Page is loading ...

Bradleys

LavCare 500

Series Patient

Care Module

Models LC500 L/F

and L/W)

Installation and

Maintenance

Instructions

215-857 Rev. B; EN 97-1016

Page 1 of 11

Table of Contents

Pre-Installation Information . . . . . . . . . . . . . . .2

LC500 Components and Dimensions . . . . . . . .3

LC500 L/F Rough-Ins . . . . . . . . . . . . . . . . . . .4

LC500 L/W Rough-Ins . . . . . . . . . . . . . . . . . . .5

Installation Instructions . . . . . . . . . . . . . . . .6-10

Cleaning and Maintenance . . . . . . . . . . . . . . .11

P.O. Box 309, Menomonee Falls, WI 53052-0309

Phone (262) 251-6000 Fax (262) 251-5817

http://www.bradleycorp.com

Pre-Installation Information

Overview

The Bradley LavCare module is a patient water closet and lavatory station in one unit. The unit

has three access panels for ease of installation and maintenance. The LC500 countertop is made

from cultured marble and the water closet is stainless steel.

Supplies required for installation:

(6) wall anchors and bolts to secure cabinet to wall at 3/4 mounting holes

Steel angles and hardware for anchoring the water closet (if concrete is lightweight or

less than 4 thick)

4 floor/wall closet waste connection fittings

Shims (for water closet or cabinet installation, if necessary)

Supply piping to water closet and faucet or foot valve

Waste outlet piping to water closet

P-trap and drain piping

Silicone caulk

Bradley LavCare 500 Series Patient Care Module

Model LC500 L/F and L/W Installation Instructions

2 Bradley Corporation 215-857 Rev. B; EN 97-1016

Bradley LavCare 500 Module Warranty Information

Bradley Corporation warrants to commercial and institutional purchasers only each unit free from defects in material and workman-

ship under normal use and service upon the following terms and conditions:

1. This warranty is limited to replacing or repairing, at our option, transportation charges prepaid by the purchaser, any Bradley unit or

part thereof which our inspection shall show to have been defective within the limitations of this warranty.

2. The period during which LC500 components are warranted is one (1) year, measured from the date of our invoice.

3. This warranty does not cover installation or any other labor charges and does not apply to any units which have been damaged by

accident, abuse, improper installation or improper maintenance.

4. The replacement or repair of defective units as stated in this warranty shall constitute the sole remedy of the purchaser and the sole

liability of Bradley Corporation under this warranty. Bradley Corporation shall not otherwise be liable under any indirect damages

caused by defects in the repair or replacement thereof.

5. This warranty extends only to commercial and institutional purchaser and does not extend to any others, including consumer customers of

commercial institutional purchasers.

6. This warranty is in lieu of all other warranties, expressed or implied, including any implied warranty of merchantability or fitness for

a particular purpose or otherwise.

IMPORTANT

Read this entire instruction sheet to ensure proper installation.

Flush all the water supply lines before making connections.

File these instructions with the owner or maintenance department.

Bradley LavCare 500 Series Patient Care Module

Installation Instructions Model LC500 L/F and L/W

3Bradley Corporation 215-857 Rev. B; EN 97-1016

LC500 Components and Module Dimensions

4 WRISTBLADE

CENTERSET FAUCET

FLUSH

ACTUATOR

RECESSED

TOILET

TISSUE

HOLDER

15 (381) X 15 (381)

ACCESS PANEL

2

(51)

(MM)

36-1/8

(918)

29 (737)

32-7/8

(835)

CULTURED

MARBLE

COUNTERTOP

WATER CLOSET

WITH HINGED SEAT

GRAB BAR

10 (254) X 24 (610)

ACCESS PANEL

17

(432)

13-7/8

(352)

33-1/4 (845)

Bradley LavCare 500 Series Patient Care Module

Model LC500 L/F and L/W Installation Instructions

4 Bradley Corporation 215-857 Rev. B; EN 97-1016

Installation Instructions

Step 1: Rough-in supply, drain and waste piping

NOTE: Use the submittal drawing when roughing in the LC500.

IMPORTANT: Flush the supply lines before making connections. Debris in supply

lines can cause the valves to malfunction.

1. Rough in supply, drain and waste piping to the LC500 module as required for your installation.

NOTE: For modules with foot pedal option or for retrofit installations, refer to special rough-ins

included with your LC500 module.

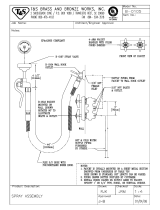

Figure 1a

LC500 L/F (floor waste)

Installation Instructions continue . . .

1/2 NPT HOT WATER

INLET TO LAVATORY

1/2 NPT COLD WATER

INLET TO LAVATORY

1-1/2 NPT

LAVATORY DRAIN

1 NPT WATER

CLOSET INLET

(6) WALL ANCHORS

AND BOLTS (SUPPLIED

BY INSTALLER

(MM)

Bradley LavCare 500 Series Patient Care Module

Installation Instructions Model LC500 L/F and L/W

5Bradley Corporation 215-857 Rev. B; EN 97-1016

Installation Instructions continue . . .

Figure 1b

LC500 L/W (wall waste)

1/2 NPT HOT WATER

INLET TO LAVATORY

1/2 NPT COLD WATER

INLET TO LAVATORY

1-1/2 NPT

LAVATORY DRAIN

1 NPT WATER

CLOSET INLET

5-1/2 FLANGED

WASTE OUTLET

(6) WALL ANCHORS

AND BOLTS (SUPPLIED

BY INSTALLER

(MM)

NOTE: For modules with foot pedal option or for retrofit installations,

refer to special rough-ins included with your LC500 module.

Bradley LavCare 500 Series Patient Care Module

Model LC500 L/F and L/W Installation Instructions

6 Bradley Corporation 215-857 Rev. B; EN 97-1016

Installation Instructions continue . . .

Figure 3

Installation Instructions continued . . .

Step 2: Install wall and floor anchors

WARNING:

All mounting hardware provided is

essential in properly anchoring the

fixture. Bradley cannot assume any

responsibility for personal injury or

damage to equipment due to an

improperly installed LC500 module.

1. Remove the #10-24 screws from the three

access panels (one on each side and one on the

front) and lift off the panels (see Figure 2a/2b).

Set the screws and access panels aside.

2. Position the LC500 module in place against

the wall and piping. Mark the locations for the

six wall anchors on the wall and the two water

closet anchors on the floor (see Figure 2a/2b).

3. Set the LC500 module aside and install six

wall anchors (supplied by installer) at the

locations marked in #2 above.

4. Using a 5/8 concrete drill bit, drill two 2-1/8

deep holes into the water closet anchoring

locations (see Figures 2a/2b and 3). Holes

must be clean and free of debris.

5. Drive the two 2-1/8 anchors provided into the

drilled holes for the water closet using the

setting tool (provided) and a hammer. The

anchor should be driven in flush with the floor

(see Figure 3).

NOTE: If the floor concrete is lightweight or less

than 4 thick, Bradley recommends through-bolting

to steel angles under the floor (hardware supplied

by installer) (see Figure 4).

6. Install the 2 threaded studs provided into the

four 2-1/8 anchors installed in #5 above.

Figure 2a

Figure 4

(6) MOUNTING HOLES

FOR SECURING TO WALL

(6) #10-24

SCREWS

ACCESS

PANEL

(2) MOUNTING

HOLES FOR

SECURING TO

FLOOR

5/8 (16) DIAMETER

DRIVE ANCHOR IN

FLUSH WITH FLOOR

2-1/8 (54)

DEEP

(MM)

WATER CLOSET

PEDESTAL BASE

Figure 2b

(6) MOUNTING HOLES

FOR SECURING TO WALL

(6) #10-24

SCREWS

ACCESS

PANEL

(2) MOUNTING

HOLES FOR

SECURING TO

FLOOR

Bradley LavCare 500 Series Patient Care Module

Installation Instructions Model LC500 L/F and L/W

7Bradley Corporation 215-857 Rev. B; EN 97-1016

Figure 6

Installation Instructions continued . .

.

Step 3: Install the LC500 cabinet

1. Position the module against the wall and align

the mounting holes in the frame with the wall

anchors. The water closet floor mounting holes

should be placed over the threaded studs

installed in Step 2 on page 6 (see Figure 5a/5b).

2. Secure the cabinet to the back wall using six

bolts (supplied by installer).

3. Bolt the water closet to the threaded studs on

the floor using the security nuts and driver

provided (see Figures 5a/5b and 6).

Figure 5a

Installation Instructions continue . . .

(6) WALL MOUNTING HOLES

(2) WATER CLOSET

FLOOR MOUNTING HOLES

LC500 FRAME

(2) THREADED

STUDS

NUT

DRIVER

SECURITY

NUT

Figure 5b

(6) WALL MOUNTING HOLES

(2) WATER CLOSET

FLOOR MOUNTING HOLES

LC500 FRAME

(2) THREADED

STUDS

Installation Instructions continue . . .

Bradley LavCare 500 Series Patient Care Module

Model LC500 L/F and L/W Installation Instructions

8 Bradley Corporation 215-857 Rev. B; EN 97-1016

Figure 7

Step 4: Make water closet supply inlet

and waste connections

NOTE: If the waste outlet goes through the back

wall, a no-hub-type connector may be used (the

connector is available as an option from your

Bradley representative) (see Figure 7).

1. Connect the flush valve water supply piping to

the flush valves 1 NPT inlet (piping supplied

by installer).

2. Connect the water closet waste piping to the

floor waste outlet or wall waste outlet (using a

waste outlet connection fitting supplied by

installer) (see Figure 8a/8b).

FINISHED WALL

LC500

CABINET

NO-HUB

CONNECTOR

Figure 8a

WATER CLOSET

WASTE FLANGE

WASTE

PIPE

GASKET

Figure 8b

GASKET

WASTE

PIPE

WATER CLOSET

WASTE FLANGE

9Bradley Corporation 215-857 Rev. B; EN 97-1016

Bradley LavCare 500 Series Patient Care Module

Installation Instructions Model LC500 L/F and L/W

Installation Instructions continued . . .

Step 5: Install the countertop to the

cabinet

1. Apply a bead of silicone caulk (supplied

by installer) around the top edge of the

cabinet and between the countertop and

the wall (see Figure 9).

2. Set the countertop in place on the cabinet.

3. Clean up any excess caulk around the

edge of the countertop.

Step 6a: Install faucet (with wrist-

blade faucet valve) and connect

water supply

NOTE: On LC500 models with the foot valve

faucet, refer to step 6b found on page 10. On

LC500 models with the optional Futura

faucet, use installation instructions specifically

for the Futura faucet when installing the

faucet and making the electrical connections.

NOTE: To make supply connections easier,

remove the access panels first.

1. Place the faucet onto the countertop,

gently inserting the two faucet supply

shanks through the holes provided in the

lavatory bowl (see Figure 10).

2. Install the two washers provided onto

the supply shanks from beneath the

countertop. Secure the washers and the

faucet to the countertop with the two

wingnuts provided (see Figure 10).

3. Connect the hot and cold water supplies

to the faucets 1/2 NPT hot and cold

supply inlets (piping supplied by

installer) (see Figure 10).

4. Install the P-trap (supplied by installer)

to the sinks 1-1/4 O.D. drain pipe

5. Connect the P-trap to the 1-1/4 NPT

drain pipe from the wall (piping supplied

by installer).

Figure 9

Figure 10

COUNTERTOP

SILICONE CAULK

WINGNUT

COUNTERTOP

1/2 NPT

HOT INLET

1/2 NPT

COLD INLET

WASHER

LAVATORY

BOWL

Installation Instructions continue . . .

Bradley LavCare 500 Series Patient Care Module

Model LC500 L/F and L/W Installation Instructions

10 Bradley Corporation 215-857 Rev. B; EN 97-1016

Installation Instructions continued . . .

Step 6b: Install faucet (with foot valve)

and connect water supply

NOTE: On LC500 models with the wristblade

faucet valve, refer to step 6a found on page 9.

On LC500 models with the optional Futura

faucet, use installation instructions specifically

for the Futura faucet when installing the

faucet and making the electrical connections.

NOTE: To make supply connections easier,

remove the access panels first.

1. Place the faucet onto the countertop, gently

inserting the two faucet supply shanks

through the holes provided in the lavatory

bowl (see Figure 11).

2. Install the two washers provided onto the

supply shanks from beneath the countertop.

Secure the washers and the faucet to the

countertop with the two wingnuts provided

(see Figure 11).

3. Connect one end of the flexible supply

hose provided to the supply shank (see

Figure 11).

4. Connect the other end of the supply hose

to the foot valve outlet connection (see

Figure 12).

5. Secure the foot valve to the floor using

anchors and bolts (supplied by installer).

6. Connect the hot and cold water supply

(piping supplied by installer) to the 1/2

NPT inlet connectors on the foot valve

(see Figure 12).

Step 7: Complete installation

1. Turn on the water supplies to your

LC500 module and check for leaks.

2. Activate the faucet and flush the valve

several times to purge the air from the

supply lines.

3. Secure the three access panels to the

LC500 with the screws provided.

Figure 11

Figure 12

Installation Instructions continue . . .

GOOSENECK

SPOUT

LAVATORY

BOWL

SUPPLY

SHANK

SUPPLY

HOSE

SUPPLY

HOSE

FOOT

VALVE

FOOT VALVE

OUTLET

CONNECTION

HOT

INLET

COLD

INLET

FOOT VALVE INLET

CONNECTORS

11Bradley Corporation 215-857 Rev. B; EN 97-1016

Bradley LavCare 500 Series Patient Care Module

Installation Instructions Model LC500 L/F and L/W

LC500 Module Cleaning and Maintenance

Regular cleaning greatly prolongs the service life of stainless steel and Brad-glazed fixtures and, at the

same time, helps to maintain a pleasing surface appearance. The amount and frequency of cleaning

depends on the service conditions involved. For best results, fixtures should be cleaned as often as

films or deposits become apparent. This will remove built-up deposits which may eventually cause

concentration cells to set on the surface.

CAUTION: USING CLEANERS THAT CONTAIN HARSH CHEMICALS,

ABRASIVES, ACIDS OR DISINFECTANTS, OR CLEANING

WITH STEEL WOOL OR BRUSHES, WILL RESULT IN DAMAGE

TO THE FIXTURES SURFACE. ALWAYS READ THE LABEL

ON ANY CLEANING PRODUCT BEFORE APPLYING TO YOUR

BRAD-GLAZED OR STAINLESS STEEL FIXTURE.

Cleanliness is of utmost importance. Ordinary deposits of dirt and grease can be quickly removed with

soap and water. To properly clean your LC500,

give the Brad-glazed fixture a thorough cleaning with a non-abrasive liquid tub-and-tile

cleaner to remove soil and maintain the glossy finish

You may safely use the following cleaners*:

Formula 409® Spic and Span® Powder

Liquid Comet® Mr. Clean®

Soft Scrub® Windex®

Glass Plus®

DO NOT use the following:

Whitecap® Lysol® Disinfectant Spray

Lestoil® Dow® Disinfectant Bathroom Cleaner

Pinesol® acetone

alcohol steel wool/steel brushes

remove all material and deposits that tend to adhere to the Brad-glazed surface, taking special

note of crevices and corners

remove all material and deposits that tend to adhere to the stainless steel surface with stainless

steel polishing powder (always rub in the direction of the polishing lines)

check for rust spots or streaks on the stainless steel surface and look for the source of the rust

(a steel nail located in some iron or steel not actually a part of the stainless steel fixture may

be the cause)

rinse the Brad-glazed and stainless steel surfaces thoroughly and dry completely after washing.

*NOTE: Use of proprietary cleanser names is intended only to suggest a type of cleanser and

does not constitute endorsement. Omission of any proprietary cleanser name is not

meant to imply its inadequacy.

/