Supplement To Form 15-047

F-15-049

March, 1995

I. GENERAL

This supplement covers the Heliarc 250 AC/DC Power

Source with "power factor correction" specifically de-

signed for 220/380/415 Volt -- 50 Hertz service. It is

identical to the standard Heliarc 250 AC/DC (P/N 31310)

unit covered in Form 15-047 except for the following:

IMPORTANT

As shipped from the factory, all 50 Hz units are hooked-

up to operate from a 415 volt input. If your input require-

ments do not match the factory-shipped provision, the

following data should be heeded:

You must change the input terminal board (TB) volt-

age links to match your actual primary input voltage -

- as described in Section II-C of this supplement.

A. Replacement Parts:

Main Transformer (MTR) - P/N 31318 replaces P/N

31313.

Terminal Board Assy. (TB) - P/N 680434 replaces P/

N 680047.

Fan Motor (FM) - P/N 2062301 replaces P/N 2062340.

II. Form 15-047 is applicable to this unit except

as follows:

A. Revised Specification following:

Rated Output@ 250 Amps @ 30 Volts

40% Duty Cycle AC/DC, Tig/Stick

Open Circuit Voltage 79 Volts AC/72 Volts DC

Output Welding Current AC/DC

Current Low Range 5 to 60 Amps

Range in High Range 15 to 320 Amps

Amperes

Input Voltage 220/380/415 VAC,

1 Ph., 50 Hz.

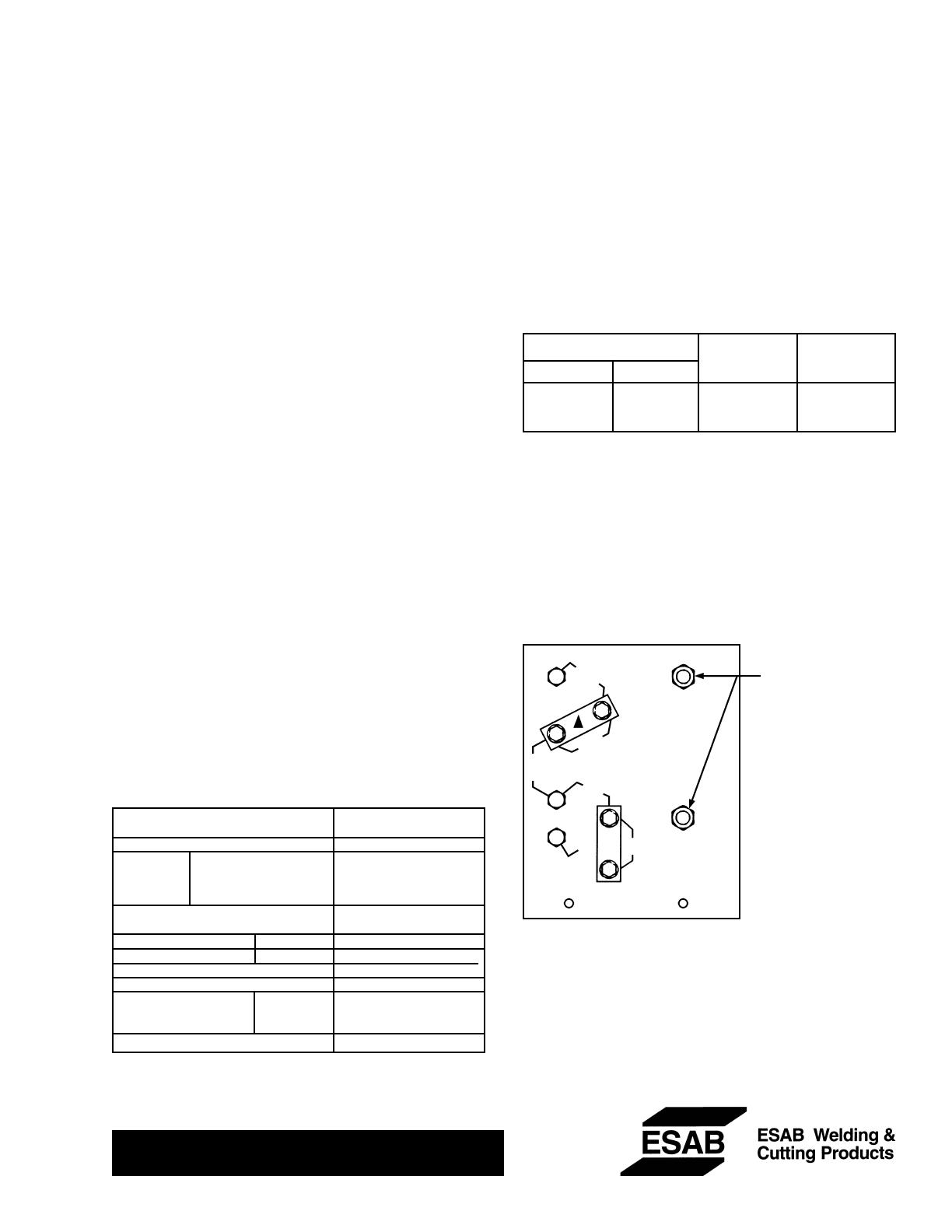

Input Current @ Voltage 220 380 415

Rated Load in Amps Full Load 78 47 38

Power Factor @ Rated Load Approx. 76%

Auxiliary Power Output 115 VAC, 15 Amp., 50 Hz.

Dimensions: Width 16-inches 406 mm

Depth 30-inches 762 mm

Height 22-inches 559 mm

Weight 385 lbs. 175 kg

Input Requirements Input & Gnd. Time-Delay

Conductor Fuse Size

Volts Amps. CU/AWG Amps.

220 78 3 125

380 47 8 70

415 38 8 60

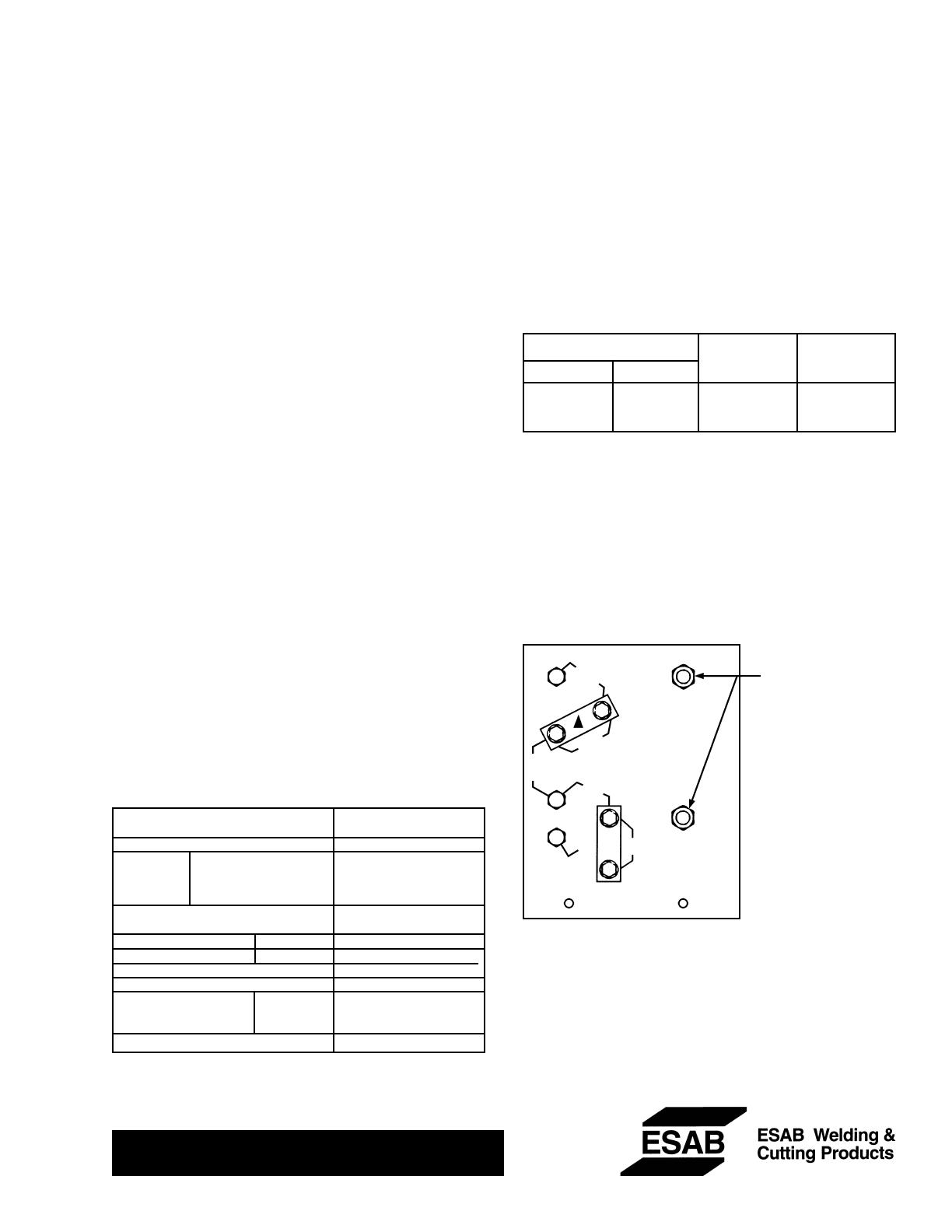

C. Primary Voltage Changeover Connections

As mentioned previously, the primary windings of the

main transformer are factory connected for 415 volt op-

eration. These connections are made by using

reconnectable links on the voltage changeover terminal

board for the main transformer. This unit's terminal board

(illustrated following) is silkscreened to show the avail-

able primary voltage connections which can be used.

Customer's Input

Cable Connection

I Double Links Provided

Voltage Changeover Terminal Board (TB)

D. Wiring Diagram -- Use revised portions contained

herein.

E. Schematic Diagram -- Use revised portions con-

tained herein.

Revised Table for Recommended Input Conductors

and Line Fuses.

Heliarc 250 AC/DC POWER SUPPLY

for 50 HZ. SERVICE

ESAB P/N 31320

L-TEC P/N 35623

Be sure this information reaches the operator.

You can get extra copies through your supplier.

2

3

1

220

7

415

220

380

415

220

L2

L1

380