- 46 -

3. INTRODUCTION

CAUTION!

All warranty undertakings of supplier cease to apply if customer attempts to rectify any faults on

machine during warranty period.

NOTE. Supplier reserves right to make changes within the unit without further notice.

3.1 GENERAL

LPH 50 is compact, self-contained plasma cutting system. As shipped, it’s fully assembled and ready to

operate after being installed. The set consists of LPH 50 power source and heavy duty PT 27 torch, and is

capable of severing materials up to 15 mm thick.

! WARNING !

Use only ESAB Plasmarc torches that are appropriated for use with this power source. Use of other

type of torch may cause ELECTRIC SHOCK HAZARD. Do not use any other torch for use with LPH

50.

3.2 SCOPE OF MANUAL

Purpose of this manual is to provide the operator all information necessary to install and operate LPH 50 set.

Technical reference materials are enclosed, to help with possible troubleshooting.

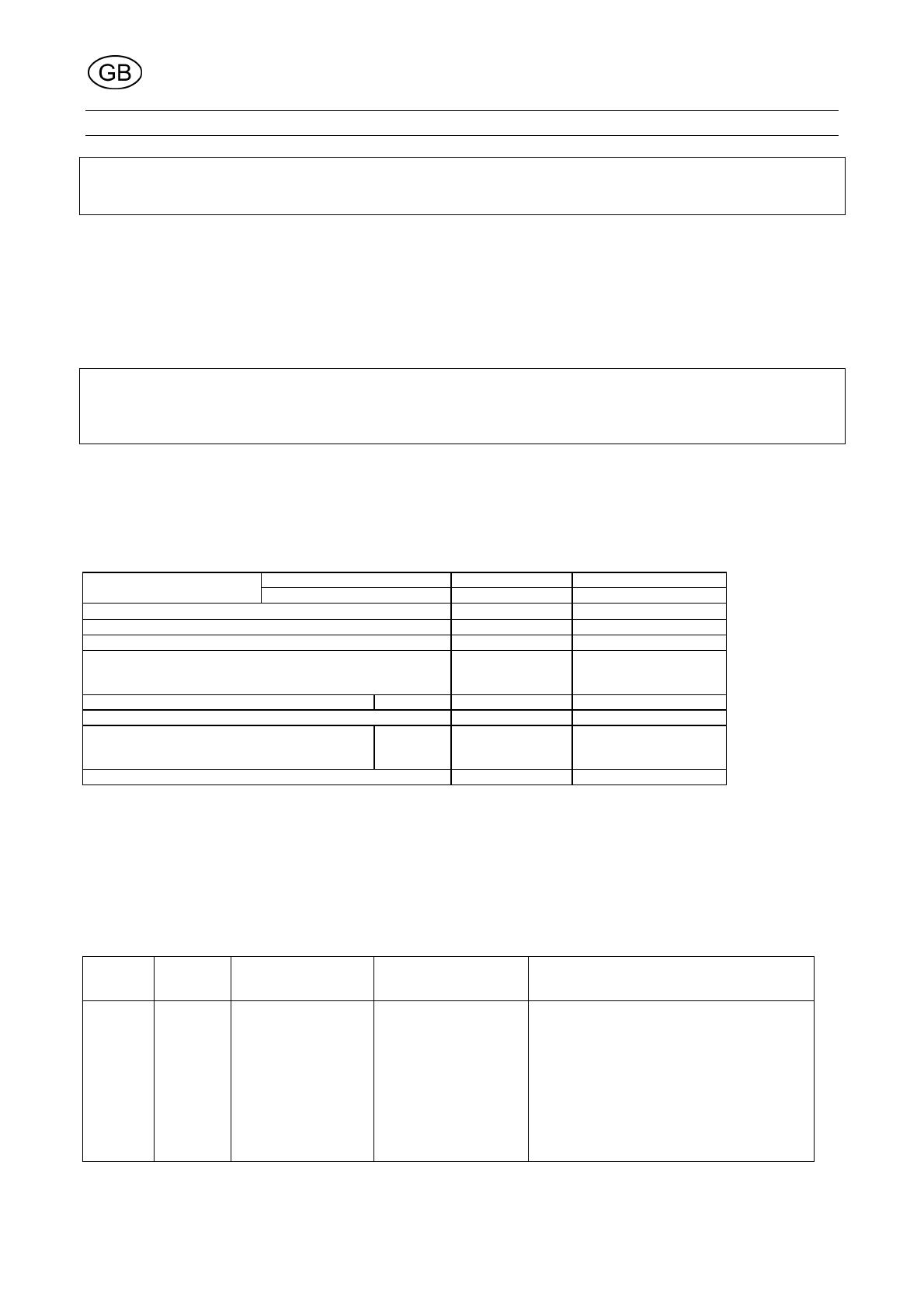

3.3 TECHNICAL DATA

Rated 60% Duty Cycle* 50A 50A

Output 100% Duty Cycle* 30A 30A

Output Current Range

30÷50A 30÷50A

Open Circuit Voltage 320V 320V

Supply cable 4x2.5 mm

2

4x6/4x2.5/4x2.5 mm

2

Rated primary input (max) 400-415V

3~50/60Hz

24A/phase

230V/400-415V/440V

3~50/60Hz

42A/24A/22A/phase

Air Requirements PT 27 118 l/min 4,5bar 118 l/min 4,5bar

Max. cutting thickness 15 mm

Dimensions Length

Height

Width

680

715

325

680

715

325

Weight of LPH 50 89kg 90kg

(*) Duty cycle is based on a 10-minute period; therefore, a 60 % duty cycle means that the power source

may operate for 6 minutes with a cool down period of 4 minutes.

100 % duty cycle means continuous operation of the power source.

NOTE: machine has enclosure class IP23 which means, that it can be operated indoors and outdoors.

NOTE: symbol S points, that unit may be operated in areas of increased electric shock hazard.

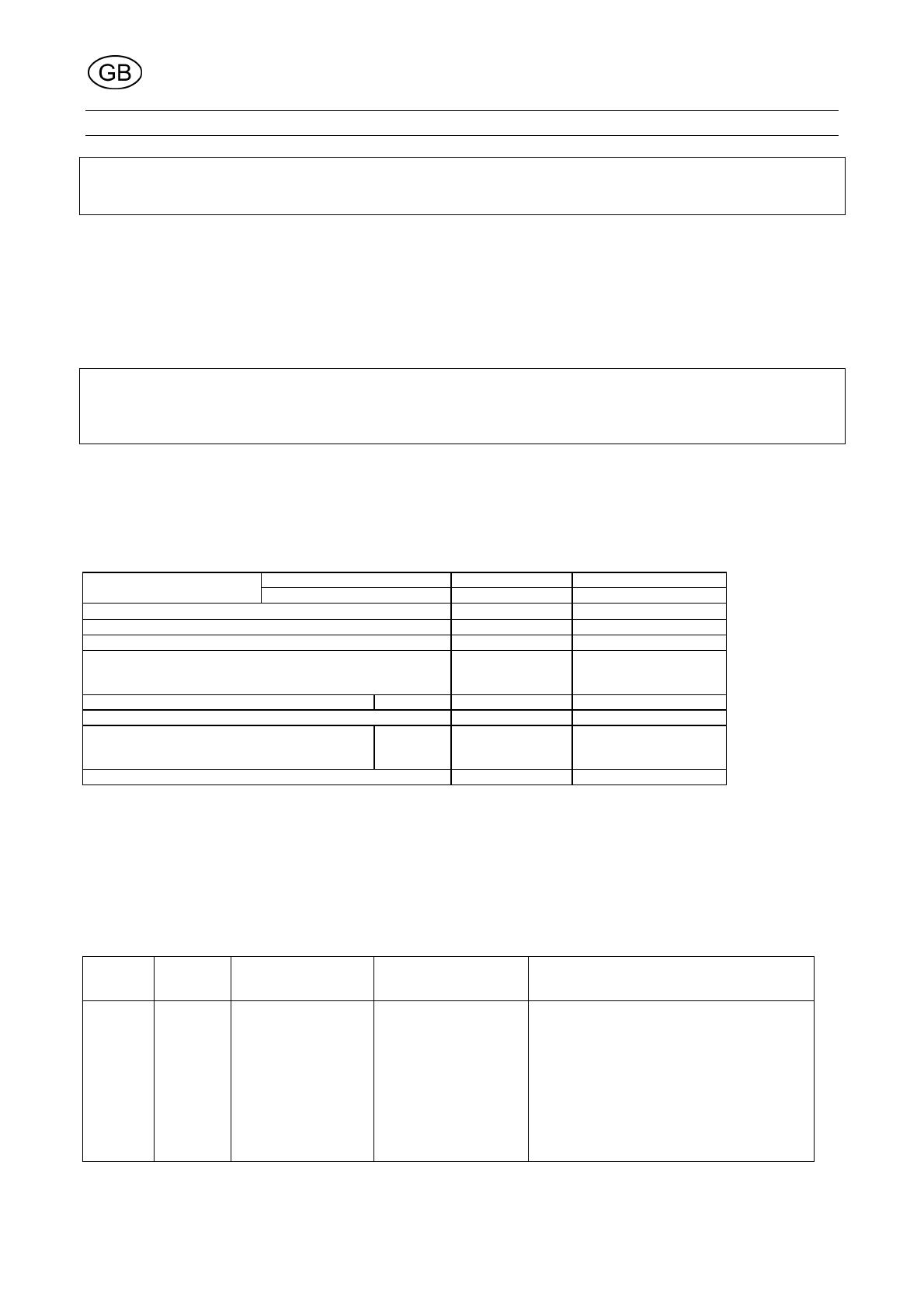

3.4 LPH 50 CUTTING SET PACKAGE

Item No. Qty. Req.

400-415V

3~ 50/60Hz

Qty. Req.

230V/400-415V/440V

3~ 50/60Hz

Part No. Description

1 1 - 0457 289 880 Plasma arc source LPH 50

2 - 1 0457 289 881 Plasma arc source LPH 50

3 1 1 0457 289 005 Current wire with clamp

4 2 2 0457 290 048 Fuse element 1,6A

5 1 1 0457 290 071 Quick detachable coupling

6 1 1 0457 290 072 Hose clip

7 1 1 0349 301 027 Instruction manual LPH 50

8 1 1 0558 000 487 Plasma cutting torch PT 27

9 1 1 0456 176 001 Instruction manual PT 27

10 1 1 0349 302 130 Stand off guide