Ingersoll-Rand VHP40RMD Operation & Maintenance Manual

- Category

- Air compressors

- Type

- Operation & Maintenance Manual

This manual is also suitable for

Onboard Power Solutions™

Operation & Maintenance Manual

Compressor Models

VHP40RMD - Diesel Drive

VHP40RMG - Gasoline Drive

This manual contains important safety information.

Do not destroy this manual.

This manual must be available to the personnel who operate and maintain this machine.

Ingersoll Rand Company

P.O. Box 868

501 Sanford Ave

Mocksville, NC 27028 USA

Book: 23221138 (12/07) Rev A

Revised (01-13)

Doosan purchased Bobcat Company from Ingersoll-Rand Company in

2007. Any reference to Ingersoll-Rand Company or use of trademarks,

service marks, logos, or other proprietary identifying marks belonging

to Ingersoll-Rand Company in this manual is historical or nominative

in nature, and is not meant to suggest a current affiliation between

Ingersoll-Rand C

ompany and Doosan

Company or the products of

e

ith

er.

QUALITY POLICY

We will supply products and services that consistently meet the requirements of our

customers and each other.

3

TABLE OF CONTENTS

Operation & Maintenance Manual

TITLE PAGE

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

One-Year Extended Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Complete Machine Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

System Description - General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mounting Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Compressor Discharge Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Receiver Tank Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Piping - General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Hydraulic Cooling Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Hydraulic Oil Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Hydraulic Reservoir. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Hydraulic Filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

GENERAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Unit Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

OPERATING INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Set-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Before Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Starting/Operating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Automatic Start and Stop Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Pressure Switch Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Gauge Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Operating Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

On Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Inside . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4

TABLE OF CONTENTS

Operation & Maintenance Manual

TITLE PAGE

MAINTENANCE/LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Compressor Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Compressor Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Oil Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Oil Change Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Hydraulic Oil Cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Exterior Finish Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Field Repair of Texture Paint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Belt Checking and Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

TROUBLE SHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Action Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Think Before Acting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Do the Simplest Things First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Double Check Before Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Find and Correct Basic Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Trouble Shooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

23221138 (12-07) Rev A 5

Safety

Operation & Maintenance Manual Safety

6 23221138 (12-07) Rev A

Safety

Safety Precautions

General Information

Ensure that the operator reads and understands the decals and consults the manuals before

maintenance or operation.

Ensure that the Operation and Maintenance manual, and the manual holder if equipped, are

not removed permanently from the machine.

Ensure that maintenance personnel are adequately trained, competent and have read the

manuals. Make sure that all protective covers are in place.

The specification of this machine is such that the machine is not suitable for use in flammable

gas risk areas. If such an application is required then all local regulations, codes of practice

and site rules must be observed.

Air discharged from this machine may contain carbon monoxide or other contaminants which

will cause serious injury or death. Do not breathe this air.

Compressed air can be dangerous if incorrectly handled. Before doing any work on the unit,

ensure that all pressure is vented from the system and that the machine cannot be started

accidentally.

Ensure that the machine is operating at the rated pressure and that the rated pressure is

known to all relevant personnel.

All air pressure equipment installed in or connected to the machine must have safe working

pressure ratings of at least the machine safety valve rating.

If more than one compressor is connected to one common downstream plant, effective check

valves and isolation valves must be fitted and controlled by work procedures, so that one

machine cannot accidentally be pressurized or over pressurized by another.

Compressed air must not be used for a feed to any form of breathing apparatus or mask.

The discharged air contains a very small percentage of compressor lubricating oil and care

should be taken to ensure that downstream equipment is compatible.

If the discharged air is to be ultimately released into a confined space, adequate ventilation

must be provided.

When using compressed air, always use appropriate personal protective equipment.

All pressure containing parts, especially flexible hoses and their couplings, must be regularly

inspected, be free from defects and be replaced according to the Manual instructions.

Avoid bodily contact with compressed air.

The safety valves located in the discharge pipe and connected receiver tank must be checked

periodically for correct operation.Avoid bodily contact with compressed air.

Never operate unit without first observing all safety warnings and carefully reading the

operation and maintenance manual shipped from the factory with this machine.

Safety Operation & Maintenance Manual

23221138 (12-07) Rev A 7

Never operate the driver engine of this machine inside a building without adequate ventilation.

Avoid breathing exhaust fumes when working on or near the machine. Do not alter or modify

this machine.

A battery contains sulfuric acid and can give off gases which are corrosive and potentially

explosive. Avoid contact with skin, eyes and clothing. In case of contact, flush area

immediately with water.

Exercise extreme caution when using booster battery. To jump battery, connect ends of one

booster cable to the positive (+) terminal of each battery. Connect one end of other cable to

the negative (-) terminal of the booster battery and other end to a ground connection away

from dead battery (to avoid a spark occurring near any explosive gases that may be present).

After starting unit, always disconnect cables in reverse order.

This machine may include such materials as oil, diesel fuel, antifreeze, brake fluid, oil/air filters

and batteries which may require proper disposal when performing maintenance and service

tasks. Contact local authorities for proper disposal of these materials.

High Pressure Air can cause serious injury or death. Relieve pressure before removing filler

plugs/caps, fittings or covers.

Air pressure can remain trapped in air supply line which can result in serious injury or death.

Always carefully vent air supply line at tool or vent valve before performing any service.

This machine produces loud noise. Extended exposure to loud noise can cause hearing loss.

Always wear hearing protection when operating this unit.

Do not use petroleum products (solvents or fuels) under high pressure as this can penetrate

the skin and result in serious illness.

Wear eye protection while cleaning unit with compressed air to prevent debris from injuring

eye(s).

Rotating fan blade can cause serious injury. Do not operate without guard in place.

Use care to avoid contacting hot surfaces (engine exhaust manifold and piping, air receiver

and air discharge piping, etc.).

Never operate unit with guards, covers or screens removed. Keep hands, hair, clothing, tools,

blow gun tips, etc. well away from moving parts

Hazardous Substance Precaution

The following substances are used in the manufacture of this machine and may be hazardous

to health if used incorrectly.

Precaution: Avoid ingestion, skin contact and breathing fumes for the following substances:

Compressor Oil, Preservative Grease, Rust Preventative, Hydraulic Fluid.

Operation & Maintenance Manual Safety

8 23221138 (12-07) Rev A

Safety Labels

Look for these signs on machines shipped to international markets outside North

America, which point out potential hazards to the safety of you and others. Read and

understand thoroughly. Heed warnings and instructions. If you do not understand,

inform your supervisor.

Corrosion risk

Hot surface

Lifting point.

No open flame

Lifting point.

WARNING: Electrical shock risk

Diesel Fuel.

No open flame

Do not operate the machine

without guard being fitted.

WARNING - Flammable liquid

When parking use prop stand,

handbrake and wheel chocks

Air/gas flow or Air discharge.

WARNING - Hot and harmful

exhaust gas.

Tie down point

Do not breathe the compressed

air from this machine

Parking Brake

P

DIESEL

Safety Operation & Maintenance Manual

23221138 (12-07) Rev A 9

Read the Operation and Maintenance

manual before operation or maintenance

of this machine is undertaken.

WARNING - Consult the operation

and maintenance manual before

commencing any maintenance.

Do not stack.

Do not use fork lift truck from this side.

WARNING - Before connecting the tow bar

or preparing to tow, consult the

operation and maintenance manual.

On (power).

Off (power).

X,X

BAR

WARNING - Maintain correct tire pressure

(Refer to the GENERAL INFORMATION

section of this manual.

Do not operate with the doors

or enclosure open

Emergency stop.

1.6m.

IP54

Rough Service Designation

Wet Location Operation

Replace any cracked

protective shield.

Operation & Maintenance Manual Safety

10 23221138 (12-07) Rev A

0° C

Pressurized component

or system.

Use fork lift truck from

this side only

Pressurized vessel.

WARNING - For operating temperature below

0° C, consult the operation and maintenance

manual

Do not remove operating and maintenance

manual and manual holder from this machine.

Read the Operation and Maintenancemanual

before operation or maintenance of this

machine is undertaken.

WARNING - Do not undertake any

maintenance on this machine until the

electrical supply is disconnected and the air

pressureis totally relieved.

Do not exceed the speed limit.

Oil Drain

Safety Operation & Maintenance Manual

23221138 (12-07) Rev A 11

Look for these signs on machines shipped to international markets outside North

America, which point out potential hazards to the safety of you and others. Read and

understand thoroughly. Heed warnings and instructions. If you do not understand,

DANGER

!

WARNING

!

CAUTION

!

NOTICE

Indicates the presence of a hazard which WILL

cause serious injury, death or property damage, if

ignored.

Indicates the presence of a hazard which CAN

cause serious injury, death or property damage, if

ignored.

Indicates the presence of a hazard which WILL or

can cause injury or property damage, if ignored.

Indicates important set-up, operating or

maintenance information.

(Red Background)

(Orange Background)

(Yellow Background)

(Blue Background)

inform your supervisor.

Operation & Maintenance Manual Safety

12 23221138 (12-07) Rev A

WARNING

Hot pressurized fluid.

Can cause severe

burns.

Do not open radiator

while hot.

WARNING

High pressure air.

Can cause serious

injury or death.

Relieve pressure before

removing filler plugs/caps,

fittings or coverrs.

WARNING

Trapped air pressure.

Can cause serious

injury or death

Close service valve and

operate tool to vent

trapped air before

performing any service

DANGER

Discahrged air can contain carbon

monoxide or other contaminants.

Will cause serious injury or death.

Do not breathe this air.

Safety Operation & Maintenance Manual

23221138 (12-07) Rev A 13

WARNING

Modification or alternation of this machine.

Can cause serious injury or death.

Do not alter modify this machine

without the express written consent of

the manufacturer.

Improper operation of this equipment.

Can cause serious injury or death.

Read Operator's Manual supplied with

this machine before operation or

servicing.

WARNING

Rotating fan blade.

Can cause serious injury.

Do not operate without

guard on place.

Disconnected air hoses whip.

Can cause serious

injury or death.

When using air tools

attach safety device

(OSHA valve) at source of

air supply for each tool.

WARNING

WARNING

Combustible gas.

Can cause serious burns,

blindness or death.

Keep sparks and open

flames away from batteries.

Falling of machine.

Can cause serious injury

or death.

Access lifting bail from

inside machine.

WARNING

WARNING

Door under pressure.

Can cause serious injury.

Use both hands to open door

when machine is running.

CAUTION

DO NOT WELD.

ELECTRONIC DAMAGE

WILL OCCUR.

This engine is equipped with an

electronic engine controller and

other electronic components.

WARNING

Excessive towing speed.

Can cause serious injury

or death.

Do NOT exceed 65 mph (105 km/hr.)

Collapsing jackstand.

Can cause serious injury.

Insert locking pin completely.

105

km/h

Operation & Maintenance Manual Safety

14 23221138 (12-07) Rev A

CAUTION

This engine is equipped with an

electric heater starting aid.

DO NOT USE ETHER.

ENGINE DAMAGE WILL OCCUR.

COOLANT FILL INSTRUCTIONS

Adding:

Replacing:

With system cool, remove radiator cap. Drain

coolant and close drain. At radiator, refill system.

Replace radiator cap. At reservoir, fill to "HOT" level.

Run for 30 minutes. Stop and allow to cool.

At reservoir, add coolant as necesary to reach

"COLD" level.

Do NOT remove radiator cap. Top offat overflow

reservoir. Use same anti-freeze mixture as in

radiator.

NOTICE

USE DIESEL

FUEL ONLY

FREE SAFETY DECALS!

To promote communication of Safety Warnings on

products manufactured by the Portable Compressor

Division in Mocksville. N.C., Safety Decals are available

free of charge. Safety decals are identified by the decal

heading: DANGER, WARNING or CAUTION.

Decal part numbers are on the bottom of each decal and

are also listed in the compressor's parts manual. Submit

order for Safety Decals to the Mocksville Parts Service

Department. The no charge order should contain only

Safety Decals. Help promote product safety! Assure that

decals are present on the machines. Replace decals that

are not readable.

23221138 (12-07) Rev A 15

Warranty

Operation & Maintenance Manual Warranty

16 23221138 (12-07) Rev A

Warranty/Registration

Ingersoll Rand Company warrants that the equipment manufactured by it and delivered

hereunder shall be free of defects in material and workmanship for the following period:

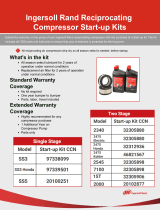

Standard Warranty

Standard warranty is for a period of twelve (12) months from the date of placing the equipment

in operation or eighteen (18) months from the date of shipment, whichever shall occur first.

The foregoing warranty shall apply to all equipment.

One-Year Extended Warranty

Standard warranty is for a period of twelve (12) months from the date of placing the equipment

in operation or eighteen (18) months from the date of shipment, whichever shall occur first.

The foregoing warranty shall apply to all equipment.

To extend the warranty, the purchaser must continually use All Season Select brand synthetic

lubricant, use genuine Ingersoll Rand parts, and demonstrate the product was maintained

based on the recommended procedures per the Operator Manual. The foregoing extended

warranty period shall apply to the bare compressor pump only and excludes package related

components.

Replacement Parts

Ingersoll Rand genuine replacement parts will be warranted for six (6) months from the date

of shipment.

Should any failure to conform to this warranty be reported in writing to Ingersoll Rand

Company within said period, Ingersoll Rand Company shall, at its option, correct such

nonconformity by suitable repair to such equipment, or furnish a replacement part F.O.B. point

of shipment, provided the purchaser has installed, maintained and operated such equipment

in accordance with good industry practices and has complied with specific recommendations

of Ingersoll Rand Company.

Accessories or equipment furnished by Ingersoll Rand Company, but manufactured by others,

shall carry whatever warranty the manufacturer conveyed to Ingersoll Rand Company and

which can be passed on to the purchaser.

Ingersoll Rand Company shall not be liable for any repairs, replacements, or adjustments to

the equipments or any costs of labor performed by the purchaser without Ingersoll Rand

Company’s prior written approval.

Ingersoll Rand Company makes no performance warranty unless specifically stated within its

proposal and the effects or corrosion, erosion and normal wear and tear are specifically

excluded from Ingersoll Rand Company’s warranty. In the event performance warranties are

expressly included, Ingersoll Rand Company’s obligation shall be to correct in the manner and

for the period of time provided above.

Warranty Operation & Maintenance Manual

23221138 (12-07) Rev A 17

INGERSOLL RAND COMPANY MAKES NO OTHER WARRANTY OF REPRESENTATION

OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND

ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE HEREBY DISCLAIMED.

Correction by Ingersoll Rand Company non-conformities, whether patent or latent, in the

manner and for the period of time provided above shall constitute fulfillment of all liabilities of

Ingersoll Rand Company and its distributors for such non-conformities whether based on

contract, warranty negligence, indemnity, strict liability or otherwise with respect to or arising

out of such equipment. The purchaser shall not operate equipment that is considered to be

defective, without first notifying Ingersoll Rand Company in writing of its intention to do so. Any

such use of equipment will be at Purchaser’s sole risk and liability.

Operation & Maintenance Manual Warranty

18 23221138 (12-07) Rev A

Warranty Registration

Complete Machine Registration

Machines shipped to locations within the United States do not require a warranty registration

unless the machine status changes (i.e. change of ownership).

Machines shipped outside the United States

require notification be made to initiate the

machine warranty.

Fill out the Warranty Registration Form in this section, keep a copy for your records and

mail form to:

Ingersoll Rand Company

Portable Compressor Division

P.O. Box 868

Mocksville, North Carolina 27028

Attn: Warranty Department

NOTE: Completion of this form validates the warranty.

Warranty Operation & Maintenance Manual

23221138 (12-07) Rev A 19

Complete the Applicable Blocks

Owner/User Type of Business (check one only)

Selling Distributor Servicing Distributor WARRANTY

Name _____________________ __________________________

___________________________

Address ___________________

__________________________ ___________________________

City _______________________

__________________________ ___________________________

County ____________________

__________________________ ___________________________

State ______________________

__________________________ ___________________________

Zip code ___________________

__________________________ ___________________________

Telephone __________________

_____________________ ___________________________

Construction-Heavy

(highway, excavation, etc.)

Asphalt Contractor

Coal Mining

Other Mining

Construction-Light

(carpentry, plumbing,

pools, mason, etc.)

Government

(municipal, state, county, etc.)

Quarry

Shallow Oil & Gas

Rental (rental center,

rental fleet, etc.)

Building Contractor

Water well

Utility Company

(gas, electric, water, etc.)

Industrial (plant use)

Other

specify __________________

Exploration

Utility Contractor

Model Unit S/N Engine S/N Date

Unit-Hours Airend S/N Truck S/N Truck

SERVICING DISTRIBUTOR/USER ACKNOWLEDGEMENT

1. The Purchaser has been instructed and/or has read the manual and understands proper

preventative maintenance, general operation and safety precautions.

2. The warranty and limitation of liability has been reviewed and understood by the owner/user.

3. In the event that this unit is to be used within a nuclear facility, the owner/user shall notify

Ingersoll Rand of such use so that Ingersoll Rand may arrange for appropriate nuclear liability

protection from the owner-licensee of the facility.

4. Ingersoll Rand reserves the right to make design changes or modifications of Ingersoll Rand

products at anytime without incurring any obligation to make similar changes or modifications

on previously sold units.

Operation & Maintenance Manual Warranty

20 23221138 (12-07) Rev A

fold

Ingersoll Rand Company

Portable Compressor Division

P.O. Box 868

Mocksville, North Carolina 27028

Attention: Warranty Department

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

Ingersoll-Rand VHP40RMD Operation & Maintenance Manual

- Category

- Air compressors

- Type

- Operation & Maintenance Manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Ingersoll-Rand P250WJDU Operating & Maintenance Manual

-

Ingersoll-Rand P250WJD Operation and Maintenance Manual

-

Ingersoll-Rand 7120 User manual

-

Ingersoll-Rand CSAXHP1070WCAT Operating & Maintenance Manual

-

Ingersoll-Rand VHP600CM Operation & Maintenance Manual

-

Ingersoll-Rand LT6K Operation and Maintenance Manual

-

Ingersoll-Rand IR21BS Operation And Maintenance

-

Ingersoll-Rand IR17JS Operation And Maintenance

-

Ingersoll-Rand RD1600A Installation, Operation & Maintenance Manual

-

Ingersoll-Rand P1IU-A9 Owner's manual

Other documents

-

Mi-T-M Hand Carry Gas Owner's manual

-

Mi-T-M Hand Carry Gas Owner's manual

-

Mi-T-M Portable Gas Owner's manual

Mi-T-M Portable Gas Owner's manual

-

Mi-T-M AC1-HH04-05M User guide

Mi-T-M AC1-HH04-05M User guide

-

Porter-Cable Air Compressor User manual

-

Craftsman 919.157260 User manual

-

John Deere PR2-8GM User manual

John Deere PR2-8GM User manual

-

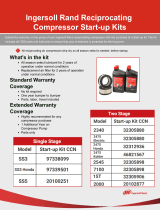

Ingersoll 2340 Start-Up Kit CCN User guide

Ingersoll 2340 Start-Up Kit CCN User guide

-

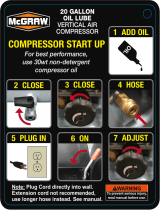

McGraw Item 64857 Quick start guide

McGraw Item 64857 Quick start guide

-

Doosan Ingersoll Rand XP375 WIR Operation & Maintenance Manual