from the shipping carton. Report any shortages or damage to

Axminster Power Tools Customer Service Department . (0800 371822)

2) Place the machine onto a suitable surface, at a height that will enable you to work

comfortably & to ensure that there is adequate room on either side for the size of timber you

plan to use. Once you are happy bolt the morticer down.

3) Locate the operating lever and the grip sleeve, fit the sleeve over the end of the lever.

(If it is difficult to slide on, try lubricating with a small amount of washing up liquid. Locate

the M8 caphead screw, then introduce the operating lever through the rack and pinion

assembly, then secure the lever in place using the M8 caphead bolt. (See figs 1 & 2 )

!

WHITE

AXMINSTER

W

07

Initial Assembly...

FREEPHONE 0800 371822

4) Locate the transverse table control lever and screw into the table control mechanism

(See fig 3)

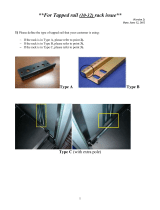

Fig 1 Fig 2

Operating lever

Operating shaft

6mm Allen key

Fig 3

transverse table

control lever

Table control

mechanism

08

WHITE

AXMINSTER

W

Initial Assembly....

5) Locate both distance stop rods and collar clamps assemblys. Slide the collar onto the

distance steel rod. Push the steel rod into the pre-drilled hole on the side of the morticers

casting and clamp in place with the grub screw. (See fig 4a ) ( Do not over tighten) Adjust

the collar to the desired position and clamp in place by turning the handle. (See fig 4b)

Repeat for the other side.

Fig 4

Specification

Axminster No. 600531(AW16BMST)

Motor Single phase 230V a.c. 50 Hz 370W

Motor Speed 1400rpm

Width of Table 180mm

Max Clamping Width 125mm

Depth of Table (in front of the backfence) 157mm

Maximum Reach (Fence to centre of auger) 37mm

Chisel Capacity 6-16mm

Chisel Mounting Shank Size 19.05mm

Chuck Capacity 1-13mm

Weight 42kgs

Footprint with Distance Stops & operating handle fitted

Width 500mm x Depth 440mm x Height 765mm

Note: You don’t have to assemble the distance stop rods unless you require to

produce a series of mortises.

Fig 4a

Fig 4b

Grub screw

Collar

Handle

Distance stop rod

WHITE

AXMINSTER

W

09

Illustration & Parts Description...

Transverse gybe strip adjusters

Worktable gybe

strip adjuster

transverse

table control

lever

Table clamp

assembly

Crossfeed table

control knob

Distance stop

assembly

Mortice depth stop

Head rise stop

Depth stop assembly

Rack & pinion rise

& fall mechanism

Operating lever

Grip sleeve

Hollow chisel

Motor

Headbox casting

Chuck access doors

Off

On

NVR switch assembly

Chisel

mounting flange

Chisel clamping bolt

Fig 5

Fig 5a

Fig 5b

Fig 5c

Locking bolt

10

WHITE

AXMINSTER

W

Parts Identification & Description...

Headbox

This is the ‘morticing machine’ and the descriptions of its various parts and

components are detailed as follows:-

Headbox casting This is the main casting to which the motor, chuck and other

(See figs 5,6) components are attached, which holds the butt of the chisel and takes

the force of the cut as you pull the chisel into your work.

To the left of the casting there are three gib strip adjusters to keep the

headbox stable while it is being moved up/down the support

column slides.

The motor Standard 230V 50Hz single phase four pole motor rated at 370W,

(See fig 5) mounted on the top of the headbox.

On/Off switch The switch assembly is mounted in a box which is bolted to the side of

(See fig 5a) the Motor assembly. The two button switches are marked with the

standard ‘O’ for stop and ‘I’ for start. The assembly is an NVR type so

any loss of the supply during operation, when re-established, will not

cause the motor to restart.

Auger mounting A 13mm drill chuck that is mounted directly onto the motor shaft. Access

chuck to the chuck is via the doors on either side of the headbox. The chuck

(See figs 7a,7b) holds the auger, which drills out the bulk of the timber as the body of the

chisel squares out the mortice.

Chisel mounting The chisel mounting flange is an annular housing machined at the

flange bottom of the headbox. It has a 3/4" adaptor pressed into it, which is

(See fig 5b) used to clamp the chisel in position.

Chuck access The keyed chuck is accessed via openings on either side of the

doors headbox casting. Hinged doors cover these apertures,and are held

(See figs 5,6,7a) closed by a sprung catch moulded into each door.

Headbox support The support column is a pillar casting which houses the rise and fall

column mechanism assembly and is bolted to the rear of the base casting by

(See fig 6) four M10 bolts and washers. Two slides, one on either side at the front

of the pillar provide the vertical travel for the headbox assembly

to plunge the chisel when the operating lever is pulled down.

Counterbalance This is a gas powered return strut mounted to the left side of the

return spring headbox casting which acts between the support column and the rear of

(See fig 6) the headbox to counterbalance the weight of the motor and headbox

assembly.

Double depth These are located on the right side of the support column, and are

stops two ring collars which can be locked in the required position by

(See fig 5) tightening the star knobs to clamp the collars in position on the depth

stop assembly to set the height of the headbox rise and the depth of the

mortice.

WHITE

AXMINSTER

W

11

Illustration & Parts Description...

FREEPHONE 0800 371822

Operating lever

Base casting

Gas powered

head return strut

Headbox support

column

Worktable gybe

strip adjusters

Headbox gybe

strip adjusters

Table clamping

assembly

Chuck access door

Fence

Mortice depth stop

Head rise stop

Motor

Table

Fig 6

Securing hole

Locking bolt

12

WHITE

AXMINSTER

W

Parts Identification & Description...

Rise and fall There is a housing machined on each side of the the Headbox support

mechanism column which mounts a through shaft. A pinion gear is mounted on the

shaft inside the support column that meshes with a rack on the headbox.

Driving the pinion shaft will cause the headbox to rise and fall up and

down the headbox support column. The part of the shaft protruding from

the headbox has a hole through it to mount the operating lever.

Operating lever This is the long arm which applies the down force to the chisel via the

(See fig 5) headbox gearing. This consists of a tube,lever, which is mounted

through the rise and fall mechanism and clamped into place with a

capheadscrew. There is a grip sleeve that fits over the end of the lever

itself, to provide a firmer grip and some cushioning to the hand.

Base casting This is a squat , hollow ‘T’ shaped casting which mounts all the

(See fig 6) component parts of the morticer. The rear surface of the ‘T’ is machined

flat, with 4 No. M10 tapped holes whereby the Headbox Support column

is mounted. There are two raised slides machined across the front

section of the casting which accept the mounting slide of the work table.

There are housings machined in the base to support the traverse

mechanism, this consists of a pinion gear mounted on a shaft. The end

of the shaft protrudes through the front of the base. Into this shaft a

small lever handle is fitted to enable the shaft to be turned left or right.

This turns the pinion, which is engaged with a rack fixed to the mounting

slide, and causes the slide to be driven from side to side. Drilled and

tapped into the end of the rear slide rail (on each side) is a hole which

allows the distance stop rod to be mounted. (See fig 4a)

Morticing table This is the casting that interconnects the worktable to the base, and

(See figs 5,5c,6) enables the transverse and X-feed movements. It has two pairs of slides

machined into it, the lower pair engage with the slides on the base

casting. The upper pair are at right angles to the lower pair and are

machined to accept the slides machined into the underside of the

worktable. In both cases the fit between the slides is maintained by gybe

strips. The lower section of the casting has a rack mounted to it which

forms part of the transverse movement mechanism, (with the pinion gear

in the base). The front upper section has a housing with a drilled and

tapped hole, into which the screwed shaft of the X-feed mechanism of

the worktable is engaged.

Worktable This is an oblong casting, with a pair of slides machined on the

(See fig 6) underside across its width. These slides engage with the slides on the

upper side of the mounting slide. At the rear of the work table is an

upright fence, against which the work piece is clamped. The front of the

table has a small rectangular platform which has two drilled and tapped

holes machined to enable the mounting of the clamp using two bolts

and washers. The underside of the platform is machined to support a

captive threaded bar that is the worktable part of the X-feed mechanism.

The end of the bar protrudes from the front of the table and is fitted with

a small hand wheel to enable the shaft to be screwed in or out to drive

the X-feed of the worktable.

WHITE

AXMINSTER

W

13

Illustration & Parts Description...

Chuck door securing screw

Door catch

Auger mounting chuck

Chuck door removed for clarity

Fig 7

Fig 7a

Fig 7b

14

WHITE

AXMINSTER

W

Setting up the Machine...

www.axminster.co.uk

Initial Set up

Introduce the chisel into the adaptor collar, press the auger up into the chuck, tighten the

chuck and withdraw the chuck key. Gently pinch the chisel in place by finger tightening the

clamping bolt. (See figs 8,9)

Setting the chisel auger clearance

The old rule of thumb for chisel auger clearance was known as “the one penny width”. This

was achieved by introducing a penny between the locating shoulder of the chisel and the

adaptor face, with the auger locked in place and with the chisel pulled hard down on the

auger. The penny was then removed and the chisel pushed up to the adaptor face and

locked in place, this established the “one penny width” between the chisel and the auger,

which for general timbers and mortice sizes is quite adequate. Traditional mortisers

normally had a cross pin in the auger mounting mandrel, to prevent the auger being pushed

back up into the chisel. The mounting method on the newer mortisers is a chuck. It is well

worth taking the extra time and care to prepare your augers to give the correct ‘reach’ when

‘bottomed’ out in the chuck. This will prevent the auger being pushed back towards the

chisel and altering the clearance setting. (See fig A)

Chuck key

Fig 8 Fig 9

Hollow Chisel

Clamping

bolt

Fig A

WHITE

AXMINSTER

W

15

Setting up the Machine...

Setting the chisel auger clearance

16

WHITE

AXMINSTER

W

Setting up the Machine...

General Notes

The mortise will generate a lot of ‘grip’ on the chisel, especially the first cut, or if the timber

is a little green. Make sure you use the table clamp assembly to help control the timber

during the raise operation of the morticer.

Setting the chisel Square

When the chisel is tightened in the machine it must normally be square to the backfence.

The easiest way to achieve this is to bring the headbox down to bring the chisel as close to

the table as possible, set a square against the backfence and set the side of the chisel

against the square. and clamp tight. (Remember to have the chip ejection slot in the chisel

to the side from which you will cut the mortice).

Quick Setting of the Mortice Depth

Put a mark on an easily accessible end of the workpiece to be mortised, at the depth you

require. Pull the headbox down, and put the end of the timber against the chisel, position

the headbox so that the chisel points or the auger point are at the depth required, raise the

depth stop collar to the underside of the headbox and tighten gently. Recheck the depth of

the chisel point, if it is satisfactory tighten securely, if not it can be gently ‘nudged’ down the

column with the headbox, then tighten. Reposition the operating handle to give the most

comfortable position and purchase on the lever, over the full distance of the movement you

have just set.

Headbox Rise Adjustment

Coupled with the depth stop on the same assembly is the head box rise limiter. This limits

the rise of the headbox / chisel to a convenient distance above the work by the use of a

locking collar positioned above the stop finger on the side of the headbox. The travel of this

assembly is then restricted to your chosen setting rather than having to return it to the top

of the slide each time.

WHITE

AXMINSTER

W

17

Maintenance...

Oil

OIL

There is very little maintenance required on your morticer.

Keep it clean

Make sure the rack and pinion gears do not become clogged with chips/sawdust.

Lightly spray oil on all exposed metal surfaces if the machine is going to stand idle

for any length of time. Keep the chisels and augers sharp.

Once a month

Blow/suck the motor to remove any debris that might have lodged in the fan cover.

Oil the chuck and exercise it over its full range to ensure the oil coats all moving

parts.

There are full ranges of mortice chisels and a useful sharpening set listed in

Section 1 of the Axminster catalogue.

18

WHITE

AXMINSTER

W

Illustrated Parts Breakdown...

www.axminster.co.uk

WHITE

AXMINSTER

W

19

Illustrated Parts Catalogue...

FREEPHONE 0800 371822

WHITE

AXMINSTER

W

2006

600531

www.axminster.co.uk

Axminster Devon EX13 5PH UK

FREEPHONE 0800 371822

Axminster Reference No: AW16BMST

Axminster AW16BMST Bench Morticer

/