iv Floating Deck Mid-Size Service Manual

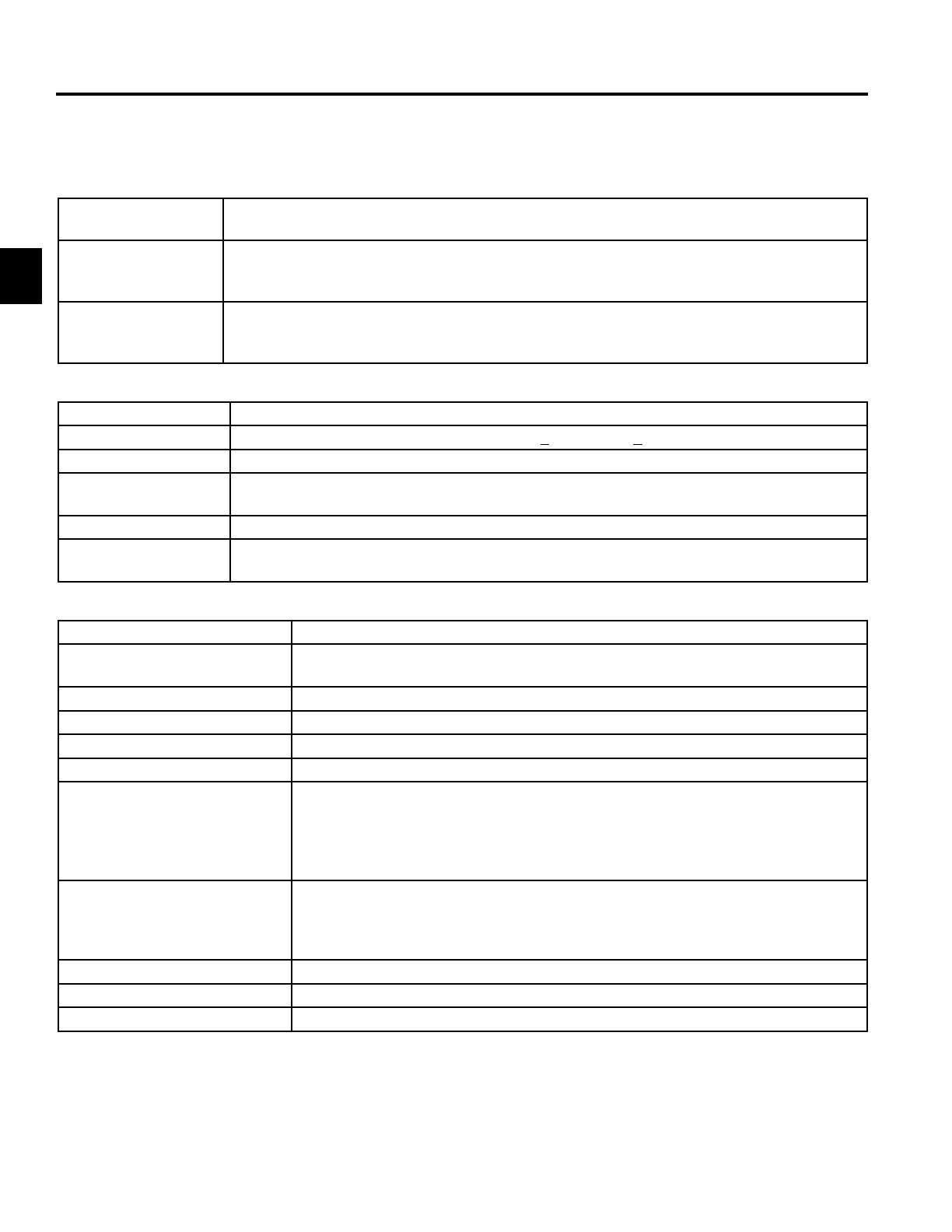

TABLE OF CONTENTS

MOWER DECKS

Mower Spindle Drive Belt Replacement .......................................................................................8-1

Mower Spindle Drive Belt Removal (40”, 48”, 52” and 60” Mower Decks) ............................8-1

Mower Spindle Drive Belt Installation (40”, 48”, 52” and 60” Mower Decks) .........................8-2

Mower Spindle Drive Belt Removal (36” Mower Deck) ..........................................................8-4

Mower Spindle Drive Belt Installation (36” Mower Deck) .......................................................8-5

PTO Drive Belt Replacement .......................................................................................................8-6

PTO Drive Belt Removal (40”, 48”, 52” and 60” Mower Decks) .............................................8-6

PTO Drive Belt Installation (40”, 48”, 52” and 60” Mower Decks) ..........................................8-7

PTO Drive Belt Removal (36” Mower Decks).........................................................................8-8

PTO Drive Belt Installation (36” Mower Decks)......................................................................8-9

Spindle Replacement and Service .............................................................................................8-11

Spindle Removal and Teardown ..........................................................................................8-11

Spindle Rebuild and Installation ...........................................................................................8-14

Idler Arm Assembly Replacement...............................................................................................8-18

Idler Arm Assembly Removal (40”, 48”, 52” and 60” Mower Decks) ....................................8-18

Idler Arm Assembly Installation (40”, 48”, 52” and 60” Mower Decks) .................................8-22

Idler Arm Assembly Replacement (36” Mower Deck) .................................................................8-27

Idler Arm Assembly Removal (36” Mower Deck) .................................................................8-27

Idler Arm Assembly Installation (36” Mower Deck) ..............................................................8-28

Adjustable Baffl e Replacement ..................................................................................................8-30

Adjustable Baffl e Removal ...................................................................................................8-30

Adjustable Baffl e Installation ................................................................................................8-32

Discharge Baffl e Replacement ...................................................................................................8-34

Discharge Baffl e Removal ...................................................................................................8-34

Discharge Baffl e Installation ................................................................................................8-35

Fixed Baffl e Replacement ..........................................................................................................8-36

Fixed Baffl e Removal (40”, 48”, 52” and 60” Mower Decks) ................................................8-36

Fixed Baffl e Installation (40”, 48”, 52” and 60” Mower Decks) .............................................8-37

Fixed Baffl e Replacement (36” Mower Deck) .............................................................................8-38

Fixed Baffl e Removal (36” Mower Deck) .............................................................................8-38

Fixed Baffl e Installation (36” Mower Deck) ..........................................................................8-39

Skid Plate Replacement (40”, 48”, 52” and 60” Mower Decks) ..................................................8-39

Skid Plate Removal (40”, 48”, 52” and 60” Mower Deck) ....................................................8-39

Skid Plate Installation (40”, 48”, 52” and 60” Mower Deck) .................................................8-40

Skid Plate Replacement (36” Mower Deck)................................................................................8-41

Skid Plate Removal (36” Mower Deck) ................................................................................8-41

Skid Plate Installation (36” Mower Deck) .............................................................................8-42

Front & Rear Deck Hanger Replacement ...................................................................................8-43

Front Deck Hanger Removal ...............................................................................................8-43

Front Deck Hanger Installation ............................................................................................8-45

Rear Deck Hanger Removal ................................................................................................8-48

Rear Deck Hanger Installation .............................................................................................8-50

Anti-Scalp Roller Replacement...................................................................................................8-52

Single Anti-Scalp Roller Removal ........................................................................................8-52

Single Anti-Scalp Roller Installation .....................................................................................8-53

Double Anti-Scalp Roller Removal .......................................................................................8-54

Double Anti-Scalp Roller Installation ....................................................................................8-54

Grass Defl ector Service..............................................................................................................8-55

Grass Defl ector Removal .....................................................................................................8-55

Grass Defl ector Disassembly ...............................................................................................8-56

Grass Defl ector Assembly ....................................................................................................8-56

Grass Defl ector Installation ..................................................................................................8-58