Page is loading ...

LM OG-AM series

Oval gear meters with MID approved register and integrated

datalogger

LM_OG-AM_BA_02_1163 (May 2019)

User Manual

LM OG-AM

LM OG-TAERM

LM OG-CNDAM

LM OG-AM series

Page II LM_OG-AM_BA_02_1163 May 2019

CONTENT

1. Disclaimer ................................................................................................................................................................................................................................... 1

2. Basic safety recommendations .......................................................................................................................................................................................... 1

3. Before putting into operation ............................................................................................................................................................................................ 2

3.1 Recommended filter sizes ........................................................................................................................................................................................ 3

4. Warranty ...................................................................................................................................................................................................................................... 3

5. Details of unit operation LM OG-AM series ................................................................................................................................................................... 4

5.1 RESET button ................................................................................................................................................................................................................. 4

5.2 Datalogger: A non-volatile memory .................................................................................................................................................................... 4

5.3 Battery ............................................................................................................................................................................................................................. 4

5.4 Interruption of batch process ................................................................................................................................................................................. 4

5.5 Functional control ....................................................................................................................................................................................................... 4

5.6 Totalizer........................................................................................................................................................................................................................... 5

5.7 Monitoring of false pulses for MID conform meters ...................................................................................................................................... 5

5.8 Installation procedure LM OG ................................................................................................................................................................................ 5

6. Programming of LM OG-AM and LM OG-TAERM series ........................................................................................................................................... 6

7. Calculating the correction factor....................................................................................................................................................................................... 7

7.1 Calculation based default settings ....................................................................................................................................................................... 7

7.2 Recalculation of an existing correction factor ................................................................................................................................................. 7

8. Pulse output at register OG-TAERM ................................................................................................................................................................................. 7

9. Browse and program data logger ..................................................................................................................................................................................... 8

9.1 Search for a dispense ................................................................................................................................................................................................. 8

9.2 Programming the datalogger ................................................................................................................................................................................ 9

10. Display correction factor .................................................................................................................................................................................................... 9

11. Checksum & serial number ............................................................................................................................................................................................ 10

12. Status messages ................................................................................................................................................................................................................. 10

13. Changing the Battery ....................................................................................................................................................................................................... 10

14. MID approval ....................................................................................................................................................................................................................... 11

15. Manufacturer declaration ............................................................................................................................................................................................... 11

16. DIN ISO and EMC certificate ........................................................................................................................................................................................... 11

17. Return of goods for repair / Harmlessness declaration....................................................................................................................................... 11

Disclaimer

May 2019 LM_OG-AM_BA_02_1163 Page 1

1. DISCLAIMER

The user/purchaser is expected to read and understand the information provided in this manual, follow any listed safety

precautions and instructions and keep this manual with the equipment for future reference. The information in this manual

has been carefully checked and is believed to be entirely reliable and consistent with the product described. However, no

responsibility is assumed for inaccuracies, nor does Badger Meter assume any liability arising out of the application and use of

the equipment described. Should the equipment be used in a manner not specified by Badger Meter, the protection provided

by the equipment may be impaired and the warranty voided. The meter is conform to the MID regulations for liquids other

than water.

2. BASIC SAFETY RECOMMENDATIONS

Before installing or using this product, please read this instruction manual thoroughly. Only qualified personnel should install

and/or repair this product. If a fault appears, contact your distributor.

Installation

Do not place any unit on an unstable surface that may allow it to fall.

Never place the units above a radiator or heating unit.

Route all cabling away from potential hazards.

Isolate from the mains before removing any covers.

Power connection

Use only the type of power source suitable for electronic equipment. If in doubt, contact your distributor. Ensure that any

power cables are of a sufficiently high current rating. All units must be earthed to eliminate risk of electric shock. Failure to

properly earth a unit may cause damage to that unit or data stored within it.

Protection class

Following devices have protection class IP65:

LM OG-AM

Standard inline meter

LM OG-KAM

Coated standard inline meter

LM OG-CDAM

Pistol meter with handle, sightglas and swivel

LM OG-CNDAM

Pistol meter with handle, sightglas, swivel and outlet

LM OG-TAERM

Inline meter with pulse output

LM OG-TAERKM

Coated inline meter with pulse output

All devices have to be protected against dripping water, water, oils, etc.

Setup & operation

Adjust only those controls that are covered by the operating instructions. Improper adjustment of other controls may result

in damage, incorrect operation or loss of data.

Cleaning

Switch off all units and isolate from mains before cleaning.

Clean using a damp cloth. Do not use liquid or aerosol cleaners.

Before putting into operation

Page 2 LM_OG-AM_BA_02_1163 May 2019

Repair of faults

Disconnect all units from power supply and have it repaired by a qualified service person if any of the following occurs:

WARNING

Failure to adhere to these safety

instructions may result in damage to the

product or serious bodily injury.

RoHs

Our products are RoHs compliant.

Battery disposal

The batteries contained in our products need to be disposed of as per your

local legislation acc. to EU directive 2006/66/EG.

3. BEFORE PUTTING INTO OPERATION

Please check that the technical data of the installation match with those of the lube meter, for example connections, pressure,

flow range and medium. Once the meter has been installed, please make sure that no air, pressure shocks or particles can

damage the meter.

Read the following information and have a thorough understanding before proceeding with meter installation. Only

qualified personnel should perform meter installation.

• Install a strainer or Y or basket as close to the inlet side of the meter as possible. Strainers prevent dirt and other fluid

contaminants from impeding meter performance. Strainers require periodic cleaning, as clogged strainers also impede

meter performance. Contact your local representative for specific information, per your specific application.

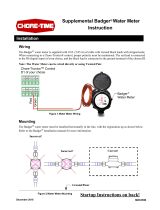

Figure 1: Meter installation

!

Strainer

Strainer

Flow direction

Warranty

May 2019 LM_OG-AM_BA_02_1163 Page 3

• Turn off any associated pumps to reduce line pressure and slowly fill the line and meter with fluid before restarting

pumps. Doing so reduces the possibility of meter damage caused by errant air pressures in the line and meter.

• Make sure all pipe conforms to the same pressure output rating as the pump.

• Make sure to apply thread sealant to all pipe threads.

• Make sure to install the meter as shown in figure 1.

• Check for and repair leaks upon initialization of fluid flow.

3.1 Recommended filter sizes

Filter / Pore size (in mesh)

Filter / Pore size (in mm)

½"

60

0,250

Please check all connections to leakage. After the installation we recommend to perform several transactions into an

approved piston. Should the use of different oil viscosities show discrepancies by the error limit, it can be immediately

corrected at the site. The pretested meters can be calibrated by technicians or the officials of the national authorities (MID).

4. WARRANTY

Badger Meter warrants meters and parts manufactured by it and supplied hereunder to be free from defects in materials and

workmanship for a period of 24 months from date of shipment. If within such period any meters or parts shall be proved to

Seller´s satisfaction to be defective, such meters or parts shall be repaired or replaced at Seller´s option. Seller´s obligation

hereunder shall be limited to such repair and replacement and shall be conditioned upon Seller´s receiving written notice of

any alleged defect within 10 days after its discovery and, at Seller´s option, return of such meters or parts to Seller, f.o.b. its

factory. THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS OR IMPLIED WARRANTIES

WHATSOEVER INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES (EXCEPT OF TITLE) OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE. Badger Meter shall not be liable for any defects attributable to acts or omissions of others after

shipment, nor any consequential, incidental or contingent damage whatsoever.

Details of unit operation LM OG-AM series

Page 4 LM_OG-AM_BA_02_1163 May 2019

5. DETAILS OF UNIT OPERATION LM OG-AM SERIES

5.1 RESET button

The display of the resettable totalizer (batch register) can be put to zero by pushing the RESET button. A RESET is not

possible during a batch process. The RESET of the non-resettable totalizer is only possible in the MID secured area of the

register configuration. Each RESET will save the dispensed quantity in the datalogger, but only if the quantity is equal or

bigger than 0,5 liters.

5.2 Datalogger: A non-volatile memory

The register is fitted with a memory device to store measurement results until their use or to keep a record of commercial

transactions, providing proof in the event of a dispute. Devices used to read stored information are considered as included in

the memory devices. It is not required that the parties interested in a transaction shall be provided continuously with the

results of measurement, but only that they shall have access to these results (for example, in the event of a dispute). In

addition, in the case of self-service (filling station, truck filling station) the owner of the measuring system is considered to

have access to the indications of the measuring system even when he does not use this possibility in practice (OIML R117-1,

Chapter 3.5).

5.3 Battery

As soon as the capacity of the battery is less than 10%, “LBat” is displayed on the electronic

register. The battery should then be replaced within the next two months. The battery is

exchangeable in all meters of the LM OG-AM and OG-TAERM series while opening the cover

on the front of the register. No data are lost, they are securely saved in an EEPROM memory -

except of the date and time. To keep the date and time settings, you have to reinsert the

battery within 30 minutes. See also chapter 13.

5.4 Interruption of batch process

By releasing the meter trigger, the batch process is interrupted. When pulled again, the batch process will be continued at the

very point where it was interrupted, unless the RESET button has been pushed in the meantime. The display will remain

unchanged during the interruption. If the batch process is interrupted by external source – e.g. failure of a transfer pump – the

procedure is the same.

5.5 Functional control

In normal operation, the register board totalizes flow in the lube meter by sensing reed switch actions. The batch display may

be reset to zero by momentarily pressing the RESET button on the front panel. This action will set the batch accumulator to

zero and cause the register to enter a self-test mode. For the self-test, it is necessary that the display is activated with all

numerics set to “8” and all other indicators set to “on” for a period of 0,8 seconds. If flow or reed switch action takes place

during the self-test period, the resultant pulses are processed as normal flow accumulations. This accumulation of flow can

only be reset by pressing the RESET button.

During the self-test period, the meter will compare the double redundant storage of the correction factor, the unit of measure

and direction of rotation. If one of the values do not correspond, the register will show a series of dashes (- - - -) and will

become inoperative.

If flow sensing or reed switch action is present at any time and it is not preceded by a pressing of the RESET button, the flow

accumulations will be added to the value already present in the batch accumulator.

Details of unit operation LM OG-AM series

May 2019 LM_OG-AM_BA_02_1163 Page 5

5.6 Totalizer

The total dispense quantity is shown in the bottom line. The factory programmed correction factor results from accuracy

testing of bare meter with the mounted electronic register: Pressing the TOTAL and the RESET button simultaneously for 3

seconds will show the programmed correction factor.

Resettable totalizer: 999,999 L (over thousand 9999,99 L)

Non resettable totalizer: 99999 L

As soon as volume signals come in, all keyboard commands will be ignored!

As soon as pulses are internally accumulated, the keypad is out of function!

5.7 Monitoring of false pulses for MID conform meters

During measurement, the microprocessor controls the phase position of both reed switches (30° to 150° phase shift).

Errors caused by incorrect phase sequence:

If more than two (2) phase errors are noted after a RESET, the LCD display is flashing (1 second interval). This type of error is

resettable by depressing the RESET button.

If it is not possible to stop the flashing, there is another fault and the register has to be exchanged.

The flashing can e. g. also be caused by a short-time reverse flow when starting up the oil dispense system, or by an

insufficiently areated oil pipe (pressure shocks). This can be prevented by installing an appropriate non-return valve.

FLDIR will indicate a reverse flow, quantity display will change to ---,--

REED will indicate a missing input channel, quantity display will change to ---,--

Errors in stored variables:

(i.e. correction factor, unit of measure, direction of rotation)

These errors are indicated by a series of dashes across the display and are not resettable. The register has to be removed from

service.

5.8 Installation procedure LM OG

The meter series LM OG is equipped with BSP female threads. In order to obtain a leakage-free connection from the meter to

the hose, the hose end must have an appropriate BSP male thread.

We recommend to proceed as follows before screwing in:

1) Clean both threads from fat.

2) Brush the male thread at the hose with liquid sealant (e.g. Eurolock 310100 or equivalent sealing of other manufacturers).

Be careful that no sealing gets into the meter.

3) Screw both parts together. Do not overtighten the screw connection, otherwise the swivel of the meter could be

damaged.

4) The instruction of the sealing manufacturer should be absolutely followed.

5) The meter mounting should only be carried out by authorized specialist staff.

The right selection of the components as well as the mounting in accordance with the regulations is in the responsibility of

the user.

Programming of LM OG-AM and LM OG-TAERM series

Page 6 LM_OG-AM_BA_02_1163 May 2019

6. PROGRAMMING OF LM OG-AM AND LM OG-TAERM SERIES

The units of measure and the correction factor can be configured in the programming mode. A program button on the

backside of the register will enable the mode, only accessible when the register has been removed from the meter. Removing

the register from the meter will break the sealing. This seal has to be restamped by the national authorities (MID).

01

Turn on the register by pressing the

TOTAL button.

07

The fifth number can now be changed.

To move forward, press “TOTAL” again.

02

By pressing the programming button on

the backside of the register you will enter

the programming mode.

08

The arrow for the flow direction flashes

now. Use RESET to change or TOTAL to

move forward.

03

The measuring unit will flash and can be

changed by pressing the RESET button (L,

GAL, QT, PT).

To move forward press the TOTAL button.

09

By pressing the programming button on

the backside of the register you will quit

the programming mode.

03

Press “TOTAL” to change the k-factor. The

number to be changed is flashing and can

be modified with “RESET”.

To change the next number, press

“TOTAL”.

10

The register went into the sleep mode.

04

The second number can now be changed.

To move to the next number, press

“TOTAL” again.

11

To wake up the register, press the RESET

button.

05

The third number can now be changed.

To move to the next number, press

“TOTAL” again.

12

Press „RESET“ for 3 seconds and the

register displays the checksum and serial

number in the bottom line.

06

The fourth number can now be changed.

To move to the next number, press

“TOTAL” again.

Calculating the correction factor

May 2019 LM_OG-AM_BA_02_1163 Page 7

7. CALCULATING THE CORRECTION FACTOR

Two different ways are described below to eliminate the existing deviation of a meter.

The reference quantity (“quantity dispensed”) should always be measured with an appropriate measuring device.

• Approved piston or bell prover

• Approved gravimetric method

7.1 Calculation based default settings

Example:

Quantity dispensed: 5,000 liters

Quantity displayed: 4,990 liters

Correction factor k: 4,990 / 5,000 = 0,9980

7.2 Recalculation of an existing correction factor

Example:

Quantity dispensed: 5,000 liters

Quantity displayed: 5,015 liters

Correction factor k: 5,015 / 5,000 = 1,003

The existing correction factor would be for example: 0,9960

Calculation: 0,9960 x 1,003 = 0,9989

The new correction factor is 0,9989

8. PULSE OUTPUT AT REGISTER OG-TAERM

The pulse output on the LM OG-TAERM register has a rating of 2x100 PPL with a 90°-135° phase-shift. Any irregular use or

malfunction will be indicated on the error channel with permanent signal on high. The correction factor will also correct the

output signal.

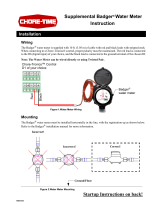

Flow direction - Inlet Top to Bottom Power supply

Output channel 1 = green 6–24 VDC = yellow

Output channel 2 = white (Error channel) GND = brown

Flow direction - Inlet Bottom to Top

Output channel 1 = white (Error channel)

Output channel 2 = green

Wiring only for MDS2000 Management System

Wiring for other Management System

MDS version included a meter detection

Viscosity 440 mPas

Factor k about 1,0000

OUTPUT 1

OUTPUT 2

GREEN

WHITE

GND

BROWN

6-24 VDC

YELLOW

OUTPUT 1

OUTPUT 2

GREEN

WHITE

GND

BROWN

6-24 VDC

YELLOW

Browse and program data logger

Page 8 LM_OG-AM_BA_02_1163 May 2019

9. BROWSE AND PROGRAM DATA LOGGER

Pushing the RESET will automatically save the current dispense in the datalogger, if the quantity is bigger than 0,49 liters. The

datalogger is capable to store 500 dispenses, any additional transaction will overwrite the oldest one without notice.

9.1 Search for a dispense

The sample below shows how to search for a dispense on a certain day. Known is the date and time of the dispense:

18.09.2012 15:46

Result: The dispensed quantity was 12,78 liters.

Pressing the RESET button once will bring you to the next older data entry, no matter if you are on the Date, Time

or Quantity menu level. If you push the RESET twice and hold the button (within 1s), the data will scroll

automatically.

Pressing the RESET for more than 2s will bring you to the next lower menu level.

Pressing the TOTAL button once will bring you to the next newer data entry, no matter if you are on the Date,

Time or Quantity menu level. If you push the TOTAL twice and hold the button (within 1s), the data will scroll

automatically.

Pressing the TOTAL for more than 2s will bring you to the next higher menu level.

Date

Time

Qty

Batch

19.09.12

17:55

2,42

0081

19.09.12

16:23

4,42

0080

etc…

18.09.12

17:23

4,53

0068

18.09.12

17:12

7,24

0067

18.09.12

15:46

12,78

0066

etc…

Sample content data logger

Opens Alibi Memory

5s

5s

Previous day

1x

Next lower level

2s

Next batch

2s

Next batch

1x

Next lower level

2s

Control buttons

Standard display

0.000

L

8793 TOTAL

19.09.12

0081

18.09.12

0068

17.23

0068

17.12

0067

15.46

0066

12.78

L

0066

Level – Date

19.09.2012 Current day

Last batch

Level – Date

18.09.2012 Day before

Batch 0068 = is the latest on this day

Level – Time

Batch 0068

Level – Time

Batch 0067

Level –

Quantity

Batch 0066

Level –

Quantity

Batch 0066

Display correction factor

May 2019 LM_OG-AM_BA_02_1163 Page 9

9.2 Programming the datalogger

Below you will find the procedure to change time and date. The date can only be changed with the program button on the

backside, which is only accessible when the register has been removed from the meter. Removing the register from the meter

will break the sealing. This seal has to be restamped by the national authorities (MID).

The ERASE button removes all the logged dispenses; it does not affect time and date.

NOTE: If no button has been pressed for more than 30 seconds, the register will automatically move back to the standard

display without saving the last entry.

10. DISPLAY CORRECTION FACTOR

To verify the programmed correction factor, press TOTAL and RESET for 2 seconds.

Correction factor

Opens Alibi Memory

5s

5s

Opens Configuration

5s

5s

Move to DATE

register backside

Move to ERASE

2s

Change to YES

1x

Confirm ERASE

register backside

0.000

L

8793 TOTAL

19.09.12

0081

15.32

Zeit

20.09.10

Datum

Nein

Loschen

Ja

Loschen

----

Loschen

Level – Date

19.09.2012 Current day

Last batch

Change the time by using the RESET and

TOTAL to move forward

Change the date by using the RESET

and TOTAL move forward

Use the RESET button to change to

YES

Use the program button to confirm

the ERASE

The ERASE will last for about 45s

Standard display

1.0000

Checksum & serial number

Page 10 LM_OG-AM_BA_02_1163 May 2019

11. CHECKSUM & SERIAL NUMBER

Pressing RESET for 3 seconds will display the checksum and serial number in the bottom line.

12. STATUS MESSAGES

13. CHANGING THE BATTERY

Important – Before starting the replacement:

The battery has to be replaced within 30 minutes, otherwise you will lose the date and time setting. The display would show

"Date" in the bottom which indicates that the date is lost. The quantity display will change to dashes "- - - -". To reconfigure

the date, you would have to remove the register, which is sealed by a MID label.

Please proceed as follows:

Picture 1:

Loosen the battery cover

Picture 2:

Take out the battery

Picture 3:

Insert the new battery and

press the reset button to wake

up the register

Picture 4:

Insert the battery cover, then

screw the battery cover tight

Battery: Lithium CR123A

3A33.07

L

AC001 TOTAL

3A33 = Checksum over the MID relevant source code

07

= Sequential version number, not MID relevant

Checksum

A = The year of production

AC001

= Sequential alphanumeric number

Serial number

0.000

L

Floir TOTAL

Wrong flow direction. Actual flow does not match with the programmed flow direction. FLDIR

flash

es in the bottom line, the quantity will change to dashes. See chapter 6 - step 8:

Programming of

LM OG

-AM and LM OG-TAERM series.

-.---

L

Reed TOTAL

Channel missing due to broken reed switch

REED flashes in the bottom line, the quantity changes

to dashes.

Call service for replacement

.

-.---

L

Datum TOTAL

Lost date due to power fa

ilure, i.e. slow battery exchange.

DATE flash

es in the bottom line, meter will not count anymore until the date has been entered

again. Quantity changes to dashes.

See chapter 13: Changing the battery

MID approval

May 2019 LM_OG-AM_BA_02_1163 Page 11

14. MID APPROVAL

You will find all approvals applying to this meter series under

www.badgermeter.de/en/downloads/approvals/

15. MANUFACTURER DECLARATION

You will find all CE declarations applying to this meter series under

www.badgermeter.de/en/downloads/ce-declarations/

16. DIN ISO AND EMC CERTIFICATE

Please refer to our valid DIN ISO and EMC certificate under

www.badgermeter.de/en/downloads/certificates/

17. RETURN OF GOODS FOR REPAIR / HARMLESSNESS DECLARATION

Please refer to our claims return form/harmlessness declaration under

www.badgermeter.de/en/service/return-of-goods.html

Return of goods for repair / Harmlessness declaration

Page 12 LM_OG-AM_BA_02_1163 May 2019

Return of goods for repair / Harmlessness declaration

May 2019 LM_OG-AM_BA_02_1163 Page 13

www.badgermeter.de

/