Page is loading ...

April

1979

FORM:

OM1517

Effective

With

Serial

No.

HJ213624

MODEL

SWINGARC

DUAL

12

SWINGARC

DUAL

16

OWN

E

RS

MANUAL

hullER

1.,

MILLER

ELECTRIC

MFG.

CO.

718

S.

BOUNDS

ST.

P.O.

Box

1079

APPLETON,

WI

54912

USA

ADDITIONAL

COPY

PRICE

75

CENTS

NWSA

CODE

NO. 4579

PRINTED

IN

U.S.A.

b~

LIMITED

WARRANTY

EFFECTIVE:

JANUARY

1,

1979

This

warranty

supersedes

all

previous

MILLER

warranties

and

is

ex

clusive

with

no

other

guarantees

or

warranties

expressed

or

implied.

.

LIMITED

WARRANTYSubject

to

the

terms

and

conditions

As

a

matter

of

general

policy

only,

Miller

may

honor

claims

hereof,

Miller

Electric

Mfg.

Co.,

Appleton,

Wisconsin

warrants

to

submitted

by

the

original

user

within

the

foregoing

periods.

its

Distributor/Dealer

that

all

new

and

unused

Equipment

furnished

~

by

Miller

is

free

from

defect

in

workmanship

and

material

as

of

the

In

the

case

of

Millers

breach

of

warranty

or

any

other

duty

time

and

place

of

delivery

by

Miller.

No

warranty

is

made

by

Miller

with

respect

to

the

quality

of

any

goods,

the

exclusive

remedies

with

respect

to

engines,

trade

accessories

or

other

items

manu-

therefor

shall

be,

at

Millers

option,

(I)

repair

or

(2)

replacement

or,

factured

by

others.

Such

engines,

trade

accessories

and

other

where

authorized

in

writing

by

Miller

in

appropriate

cases,

(3)

the

items

are

sold

subject

to

the

warranties

of

their

respective

manu-

reasonable

Cost

of

repair

or

replacement

at

an

authorized

Miller

ser

facturers,

if

any.

At

the

present

time,

the

manufacturers

warranty

on

VICC

Station

or

(4)

payment

of

or

credit

for

the

purchase

price

(less

the

Mag-Diesel

engine

on

DEL-200

is

limited

to

six

months

and

on

reasonable

depreciation

based

upon

actual

use)

upon

return

of

the

all

other

engines

to

one

year.

goods

at

Customers

risk

and

expense.

Upon

receipt

of

notice

of

apparent

defect

or

failure,

Miller

shall

instruct

the

claimant

on

the

Except

as

specified

below,

Millers

warranty

does

not

apply

to

warranty

claim

procedures

to

be

followed.

components

having

normal

useful

life

of

less

than

one

(1)

year,

such

ANY

EXPRESS

WARRANTY

NOT

PROVIDED

HEREIN

AND

as

spot

welder

tips,

relay

and

contactor

points,MILLERMATIC

parts

ANY

IMPLIED

WARRANTY

GUARANTY

OR

REPRESENTA

~

that

come

in

contact

with

the

welding

wire

including

nozzles

and

lION

AS

TO

PERFORMANCE,

AND ANY

REMEDY

FOR

nozzle

insulators

where

failure

does

not

result

from

defect

in

BREACH

OF

CONTRACT

WHICH,

BUT

FOR

THIS

PROVISION,

workmanship

or

material.

MIGHT

ARISE

BY

IMPLICATION,

OPERATION

OF

LAW,

CUS

TOM

OF

TRADE

OR

COURSE

OF

DEALING

INCLUDING

ANY

Miller

shall

be

required

to

honor

warranty

claims

on

warranted

IMPLIED

WARRANTY

OF

MERCHANTABILITY

OR

OF

FITNESS

Equipment

in

the

event

of

failure

resulting

from

a

defect

within

the

FOR

PARTICULAR

PURPOSE,

WITH

RESPECT

TO

ANY

AND

following

periods

from

the

date

of

delivery

of

Equipment

to

the

.

ALL

EQUIPMENT

FURNISHED

BY

MILLER

IS

EXCLUDED

)

original

user:

AND

DISCLAIMED

BY

MILLER.

I.

Arc

welders,

power

sources

and

components

- .

.

-

1

year

EXCEPT

AS

EXJRESSLY

PROVIDED

BY

MILLER

IN

WRIT-

)

2.

Original

main

power

rectifiers

3

years

ING

MILLER

PRODUCTS

ARE

INTENDED

FOR

ULTIMATE

(labor

-

1

year

only)

PURCHASE

BY

COMMERCIAL/INDUSTRIAL

USERS

AND

FOR

3.

A1Iweldsnggunsandfeeder(g~ais

90days

OPERATION

BY

PERSONS

TRAINED

AND

EXPERIENCED

IN

4.

All

other

Millermatic

Feeders

1

year

THE

USE

AND

MAINTENANCE

OF

WELDING

EQUIPMENT

AND

5.

Replacement

or

repair

parts,

exclusive

of

labor

:

.

-

60

days

NOT

FOR

CONSUMERS

OR

CONSUMER

USE.

MILLER

WAR-

6.

Batteries

6

months

RANTIES

DO

NOT

EXTEND

TO,

AND

NO

RESELLER

IS

provided

that

Miller

is

notified

in

writing

within

thirty

(30)

days

of

AUTHORIZED

TO

EXTEND

MILLERS

WARRANTIES

TO,

the

date

of

such

failure.

ANY

CONSUMER.

..

,,

~

-...-,~,

J~

--.

~1,

.....

-.....

.

ERRATA

SHEET

After

this

manual

was

printed,

refinements

in

equipment

design

occurred.

This

sheet

lists

exceptions

to

data

appearing

later

in

this

manual.

AMENDMENT

TO

SECTION

2

INSTALLATION

Amend

Section

2-6C.

Inlet

Wire

Guide

I~.1l~

An

extension

liner

(082

050)

and

inlet

wire

guide

(082

036)

are

provided

with

mode/s

effective

with

Serial

No.

JA420762

for

use

with

small

diameter

wire.

The

liner

will

handle

wire

up

to

5/64

diameter.

1.

For

.030-5/64

wire.

a.

Insert

liner

(082

050)

into

inlet

w

guide

(082

036)

and

secure

with

set

screw.

b~

Loosen

the

inlet

wire

guide

securing

screw

(

I~1IsTt~

Wire

guides

should

be

installed

so

that

the

tip

of

the

guide

is

as

close

to

the

drive

roll

as

possible

without

touching.

c.

Insert

guide

assembly

into

drive

assembly.

Secure

by

tightening

screw

(3).

2.

For

3/32-l

/8

wire.

a.

Remove

anti-wear

guide(s)

(045

233)

from

inlet

wire

guide.

b.

Loosen

the

inlet

wire

guide

securing

screw

(3).

I~Is~I~

Wfre

guides

should

be

installed

so

that

the

tip

of

the

guide

is

as

close

to

the

drive

roll

as

possible

without

touching.

c.

Insert

tt~e

inlet

wire

guide

(1)

into

drive

assembly

as

illustrated

in

Figure

2-4.

Secure

by

tightening

screw

(3).

d.

Install

anti-wear

guide(s)

onto

inlet

wire

guide

and

secure

with

set

screw.

I~Isfl~

Behind

the

drive

gear

is

a

spring

washer(s).

To

obtain

proper

alignment

of

the

drive

roll

on

the

drive

gear

with

the

wire

guides

rotate

the

drive

gear

securing

bolt

(11)

thereby

moving

the

drive

roll

in

or

out

to

the

desired

posi

tion.

The

drive

roll

on

the

pressure

gear

will

locate

itself

on

the

wire

when

the

gear

cover

is

rep/aced

and

the

gears

mesh

together.

Amend

Section

2-7.

WATER

CONTROL

KIT

Add

IMPORTANT

block

at

beginning

of

Section.

If

a

recirculating

coolant

system

is

used,

do

not

make

connections

from

the

coolant

pump

to

the

Water

valve

but

rather

connect

directly

to

the

gun

water

hoses.

Failure

to

comply

may

result

in

damage

to

the

coolant

pump

and/or

gun.

Amend

SectiOn~

2~8D.

Switch

Control

Two

four-contact

receptacles

extend

out

of

the

motor

end

of

the

boom

for

connecting

the

gun

switch

plugs

to

the

control.

Connect

the

Left

Gunto

the

gun

switch

receptacle

labeled

LEFT

TRIGGER,

and

the

Right

Gun

to

the

other

gun

switch

receptacle

by

inserting

the

plugs

fully

into

the

receptacles

and

rotating

the

locking

rings.

When

one

welding

power

source

is

utilized,

both

electrode

wires

will

be

electrically

energized

when

either

gun

switch

is

closed.

Amend

Section

2-14.

CONTACTOR

CONTROL

CONNECTIONS

(Figure

2-8)

______________

The

contactor

control

circuitry

that

is

to

be

used

in

conjunction

with

this

control/feeder

must

be

of

the

type

that

operates

on

115

volts

60

Hertz

power.

This

is

necessary

because

the

control

will

supply

115

volts

ac

through

the

contactor

control

cable

whenever

the

gun

switch

is

closed.

IMPORTANT

CAUTION

IMPORTANT

OM-1517

Page

A

A.

Using

One

Welding

Power

Source

1

The

contactor

control

circuitry

in

this

control/feeder

is

connected

to

operate

both

guns

from

one

welding

power

source.

Insert

the

plug

on

one

contactor

control

cable

fully

into

the

Left

Contactor

Control

receptacle

and

rotate

the

plug

clockwise.

Connect

the

remaining

end

of

the

contactor

control

cable

to

the

contact~

control

receptacle

on

the

welding

power

source.

Store

the

remaining

contactor

control

cable.

CAUTION

Both

electrode

wires

will

be

electrically

energized

when

either

gun

switch

is

closed;

B.

Using

Two

Welding

Power

Sources

Through

minor

modification,

the

contactor

control

circuitry

of

the

control/feeder

can

be

adapted

to

operate

two

welding

power

sources,

that

is,

the

left

gun

switch

governing

contactor

control

to

one

welding

power

source

and

the

right

gun

switch

governing

contactor

control

to

the

other.

Two

contactor

control

cables

are

supplied

with

the

unit

for

making

connections

to

the

contactor

control

circuitries

in

the

welding

power

sources.

CAUTION

__________

Placing

the

POWER

switch

in

the

OFF

position

does

not

remove

power

from

all

of

the

controls

internal

circuitry.

Completely

terminate

all

electrical

power

to

the

control

by

removing

the

115

volts

ac

plug

from

its

power

supply,

and

ensure

that

machinery

lockout

procedures

have

been

employed

on

the

welding

power

sources

input

line

(see

Instruction

Manual

on

welding

power

source)

before

attempting

any

inspection

or

work

inside

the

unit.

1.

Remove

the

wrapper

from

the

control

box

on

the

control/feeder

2..

Locate

terminal

strip

IT

on

the

bottom

panel

of

the

control.

3.

Disconnect

lead

No.

39

from

terminal

A

on

terminal

strip

iT

and

reconnect

it

to

terminal

B.

4.

Replace

wrapper.

5..

Insert

the

plug

on

the

contactor

control

cable

fully

into

the

Left

Contactor

Control

receptacle

and

rotate

the

plug

clockwise;

connect

the

remaining

end

of

the

cable

to

the

contactor

control

circuitry

in

the

appropriate

welding

power

source.

Insert

the

plug

on

the other

contactor

control

cable

fully

into

the

Right

Contactor

Control.

recep

tacle

and.

rotate

the

plug~clockwise;

connectthe

remaining

end

of

the

cable

to

the

contactor

control

circuitry

in

the

other

welding

power

source~

~

-~

~

-..~.-.,.

~

~

-

~-~

.~

-

-.

-.

-~.~---

~

OM-1517

Page

B

o~

-J -u

as

as

C)

F

CRS!.

RIGHT

p~O12

3

3

-1-

~

162

~j

I

I

L

J

~

Ce

Tt

32

3,

RIGHT

INCH

SW

~~~Tl4

I

/

VI

I

CR

CR1

CAs

a

Z

0

C

m

~

2

C)

-~

-I

Li

-I

0

C

ii

Cl)

x

00

-.4

2

C)

IISV

AC

3/

I~IPLGR

DII

VE

RI

A

PIG?

PC?

CR0.

SILVER

4

PURGE-LEFT

SIDE

CR1

~

~

CR9

6

CR2

TOR~~

1

LEFTp~2

?

~

DC

,0

18

a

~47

a

148

45

R

I

R

L_~J

~

RC3

PIGS

PLGI2

lIST,

FOR

111111

______-~<_~-<

CONTACIOR

-

LEFT

SIDE

SILVER

CS1

GAS

ILEFT

SIDE

SOLENOID

___

WATER

I

L.<2<

~OLENOIGJ

-<1<

OPTIONAL

ESTRA

PLGH

Caa~

PURGE-RIGHT

SIDE

L~

60

PART

OF

LEFT

RURNOACK

PART

OF

RIGHT

BURN8HCK

HLGI4

PLG2

RCZ

2>WfiT

~

1.

>

WIDE

SLOT

TRIGGER

LEFT

SIDE

PLG,5

WI8113

I

RCa

PIGR

~

~

~

I1SV

FOR

C

ON

T

V

CTOR

RIGHT

SIDE

I

SILVER

CS

GAS

<4<

RIGHT

SIDE

L<

2<

<1<

RC1O

PLCIO

*

OPTIONAL

aCts

RMT

-

A>

8>

STD.

RIGHT

C>-~-

REMOTE

F>

2

HC8

SlIT.

_!~_

0

CRs

I

<-C

40

HI

I

I

LEFT

~

J~h~~R1C.3

:

03

I

REMOTE

0>

1SPEED

4~

<<I

I

>*

L((

I

F>

J

~

C~

LI

08

54f*21f

T

<<

-

I

f~1

j

*CRV

I

I

I

CI

RT

~

I

~

C3

22

__

1

I

~-,

a

I

~

C,~

2

~

I

I

/L~

H

I

I

I

0

H

I

1

aJ

04

]%C9

I

I

/~~J

LjJ

I

i

D~

9

~I

I

23

02

05

I

1

2

0

(I

181

HIGVT

c~2

D~

ri

WIRE

I

194

SPEED

.L

A

Cm

02

I

I

C7rn

________

A

]

I

Ct~

I

F

I

<~

_I_

I

1f-T1.

I

I

t1YI

I

CO1

~13

I

29

1

I

~I

___________________________________________________

III

I

4A2

<

&

I

A4~

41.APLGI

Fl

I

~.

HCSL

CI~U~!O~R~

rU1

I

K~)~CW

-

I

WIRE

DRIVE

I

L

~

Circuit

Diagram

No.

C-047

894

I9VT

aLE

__________

WIDE

SLOT

CR1

~

j

TRIGGER

RIGHT

SIDE

69

38

3?

59

1835

22

10

72

33

65

34

4

1

o

q

p

0

q

p

e

0

q

p

q

p

0

0

IT

A

ot

0

E

F

CII

2

IlL

UN

P

391

nO

figure

6-1.

Circuit

Diagram

for

Models

Effective

With

Serial

No.

HK300259

Quantity

Models

Item

Dia.

Part

Replaced

No.

Mkgs.

No.

With

Description

12

16

12

073 839

056

112

FITTING,

hose

-

ferrule

0.475

1D

x

23/32

6

6

27

073

839

056

112

FITTING,

hose-ferrule

0.475

ID

x23/32

2

2

34

604

525

604

525

CORD,

portable

(order

by

ft)

(qty

chg)

16

ft

20

ft

110

RC3,9

039

885

039

602

RECEPTACLE,

twistlock2P2W2O

amp

250

volts

2

2

145

R15

030

853

028

276

RESISTOR,carbon0.5watt2200

ohm

1

1

Pg

7

C2,3

031

694

044

602

CAPACITOR,

poly

film

0.47

uf

400

volts

dc

2

2

180

079029

079029

NUT(qtychg)

1

605

884

NUT,

hex

-

half

3/4-16

1

186

073

664

024

605

BEARING,

ball

1

194

073695

047224

KNOB,Tbar

1

1

048 336

STOP,

cover

2

2

010

193

TUBING,steel3/8ODxl8gawalIxl/4

2

2

045

233

GUIDE,

anti-wear

1 1

604

612

.

SCREW,

set-

socket

hd8-32

x

1/8

1

1

082

036

GUIDE,

inlet

-

wire

(Eff

w/JA420762)

2 2

082

050

LINER,

monocoil

-

inlet

wire

(Effw/JA420762)

2

2

604

612

SCREW,

set-sockethd8-32x

1/8

(Effw/JA420762)

2 2

051

297

ADAPTER

(add

to

itemS)

1

1

047

171

LINER,monocoilxl3

1

1

023

562

CLAMP,

hose

5/16-7/8

clamp

dia

1

1

602

204

WASHER,

lock

-

external

tooth

No.

10

1

1

BE

SURE

TO

PROVIDE

MODEL

AND

SERIAL

NUMBERS

WHEN

ORDERING

REPLACEMENT

PARTS.

OM-1517

Page

D

TABLE

OF

CONTENTS

Section

No.

Page

No.

SECTION

1

INTRODUCTION

1-1.

General

1

1

-

2.

Receiving-Handling

1

1

-

3.

Description

1

1-4.

Safety

1

SECTION

2

INSTALLATION

2

-

1.

Location

And

Assembly

1

2

-

2.

Drive

Motor

3

2

-

3.

Installation

of

Wire

Support

3

2

-

4.

Reinstallation

of

Hub

Assembly

3

2

-

5.

Installation

of

Wire

Reel

3

2

-

6.

Drive

Roll

and

Wire

Guide

Installation

3

2

-

7.

Water

Control

Kit

Connections

4

2

-

8.

Welding

Gun

Connections

5

2

-

9.

Shielding

Gas

Connections

5

2-10.

Boom

Adjustments

6

2-11.

Motor

Control

Connection

6

2-12.

Switch

Control

Connections

6

2-13.

Weld

Cable

Connection

6

2-14.

Contactor

Control

Connections

6

2-15.

115

Volts

AC

Connections

7

2-16.

Installation

of

Spool-Type

Wire

7

2-17.

Installation

of

Reel-Type

Wire

7

2-18.

Adjustment

of

Hub

Tension

7

2-19.

Welding

Wire

Threading

7

SECTION

3

FUNCTION

OF

CONTROLS

3

-

1.

Power

Switch

8

3

-

2.

Wire

Speed

Controls

8

3

-

3.

Remote

Control

Receptacles

and

Switches

8

3-4.

Purge

Buttons

8

3

-

5.

Inch

Switches

8

3

-

6.

Reset

Circuit

Breaker

8

3-

7.

Burnback

Controls

8

SECTION

4

SEQUENCE

OF

OPERATION

4

-

1.

Gas

Metal-Arc

Welding

(GMAW)

9

4

-

2.

Shutting

Down

9

SECTION

5MAINTENANCE

5-

1.

Inspection

and

Upkeep

9

5

-

2.

Cleaning

of

Drive

Rolls

9

SECTION

6

TROUBLESHOOTING

PARTS

LIST

SECTION

1

-

INTRODUCTION

Model

Dual 12

Dual

16

Speed

Range

70-750

I.P.M.

Boom

Length

12

ft.

I

16

ft.

Swing

360

Vertical

Lift

Horizontal

To

600

Above

Maximum

Height

(With

4

Ft

Post)

At_Full_Lift_Of_Boom

17

ft.

21

ft.

.

Counterbalance

(Patented)

Compression

Spring

Is

Designed

To

Bal

ance

Boom

At

Any

Angle.

Pressure

Ad~ustment

Is

Provided

To

Hold

The

Boom

At

Any

Desired

Angle

Or

To

Limit

The

Vertical

Lift

At

40,

500,

or

60.

Weight

(Pounds)

Net

Ship

I

Net

Ship

205

325

j

290

410

Figure

1-1.

Specifications

1-1.

GENERAL

This

manual

has

been

prepared

especially

for

use

in

familiar

izing

personnel

with

the

design,

installation,

operation,

main

tenance,

and

troubleshooting

of

this

equipment.

All

informa

tion

presented

herein

should

be

given

careful

consideration

to

assure

optimum

performance

of

this

equipment.

1

-2.

RECEIVING-HANDLING

Prior

to

installing

this

equipment,

clean

all

packing

material

from

around

the

unit

and

carefully

inspect

for

any

damage

that

may

have

occurred

during

shipment.

Any

claims

for

loss

or

damage

that

may

have

occurred

in

transit

must

be

filed

by

the

purchaser

with

the

carrier.

A

copy

of

the

bill

of

lading

and

freight

bill

will

be

furnished

by

the

carrier

on

request

if

occasion

to

file

claim

arises.

When

requesting

information

concerning

this

equipment,

it

is

essential

that

Model

Description

and/or

Stock

Number

and

Serial

(or

Style)

Numbers

of

the

equipment

be

supplied.

1

-

3.

DESCRIPTION

This

unit

is

a

boom

mounted

wire

control/feeder.

The

control/feeder

is

of

the

constant

wire

feed

speed

type

which

feeds

wire

alternately

from

two

welding

guns.

It

is

designed

to

be

used

in

conjunction

with

1

or

2

constant

potential

welding

power

sources.

1

-

4.

SAFETY

Before

the

equipment

is

put

into

operation,

the

safety

sec

tion

at

the

front

of

the

wetding

power

source

or

welding

generator

manual

should

be

read

completely.

This

will

help

avoid

possible

injury

due

to

misuse

or

improper

welding

applications.

The

following

definitions

apply

to

CAUTION,

IMPORTANT,

and

NOTE

blocks

found

throughout

this

manual:

CAUTION__j

Under

this

headin;,

ins

tallation,

oper~g,

and

main

tenance

procedures

or

practices

will

be

found

that

if

not

carefully

followed

may

create

a

hazard

to

per

sonnel.

I

Under

this

heading,

Installation,

operating,

and

main.

tenance

procedures

or

practices

will

be

found

that

if

not

carefully

followed

may

result

in

damage

to

equip

ment.

The

boom

is

a

patented

design

allowing

both

vertical

lift

and

swing.

Cables

are

routed

through

the

boom

from

the

feeder

control

to

the

wire

drive

assembly.

The

control/feeder

is

a

heavy

duty

wire

feeding

unit

combining

both

the

wire

feeder

and

the

control.

It

contains

all

the

controls

and

equipment

needed

to

supply

welding

wire

and

shielding

gas

to

the

welding

guns.

I

I

H..

Under

this

heading,

explanatory

statements

will

be

found

that

need

special

emphasis

to

obtain

the

most

efficient

operation

of

the

equipment.

SECTION

2

-

INSTALLATION

2-

1.

LOCATION

AND

ASSEMBLY

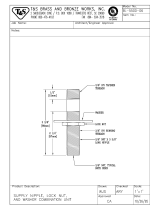

(Figure

2-1)

A. Location

LIMPORTANT

1

A

suitable

location

for

this

unit

will

allow

room

for

the

boom

to

swing

horizontally

in

the

desired

arc,

and

to

pivot

upward

to

the

desired

angle.

Proper

placement

will

also

provide

sufficient

clearance

from

obstruction

at

the

wire

support

end

of

the

unit

when

the

boom

swings.

The

structure

to

which

the

unit

is

being

installed

should

be

of

sufficient

Construction

to

support

the

weight

of

the

Unit

when

the

boom

is

in

the

horizontal

position.

B.

Assembly

1.

Existing

Support

(Customer

Supplied)

In

selecting

the

pipe

used

to

support

the

unit

the

model

utilizing

a

12

foot

boom

requires

a

2-1/2

inch

diameter,

Schedule

40

pipe

(wall

thickness

of

.203

inches).

The

model

with

a

16

foot

boom

requires

a

5

inch

diameter,

Schedule

40

pipe

(wall

thickness

of

.258

inches).

a.

Uncrate

and

remove

all

packing

material

from

the

unit.

b.

Mount

pipe

post

(14)

to

the

desired

structure.

.

I

I

OM-1517

Page

1

Figure

2-1.

Base

And

Boom

Assembly

CAUTION

The

Structure

to

which

the

pipe

post

is

mounted

must

be

of

sufficient

Construction

to

support

the

weight

of

the

unit

when

the

boom

is

in

the

horizontal

position.

c.

Proceed

to

Subsection

B2,

Steps

c

through

k.

2.

Post

Support

(Optional)

a.

Uncrate

and

remove

all

packing

material

from

the

unit.

b.

Mount

post

support

(14)

to

the

desired

structure.

!

The

structure

to

which

the

post

support

is

mounted

must

be

of

sufficient

construction

to

support

the

weight

of

the

unit

when

the

boom

is

in

the

horizontal

position.

c.

Remove

yoke

pin

(1),

nut

(10)

washers

(9

&

17)

and

bolt

(18)

from

the

yoke

(3)

and

swivel

plates

(16).

d.

Place

bearing

(13)

on

top

of

post

(14)

and

insert

swivel

(8)

into

post

(14).

a.

Place

the

boom

base

plate

(19)

in

between

the

two

swivel

plates.

f.

Slide

washer

(17)

onto

bolt

(18)

and

insert

bolt

(18)

through

hole

(15).

Slide

washer

(9)

onto

bolt

(18)

and

install

nut

(10)

onto

bolt

(18).

Tighten

nut

(10);

then

back

off

nut

(10)

1/2

turn.

g.

Insert

pin

(1)

through

yoke

(3),

hole

(2).

and

install

cotter

pin

(4)

through

pin

(1).

h.

Connect

the

welding

guns

to

the

drive

assembly

as

instructed

in

the

Owners

Manual

for

the

desired

welding

guns.

i.

Grasp

bar

(20)

and

pull

boom

down

slightly.

The

boom

should

be

pulled

down

only

far

enough

to

remove

the

pressure

which

is

applied

to

the

safety

collar

(11).

j.

Remove

the

safety

collar

(11).

k.

The

boom

should

now

balance

in

any

position

from

horizontal

to

60

degrees

above

horizontal.

If

the

boom

does

not

balance

properly,

proceed

to

Section

2-10.

NOTE

]

The

post

support

(14)

is

provided

with

a

fitting

for

lubricating

the

swivel

periodically,

to

prevent

pre

mature

wear

and

to

ease

turning

during

operation.

Excessive

greasing

of

support

fitting

is

not

required

or

recommended.

I

I

3.

Base

Support

(Optional)

I

NOTE]

If

an

optional

base

support

was

purchased

with

the

unit,

mounting

holes

are

provided

for

fastening

the

base

support

to

the

floor.

I

EA71

I

When

an

optional

base

support

is

used,

the

base

must

be

securely

mounted

to

the

floor.

As

a

minimum,

1/2

dia.,

S.A.E.

grade

5

bolts,

with

adequate

corrosion

protection

should

be

used

to

secure

the

base,

If

the

unit

is

to

be

mounted

in

an

extremely

damp

environ

ment,

mounting

bolts

made

of

a

non-corrosive

mater

ial

with

a

strength

equivalent

to

S.A.E.

grade

5

steel

should

be

used.

a.

Uncrate

and

remove

all

packing

material

from

the

Unit.

b.

Fasten

base

support

to

the

floor.

c.

Complete

Steps

c

through

k

Subsection

B2.

I

NOTE]

The

base

support

is

provided

with

a

fitting

for

lubricating

the

swivel

periodically,

to

prevent

pre

mature

wear

and

to

ease

turning

during

operation.

Excessive

greasing

of

support

fitting

is

not

required

or

recommended.

4.

Swingpak

Base

(Optional)

J

a.

Uncrate

and

remove

all

packing

material

from

the

Swingpak

base.

12

13

14

U

.

TB-081

753

U

I

U

Do

not

remove

safety

collar

(11)

until

instructed

to

do

so.

The

swivel

base

(8)

contains

high

pressure

springs

to

counter

balance

the

weight

at

the

weld

head.

I

I

I

Page

2

IMPORTANT

The

installation

of

the

welding

power

source

onto

the

Swingpak

base

should

precede

mounting

of

the

Swing-

arc

unit

in

order

to

prevent

tipping

of

the

frame

under

the

weight

of

the

boom.

b.

Uncrate

and

remove

all

packing

material

from

the

Swingarc

unit.

c.

Complete

Steps

c

through

k,

Subsection

82.

NOTE

The

Swingpak

base

is

provided

with

a

fitting

for

lubricating

the

swivel

periodically,

to

prevent

pre

mature

wear

and

to

ease

turning

during

operation.

Excessive

greasing

of

support

fitting

is

not

required

or

recommended.

2-2.

DRIVE

MOTOR

The

drive

motor

is

provided

with

a

vent

screw

which

must

be

removed

prior

to

the

operation

of

the

control/feeder.

The

vent

screw

can

be

removed

through

the

hole

provided

in

the

motor

shroud

(see

Figure

2-6).

2-3.

INSTALLATION

OF

WIRE

SUPPORT

(Figure

2-1)

1.

Remove

the

securing

screws

(5)

and

lock

washers

(6)

from

the

swivel

base

(8).

2.

Lift

the

wire

support

(7)

in

place

over

the

holes

in

the

swivel

base

(8).

3.

Insert

securing

screws

(5)

with

lock

washers

(6)

and

tighten.

2-4.

REINSTALLATION

OF

HUB

ASSEMBLY

(Figure

2-2)

11

12

TB-081

754

2.

Rotate

hex

nut

(10)

onto

support

shaft

(1).

Hex

nut

should

be

rotated

only

until

a

slight

drag

is

felt

while

turning

hub

(4).

3.

Depress

the

two

spring

loaded

stops

(11)

on

the

retaining

ring

(12)

and

slide

the

retaining

ring

(12)

into

proper

position

on

the

hub

(4).

Release

the

two

stops

(11).

J

2-

5.

INSTALLATION

OF

WIRE

REEL

(Optional)

(Figure

2-3)

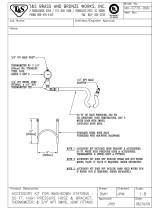

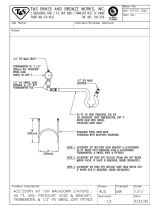

Figure

2-3.

Reel

Installation

The

following

procedures

for

the

installetion

of

the

wire

reels

are

applicable

to

the

left

and/or

right

sides.

1.

Remove

the

retaining

ring

(5).

2.

Slide

the

wire

reel

(1)

onto

the

hub

(6).

Rotate

the

wire

reel

(1)

until

the

hub

guide

pin

(7)

is

seated

in

the

reel

(1).

3.

Depress

the

two

spring-loaded

stops

(4)

on

the

retaining

ring

(5)

and

slide

the

retaining

ring

(5)

into

proper

position

on

the

hub

(6).

Release

the

two

stops

(4).

2-6.

DRIVE

ROLL

AND

WIRE

GUIDE

INSTALLATION

(Figure

2-4)

Upon

initial

installation,

or

as

a

result

of

changes

in

wire

size

and

type,

it

is

necessary

to

install

the

required

drive

rolls

and

wire

guides.

Figure

2-2.

Wire

Support

And

Hub

Assembly

If

it

should

become

necessary

to

replace

part

or

all

of

the

hub

assembly(s),

reinstall

the

new

hub

assembly(s)

as

follows:

1.

Slide

the

following

items

onto

the

spindle

support

shaft

(1)

in

order

given:

A.

Fiber

Washer

(2)

8.

Flat

Washer

(3)

C.

Hub

(4)

D.

Flat

Washer

(5)

E.

Fiber

Washer

(6)

F.

Keyed

Washer

(7)

G.

Spring

(8)

H.

Flat

Washer

(9)

Base

selection

of

drive

rolls

upon

the

following

recommended

usages:

1.

V-Groove

rolls

for

hard

wire.

2.

U-Groove

rolls

for

soft

and

soft

shelled

cored

wires.

3.

U-Cog

rolls

for

extremely

soft

shelled

wires

(usually

hard

surfacing

types).

4.

Split

V-Knurled

rolls

for

hard

shelled

cored

wires

(self-shielding

and

CO2

shielded

types).

5.

Drive

roll

types

may

be

mixed

to

suit

particular

requirements

(example:

V-knurled

roll

in

combination

with

U-groove).

Having

selected

the

appropriate

drive

rolls

and

wire

guides

proceed

to

the

installation

instructions

for

the

type

of

drive

roll

to

be

used.

TB-081

755

U

U

U

I

OM-1517

Page

3

Figure

2-4.

Drive

Rolls

Installation

A.

One

Piece

Drive

Rolls

(Figure

2-4)

NOTE

Drive

rolls

(8

&

13)

are

of

the

double

usage

type.

When

the

grooves

become

worn,

reverse

each

drive

roll,

locating

the

unused

groove

in

position

to

feed

the

wire.

I

I

1.

Loosen

the

pressure

adjustment

wing

nut

(item

2,

Figure

2-4)

and

pivot

it

free

of

the

cover.

2.

Pivot

gear

cover

(4)

away

until

it

is

in

an

open

position.

3.

Loosen

and

remove

the

three

securing

screws

(7

&

12)

on

each

gear

(5

&

9).

4.

Separately

align

the

holes

on

each

pair

of

split

drive

rolls

(6

&

10)

and

insert

a

securing

screw

(7

&

12).

5.

Slide

a

pair

of

drive

rolls

(10)

with

securing

screw

(12)

Onto

drive

gear

(9)

in

line

with

one

of

the

threaded

holes.

6.

Insert

remaining

screws

and

tighten.

1.

Loosen

the

pressure

adjustment

wing

nut

(item

2,

Figure

2-4)

and

pivot

it

free

of

the

cover.

2.

Pivot

gear

cover

(4)

away

until

it

is

in

an

open

position.

3.

Loosen

and

remove

the

three

securing

screws

(7

&

12)

on

each

gear

(5

&

9).

4.

Slide

one

drive

roll

(13)

onto

drive

gear

(9)

with

holes

aligned.

Insert

securing

screws

(12)

and

tighten.

7.

Repeat

Steps

4

through

6

for

installation

of

drive

rolls

Onto

the

pressure

gear

(5).

C.

Inlet

Wire

Guide

(Figure

2-4)

1.

Loosen

the

inlet

wire

guide

securing

screws

(3).

m

Wire

guides

should

be

installed

so

that

the

tip

of

the

guide

is

as

close

to

the

drive

roll

as

possible

without

touching.

2.

Insert

the

inlet

wire

guides

(1)

into

drive

assembly

as

illustrated

in

Figure

2-4.

Secure

by

tightening

screws

(3).

I

Fl

Behind

the

drive

gear

is

a

spring

washer(s).

To

obtain

proper

alignment

of

the

drive

roll

on

the

drive

gear

with

the

wire

guides

rotate

the

drive

gear

securing

bolt

(11)

thereby

moving

the

drive

roll

in

or

out

to

the

desired

position.

The

drive

roll

on

the

pressure gear

will

locate

itself

on

the

wire

when

the

gear

cover

is

replaced

and

the

gears

mesh

together.

I

2-7.

WATER

CONTROL

KIT

(Optional)

CONNECTIONS

A.

Installation

Of

Water

Hoses

Water

coolant

is

supplied

to

either

one

gun

or

both

guns

utilizing

one

water

solenoid

and

the

same

input,

Output,

and

return

hoses.

The

solenoid

is

energized

when

the

POWER

switch

is

placed

in

the

ON

position.

Connect

a

hose

from

the

water

supply

to

the

Water

input

fitting

at

the

rear

of

the

control.

This

fitting

has

a

left-hand

thread.

The

water

supply

hose

routed

through

the

boom,

connects

to

the

Water

fitting

at

the

front

of

the

control.

NOTE

16

To

ensure

proper

gripping

action

of

U-Cog

drive

rolls,

both

rolls

should

be

installed

showing

slots

on

the

side

or

both

should

show

the

side

without

slots.

Also,

it is

necessary

to

line

up

the

blunted

teeth

on

the

pressure

gear

roll

directly

over

the

spaces

between

the

teeth

on

the

drive

gear

roll

as

illustrated

in

Figure

2-5.

I

U

5.

Slide

remaining

drive

roll

(8)

onto

pressure

gear

(5)

with

holes

aligned.

Insert

securing

screws

(7)

and

tighten.

B.

Split

Drive

Rolls

(Figure

2-4)

NOTE

J

TB-081

810

U

.

Drive

rolls

(6

&

10)

are

of

the

double

usage

type.

When

the

knurled

groove

of

the

drive

rolls

becomes

worn,

the

split

halves

may

be

reversed

so

that

the

unused

edges

will

now

provide

a

new

knurled

groove.

I

I

U

I

Gear

Roll

TA-081

756

Figure

2-5.

U-Cog

Drive

Rolls

Installation

Page

4

When

water

is

required

for

one

g~n

only,

connect

the

adapter

to

the

appropriate

weld

terminal

on

the

drive

assembly

and

connect

the

water

return

hose

to

this

adapter.

If

water

is

required

for

both

guns,

connect

the

return

hose

Y

assembly

to

an

adapter

at

each

weld

terminal.

The

water

return

hose

is

routed

through

the

boom.

Connect

this

hose

to

an

appropriate

disposal.

B.

Electrical

Reconnection

Of

Water

Solenoid

The

control

is

shipped

connected

to

supply

water

when

the

POWER

switch

is

in

the

ON

position.

The

water

solenoid

circuitry

can

be

modified

to

supply

water

when

the

appro

ptiate

gun

trigger

is

depressed.

1.

Shut

unit

down

and

disconnect

from

line

voltage.

CAUTION

Placing

the

POWER

switch

in

the

OFF

position

does

not

remove

power

from

all

of

the

controls

internal

circuitry.

Completely

terminate

all

electrical

power

to

the

control

by

removing

the

115

volts

ac

plug

from

its

power

supply,

and

ensure

that

machinery

lockout

procedures

have

been

employed

on

the

welding

power

sources

input

line

(see

Instruction

Manual

on

welding

power

source)

before

attempting

any

inspec

tion

or

work

inside

the

unit.

2.

Remove

control

box

wrapper.

3.

Locate

terminal

strip

iT

on

bottom

panel

of

control

4.

Right

Side

Only:

To

supply

water

on

the

right

side

when

the

Right

Gun

trigger

is

depressed,

move

lead

No.

6

from

terminal

P

on

terminal

strip

iT

to

terminal

M.

Left

Side

Only:

To

supply

water

on

the

left

side

when

the

Left

Gun

Trigger

is

depressed,

more

lead

No.

6

from

terminal

P

on

terminal

strip

iT

to

terminal

B.

Either

side:

To

supply

water

on

either

side

when

the

appropriate

gun

trigger

is

depressed,

move

lead

No.

6

from

terminal

P

on

terminal

strip

iT

to

terminal

A.

5.

Replace

wrapper.

2-8.

WELDING

GUN

CONNECTIONS

A.

Outlet

Wire

Guides

(Figure

24)

NOTE

The

outlet

guide

is

provided

as

part

of

each

gun

assembly.

1.

Loosen

the

gun/feeder

connector

securing

knob(s)

(16).

NOTE

Wire

guides

should

be

installed

so

that

the

tip

of

the

guide

is

as

close

to

the

drive

roll

as

possible

without

touching.

2.

Inserf

the

gun/feeder

connector(s)

(14)

from

the

gun(s)

which

includes

the

installed

outlet

guide(s),

into

the

grive

assembly

opposite

the

respective

inlet

wire

guide(s)

(1)

as

illustrated

in

Figure

2-4.

3.

Tighten

the

gun/feeder

connector

securing

knob(s)

(16).

B.

Weld

Cables

(Figure

2-6)

Two

holes

are

provided

in

the

drive

assembly

for

connecting

the

boom

weld

cables

and

the

corresponding

gun

weld

cables

(see

Figure

2-6).

Connect

the

Left

Gun

weld

cable

(if

so

equipped)

to

the

boom

weld

cable

on

the

left

side

of

the

drive

assembly

and

the

Right

Gun

weld

cable

(if

so

equipped)

to

the

boom

weld

cable

on

the

right

side

of

the

drive

assembly

using

the

supplied

hardware.

C.

Shielding

Gas

The

shielding

gas

hose

from

each

gun

is

to

be

connected

to

the

appropriate

gas

hose

which

extends

out

of

the

motor

end

of

the

boom.

Connect

the

gas

hose

from

the

Left

Gun

to

the

hose

labeled

LEFT

GAS

and

the

gas

hose

from

the

Right

Gun

to

the

other

gas

hose.

NOTE

Integral

gas

input

fittings

are

provided

on

the

drive

assembly

for

guns

utilizing

this

type

of

connection

(see

Figure

2-6).

If

the

gas

hoses

which

extend

out

of

the

motor

end

of

the

boom,

are

provided

with

fittings,

cut

the

fittings

off

and

push

the

hoses

onto

the

appropriate

barbed

fittings

on

the

drive

assembly.

See

the

appropriate

welding

gun

Owners

Manual

for

instructions

on

making

this

connection.

D.

Switch

Control

Two

four-contact

receptacles

extend

out

of

the

motor

end

of

the

boom

for

connecting

the

gun

switch

plugs

to

the

control.

Connect

the

Left

Gun

to

the

gun

switch

receptacle

labeled

LEFT

TRIGGER,

and

the

Right

Gun

to

the

other

gun

switch

receptacle

by

inserting

the

plugs

fully

into

the

receptacles

and

rotating

the

locking

rings.

When

the

Left

Gun

switch

is

closed,

the

contactor

in

the

welding

power

source

connected

to

the

Left

control

will

energize, shielding

gas

will

flow

and

wire

will

feed.

When

the

Right

Gun

switch

is

closed,

the

contactor

in

the

welding

power

source

connected

to

the

Right

control

will

energize,

shielding

gas

will

flow

and

wire

will

feed.

~contactorcontroIcirc~tryinthecontrol/fder

has

been

modified

to

operate

one

welding

power

source

both

electrode

wires

will

be

electrically

ener

gized

when

either

gun

switch

is

closed

(see

Section

2-14B).

E.

Water

(If

Applicable)

If

water

coolant

is

required

for

one

gun

only,

connect

the

gun

water

input

hose

to

the

water

output

hose

at

the

motor

end

of

the

boom.

(If

water

is

required

for

both

guns,

the

water

output

hose

from

the

control

divides

at

the

motor

end

of

the

boom

to

accept

connections

from

both

gun

water

input

hoses.)

Connect

the

water

return

hose

from

the

gun

to

the

adapter

at

the

appropriate

weld

terminal

on

the

drive

assembly.

Reducing

bushings

are

provided

to

accept

5/8-18

L.H.

fittings.

If

the

reducing

bushings

are

removed,

7/8-14

L.H.

fittings

can

be

accomodated.

Vent

Screw

Access

Hole

Figure

2-6.

Gun

Weld

Cable

Connections

TA-081

811

I

I

I

.

OM-1517

Pages

2-9.

SHIELDING

GAS

CONNECTIONS

A

divided-hose

assembly

is

supplied

with

the

Unit

for

making

connections

to

the

Shielding

Gas

input

fittings

at

the

rear

of

the

control

from

one

shielding

gas

source.

These

fittings

have

a

right-hand

thread.

NOTE

I

..

I

If

a

different

shielding

gas

is

required

for

each

welding

gun,

a

separate

hose

can

be

connected

from

each

shielding

gas

source

to

the

appropriate

input

fitting

at

the

control.

I

The

gas

hoses,

routed

through

the

boom,

connect

to

the

appropriate

Shielding

Gas

output

fittings

at

the

front

of

the

control.

2-10.

BOOM

ADJUSTMENTS

(Figure

2-7)

A.

Weight

Lift

Adjustment

CAUTION

Nut

istment

Rod

TA-081

757

I

Ensure

that

during

all

adjustment

procedures,

full

threads

on

the

adjustment

rod

are

maintained

through

the

yoke.

If

full

threads

are

not

maintained,

the

boom

may

suddenly

drop

down

and

cause

injury

to

person

nel

or

damage

to

equipment.

The

amount

of

weight

which

the

boom

can

retract

into

the

upright

position

when

released

can

be

varied

by

adjusting

the

jam

nut

and

adjustment

rod

located

at

the

base

of

the

boom.

If

heavier

guns

are

installed

on

the

end

of

the

boom

thereby

making

it

necessary

to

increase

the

amount

of

weight

that

the

boom

can

lift,

loosen

the

jam

nut

and

rotate

the

adjustment

rod

so

that

the

adjustment

rod

threads

into

the

yoke.

When

the

proper

adjustment

is

obtained,

tighten

the

jam

nut

against

the

base

of

the

yoke.

If

lighter

guns

are

used

with

the

Swingarc,

rotate

the

adjustment

rod

so

that

the

adjustment

rod threads

out

of

the

yoke.

B.

Locking

Knob

By

rotating

the

Locking

knob,

located

on

the

side

of

the

swivel

plate,

in

a

clockwise

direction,

the

boom

may

be

held

in

any

desired

position.

Rotating

the

Locking

Knob

in

a

counterclockwise

direction

will

permit

the

boom

to

free

travel.

Changing

the

position

of

the

Locking

Knob

to

the

other

threaded

holes

provided

along

the

side

of

the

swivel

plate,

limits

the

lift

of

the

boom

to

50

degrees

or

40

degrees

respectively

during

free

travel.

2-11.

MOTOR

CONTROL

CONNECTION

(Figure

2-8)

NOTE

A

four-contact

connector

is

provided

on

the

rear

panel

of

the

control.

Insert

the

four-pin

plug

from

the

control

end

of

the

boom

into

this

connector.

2-12.

SWITCH

CONTROL

CONNECTIONS

(Figure

3-1)

Two

two-pole,

twistlock

receptacles

are

provided

on

the

front

panel

of

the

control

for

making

switch

control

connections.

The

switch

control

cables

extend

out

of

the

control

end

of

the

boom.

Insert

the

switch

control

ptug,

labeled

LEFT

TRIGGER,

into

the

Switch

Control

receptacle

on

the

Left

control

and

the

other

switch

control

plug

into

the

Switch

Control

receptacle

on

the

Right

control

and

rotate

the

plugs

clockwise.

2-13.

WELD

CABLE

CONNECTION

Two

weld

cables

extend

Out

of

the

control

end

of

the

boom

for

making

secondary

connections

to

the

welding

power

sources.

The

end

of

each

weld

cable

is

equipped

with

a

terminal

for

a

1/2

stud.

Connect

weld

cables

to

the

desired

POSITIVE

output

terminal

on

the

applicable

welding

power

source.

1.

r~n

If

one

welding

power

source

is

used,

connect

the

weld

cables

from

the

control/feeder

to

the

welding

power

source

High

and

Low

POSITIVE

output

terminals

as

desired.

2-14.

CONTACTOR

CONTROL

CONNECTIONS

(Figure

2-8)

flTANT

The

contactor

control

circuitry

that

is

to

be

used

in

conjunction

with

this

control/feeder

must

be

of

the

type

that

operates

on

115

volts

60

Hertz

power.

This

is

necessary

because

the

control

will

supply

115

volts

ac

through

the

contactor

control

cable

whenever

the

gun

switch

is

closed.

I

I

A.

Using

Two

Welding

Power

Sources

Two

contactor

control

cables

are

supplied

with

the

unit

for

making

connections

to

the

contactor

control

circuitries

in

the

welding

power

sources.

The

control/feeder

is

shipped

con

nected

to

operate

two

welding

power

sources,

that

is.

the

Left

Gun

governing

contactor

control

to

one

welding

power

source

and

the

Right

Gun

governing

contactor

control

to

the

other.

Insert

the

plug

on

the

contactor

control

cable

fully

into

the

Left

Contactor

Control

receptacle

and

rotate

the

plug

clockwise;

connect

the

remaining

end

of

the

cable

to

the

contactor

control

circuitry

in

the

appropriate

welding

power

source.

Insert

the

plug

on

the

other

contactor

control

cable

fully

into

the

Right

Contactor

Control

receptacle

and

rotate

Yoke

Control

Fuse

TA-081

758

Figure

2-8.

Rear

Panel

Connections

Figure

2-7.

Boom

Adjustments

Examine

the

Motor

Control

plug

and

connector

carefully

to

determine

proper

alignment

of

the

pin

arrangement

with

the

contacts.

Page

6

the

plug

clockwise;

connect

the

remaining

end

of

the

cable

to

the

contactor

control

circuitry

in

the

other

welding

power

source.

B.

Using

One

Welding

Power

Source

Through

minor

modification,

the

contactor

control

circuitry

in

this

control/feeder

can

be

adapted

to

operate

one

welding

power

source

from

both

guns.

If

only

one

welding

power

source

is

to

be

used

to

supply

weld

current

to

both

guns,

it

will

be

necessary

to

perform

the

following

wiring

change

in

the

control

unit

contactor

control

circuitry.

I.

_~,

Placing

the

POWER

switch

in

the

OFF

position

does

not

remove

power

from

all

of

the

controls

internal

circuitry.

Completely

terminate

all

electrical

power

to

the

control

by

removing

the

115

volts

ac

plug

from

its

power