Page is loading ...

RECOGNIZE THIS SYMBOL AS AN INDICATION OF IMPORTANT SAFETY INFORMATION!

!

DO NOT DESTROY THIS MANUAL

PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE FOR FUTURE REFERENCE BY A SERVICEMAN

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO

QUALIFIED, LICENSED SERVICE PERSONNEL FOR PROPER

INSTALLATION, ADJUSTMENT AND OPERATION OF THIS UNIT.

READ THESE INSTRUCTIONS THOROUGHLY BEFORE

ATTEMPTING INSTALLATION OR OPERATION. FAILURE TO FOL-

LOW THESE INSTRUCTIONS MAY RESULT IN IMPROPER

INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE

POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK,

PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

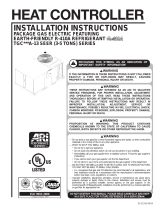

INSTALLATION INSTRUCTIONS

PACKAGE GAS ELECTRIC FEATURING

EARTH-FRIENDLY R-410A REFRIGERANT

RKNL-B SERIES 15, 20 & 25 TON [52.8, 70.3, 87.9 kW]

COMPLIES WITH ASHRAE 90.1-2007

92-23577-84-00

[ ] INDICATES METRIC CONVERSIONS

e

a r t h f r i e n d l y r e f r i g e r a n t

e

a

r

t

h

r

y

r

d

ly

e

n

r

ie

n

f

r

h

25 TON IS OUTSIDE THE SCOPE

OF ARI STANDARD 340/360

2

TABLE OF CONTENTS

I. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

M

ajor Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

R410A Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

II. INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Location Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Outside Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Exhaust & Combustion Hoods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cover Panel Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Rooftop Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Ducting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Return Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

III. GAS SUPPLY, CONDENSATE DRAIN AND PIPING. . . . . . . . . . . . . . 24

Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

LP Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Adjusting or Checking Furnace Input . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Condensate Drain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

IV. WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Hook-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Internal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

V. FURNACE SECTION CONTROLS AND IGNITION SYSTEM. . . . . . . 30

Normal Furnace Operating Sequence . . . . . . . . . . . . . . . . . . . . . . . . . 30

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Manual Reset Overtemperature Control . . . . . . . . . . . . . . . . . . . . . . . 33

Pressure Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Limit Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

VI. COOLING SECTION OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Cooling Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Continuous Fan Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

VII. SYSTEM OPERATING INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . 34

Advise the Customer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Furnace Section Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Cooling Section Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

VIII. AIRFLOW PERFORMANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-39

IX. ELECTRICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-42

X. TROUBLESHOOTING CHART. . . . . . . . . . . . . . . . . . . . . . . . . . . . 43-45

XI. WIRING DIAGRAMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46-49

XII. CHARGE CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50-52

3

CHECKING PRODUCT RECEIVED

T

his booklet contains the installation and operating instructions for your combination

gas heating/electric cooling unit. There are some precautions that should be taken to

derive maximum satisfaction from it. Improper installation can result in unsatisfactory

operation or dangerous conditions.

Read this booklet and any instructions packaged with separate equipment required

t

o make up the system prior to installation. Give this booklet to the owner and explain

its provisions. The owner should retain this booklet for future reference.

EQUIPMENT PROTECTION FROM THE

ENVIRONMENT

Upon receiving the unit, inspect it for any damage from shipment. Claims for dam-

age, either shipping or concealed, should be filed immediately with the shipping com-

pany. IMPORTANT: Check the unit model number, heating size, electrical character-

istics, and accessories to determine if they are correct.

I. SPECIFICATIONS

A. GENERAL

The Combination Gas Heating/Electric Cooling Rooftop is available in 250,000 AND

350,000 BTUH heating input with nominal cooling capacity of 15 tons. 300,000 and

400,000 BTUH heating inputs are available in nominal cooling capacity of 20 & 25

tons. Units are convertible from bottom supply and return to side supply and return

by relocation of supply and return air cover panels. See cover installation detail and

Figures 10 &11.

The units are weatherized for mounting outside of the building.

B. MAJOR COMPONENTS

The unit includes a hermetically-sealed refrigerating system consisting of a scroll

compressor, condenser coil, evaporator coil with capillary tube assembly or TXV, a

circulation air blower, condenser fans, a heat exchanger assembly, gas burner and

control assembly, combustion air motors and fan, and all necessary internal electrical

wiring. The cooling system of these units is factory-evacuated, charged and perform-

ance tested. Refrigerant amount and type are indicated on rating plate.

C. R410A REFRIGERANT

All units are factory charged with R-410A refrigerant.

1. Specification of R-410A:

Application: R-410A is not a drop-in replacement for R-22; equipment designs must

accommodate its higher pressures. It cannot be retrofitted into R-22 units.

Pressure: The pressure of R-410A is approximately 60% (1.6 times) greater than R-

22. Recovery and recycle equipment, pumps, hoses, and the like need to have design

pressure ratings appropriate for R-410A. Manifold sets need to range up to 800 psig

high-side and 250 psig low-side with a 550 psig low-side retard. Hoses need to have a

service pressure rating of 800 psig. Recovery cylinders need to have a 400 psig service

pressure rating. DOT 4BA400 or DOT BW400.

Combustibility: At pressures above 1 atmosphere, mixture of R-410A and air can

become combustible. R-410A and air should never be mixed in tanks or supply

lines, or be allowed to accumulate in storage tanks. Leak checking should never

be done with a mixture of R-410A and air. Leak checking can be performed safely with

nitrogen or a mixture of R-410A and nitrogen.

2. Quick Reference Guide For R-410A

• R-410A refrigerant operates at approximately 60% higher pressure (1.6 times) than R-

22. Ensure that servicing equipment is designed to operate with R-410A.

• R-410A refrigerant cylinders are pink.

• R-410A, as with other HFC’s is only compatible with POE oils.

• Vacuum pumps will not remove moisture from POE oil.

Recognize this symbol as an

indication of Important Safety

Information!

!

UNITS ARE NOT DESIGN CERTIFIED

TO BE INSTALLED INSIDE THE

STRUCTURE. DOING SO CAN

CAUSE INADEQUATE UNIT PER-

FORMANCE AS WELL AS PROPERTY

DAMAGE AND CARBON MONOXIDE

POISONING RESULTING IN PERSON-

AL INJURY OR DEATH.

▲WARNING

!

PROVIDE ADEQUATE COMBUSTION

AND VENTILATION AIR TO THE UNIT

SPACE AS SPECIFIED IN THE COM-

BUSTION AND VENTILATION AIR

SECTION OF THESE INSTRUCTIONS.

▲WARNING

!

THE MANUFACTURER’S WARRANTY

DOES NOT COVER ANY DAMAGE OR

DEFECT TO THE AIR CONDITIONER

CAUSED BY THE ATTACHMENT OR

USE OF ANY COMPONENTS,

ACCESSORIES OR DEVICES (OTHER

THAN THOSE AUTHORIZED BY THE

MANUFACTURER) INTO, ONTO OR

IN CONJUNCTION WITH THE AIR

CONDITIONER. YOU SHOULD BE

AWARE THAT THE USE OF UNAU-

THORIZED COMPONENTS, ACCES-

SORIES OR DEVICES MAY

ADVERSELY AFFECT THE OPERA-

TION OF THE AIR CONDITIONER

AND MAY ALSO ENDANGER LIFE

AND PROPERTY. THE MANUFAC-

TURER DISCLAIMS ANY RESPONSI-

BILITY FOR SUCH LOSS OR INJURY

RESULTING FROM THE USE OF

SUCH UNAUTHORIZED COMPO-

NENTS, ACCESSORIES OR DEVICES.

▲WARNING

!

4

• R-410A systems are to be charged with liquid refrigerants. Prior to March 1999, R-

410A refrigerant cylinders had a dip tube. These cylinders should be kept upright for

equipment charging. Post March 1999 cylinders do not have a dip tube and should be

inverted to ensure liquid charging of the equipment.

•

Do not install a suction line filter drier in the liquid line.

• A liquid line filter drier is standard on every unit.

• Desiccant (drying agent) must be compatible for POE oils and R-410A.

3. Evaporator Coil/ TXV

The thermostatic expansion valve is specifically designed to operate with R-410A. DO

N

OT use an R-22 TXV. The existing evaporator must be replaced with the factory

specified TXV evaporator specifically designed for R-410A.

4. Tools Required For Installing & Servicing R-410A Models

Manifold Sets:

-Up to 800 PSIG High Side

-Up to 250 PSIG Low Side

-550 PSIG Low Side Retard

Manifold Hoses:

-Service Pressure Rating of 800 PSIG

Recovery Cylinders:

-400 PSIG Pressure Rating

-Dept. of Transportation 4BA400 or BW400

R-410A systems operate at higher pressures than R-22 systems. Do not use

R-22 service equipment or components on R-410A equipment.

▲CAUTION

!

5

SAFETY INFORMATION

USE ONLY WITH TYPE OF GAS

APPROVED FOR THIS UNIT. REFER

T

O THE UNIT RATING PLATE.

▲WARNING

!

INSTALL THIS UNIT ONLY IN A

LOCATION AND POSITION AS SPEC-

IFIED IN THE LOCATION REQUIRE-

MENTS AND CONSIDERATIONS

SECTION OF THESE INSTRUCTIONS.

PROVIDE ADEQUATE COMBUSTION

AND VENTILATION AIR TO THE UNIT

SPACE AS SPECIFIED IN THE VENT-

ING SECTION OF THESE INSTRUC-

TIONS.

▲WARNING

!

PROVIDE ADEQUATE COMBUSTION

AND VENTILATION AIR TO THE UNIT

SPACE AS SPECIFIED IN THE COM-

BUSTION AND VENTILATION AIR

SECTION OF THESE INSTRUCTIONS.

▲WARNING

!

COMBUSTION PRODUCTS MUST BE

DISCHARGED OUTDOORS.

CONNECT THIS UNIT TO AN

APPROVED VENT SYSTEM ONLY, AS

SPECIFIED IN VENT PIPE

INSTALLATION SECTION OF THESE

INSTRUCTIONS.

▲WARNING

!

ALWAYS INSTALL UNIT TO OPERATE WITHIN THE UNIT'S INTENDED TEM-

PERATURE-RISE RANGE WITH A DUCT SYSTEM WHICH HAS AN EXTER-

NAL STATIC PRESSURE WITHIN THE ALLOWABLE RANGE, AS SPECIFIED

IN DUCTING SECTION OF THESE INSTRUCTIONS. SEE ALSO UNIT RATING

PLATE.

▲WARNING

!

NEVER TEST FOR GAS LEAKS WITH AN OPEN FLAME. USE A COMMER-

CIALLY AVAILABLE SOAP SOLUTION MADE SPECIFICALLY FOR THE

DETECTION OF LEAKS TO CHECK ALL CONNECTIONS, AS SPECIFIED IN

GAS SUPPLY AND PIPING SECTION OF THESE INSTRUCTIONS.

▲WARNING

!

WHEN A UNIT IS INSTALLED SO THAT SUPPLY DUCTS CARRY AIR CIRCU-

LATED BY THE UNIT TO AREAS OUTSIDE THE SPACE CONTAINING THE

UNIT, THE RETURN AIR SHALL ALSO BE HANDLED BY DUCT(S) SEALED

TO THE UNIT CASING AND TERMINATING OUTSIDE THE SPACE CONTAIN-

ING THE UNIT.

▲WARNING

!

THIS UNIT MAY BE USED TO HEAT THE BUILDING OR STRUCTURE DUR-

ING CONSTRUCTION IF THE FOLLOWING INSTALLATION REQUIREMENTS

ARE MET. INSTALLATION MUST COMPLY WITH ALL INSTALLATION

INSTRUCTIONS INCLUDING:

• PROPER VENT INSTALLATION;

• FURNACE OPERATING UNDER THERMOSTATIC CONTROL;

• RETURN AIR DUCT SEALED TO THE FURNACE;

• AIR FILTERS IN PLACE;

• SET FURNACE INPUT RATE AND TEMPERATURE RISE PER RATING

PLATE MARKING;

• MEANS OF PROVIDING OUTDOOR AIR REQUIRED FOR COMBUSTION;

• RETURN AIR TEMPERATURE MAINTAINED BETWEEN 55°F (13°C) AND

80°F (27°C); AND

• INSTALLATION OF EXHAUST AND COMBUSTION AIR INLET HOODS

COMPLETED;

• CLEAN FURNACE, DUCT WORK AND COMPONENTS UPON SUBSTAN-

TIAL COMPLETION OF THE CONSTRUCTION PROCESS, AND VERIFY

FURNACE OPERATING CONDITIONS INCLUDING IGNITION, INPUT RATE,

TEMPERATURE RISE AND VENTING ACCORDING TO THE INSTRUC-

TIONS.

▲WARNING

!

6

C

ONTROLS &

F

ILTER

ACCESS

R

ETURN

AIR

SUPPLY

A

IR

C

ONDENSER

COIL #1

(RIGHT SIDE)

BLOWER

ACCESS

FIGURE 1

B

OTTOM VIEW

ELECTRICAL ENTRY

GAS ENTRY

C

O

N

D

E

N

S

E

R

C

O

I

L

SUPPLY AIR

RETURN

AIR

FIGURE 2

SUPPLY AND RETURN DIMENSIONS FOR DOWNFLOW APPLICATIONS – BOTTOM VIEW

Unit

Dimensions

FOR CLEARANCES

SEE PAGE 12, FIGURE 12.

IMPORTANT: THIS

UNIT MUST BE

MOUNTED LEVEL IN

BOTH DIRECTIONS

TO ALLOW WATER TO

DRAIN FROM THE

CONDENSER SEC-

TION AND CONDEN-

SATE PAN.

ST-A1125-02A

ST-A1125-09A

Typical Dimensions Shown

in Inches

(FRONT SIDE)

(RIGHT

SIDE)

7

F

IGURE 3

COMPONENT

L

OCATIONS &

D

IMENSIONS

FRONT VIEW

ST-A1125-06A

FURNACE ACCESS

CONTROL/FILTER

ACCESS

POWER ENTRY

FIGURE 4

COMPONENT LOCATIONS & DIMENSIONS

ST-A1125-01A

FILTER OPENING

BLOWERS

FURNACE

INDOOR MOTOR

COMPRESSOR #1

OUTDOOR COIL

OUTDOOR FAN #1

OUTDOOR FAN #4

OUTDOOR FAN #5

OUTDOOR FAN #6

OUTDOOR FAN #3

OUTDOOR FAN #2

CONTROL COMPARTMENT

1

2

3

4

5

6

FIGURE 5

COMPONENT LOCATIONS

ST-A1125-04

Typical Dimensions Shown

in Inches

Condenser

Coil

(RIGHT

SIDE)

(FRONT SIDE)

8

FIGURE 7

C

OMPONENT ACCESS

L

OCATIONS & DIMENSIONS

ST-A1125-08A

ST-A1125-03

OUTDOOR FAN #4

OUTDOOR FAN #1

OUTDOOR FAN #2

OUTDOOR FAN #5

OUTDOOR FAN #3

OUTDOOR FAN #6

1

2

3

6

5

4

OUTDOOR COIL

HEAT EXCHANGER

FILTER RACK

RETURN COMPARTMENT

FIGURE 8

COMPONENT

LOCATIONS

ST-A1125-05

FIGURE 6

DIMENSIONS

(REAR SIDE)

*

RECOMMENDED DUCT CONNECTION SIZE

SUPPLY: 24 x 40.8 INCHES

RETURN: 47 x 20 INCHES

9

M

od

e

l R

K

N

L

-

Ser

i

es

B

1

8

0

C

L

2

5

E

B180CL35

E

C

o

ol

i

ng

P

e

r

f

or

m

a

n

c

e

1

Co

n

ti

n

u

e

d

->

Gr

oss

C

o

ol

i

ng C

a

pa

c

i

t

y

B

tu [kW]

1

8

8

,0

0

0 [

55

.0

8

]

1

8

8

,

0

0

0

[

55.

0

8

]

EER

/

SEE

R

2

1

1

.

1

/N

A1

1

.

1

/

N

A

N

om

i

n

a

l CFM/

A

RI

Ra

t

ed

C

FM

[

L/s]

6

0

0

0

/5900 [2831/

2

7

8

4

]

6000

/

5900

[

2

8

3

1/

27

8

4

]

A

R

I

N

e

t

Cool

i

ng

C

a

p

a

c

i

ty B

t

u [

k

W

]

1

8

2

,0

0

0

[

5

3

.3

3

]

1

8

2

,0

0

0

[53.

3

3

]

N

e

t

S

ensi

b

l

e

C

a

pa

c

i

t

y Btu

[k

W

]

1

3

5

,7

0

0

[

39.

7

6

]

1

35,700

[39.

7

6

]

N

e

t

L

a

t

e

n

t

C

a

p

a

c

i

ty

Bt

u

[kW]

46,300 [1

3

.57]

4

6,300

[

13.

5

7]

In

t

e

gr

a

te

d

Pa

rt

L

o

a

d

V

a

l

ue

3

13.4

13.

4

N

e

t

Sy

s

tem

P

ow

e

r

kW

16.3

5

16.

3

5

H

e

a

t

i

n

g

P

e

r

f

o

r

m

a

n

ce

(

Ga

s

)

4

H

ea

ti

ng Inpu

t

Bt

u [kW]

(1

st

Sta

ge

/ 2

n

d S

ta

ge

)

1

25,000/

2

5

0

,

0

0

0

[36.

6

2

/

7

3.2

5

]

1

7

5

,

0

00

/

3

50,000

[

51.

2

7/

1

02.

5

5

]

H

ea

ti

ng

O

u

tput B

t

u [k

W

]

(

1

s

t

S

ta

g

e

/ 2

nd

Sta

ge

)

101,500/203,000 [29.74/59.48

]

142,000/284,000 [41.61/83.21

]

Te

m

p

era

t

ure R

i

s

e Ra

nge

º

F

[

º

C

]

1

5-45 [8.3/25] 3

0

-

6

0

[

16.

7/

3

3.

3]

Stea

d

y Sta

t

e Effi

c

i

en

c

y (

%

)

8

1

8

1

N

o.

B

u

r

n

er

s

1

0

1

4

N

o. St

a

g

es

2

2

Ga

s

C

on

n

ec

t

i

on

Pi

pe

Si

z

e i

n.

[m

m

]

0.75 [19] 0.75 [19]

Co

m

pr

es

s

or

N

o

./

T

y

p

e

2/Scroll 2/S

cr

o

ll

O

u

t

d

o

o

r

Sou

n

d

R

a

t

in

g

(

d

B

)

5

91 91

O

u

td

o

o

r Coi

l -

Fi

n T

y

p

e

L

o

uvered Louvered

T

u

be

Ty

p

e

Rifled Rifled

M

i

c

roC

h

a

nn

el

Dep

t

h i

n

.

[m

m]

0

.

375

[

9

.5] 0

.

37

5 [

9

.

5]

Fa

c

e A

rea

sq. ft

. [

sq. m

]

53.3

[

4.95] 53.3 [4.95]

Row

s

/

FPI

[F

P

c

m

]

1 / 22 [9] 1 / 22 [9]

I

n

d

o

o

r

Co

i

l

-

Fi

n

Typ

e

L

o

uvered Louvered

T

u

be

Ty

p

e

R

if

le

dR

i

fl

e

d

T

u

be Si

z

e i

n.

[m

m

]

0

.

3

75

[

9

.5] 0

.

3

75

[

9

.5]

Fa

c

e A

rea

sq. ft

. [

sq. m

]

2

6.6

7

[

2.4

8]

2

6.67

[

2.

4

8

]

Row

s

/

FPI

[F

P

c

m

]

2

/ 18 [7] 2 / 18 [7]

Ref

r

i

g

era

nt

C

o

n

t

r

o

l

TX

V

alves TX Valves

Dra

i

n

C

on

n

ec

t

i

on N

o./

S

i

z

e

i

n.

[

m

m

]

1/1

[25.

4] 1

/1

[

25.4]

O

u

td

oo

r Fa

n -

T

yp

e

P

ropelle

r

Pr

op

el

l

e

r

N

o. U

sed

/D

i

a

m

e

t

e

r

i

n. [

m

m

]

4/24 [609

.

6]

4

/24 [609.

6

]

Dri

v

e

Ty

pe

/N

o.

Sp

eed

s

Dire

c

t/

1

Direct/1

C

FM

[

L

/

s

]

16000 [7

5

5

0] 160

0

0

[7550]

N

o.

M

ot

o

r

s/H

P

4 a

t

1/

3 H

P 4 a

t

1

/

3 HP

M

otor

RP

M

1075 1075

I

n

do

o

r

Fa

n

-

Ty

p

e

F

C C

en

t

rifugal FC

Centrif

u

gal

N

o. U

sed/Diame

t

e

r

in.

[

mm]

2

/18x9

[457x

2

29] 2/18x9 [457x229]

Dr

i

ve

T

y

pe

/N

o. S

pe

ed

s

Belt/Var

i

a

b

l

e

B

elt

/

Variabl

e

N

o.

Mot

o

r

s

11

M

otor

H

P

33

Mo

t

or RPM

1725 1725

Motor Frame

Si

z

e

56 56

Fil

te

r - T

y

p

e

Di

s

p

o

s

a

ble Dis

p

osa

b

le

F

ur

n

ished

Y

e

s Yes

(

NO

.)

Size

R

e

commende

d i

n. [mm

x mm

x

mm]

(

8)

2

x25x

20 [

51x635x

5

0

8

]

(8

)

2x2

5

x20

[5

1

x

635x

5

0

8

]

Refri

ge

ran

t

Ch

ar

ge Oz

.

(

Sy

s

.

1

/

S

ys

. 2) [

g]

2

0

5

/211 [5812/5

9

8

2

]

205/211 [5

8

1

2

/5982

]

W

ei

g

hts

Ne

t We

i

ght

lb

s.

[

k

g

]

1958 [

888]

1971 [

8

9

4

]

Ship W

e

igh

t

l

bs

.

[

k

g

]

2

0

58

[9

3

4

]

2

0

7

1 [939]

B

1

8

0

CM2

5

E

B

1

8

0

C

M3

5

E

1

8

8

,0

0

0 [5

5

.0

8

]

1

8

8

,0

0

0 [5

5

.0

8

]

1

1

.

1

/

N

A1

1

.

1

/

N

A

6

0

0

0

/

5

9

0

0

[

2

8

3

1

/

2

7

8

4

]

6

0

0

0

/5

9

0

0

[

2

8

3

1

/2

7

8

4

]

1

8

2

,0

0

0 [5

3

.3

3

]

1

8

2

,0

0

0

[

5

3

.3

3

]

1

3

5

,7

0

0

[3

9

.

7

6

]

1

3

5

,7

0

0 [3

9

.7

6

]

4

6

,3

0

0

[

1

3

.5

7

]

4

6

,3

0

0

[1

3

.

5

7

]

1

3

.

4

1

3

.4

1

6

.3

5

1

6

.

3

5

1

2

5

,

0

0

0

/

2

5

0

,

0

0

0

[3

6

.

6

2

/

7

3

.

2

5

]

1

7

5

,

0

0

0

/3

5

0

,

000 [

51

.

27/1

02.

5

5

]

1

0

1

,5

0

0

/2

0

3

,0

0

0

[2

9

.7

4

/5

9

.4

8

]

1

4

2

,0

0

0

/284,000

[41

.6

1

/

83.

21

]

1

5

-4

5 [8

.3

/2

5

]3

0

-6

0

[1

6

.

7

/33.3

]

8

1

8

1

10 14

2

2

0

.

7

5 [1

9

]

0

.

7

5 [1

9

]

2

/

Sc

r

o

l

l

2

/

Sc

r

o

l

l

9

191

L

ou

v

ered L

ou

ve

r

e

d

R

i

fl

e

d

R

if

led

0

.

3

7

5

[9.5

]

0.

3

7

5

[9.5

]

5

3

.

3

[4

.9

5

]

5

3

.

3

[

4

.9

5

]

1

/ 2

2

[

9

]

1

/ 22

[

9

]

Louv

ered

L

o

uve

r

e

d

R

ifled

R

if

led

0.

375

[9.

5

]0.

375

[9.

5

]

2

6

.

6

7

[

2

.4

8

]

2

6

.

67 [2

.

48]

2 / 1

8

[7

]

2 / 18

[

7

]

TX

V

a

l

v

es TX

V

a

l

v

es

1

/

1 [25.4

]

1

/

1 [

2

5.

4]

Prop

e

lle

r

Pr

o

p

e

l

l

e

r

4

/

24 [609.6] 4/

2

4 [6

0

9

.6

]

Direct/1

D

irect/1

16000 [7550]

160

0

0

[

7

5

5

0]

4

a

t

1/

3

HP 4 at

1

/3

HP

1075 1075

FC C

e

ntrifu

ga

l FC Ce

n

trifugal

2/

1

8

x

9

[4

5

7

x229] 2/18x

9

[457x

2

29

]

B

e

lt

/Var

i

abl

e

Belt

/

Va

r

iabl

e

11

55

1725 1725

184

18

4

Disposable Dispo

s

ab

l

e

Yes

Y

e

s

(

8)

2x

25

x2

0 [5

1x635x5

08

]

(8)2x25

x

20

[5

1x635x

508

]

2

05

/

211 [5812/

5

98

2

]

205/211 [

5

8

1

2

/

5982

]

1987

[9

01

]

2

0

0

0 [907]

2

08

7

[947

]

2100 [953]

GENERAL DATA - RKNL

NOM. SIZES 7.5-10 TON [26.4 & 35.2 kW] ENERGYSTAR COMPLIANT MODELS

10

M

od

e

l R

K

N

L

-

Ser

i

es

B

1

8

0

D

L

2

5

E

B180DL

3

5

E

C

o

ol

i

ng

P

e

r

f

or

m

a

n

c

e

1

Co

n

ti

n

u

e

d

-

>

Gr

oss

C

o

ol

i

ng C

a

pa

c

i

t

y

B

tu [kW]

1

8

8

,0

00

[

5

5

.08]

1

8

8

,000

[

5

5

.

08

]

EER

/

SEE

R

2

1

1

.

1

/NA 11.

1/

NA

N

om

i

n

a

l CFM/

A

RI

Ra

t

ed

C

FM

[

L/s]

6000/

5

9

0

0 [2831/

2784

]

6

000

/

5900

[2831/

2

7

8

4

]

A

R

I

N

e

t

Cool

i

ng

C

a

p

a

c

i

ty B

t

u [

k

W

]

182,000 [5

3

.33

]

1

8

2

,00

0

[

53.

33]

N

e

t

S

ensi

b

l

e

C

a

pa

c

i

t

y Btu

[k

W

]

1

3

5

,7

0

0

[

3

9

.76]

1

3

5

,7

0

0

[

39.

7

6

]

N

e

t

L

a

t

e

n

t

C

a

p

a

c

i

ty

Bt

u

[kW]

4

6,300 [13.57]

4

6,300

[

13.

5

7

]

In

t

e

gr

a

te

d

Pa

rt

L

o

a

d

V

a

l

ue

3

13.

4

1

3.

4

N

e

t

Sy

s

tem

P

ow

e

r

kW

1

6

.

35 1

6

.

3

5

H

e

a

t

i

n

g

P

e

r

f

o

r

m

a

n

ce

(

Ga

s

)

4

H

ea

ti

ng Inpu

t

Bt

u [kW]

(1

st

Sta

ge

/ 2

n

d S

ta

ge

)

125,000/

250,000

[3

6

.

62/

73.

25

]

175,0

00/

350

,00

0

[51.

2

7/

102.

5

5

]

H

ea

ti

ng

O

u

tput B

t

u [k

W

]

(

1

s

t

S

ta

g

e

/ 2

nd

Sta

ge

)

1

01,5

00/203,000 [29.74/5

9

.48

]

142,000/

2

84

,00

0

[

41.

6

1

/83.

2

1

]

Te

m

p

era

t

ure R

i

s

e Ra

nge

º

F

[

º

C

]

15-

4

5 [8.

3

/25] 3

0

-

60

[

16

.

7/3

3

.3

]

Stea

d

y Sta

t

e Effi

c

i

en

c

y (

%

)81 8

1

N

o.

B

u

r

n

er

s

10

14

N

o. St

a

g

es

2

2

Ga

s

C

on

n

ec

t

i

on

Pi

pe

Si

z

e i

n.

[m

m

]

0.7

5 [1

9]

0.

75

[19]

Co

m

pr

es

s

or

N

o./

T

y

p

e

2/

Scroll 2/

S

croll

O

u

t

d

o

o

r

Sou

n

d

R

a

t

in

g

(

d

B

)

5

9

1

91

O

u

td

o

o

r Coi

l -

Fi

n T

y

p

e

L

ou

vered

Louv

ered

T

u

be

Ty

p

e

Rifled

R

i

fle

d

T

u

be Si

z

e i

n.

[m

m

]

O

D

0.

37

5 [9.5

]

0.375 [9.

5

]

Fa

c

e A

rea

sq. ft

. [

sq. m

]

5

3.

3

[

4.

95

]

53

.

3 [

4.

95

]

Row

s

/

FPI

[F

P

c

m

]

1

/ 22

[

9] 1

/

22

[9]

I

n

d

o

o

r

Co

i

l

-

Fi

n

Typ

e

L

o

u

vered

L

ouv

ered

T

u

be

Ty

p

e

Rifled

R

i

fled

T

u

be Si

z

e i

n.

[m

m

] 0.375 [9.

5]

0.375 [9.5

]

Fa

c

e A

rea

sq. ft

. [

sq. m

]

26.67

[

2.48] 26.67 [2.

48

]

Row

s

/

FPI

[F

P

c

m

]

2

/ 18

[

7] 2

/

18

[7]

Ref

r

i

g

era

nt

C

o

n

t

r

o

l

TX

V

al

ve

s

T

X

Va

l

v

e

s

Dra

i

n

C

on

n

ec

t

i

on N

o./

S

i

z

e

i

n.

[

m

m

]

1/1

[2

5.4

]

1

/

1 [25.4]

O

u

td

oo

r Fa

n -

T

yp

e

Prop

e

lle

r

Pro

p

elle

r

N

o. U

sed

/D

i

a

m

e

t

e

r

i

n. [

m

m

]

4/

24 [609.6] 4/2

4

[60

9

.6

]

Dri

v

e

Ty

pe

/N

o.

Sp

eed

s

Direct/1 Direct/

1

C

FM

[

L

/

s

]

16000

[

7550]

16000

[7

5

5

0

]

N

o.

M

ot

o

r

s/H

P

4

at

1

/3

HP

4

at

1

/3 H

P

M

otor

RP

M

1075 1075

I

n

do

o

r

Fa

n

-

Ty

p

e

F

C

Ce

n

trifugal FC Centrifu

ga

l

N

o. U

sed/Diame

t

e

r

in.

[

mm] 2

/

18x9 [457x2

2

9

]

2/1

8

x9 [457x229]

Dr

i

ve

T

y

pe

/N

o. S

pe

ed

s

Belt/

V

a

ri

abl

e

Bel

t

/

Va

ri

a

bl

e

N

o.

Mot

o

r

s1

1

M

otor

H

P33

Mo

t

or RPM 1725 1725

Motor Frame

Si

z

e

56 56

Fil

te

r - T

y

p

e

D

is

p

osab

l

eDi

s

p

osa

b

l

e

F

ur

n

ished Yes

Y

e

s

(

NO

.)

Size

R

e

commende

d i

n. [mm

x mm

x

mm]

(

8)

2

x25x

2

0 [51x

6

3

5

x508

]

(8)2

x

25x20

[

51x635x

5

0

8

]

Refri

ge

ran

t

Ch

ar

ge Oz

.

(

Sy

s

.

1/S

ys

. 2) [

g]

205/

2

1

1

[5812/5982

]

2

0

5

/

211

[

5812/5

9

8

2

]

We

i

gh

ts

Ne

t We

i

ght

lb

s.

[

k

g

]

1958

[888] 1971 [894]

Ship W

e

igh

t

l

bs

.

[

k

g

]

2058

[

934] 2071 [939]

B

1

8

0

D

M

2

5

E

B

1

8

0

D

M3

5

E

1

8

8

,0

0

0 [5

5

.0

8

]

1

8

8

,0

0

0 [5

5

.0

8

]

1

1

.

1

/

N

A1

1

.

1

/

N

A

6

0

0

0

/

5

9

0

0

[

2

8

3

1

/

2

7

8

4

]

6

0

0

0

/5

9

0

0

[2

8

3

1

/2

7

8

4

]

1

8

2

,0

0

0 [5

3

.3

3

]

1

8

2

,0

0

0

[

5

3

.3

3

]

1

3

5

,7

0

0

[3

9

.

7

6

]

1

3

5

,7

0

0 [3

9

.7

6

]

4

6

,3

0

0

[

1

3

.5

7

]

4

6

,3

0

0

[1

3

.

5

7

]

1

3

.

4

1

3

.4

1

6

.3

5

1

6

.

3

5

1

2

5

,

0

0

0

/

2

5

0

,

0

0

0

[3

6

.

6

2

/

7

3

.

2

5

]

1

7

5

,

0

0

0

/3

5

0

,

000 [

51

.

27/1

0

2

.

5

5

]

1

0

1

,5

0

0

/2

0

3

,0

0

0

[2

9

.7

4

/5

9

.4

8

]

1

4

2

,0

0

0

/284,000

[41

.6

1

/

83.

21

]

1

5

-4

5 [8

.3

/2

5

]3

0

-6

0

[1

6

.

7

/33.3

]

8

1

8

1

10 14

2

2

0

.

7

5 [1

9

]

0

.

7

5

[

1

9

]

2

/

Sc

r

o

l

l

2

/

Scro

l

l

9

191

L

ou

v

ered L

o

uve

r

ed

R

i

fl

e

d

R

if

led

0

.

3

7

5

[9.5

]

0.

3

7

5

[9.5

]

5

3

.

3

[4

.9

5

]

5

3.

3

[

4

.9

5

]

1

/ 2

2

[

9

]

1

/ 22

[

9]

Louv

ered

Louve

r

ed

R

ifled

R

if

led

0.

375

[9.

5

]0.

375

[9.

5

]

2

6

.

6

7

[

2

.4

8

]

2

6

.

67 [2

.

48]

2 / 1

8

[7

]

2 / 18

[

7

]

TX

V

a

l

v

es TX

V

a

l

v

es

1

/

1 [25.

4

]

1

/

1 [

2

5.

4]

Prop

e

lle

r

P

r

o

p

e

ll

e

r

4

/

24 [609.6] 4/

2

4 [609

.6

]

Direct/1

D

irect/

1

16000 [7550] 1

60

00 [

75

50]

4

a

t

1/

3

HP 4 at

1

/3

HP

1075 1075

FC C

e

ntrifug

al

FC Centrifugal

2/

1

8

x

9

[4

5

7

x229] 2/18x

9

[457x

2

29

]

B

e

lt

/Var

i

abl

e

B

e

lt

/

Va

r

iabl

e

11

55

1725 1725

184

18

4

Disposable

D

ispo

s

ab

l

e

Yes

Y

e

s

(

8)

2x

25x

2

0 [5

1x635x5

08

]

(

8)2x25

x2

0

[

51x635x

508

]

2

05

/

211 [5812/

5

98

2

]

205/211 [

5

8

1

2

/

5982

]

1987

[9

01

]

2

0

0

0 [907]

2

08

7

[947

]

2100 [953]

GENERAL DATA - RKNL

NOM. SIZES 7.5-10 TON [26.4 & 35.2 kW] ENERGYSTAR COMPLIANT MODELS

11

M

od

e

l R

K

N

L

-

Ser

i

es

B

1

8

0

Y

L

3

5

E

B180YM3

5

E

C

o

ol

i

ng

P

e

r

f

or

m

a

n

c

e

1

Co

n

ti

n

u

e

d

-

>

Gr

oss

C

o

ol

i

ng C

a

pa

c

i

t

y

B

tu [kW]

1

8

8

,0

00

[

5

5

.08]

1

8

8

,000

[

5

5

.

08

]

EER

/

SEE

R

2

1

1

.

1

/NA 11.

1/

NA

N

om

i

n

a

l CFM/

A

RI

Ra

t

ed

C

FM

[

L/s]

6000/

5

9

0

0 [2831/

2784

]

6

000

/

5900

[2831/

27

8

4

]

A

R

I

N

e

t

Cool

i

ng

C

a

p

a

c

i

ty B

t

u [

k

W

]

182,000 [5

3

.33

]

1

8

2

,00

0

[

53.

33]

N

e

t

S

ensi

b

l

e

C

a

pa

c

i

t

y Btu

[k

W

]

1

3

5

,7

0

0

[

3

9

.76]

1

3

5

,7

0

0

[

39.

7

6

]

N

e

t

L

a

t

e

n

t

C

a

p

a

c

i

ty

Bt

u

[kW]

4

6,300 [13.57]

4

6,300

[

13.

5

7

]

In

t

e

gr

a

te

d

Pa

rt

L

o

a

d

V

a

l

ue

3

13.

4

1

3.

4

N

e

t

Sy

s

tem

P

ow

e

r

kW

1

6

.

35 1

6

.

3

5

H

e

a

t

i

n

g

P

e

r

f

o

r

m

a

n

ce

(

Ga

s

)

4

H

ea

ti

ng Inpu

t

Bt

u [kW]

(1

st

Sta

ge

/ 2

n

d S

ta

ge

)

175,000/

350,000

[5

1

.

27/

102

.55

]

175,0

00/

350

,00

0

[51.

2

7/

102.

5

5

]

H

ea

ti

ng

O

u

tput B

t

u [k

W

]

(

1

s

t

S

ta

g

e

/ 2

nd

Sta

ge

)

1

42,0

00/284,000 [41.61/8

3

.21

]

142,000/

2

84

,00

0

[

41.

6

1

/83.

2

1

]

Te

m

p

era

t

ure R

i

s

e Ra

nge

º

F

[

º

C

]

30-

6

0 [16.7

/

33.

3

]

30-60

[

16.

7

/

33.3]

Stea

d

y Sta

t

e Effi

c

i

en

c

y (

%

)81 8

1

N

o.

B

u

r

n

er

s

14

14

N

o. St

a

g

es

2

2

Ga

s

C

on

n

ec

t

i

on

Pi

pe

Si

z

e i

n.

[m

m

]

0.7

5 [1

9]

0.

75

[19]

Co

m

pr

es

s

or

N

o./

T

y

p

e

2/

Scroll 2/

S

croll

O

u

t

d

o

o

r

Sou

n

d

R

a

t

in

g

(

d

B

)

5

9

1

91

O

u

td

o

o

r Coi

l -

Fi

n T

y

p

e

L

ou

vered

Louv

ered

T

u

be

Ty

p

e

Rifled

R

i

fle

d

T

u

be Si

z

e i

n.

[m

m

]

O

D

0.

37

5 [9.5

]

0.375 [9.

5

]

Fa

c

e A

rea

sq. ft

. [

sq. m

]

5

3.3

[

4.

95

]

53

.

3 [

4

.95

]

Row

s

/

FPI

[F

P

c

m

]

1

/ 22

[

9] 1

/ 2

2

[9]

I

n

d

o

o

r

Co

i

l

-

Fi

n

Typ

e

L

o

u

vered

L

ouv

ered

T

u

be

Ty

p

e

Rifled

R

i

fled

T

u

be Si

z

e i

n.

[m

m

] 0.375 [9.

5]

0.375 [9.5

]

Fa

c

e A

rea

sq. ft

. [

sq. m

]

26.67

[

2.48] 26.67 [2.

48

]

Row

s

/

FPI

[F

P

c

m

]

2

/ 18

[

7] 2

/

18

[7]

Ref

r

i

g

era

nt

C

o

n

t

r

o

l

TX

V

a

l

v

e

s

T

X

Va

l

v

e

s

Dra

i

n

C

on

n

ec

t

i

on N

o./

S

i

z

e

i

n.

[

m

m

]

1/1

[2

5.4

]

1

/

1 [25.4]

O

u

td

oo

r Fa

n -

T

yp

e

Prop

e

lle

r

Pro

p

elle

r

N

o. U

sed

/D

i

a

m

e

t

e

r

i

n. [

m

m

]

4/

24 [609.6] 4/2

4

[60

9

.6

]

Dri

v

e

Ty

pe

/N

o.

Sp

eed

s

Direct/1 Direct/

1

C

FM

[

L

/

s

]

16000

[

7550]

16000

[7

5

5

0

]

N

o.

M

ot

o

r

s/H

P

4

at

1

/3

HP

4

at

1

/3 H

P

M

otor

RP

M

1075 1075

I

n

do

o

r

Fa

n

-

Ty

p

e

F

C

Ce

n

trifugal FC Centrifu

ga

l

N

o. U

sed/Diame

t

e

r

in.

[

mm] 2

/

18x9 [457x2

2

9] 2/1

8

x9 [457x229]

Dr

i

ve

T

y

pe

/N

o. S

pe

ed

s

Belt/

V

a

ri

abl

e

Bel

t

/

Va

ri

a

bl

e

N

o.

Mot

o

r

s1

1

M

otor

H

P35

Mo

t

or RPM 1725 1725

Motor Frame

Si

z

e

56 184

Fil

te

r - T

y

p

e

D

is

p

osab

l

eDi

s

p

osa

b

l

e

F

ur

n

ished Yes

Y

e

s

(

NO

.)

Size

R

e

commende

d i

n. [mm

x mm

x

mm]

(

8)

2

x25x

2

0 [51x

6

3

5

x508

]

(8)2

x

25x20

[

51x635x

5

0

8

]

Refri

ge

ran

t

Ch

ar

ge Oz

.

(

Sy

s

.

1

/

S

ys

. 2) [

g]

205/

2

1

1

[5812/5982

]

2

0

5

/

211

[

5812/5

9

8

2

]

W

ei

g

hts

Ne

t We

i

ght

lb

s.

[

k

g

]

1986

[901] 2015 [914]

Ship W

e

igh

t

l

bs

.

[

k

g

]

2086

[

946] 2115 [959]

B

2

4

0

CL

3

0

E

B

2

4

0

C

L

4

0

E

2

4

4

,0

0

0 [7

1

.4

9

]

2

4

4

,0

0

0 [7

1

.4

9

]

1

1

.

1

/

N

A1

1

.

1

/

N

A

8

0

0

0

/

7

7

2

5

[

3

7

7

5

/

3

6

4

5

]

8

0

0

0

/7

7

2

5

[

3

7

7

5

/3

6

4

5

]

2

3

4

,0

0

0 [6

8

.5

6

]

2

3

4

,0

0

0

[

6

8

.5

6

]

1

7

1

,6

0

0

[5

0

.

2

8

]

1

7

1

,6

0

0 [5

0

.2

8

]

6

2

,4

0

0

[

1

8

.2

8

]

6

2

,4

0

0

[1

8

.

2

8

]

1

2

.

2

1

2

.2

2

1

.0

4

2

1

.

0

4

1

5

0

,

0

0

0

/

3

0

0

,

0

0

0

[4

3

.

9

5

/

8

7

.

9

]

2

0

0

,

0

0

0

/4

0

0

,

000 [

58

.

6/

1

1

7.

2

]

1

2

1

,5

0

0

/2

4

3

,0

0

0

[3

5

.6

/7

1

.2

]

1

6

2

,0

0

0

/324,000

[47

.4

7

/

94.

93

]

1

5

-4

5 [8

.3

/2

5

]2

5

-5

5

[1

3

.

9

/30.6

]

8

1

8

1

12 14

2

2

0

.

7

5 [1

9

]

0

.

7

5 [1

9

]

2

/

Sc

r

o

l

l

2

/

Sc

r

o

l

l

9

191

L

ou

v

ered L

ou

ve

r

e

d

R

i

fl

e

d

R

if

led

0

.

3

7

5

[9.5

]

0.

3

7

5

[9.5

]

5

3

.

3

[4

.9

5

]

5

3

.

3

[

4

.9

5

]

2

/ 2

2

[

9

]

2

/ 22

[

9]

Louv

ered

Louve

r

ed

R

ifled

R

if

led

0.

375

[9.

5

]0.

375

[9.

5

]

2

6

.

6

7

[

2

.4

8

]

2

6

.

67 [2

.

48]

3 / 1

3

[5

]

3 / 13

[

5

]

TX

V

a

l

v

es TX

V

a

l

v

es

1

/

1 [25.4

]

1

/

1 [

2

5.

4]

Prop

e

lle

r

Pr

o

p

e

ll

e

r

6

/

24 [609.6] 6/

2

4 [609

.6

]

Direct/1

D

irect/1

19800 [9344] 1

98

00 [

934

4]

6

a

t

1/

3

HP 6 at

1

/3

HP

1075 1075

FC C

e

ntrifu

ga

l FC Centrifugal

2/

1

8

x

9

[4

5

7

x229] 2/18x

9

[457x

2

29

]

B

e

lt

/Var

i

abl

e

B

e

lt

/

Va

r

iabl

e

11

55

1725 1725

184

18

4

Disposable

D

ispo

s

ab

l

e

Yes

Y

e

s

(

8)

2x

25x

2

0 [5

1x635x5

08

]

(8)2x25

x2

0

[

51x635x

508

]

4

02

/

331 [11397/93

84

]

402/331 [

1

1

3

9

7

/9384

]

2289

[1

03

8] 2

3

0

3

[10

4

5

]

2

38

9

[108

4

]24

0

3 [1090]

GENERAL DATA - RKNL

NOM. SIZES 7.5-10 TON [26.4 & 35.2 kW] ENERGYSTAR COMPLIANT MODELS

12

M

od

e

l R

KN

L

-

Ser

ies

B2

4

0

C

M

3

0

E

B240CM40

E

C

o

ol

i

ng

P

e

r

f

or

m

a

n

c

e

1

Co

n

ti

n

u

e

d

-

>

Gr

oss

C

o

ol

i

ng C

a

pa

c

i

t

y

B

tu [kW]

2

4

4

,0

00

[

7

1

.49]

2

4

4

,000

[

7

1

.

49

]

E

ER

/

S

EE

R

2

1

1

.

1

/NA 11.

1

/

NA

N

om

i

n

a

l CFM/

ARI

Ra

ted

C

FM

[

L/s]

8000/

7

7

2

5 [3775/

3645

]

8

000

/

7725

[3775/

3

6

4

5

]

A

R

I

N

et

Cool

i

ng

C

a

p

a

c

i

ty B

tu

[

k

W]

234,000 [6

8

.56

]

2

3

4,00

0

[6

8.

56]

N

e

t

Sensi

b

l

e

Ca

pa

c

i

ty

Btu

[k

W]

1

7

1

,6

0

0

[

5

0.

28]

1

7

1

,600

[50.

2

8

]

N

e

t

L

a

t

e

n

t

C

a

p

a

c

i

ty

Bt

u [kW]

62,400 [18.28]

62,400

[18.

2

8]

In

t

e

gr

a

te

d

Pa

rt

L

o

a

d

V

a

l

ue

3

12.

2

1

2.

2

N

e

t

Sy

s

tem

P

ow

e

r

kW

2

1

.

04

21

.

0

4

He

a

ti

n

g

P

e

r

f

o

r

m

a

n

ce

(

Ga

s)

4

H

ea

ti

ng Inpu

t

Bt

u [kW]

(1

st

Sta

ge

/ 2

n

d S

ta

ge

)

1

50,000/

300,000

[

4

3

.

95/

8

7

.9

]

200,0

00/

400

,

00

0

[58.

6

/

117.

2

]

H

ea

ti

ng

O

u

tput B

t

u [k

W

]

(

1

s

t

S

ta

ge

/ 2

nd

Sta

ge

)

121,5

00/243,000 [35.6/

7

1

.

2

]

162,000/

324

,00

0

[

47.

4

7

/94.

93

]

Te

mp

era

ture R

i

se Ra

nge

º

F [

º

C

]

15-

4

5 [8.

3

/25] 2

5-

55

[

1

3.

9/3

0.6

]

Stea

d

y Sta

t

e Effi

c

i

en

c

y (

%

)81

81

N

o.

B

u

r

n

er

s

12

1

4

N

o

. St

a

g

es

2

2

Ga

s

C

on

n

ec

t

i

on

Pi

pe

Si

z

e i

n.

[m

m

]

0

.7

5 [1

9

]

0.

75

[19]

Co

m

pr

es

s

or

N

o./

T

y

p

e2

/

Scroll 2/

S

croll

O

u

td

o

o

r Sou

n

d R

a

tin

g

(

d

B

)

5

9

1

91

O

u

td

o

o

r Coi

l

-

Fi

n

T

y

p

e

L

ou

vered

Louv

ered

Tu

be

Ty

p

e Rifled

R

ifled

T

u

be Si

z

e i

n.

[m

m

]

O

D

0.

37

5 [9.5] 0.375

[9.

5

]

F

a

c

e

A

rea

sq. ft

.

[

sq. m

]

5

3.

3

[

4.

95

]

53

.

3 [

4

.

95

]

Row

s

/

FPI

[F

P

c

m

]

2

/ 22

[

9] 2

/

22

[9]

In

d

o

or

Co

i

l -

Fi

n Typ

e

L

ou

vered

Louv

ered

Tu

be

Ty

p

e Rifled

R

ifled

T

u

be Si

z

e i

n.

[m

m

] 0.375 [9.

5]

0.375 [9.5

]

Fa

c

e A

rea

sq. ft

. [

sq. m

]

26.67

[

2.48] 26.67 [2.4

8

]

R

ow

s

/

F

PI

[F

P

c

m

]

3

/

13

[

5

]3

/

1

3

[5]

Ref

r

i

g

era

n

t

C

o

n

t

r

o

l

TX

V

al

v

e

s

T

X

V

a

l

v

e

s

Dra

i

n

C

on

n

ec

t

i

on N

o./

S

i

z

e

i

n.

[m

m

]

1/1

[25

.4

]

1

/

1 [25.4]

O

u

td

oo

r Fa

n -

T

yp

e

Prop

e

lle

r

Pro

p

elle

r

N

o. U

sed

/D

i

a

m

e

t

e

r

i

n. [

m

m

]6

/

24 [609.6] 6/2

4

[60

9

.6

]

Dri

v

e

Ty

pe

/N

o.

Sp

eed

s

Direct/1 Direct/

1

C

FM

[

L

/

s

]

19800

[

9344]

19800

[9

3

4

4

]

N

o.

M

ot

o

r

s/H

P

6

at

1

/3

HP

6

at

1

/3 H

P

M

otor

RP

M

1075 1075

I

n

do

o

r

Fa

n

-

Ty

p

e

F

C

Ce

n

trifugal FC Centrifu

ga

l

N

o. U

sed/Diame

t

e

r

in.

[

mm] 2

/

18x9 [457x2

2

9

]

2/1

8

x9 [457x229]

Dr

i

ve

T

y

pe

/N

o. S

pe

ed

s

Belt/

V

a

ri

a

b

l

e

Bel

t

/

Va

ri

a

bl

e

N

o.

Mot

o

r

s1

1

M

otor

H

P 7 1/

2

7 1/

2

Mo

t

or RPM 1725 1725

Motor Frame S

i

z

e

213 213

Fil

te

r - T

y

p

e

D

is

p

osab

l

eDi

s

p

osa

b

l

e

F

ur

n

ish

e

d Yes

Y

e

s

(

NO

.

) Size

R

e

commende

d i

n. [mm

x mm x mm]

(

8)

2

x25x

2

0 [51x

6

3

5

x508

]

(8)2

x

25x20

[

51x635x

5

0

8

]

Refri

ge

ran

t

Ch

ar

ge

O

z.

(Sy

s

. 1/

S

ys

. 2)

[g]

402/

331

[11397/9384

]

402/

331 [11397/

938

4

]

W

ei

g

hts

Ne

t Weight

lbs. [k

g

] 2327

[

1056] 2341 [1062]

Ship

W

eight

lb

s

.

[

k

g]

2427

[1101]

2441

[1107]

B

2

4

0

CN

3

0

E

B

2

4

0

CN

4

0

E

2

4

4

,

0

0

0

[7

1

.

4

9

]

2

4

4

,

0

0

0

[7

1

.

4

9

]

1

1

.

1

/

N

A1

1

.

1

/

N

A

8

0

0

0

/7

7

2

5

[3

7

7

5

/3

6

4

5

]

8

0

0

0

/7

7

2

5

[

3

7

7

5

/3

6

4

5

]

2

3

4

,0

0

0 [6

8

.5

6

]

2

3

4

,0

0

0

[

6

8

.5

6

]

1

7

1

,6

0

0

[5

0

.

2

8

]

1

7

1

,6

0

0 [5

0

.2

8

]

6

2

,4

0

0

[

1

8

.2

8

]

6

2

,4

0

0

[1

8

.

2

8

]

1

2

.

2

1

2

.2

2

1

.

0

4

2

1

.

0

4

1

5

0

,0

0

0

/

3

0

0

,0

0

0 [4

3

.9

5

/8

7

.9

]

2

0

0

,0

0

0

/4

0

0

,000 [

58

.6/

117.

2

]

1

2

1

,5

0

0

/2

4

3

,0

0

0

[3

5

.6

/7

1

.2

]

1

6

2

,0

0

0

/32

4

,0

0

0

[47

.4

7

/

94.

9

3

]

1

5

-4

5 [8

.3

/2

5

]2

5

-5

5

[13.

9

/30.6

]

8

1

8

1

1

2

14

2

2

0

.

7

5 [1

9

]

0

.

7

5 [1

9

]

2

/

Sc

r

o

l

l

2/Sc

r

o

ll

9

191

L

ou

v

ered L

ou

ve

r

e

d

R

i

f

l

e

dR

if

led

0

.

3

7

5

[9

.5

]

0.

3

7

5

[9.5

]

5

3

.

3

[4

.

9

5]

5

3

.

3

[

4

.9

5

]

2

/ 22 [9

]2

/ 22

[

9

]

Louv

ered

L

ou

ve

r

e

d

R

ifled

R

if

led

0.3

7

5 [9.

5

]0.

37

5 [9.5]

2

6

.

6

7

[

2

.

48] 26

.

6

7 [2.48]

3 / 13 [5

]3

/

13

[

5]

TX

V

alv

es T

X

Va

lv

e

s

1

/1

[25.4

]

1/1 [

2

5.

4]

Prop

e

lle

r

P

rop

el

l

e

r

6

/

24 [609.6

]

6/24

[

6

09

.

6]

D

irect/1 Direct/1

19800

[

9344]

19800 [

9

34

4]

6

a

t

1/

3 H

P6

a

t 1/

3

HP

1075 1075

FC C

e

ntrifugal FC Cen

t

r

ifu

g

al

2/

1

8x9

[

4

57

x229] 2

/

18x

9

[4

5

7

x

229]

B

e

lt

/Var

ia

bl

e

Be

l

t/

Va

r

iab

l

e

11

7

1/

2

7 1/2

172

5

1725

213 2

1

3

Dis

p

osable

D

ispo

s

ab

l

e

Y

es Y

e

s

(8)2x25x20

[51

x635x5

08

]

(

8

)2x

2

5

x

20

[

5

1

x635x

508

]

402/

331 [11397/

9384

]

402/331

[11397/

9384

]

2325 [1055] 2340 [1061]

2425 [

110

0

]

2440 [11

07]

GENERAL DATA - RKNL

NOM. SIZES 7.5-10 TON [26.4 & 35.2 kW] ENERGYSTAR COMPLIANT MODELS

13

M

od

e

l R

KN

L

-

Ser

ies

B2

4

0

D

L

3

0

E

B

240DL

4

0

E

C

o

ol

i

ng

P

e

r

f

or

m

a

n

c

e

1

Co

n

ti

n

u

e

d

-

>

Gr

oss

C

o

ol

i

ng C

a

pa

c

i

t