Page is loading ...

7

4247530-Rev A 7-1

Chapter 7

Steering

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Checks and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Steering Cable Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Steering Wheel (Manual Steering) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Steering Wheel (Power Steering) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Steering Unit (PN 4196484) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Steering Unit (PN 4136214) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Steering Tower Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Steering Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Steering Fork (Manual Steering) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Steering Fork (Power Steering) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

7-2 4247530-Rev A

STEERING

7

Specifications

Checks and Adjustments Specifications

Steering Cable Deflection in. (mm) 0.500–0.625 (12.7–15.8) with 3–5 lb

(13.3–22.2 N) of pull

Repair Specifications

Steering Wheel Nut Torque lb-ft (N·m) 25–30 (34–41)

Steering Unit (PN 4196484) Special Screws Torque

lb-ft (N·m) 20–24 (27–33)

Steering Unit (PN 4136214) Special Bolt Nut Torque

lb-ft (N·m) 20–24 (27–33)

Steering Unit Hydraulic Hoses Torque

lb-ft (N·m) 25 (34)

Steering Cylinder Ball Joint Center-to-Center Distance

in. (mm) 15.875 ± 0.060 (403 ± 1.5)

Steering Fork Jam Nut (Manual Steering) Torque

lb-ft (N·m) 55 ± 5 (74.5 ± 6.8)

Steering Fork Jam Nut (Power Steering) End Play

in. (mm) 0.001–0.008 (0.025–0.203)

7-4 4247530-Rev A

STEERING

7

Checks and Adjustments

Steering Cable Adjustment

See Figure 7-2.

1. Park the mower safely. (See “Park Mower Safely” on

page 1-6.)

2. Remove front seat skirt. (See “Front Seat Skirt” on

page 9-16.)

3. Remove fuel tank. (See “Fuel Tank (Gasoline)” on

page 9-8.)

Figure 7-2

4. Raise and support rear of machine with jackstands.

5. Position rear steering pulley (2) straight and neutral.

6. Adjust nuts (1) at cable ends until deflection at

midpoint (3) is 0.500–0.625 in. (12.7–15.8 mm) with

3–5 lb (13.3–22.2 N) of pull.

Repair

Steering Wheel (Manual Steering)

Removal and Installation

See Figure 7-3.

1. Park the mower safely. (See “Park Mower Safely” on

page 1-6.)

Figure 7-3

2. Remove nuts (5), lock washers (4), washers (3), and

screws (2).

3. Remove steering wheel (1) from steering column (6).

Installation Notes

• Install steering wheel by reversing the order of

removal.

• Adjust steering wheel angle prior to tightening

hardware.

TN3378

3

1

1

3

2

TN3407

3

1

2

5

4

3

6

STEERING

4247530-Rev A 7-5

7

Steering Wheel (Power Steering)

Removal and Installation

See Figure 7-4.

1. Park the mower safely. (See “Park Mower Safely” on

page 1-6.)

Figure 7-4

2. Remove (unsnap) cap (1) from steering wheel (4).

3. Remove nut (2) and internal-tooth lock washer (3).

4. Remove steering wheel (4) and four washers (5)

from steering column (6).

Installation Notes

• Install steering wheel by reversing the order of

removal.

• Tighten the steering wheel nut (2) to 25–30 lb-ft (34–

41 N·m).

Steering Unit (PN 4196484)

Removal and Installation

See Figures 7-5 and 7-6.

1. Park the mower safely. (See “Park Mower Safely” on

page 1-6.)

2. Remove steering wheel. (See “Steering Wheel

(Power Steering)” on page 7-5.)

3. Remove steering tower cover. (See “Steering Tower

Cover” on page 7-21.)

Figure 7-5

4. Remove four screws (2) and lock washers (3), and

remove steering column (1) from steering unit (4).

TN2969

TN2969

3

2

6

1

4

5

TN3780

1

2 3

4

7-6 4247530-Rev A

STEERING

7

Figure 7-6

NOTES

• Label all hydraulic hoses and record their locations to

ensure correct installation.

• Plug hydraulic hoses after disconnecting to prevent

loss of hydraulic oil.

5. Disconnect hydraulic hose (5) from steering unit port

“L.”

6. Disconnect hydraulic hose (6) from steering unit port

“R.”

7. Disconnect hydraulic hose (7) from steering unit port

“T.”

• Disconnect hydraulic hose (8) from steering unit port

“P.”

8. Remove steering unit (4).

Installation Notes

• Install steering unit by reversing the order of removal.

• Tighten hydraulic hoses to 25 lb-ft (34 N·m).

• Check hydraulic oil level. Add oil as needed.

• Start the machine and check for hydraulic leaks and

cylinder operation. Repair as necessary.

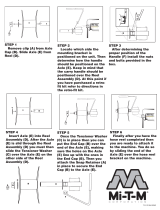

Steering Unit (PN 4196484) Service Fixture

See Figures 7-7 and 7-8.

Figure 7-7: Steering Unit Service Fixture

NOTICE

E

TN2148

8

5

6

7

Required Tools or Equipment

Steering Unit Service Fixture

1 0.165 in. (4.2 mm) 6 2.0 in. (50.8 mm)

2 0.250 in. (6.35 mm) Ø Hole (4) 7 4.0 in. (101.5 mm)

3 2.280 in. (58.0 mm) Ø 8 1.5 in. (38.1 mm) Ø Hole

48.0 in. (202 mm) 945° (4)

5 2.0 in. (50.8 mm)

Do not clamp the steering unit directly into a vise.

Clamping the steering unit directly into a vise

may damage or distort the steering unit.

TN2142

1

5

3

2

6

7

8

4

9

STEERING

4247530-Rev A 7-7

7

Figure 7-8

1. Place the steering unit service fixture (11) securely in

a vise.

2. Place the steering unit (10) into the service fixture

(11), input shaft down.

3. Secure the steering unit to the service fixture using

four M6-1 x 20 mm screws and M6 lock washers (12

and 13).

TN2143

TN2143

10

11

1312

7-8 4247530-Rev A

STEERING

7

Disassembly

See Figures 7-9 and 7-10.

Figure 7-9

1 Special Screw (4) 8 Gearwheel Rim 15 Spring Retaining Ring 22 Ball Stop

2 Special Screw (1) 9 Distributor Plate 16 Spool 23 Emergency Steering Ball

3 O-Ring (5) 10 Cardan Shaft 17 Thick Bearing Race 24 Housing

4 End Cover 11 O-Ring 18 Bearing 25 Name Plate

5 Spacer 12 Sleeve 19 Thin Bearing Race 26 Steering Relief Valve

6 O-Ring (2) 13 Cross Pin 20 Shaft Seal 27 Steering Relief Valve Spring

7 Gearwheel 14 Spring Set 21 Check Valve Ball

R

L

P

T

TN4344

1

3

4

5

6

8

6

9

10

11

12

13

14

15

16

17

18

23

20

21

22

24

25

26

27

7

19

2

STEERING

4247530-Rev A 7-9

7

!

CAUTION

NOTES

• Before attempting repairs or disassembly of any

hydraulic components, thoroughly clean the

components and work area. A clean work area is

essential to satisfactory operation of repaired

hydraulic components.

• Utilize steering unit service fixture for disassembly.

(See “Steering Unit (PN 4196484) Service Fixture”

on page 7-6.)

1. Scribe a line from port “P” to bottom of steering unit.

This line can be used to determine port “P” with end

cover removed and for proper orientation of sections

for assembly.

2. Remove four special screws (1), one special screw

(2), and five O-rings (3).

3. Remove end cover (4) by sliding it off to the side.

4. Remove cardan shaft spacer (5).

5. Hold a hand under the gearwheel rim (8) and

gearwheel (7) to keep the gearwheel from falling out,

and remove the gearwheel rim (8), gearwheel (7),

and two O-rings (6).

6. Remove cardan shaft (10).

7. Remove distributor plate (9).

8. Remove O-ring (11) from housing (24).

9. Remove spool assembly.

10. Remove thin bearing race (19), bearing (18), and

thick bearing race (17).

11. Remove shaft seal (20).

12. Remove spring retaining ring (15).

13. Carefully press cross pin (13) out of the spool (16)

and sleeve (12), and remove spool from sleeve.

14. Press spring set (14) out of spool (16).

15. Remove fixture from vise and shake out check valve

ball (21), emergency steering ball (23), and ball stop

(22). Re-secure service fixture in vise with input shaft

down.

16. Remove housing (24) from service fixture.

17. Remove steering relief valve (26) and steering relief

valve spring (27).

Figure 7-10

Wear eye protection when assembling and

disassembling the steering unit. Springs and

other objects may be propelled into the air,

causing eye injury.

R

L

P

T

TN4345

1

Steps 1-3

Scribe line

aligned with

port “P.”

Steps 4-5

Steps 6-8 Steps 9-11

Steps 12-14 Step 15

Step 17

Spool

Assembly

Included in Seal Kit

3

4

5

7

8

6

10

9

11

24

17

18

19

20

24

13

16

12

15

14

21

22

23

24

26

27

24

2

7-10 4247530-Rev A

STEERING

7

Assembly

See Figures 7-11 through 7-13.

Figure 7-11

1 Special Screw (4) 8 Gearwheel Rim 15 Spring Retaining Ring 22 Ball Stop

2 Special Screw (1) 9 Distributor Plate 16 Spool 23 Emergency Steering Ball

3 O-Ring (5) 10 Cardan Shaft 17 Thick Bearing Race 24 Housing

4 End Cover 11 O-Ring 18 Bearing 25 Name Plate

5 Spacer 12 Sleeve 19 Thin Bearing Race 26 Steering Relief Valve

6 O-Ring (2) 13 Cross Pin 20 Shaft Seal 27 Steering Relief Valve Spring

7 Gearwheel 14 Spring Set 21 Check Valve Ball

R

L

P

T

TN4344

1

3

4

5

6

8

6

9

10

11

12

13

14

15

16

17

18

23

20

21

22

24

25

26

27

7

19

2

STEERING

4247530-Rev A 7-11

7

!

CAUTION

NOTES

• Inspect all parts for wear or damage and replace as

necessary.

• Lubricate all parts with clean hydraulic oil before

assembly.

• Always install new O-rings for assembly; used parts

may leak.

• Utilize steering unit service fixture for assembly. (See

“Steering Unit (PN 4196484) Service Fixture” on

page 7-6.)

• Letter references (A-C) refer to components of Sauer

Danfoss Shaft Seal Tool.

1. Assemble relief valve (26 and 27) to housing (24).

Use new check valve o-ring included in seal kit.

2. Assemble shaft seal (20) onto guide (A).

3. Insert outer sleeve (B) into housing (24).

4. Place guide (A) on end of guide tool (C). Lubricate

shaft seal and O-ring.

5. Slide guide tool (C) into outer sleeve (B) and press

shaft seal into position. Remove outer sleeve and

guide tool. Guide (A) should remain inside housing

after seal is installed.

6. Install thin bearing race (19), bearing (18), and thick

bearing race (17) into housing (24).

7. Slide spool (16) into sleeve (12) and align so that

cross pin slots are adjacent to each other.

8. Center the spring set (14) in the spool and sleeve

assembly, and install spring retaining ring (15).

NOTES

• When installing spring set, insert the curved springs

between the flat springs and push in place.

• Spring retaining ring (15) must be able to rotate

unimpeded by the springs.

9. Press cross pin (13) in the spool and sleeve

assembly.

10. While holding the cross pin in place, guide the spool

and sleeve assembly into housing (23). When

installed, cross pin (12) must point towards port “P.”

Spool will push seal guide (A) out of housing as it is

installed.

Figure 7-12

Wear eye protection when assembling and

disassembling the steering unit. Springs and

other objects may be propelled into the air,

causing eye injury.

Required Tools and Materials

Seal Kit (Jacobsen PN 4197940)

Shaft Seal Tool (Sauer Danfoss SJ150L4011-01)

TN4341

Step 1

Included in Seal Kit

Step 2

Steps 3-5

Step 6 Steps 7-9

Step 10

26

27

24

20

A

A

B

C

24

17

18

19

24

12

13

16

14

15

24

Spool

Assembly

Cross

Pin

L

R

P

T

E

7-12 4247530-Rev A

STEERING

7

11. Place emergency steering ball (23) in port “P.”

12. Place ball stop (22) in port “P.”

13. Place check valve ball (21) in port “P.”

14. Install O-ring (11) in housing (24).

15. Place distributor plate (9) on housing (24) and align

scribe line and mounting holes.

16. Assemble cardan shaft (10) to spool (16) ensuring

cardan shaft engages with cross pin (13).

17. Place gearwheel (7) over the distributor plate (9).

NOTE

See step 16 in Figure 7-13. When installing the

gearwheel, the gearwheel must be correctly aligned so

that it engages with the cardan shaft. The cross pin (13)

in the spool assembly must line up with the bottom of the

spline in the gearwheel (7).

18. Install O-rings (6) into groove on each side of the

gearwheel rim.

19. Place gearwheel rim (8) over the distributor plate (9)

and gearwheel (7). Align scribe line and mounting

holes.

20. Install spacer (5) over the cardan shaft (10).

NOTES

• Place end cover so that the hole marked “P” lines up

with port “P” in the housing.

• Special screw (2) (with no oil flow connection) must

be fitted in port “E.”

21. Using scribe line, align end cover (4) to housing (24).

Install special screws (1) with O-rings (3) into ports

“T,” “P,” “L,” and “R.” Install special screw (2) with

O-ring (3) into port “E.” Tighten screws in an

alternating pattern to 20–24 lb-ft (27–33 N·m).

22. Remove the steering unit from the service fixture.

23. Assemble steering unit into mower.

NOTE

Do not tighten steering column mounting hardware until

steering relief pressure has been set. Column must be

removed when adjusting relief valve.

24. Set steering unit relief pressure. (See “Steering

Relief Valve Adjustment” on page 6-52.)

!

WARNING

Figure 7-13

Keep hands and arms clear of steering wheel on

initial startup of engine. Steering unit can

become a hydraulic motor if step 17 is not

correctly performed.

R

L

P

T

TN4342

21

22

23

24

Steps 11-13 Steps 14-16

Step 16

Steps 17-20 Step 21

10

9

11

24

5

6

7

9

Cross

Pin

Spline

Bottoms

8

1

3

4

Scribe line

aligned with

port “P.”

Included in Seal Kit

L

P

R

E

T

Port

“P”

2

STEERING

4247530-Rev A 7-13

7

Steering Unit (PN 4136214)

Removal and Installation

See Figures 7-14 and 7-15.

1. Park the mower safely. (See “Park Mower Safely” on

page 1-6.)

2. Remove steering wheel. (See “Steering Wheel

(Power Steering)” on page 7-5.)

3. Remove steering tower cover. (See “Steering Tower

Cover” on page 7-21.)

Figure 7-14

NOTES

• Label all hydraulic hoses and record their locations to

ensure correct installation.

• Plug hydraulic hoses after disconnecting to prevent

loss of hydraulic oil.

4. Disconnect hydraulic hose (1) from steering unit port

“In.”

5. Disconnect hydraulic hose (2) from steering unit port

“RT.”

6. Disconnect hydraulic hose (3) from steering unit port

“LT.”

7. Disconnect hydraulic hose (4) from steering unit port

“Out.”

Figure 7-15

8. Support the steering unit (7).

9. Remove four lock nuts (5) and flat washers (8).

10. Remove steering unit (7) from bracket (6).

Installation Notes

• Install steering unit by reversing the order of removal.

• Tighten hydraulic hoses to 25 lb-ft (34 N·m).

• Check hydraulic oil level. Add oil as needed.

• Start the machine and check for hydraulic leaks and

cylinder operation. Repair as necessary.

TN1389A

3

4

1

2

5

6

7

8

7-14 4247530-Rev A

STEERING

7

Steering Unit (PN 4136214) Service Fixture

See Figures 7-16 and 7-17.

Figure 7-16

NOTICE

Figure 7-17

1. Place the steering unit service fixture (2) securely in

a vise.

2. Place the steering unit (1) into the service fixture (2),

input shaft down.

3. Secure the steering unit to the service fixture using

four nuts (3).

IMPORTANT

Scribe a line from the top to the bottom of the

steering unit assembly, not including the steering

tube. Use the scribed line for reference when

assembling the valve sections.

Required Tools or Equipment

Steering Unit Service Fixture

Do not clamp the steering unit assembly directly

into a vise. Clamping the steering unit directly

into a vise may damage or distort the steering

unit.

TN1435

TN1437

3

1

2

STEERING

4247530-Rev A 7-15

7

Disassembly

See Figure 7-18.

Figure 7-18

1Nut

2Port Cover

3 Relief Valve Assembly

4 Seal Ring

5 Ball 9/32 inch

6O-Ring (4)

7Port Manifold

8Alignment Pin

9Spring

10 Seal Ring

11 Valve Ring (Matched Set)

12 Valve Plate (Matched Set)

13 Spring

14 Seal Ring

15 Hex Drive Assembly

16 Isolation Manifold

17 Alignment Pin

18 Drive Link

19 Seal Ring

20 Metering Ring

21 Seal Ring

22 Socket Head Cap Screw (11)

23 Commutator Seal

24 Commutator Cover

25 Commutator Ring

26 Commutator

27 Alignment Pin

28 Drive Link Spacer

29 Rotor

30 Stator

31 Drive Plate

32 Spacer

33 Thrust Bearing

34 Face Seal

35 Seal Spacer

36 Upper Cover Plate

37 Retaining Ring

38 Steering Shaft

39 Steering Tube

40 Bearing

41 Seal

42 Shaft Nut

43 Special Bolt

3

1

11

10

9

8

7

6

5

4

2

17

16

15

14

13

12

29

28

27

26

25

24

23

22

21

20

19

18

33

32

31

30

36

34

35

37

38

39

40

41

42

43

TN1428

7-16 4247530-Rev A

STEERING

7

!

CAUTION

NOTE

Before attempting repairs or disassembly of any

hydraulic components, thoroughly clean the components

and work area. A clean work area is essential to

satisfactory operation of repaired hydraulic components.

1. Remove nuts (1) and port cover (2).

2. Remove relief valve (3) from the port cover (2).

3. Carefully remove the port manifold (7). Be prepared

to catch the three springs (9). Remove the springs.

4. Remove the valve ring (11), valve plate springs (13),

and valve plate (12).

5. Remove the hex drive (15) and isolation manifold

(16).

NOTE

Secure the alignments pins (17) to prevent loss.

6. Remove the drive link (18) and metering ring (20).

7. Remove the metering package (24–31) and

commutator seal (23). The metering package is

serviced as an assembly kit. Refer to the Parts &

Maintenance Manual.

NOTE

The metering package should be disassembled for

inspection purposes only. Proceed with step 8 for

disassembly and inspection procedures. If you are not

disassembling the metering package, proceed to step 11.

8. Remove the socket head cap screws (22),

commutator cover (24), commutator ring (25), and

commutator (26).

9. Remove the five alignment pins (27).

10. Remove the drive link spacer (28), rotor (29), and

stator (30) from the drive plate (31).

11. Remove the face seal (34) and seal spacer (35).

12. Remove the thrust bearing (33) and spacer (32).

13. Remove the upper cover plate (36) and retaining ring

(37).

14. Remove the special bolts (43).

15. Remove the steering shaft (38) out of tube (39).

16. Remove the bearing (40) and seal (41).

Wear eye protection when assembling and

disassembling the steering unit. Springs and

other objects may be propelled into the air

causing eye injury.

STEERING

4247530-Rev A 7-17

7

Inspection

See Figures 7-19 and 7-20.

Figure 7-19

1Nut

2Port Cover

3 Relief Valve Assembly

4 Seal Ring

5 Ball 9/32 inch

6 O-Ring (4)

7 Port Manifold

8 Alignment Pin

9Spring

10 Seal Ring

11 Valve Ring (Matched Set)

12 Valve Plate (Matched Set)

13 Spring

14 Seal Ring

15 Hex Drive Assembly

16 Isolation Manifold

17 Alignment Pin

18 Drive Link

19 Seal Ring

20 Metering Ring

21 Seal Ring

22 Socket Head Cap Screw (11)

23 Commutator Seal

24 Commutator Cover

25 Commutator Ring

26 Commutator

27 Alignment Pin

28 Drive Link Spacer

29 Rotor

30 Stator

31 Drive Plate

32 Spacer

33 Thrust Bearing

34 Face Seal

35 Seal Spacer

36 Upper Cover Plate

37 Retaining Ring

38 Steering Shaft

39 Steering Tube

40 Bearing

41 Seal

42 Shaft Nut

43 Special Bolt

TN1428

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

12

13

14

15

16

17

3

18

19

20

21

22

23

24

25

26

27

6

7

8

9

10

11

1

2

4

5

7-18 4247530-Rev A

STEERING

7

IMPORTANT

Always replace springs as a set.

1. Inspect the springs (9 and 13) for bent, broken, or

distorted coils.

2. Inspect the finished ground surfaces of all the

components.

3. Inspect the slot edges and surface for nicks, scoring,

and rounding edges.

NOTE

The valve ring (11) and valve plate (12) are a matched

set and are not serviceable.

4. Inspect the hex drive (15) for wear.

5. Inspect the isolation manifold (16) for nicks,

scratches, and scoring. A polished wear pattern due

to valve plate rotation is normal.

6. Inspect the drive link (18) for wear and damage.

7. Inspect the thrust bearing (33) for dents, spalling,

and missing rollers.

8. Discard all seals and seal rings.

9. Inspect the commutator cover (24) and drive plate

(31) for wear and damage. A polished wear pattern is

normal.

Figure 7-20

10. Inspect the rotor (45) and stator (46) fit for wear and

damage.

11. Install rotor in stator and center the rotor lobe (47)

across from a lobe to be measured (44). Measure

rotor (45) and stator (46) fit for maximum trip

clearance of 0.003 in. (0.08 mm).

Assembly

See Figures 7-21 through 7-24.

45

46

44

47

TN3850

Service Part Kits

Seal Kit (Jacobsen P/N 557738)

Metering Assembly Kit (Jacobsen P/N 5003220)

Spring Kit (Jacobsen P/N 502924)

Jacket Tube Kit (Jacobsen P/N 5003219)

Needle Roller Kit (Jacobsen P/N 502925)

STEERING

4247530-Rev A 7-19

7

Figure 7-21

NOTE

In the following assembly steps, it is important to align

the components for proper operation of the steering unit.

Use the scribed line for reference when assembling the

valve sections.

1. Install a new bearing (32) and seal (33) in the

steering tube (31). Crimp the tube end in two places,

90° apart.

2. Place the steering tube (31) and special bolts (28) in

the service fixture.

3. Install the retaining ring (29) on the steering shaft

(30) and install into steering tube (31).

4. Install the upper cover plate (27).

5. Assemble the seal spacer (26) and face seal (25).

6. Grease the upper cover plate (27) and install the

assembled seal, backup ring, and seal spacer.

1 Nut 10 Spring (3) 19 Metering Ring 27 Upper Cover Plate

2 Port Cover 11 Valve Plate (Matched Set) 20 Seal Ring 28 Special Bolt

3 Relief Valve Assembly 12 Seal Ring 21 Commutator Seal 29 Retaining Ring

4 O- Ring (4) 13 Hex Drive Assembly 22 Metering Package 30 Steering Shaft

5 Seal Ring 14 Alignment Pin 23 Spacer 31 Steering Tube

6 Port Manifold 15 Isolation Manifold 24 Thrust Bearing 32 Bearing

7 Spring (3) 16 Alignment Pin 25 Face Seal 33 Seal

8 Seal Ring 17 Seal Ring 26 Seal Spacer 34 Shaft Nut

9 Valve Ring (Matched Set) 18 Drive Link

TN1439

16

8

7

6

5

3

2

1

21

22

23

24

25

26

27

28

29

30

31

32

33

34

10

12

11

9

14

13

15

17

18

19

20

4

7-20 4247530-Rev A

STEERING

7

NOTE

If the metering package was disassembled, proceed with

step 7. If the metering package was not disassembled or

a new one is being installed, proceed with step 19.

Figure 7-22

7. Place the drive plate (52) on a flat lint, free surface.

8. Place the stator (51) on the drive plate (52) and insert

the rotor (50) into the stator.

9. Apply a small amount of grease to the drive link

spacer (49) and install in the rotor (50).

10. Place the commutator (47) on top of the rotor (50)

with the aligning pin holes facing up. Place a few

drops of oil in each recess of the commutator (47).

NOTE

Make sure the pins (48) are pressed below the surface of

the commutator (47).

11. Align the five pin holes in the commutator (47) with

the holes in the rotor (50) and install the five pins

(48).

12. Install the commutator ring (46) and commutator

cover (45), flat surface down with ring screw

recesses, stator screw slots, and cover screw holes

aligned. Install the 11 socket head cap screws (44).

NOTE

Do not tighten the cap screws.

13. Place the metering ring (19) on a hard flat, surface.

14. Place the assembled metering package in the center

of the metering ring (19) with the commutator cover

down.

15. Place a 0.007 in. (0.18 mm) shim stock, 0.5 in. (13

mm) wide by 1.5 in. (38 mm) long, in three places,

equal distance apart, between the metering ring and

metering package.

Figure 7-23: Metering Package Torque Sequence

16. Tighten the capscrews (44) twice in sequence to

11–13 lb-in. (1.2–1.5 N·m).

17. Remove the metering package and shims. Place the

drive link (18) large tang into the rotor. Turn the

metering package by hand to make sure there is no

binding.

NOTE

The metering package should rotate inside the stator. If

binding occurs, disassemble the metering package,

correct the cause, and repeat the assembly process.

18. Place the metering ring (19) on top of the upper

cover plate (27) with the alignment pin holes up.

19. Lubricate and install the thrust bearing spacer (23)

and thrust bearing (24) into the metering ring (19).

20. Place the metering package (22) into the metering

ring (19), engaging the drive slot with the steering

shaft.

21. Install the commutator seal (21), seal ring (20), and

drive link (18).

22. Place the isolation manifold (15) on the metering ring

(19) with the alignment pin holes up. Install the

alignment pins (16) into the metering ring (19).

23. Install alignment pins (14) into the isolation manifold

(15).

24. Install the three springs (10) into the isolation

manifold (15) and install the valve ring (9).

44

45

46

47

48

49

50

51

52

TN1391

TN1438

1/108