1

1071288-AN2-F 09/03/12

IMPORTANT

INSTALLER: THIS MANUAL IS THE PROPERTY OF THE

CUSTOMER AND MUST BE RETAINED WITH THE PRODUCT

FOR MAINTENANCE AND OPERATIONAL PURPOSES.

Installation and User Guide

Watertile Rainshower

MODEL NUMBERS

Important! Please quote the above model number(s) when ordering spares

8030A

2

1071288-AN2-F 09/03/12

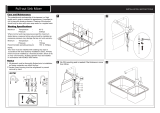

DIMENSIONS

1/2" NPT

79 mm

Min Clearance

Center of

Water Inlet

251 mm

67 mm

60 mm

217 mm

127 mm

All information is based on the latest product information available at the time

of publication. Kohler Co. reserves the right to make changes in product

characteristics, packaging, or availability at any time without notice.

Please leave these instructions for the consumer.

NOTES:

1. Flush the water supply pipes thoroughly to remove any debris.

2. An in line water filter must be used with this product.

3. Inspect the supply pipes for damage. Replace as necessary.

4. Observe local plumbing codes.

5. The recommended working pressure for the shower head is 150KPa to

500KPa. If the pressure exceeds 500KPa a pressure reducer is required.

6. Maximum water and environmental temperature for the shower head is

60C. Note: If a heater is present, make sure to keep it away from the shower

head as otherwise the environmental temperature may exceed 60C.

7. All installations should comply with the relevant requirements of AS/NZS

3500 and AS/NZS 6400.

BEFORE YOU BEGIN

3

1071288-AN2-F 09/03/12

INSTALLATION

SPECIFICATION

Before you Begin

1. Turn off the water supply.

2. Make sure that the Watertile Rainshower is installed by a competent installer.

3. Before installation carefully inspect the new fixture for any signs of damage.

4. Kohler Co. reserves the right to make revisions in the design of products without

notice.

Pressures

The minimum recommended operating pressure is 1.5 bar.

For multiple outlets an operating pressure of 3.0 bar or greater is recommended to

ensure optimum performance.

Plumbing Connections

Mixed water from a valve must be connected to the inlet of a pressure balance

loop.

Building in Depth

Note! Minimum building in depth is 79 mm. It is recommended that a minimum stud

wall cavity of 100 mm is provided to ease installation.

4

1071288-AN2-F 09/03/12

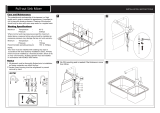

Install the Supply Pipework - Single Supply

1. Install the water supply pipes.

2. Use the soldering template to construct a pressure balancing loop, this will

ensure correct alignment with the product.

Note! The loop pack is made from stronger pipe to give the pipework rigidity.

It is not standard copper pipe.

3. Assemble the pressure balancing loop with a tee positioned over each of the

four raised locations on the soldering template.

4. If necessary, make each G½” tee fit snug to the soldering template by slightly

bending one tab on the template outward. Bend the same tab at each tee

position.

5. Repeat with the same relative tab on the remaining three nipple locations.

Note! The face of the G½” nipple must fit flush to the surface of the template.

6. Solder the assembly whilst it is still attached to the soldering template.

7. Remove the pressure balancing loop from the soldering template.

8. After allowing the pressure balancing loop to cool, assemble the G 1/2” male

thread adapter with flow control to the loop.

9. Connect the pressure balancing loop to the water supply.

10. Temporarily install a nipple to each tee. Do not use any sealant.

G1/2" Nipple

127 mm

127 mm

Soldering Template

Pressure

Balancing Loop

Pressure

Balancing Loop

Soldering

Template

G1/2" Male Thread

Adapter with Flow

Control

5

1071288-AN2-F 09/03/12

Install the Support Framework

1. Construct the support framework as shown in the above diagram.

The 2 x 2 should be offset 30 mm from the edges of the 2 x 4’s to support the

pressure balancing assembly at the correct depth.

2. Install the support framework under the pressure balancing loop(s) as

illustrated.

The face of the 2x4’s should be installed flush with the face of the existing

ceiling joists.

Install the Finished Ceiling

1. Install the water-resistant board.

2. Cut out a 229 mm to 235 mm square at the desired installation location.

3. Install the finished ceiling material.

30 mm

Existing

Ceiling

Joist

Existing

Ceiling

Joist

2 x 2

(50 mm x 50 mm)

2 x 4

(50 mm x 100 mm)

2 x 4

50 mm x 100 mm)

368 mm

Typical

Pressure

Balancing

Loop

Existing

Ceiling Joist

2 x 4

(50 mm x 100 mm)

2 x 4

(50 mm x 100 mm)

229mm

2 x 2

(50 mm x 50 mm)

Finished

Ceiling

229 mm -

235 mm

229 mm -

235 mm

57 mm Min

Cutout

Finished Ceiling

Tee

Tee

Nipple

Cutout

229 mm -

235 mm

6

1071288-AN2-F 09/03/12

Install the Waterway

1. Insert the concealing plate into the opening. The double ribs of the leak shields

should be facing up.

2. If any of the leak shields make contact with an elbow, make sure

that you enlarge the hole in the back of the leak shield t o

32 mm.

Install the Pipe Nipples

1. Remove the pipe nipples.

Note! The minimum distance between the face of the tees/elbows and the

surface of the finished ceiling should be 57 mm. The measurement for typical

installations is 70 mm.

2. Measure the distance from the face of the tees/elbows to the surface of the

finished ceiling. Make any adjustments as needed.

3. Install the nipples into the tee/elbows hand tight.

4. Measure the distance form the end of the nipples to the surface of the finished

ceiling. Make sure that the distance is at least 38 mm and no more than

44 mm.

5. If necessary, cut the G½” pipe nipples to length. Debur the ends.

6. Remove the nipples.

7. Apply thread sealant to the ends of the nipples and re-install the nipples to the

tees/elbows.

8. Run water through the system to flush out any dirt or debris.

Waterway

Screw

Leak Shield

Concealing

Plate

Adapter

Extension

Socket Wrench

With Bit

7

1071288-AN2-F 09/03/12

3. Install the adapter onto one of the nipples using the 11 mm bit (supplied), 11

mm or 7/16” socket, the extension and the socket wrench.

Note! Use masking tape to hold the bit in place, as the bit could fall off and

cause damage.

Important! The concealing plate should sit loosely at this point. If it is tight

against the ceiling, use a longer pipe nipple.

4. Align the groove in the waterway with the double ribs on the leak shield.

5. Press the waterway into place over the adapter. Secure the waterway to the

adapter with the screw.

6. Make sure that the concealing plate does not turn or move.

Important! If the concealing plate is still loose after this step, then use a shorter

pipe nipple.

7. Repeat the procedure for the remaining waterways.

Ribs

Hex Screws

Groove

Waterway

Sprayhead

Nozzle Membrane

Install the Trim

Install the Sprayhead

1. With the ribs of the sprayhead facing upwards, attach the sprayhead to the

waterway.

2. Using a 3/16” hexagonal wrench, install the hexagonal screws to secure the

sprayhead in position. Do not overtighten.

3. Check the sprayhead for upward and downward movement and make sure

that it sits squarely within the concealing plate.

4. Place the nozzle membrane over the sprayhead.

5. Align the long edge of the membrane with the hinge ribs (horizontal).

Note! For optimum performance, make sure that the membrane is applied

evenly.

8

1071288-AN2-F 09/03/12

6. Applying pressure evenly, press the membrane seal into the sprayhead

groove.

Install the Sprayface

1. Tilt the sprayhead downward so that the ribs on the top of the sprayhead are

exposed.

Note! For product with brushed finishes, align the brush pattern of the sprayfaces

with the direction of the brushed pattern of the concealing plate.

2. Insert the grooves of the sprayface over the ribs of the sprayhead.

3. Press the sprayface down to cover the sprayhead, as illustrated.

4. Using a 5/64” hexagonal wrench, turn the setscrews anti-clockwise until they

are flush with the edge of the sprayface frame.

Important! The setscrews must be flush with the edge of the sprayface frame.

If the setscrews protrude outside the sprayface frame, product damage will

occur.

5. Repeat for the remaining sprayfaces.

Setscrews

Sprayface

Ribs

Finished Ceiling

9

1071288-AN2-F 09/03/12

SPARE PARTS

1051681

Screen Washer

1036043

Shield

Template

1055233

Adapter

1059024**

Escutcheon

1055988

Gasket

1044060

O-Ring

**Finish/color code must be specified when ordering.

1044058

O-Ring

1044059

O-Ring

1045772

Elbow

1047041

Washer

1059514

Screw

1036040

Spacer

1056104

Spring Washer

1036038

Screw

1041362

Wire

1045773

Base

(Includes

Clamps)

1054349

1071652

11 mm

Hex Bit

1051498

Nipple G1/2”

1056179

3/16” Wrench

1032955

5/64” Wrench

Setscrew

1039745

Setscrew

1039745

1051487

Nozzle

1045769

Sprayhead

1051682

Nozzle

1036041**

Spray Face

1041573**

Spray Face

1045768

Sprayhead

1036044

Clamp

1036044

Clamp

10

1071288-AN2-F 09/03/12

1097221

Flow Control

1097222

Adapter

1080649

Kit - Pressure Balance Loop

Like anything of lasting quality, Kohler tapware and fittings require a certain amount of periodic care to

preserve their lustrous finish. Clean your new Kohler tapware and fittings with a mild soap, rinse thoroughly

with warm water and dry with a clean, soft cloth. The ideal cleaning technique is to always blot dry any

water from metal surfaces.

Allowing water to evaporate on metal will form water deposits. It is important to use a dabbing action to

dry metal, not an abrasive or rubbing action.

Never use cleaners containing abrasive cleansers, ammonia, bleach, acids, or chemicals that can damage

the finish. By taking the time to dry your tapware often, soap and water deposits can be prevented.

Failure to comply with these cleaning instructions may void Kohler’s warranty obligations.

CARE AND CLEANING

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

Kohler 8030A User manual

- Type

- User manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Kohler 8022A User manual

-

Kohler 8002A User manual

-

Kohler 10743A-CP User manual

-

Kohler K-98741-K1-BV Installation guide

-

Kohler K-98740-BN Installation guide

-

Kohler K-8002-CP Installation guide

-

Kohler K-8002-BGD Installation guide

-

Kohler K-8022 Installation guide

-

Kohler K-8014-TT Installation guide

-

Kohler K-6227A User manual

Other documents

-

WaterWay Suction Load Washer User guide

WaterWay Suction Load Washer User guide

-

Kado 9507740 Installation guide

-

Kado 9507741 Installation guide

-

Kado 9507543 Installation guide

-

Balboa Freedom Series Conversion Kit Installation guide

-

Moen 21999 User guide

-

T & S Brass & Bronze Works B-24K Datasheet

T & S Brass & Bronze Works B-24K Datasheet

-

Gareth Ashton 3K6 Installation guide

Gareth Ashton 3K6 Installation guide

-

GREENS OAKLEY Installation guide

-

Signature Hardware 415362 Installation guide