16

OPERATING DESCRIPTION

CHLORINE MEASUREMENT

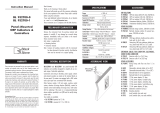

Referring to the drawing on page 10 and the Fluidic Diagram

on page 17, the Sample Line is connected to the instrument at

the Sample Port (#17); an internal Regulator (#15) reduces

the inlet pressure from a maximum of 4 bar (57.2 psi) down to

1 bar (14.3 psi); from the Regulator a nylon tube is connected

to the input of the Electrovalve (#21). The output of the valve

goes to the Drain Port (#11) and then to the Measuring Cell

(#7). An optional Filter can be installed to the sample port if

the stream is excessively turbid.

The sample coming from the line normally flows through the

Measuring Cell (#7). It goes out from the Measuring Cell

through the Drain Tube (#8) and the Output Port (#9).

The Measuring Cell is accessible from the port placed on the

top (#6) for speedy cleaning and maintenance.

During the 100 seconds preceding the sampling, the ana-

lyzer solenoid input valve is open to allow sample flow to flush

the colorimeter cell. Every 3 to 90 minutes (user selectable),

the electrovalve closes stopping the sample flow and leaving

the sample cell full of fresh sample. Cell volume is controlled

by an overflow gateway.

As the sample inlet electrovalve closes, a series of measure-

ments (with LED on and off) of the unreacted sample is taken

to determine an average blank level prior to reagent addition.

The measurement of sample blank signal permits compensa-

tion for any turbidity or natural color, and provides the zero

reference point for the measurement.

The two channel Peristaltic Pump (#5) starts rotating causing

a precise quantity of buffer and indicator (#13 and #16) to

enter the colorimeter sample cell. Here a magnetically coupled

stirrer mixes the reagents with the sample.

After a delay for the color development, a series of measure-

ments (with LED on and off) are taken (sample level) to deter-

mine an average chlorine concentration measurement. The

reacted sample signal is then measured and displayed.

This sequence is repeated every 3 to 90 minutes (user-select-

able).