INSTALLING THE INLET TUBING

When your planning is complete, you will have to determine

where all the inlets and the power unit will be located. You

have also mapped out the location of your trunk line and

found the access you need to run vertical tubing from one

level of your house to another level. You should have

acquainted yourself with the methods of joining plastic

tubing and acquired the tools you’ll need to install your

NuTone Central Vacuum System. Now, you can begin installation.

The first step to install the inlet tubing which connects the

wall inlets to the branch lines. As explained before, the inlet

lines run inside interior walls. You will find access to these

walls through your attic or basement. Briefly, you want to find

the exact location in the wall, drill an access hole through the

wall plate or header, and insert the tubing into the wall cavity.

This part of your installation requires close observation and

careful measurements. Take your time and make sure you

accurately line up your access holes with the locations

you’ve chosen for your wall inlets.

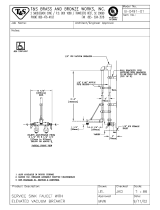

Locating Attic Access Holes

Drill the access holes directly above the inlet location.

To accurately locate the access hole, you must find the

space between wall studs where the inlet is to be located.

Observe the area around the inlet location. Look for

references you might be able to find in the attic: electrical

wiring, ductwork, doorways, etc. Measure and note the

distance from these references to the inlet location.

Enter the attic and find the inlet wall. Have a helper

downstairs knock on the top of the wall right above the inlet

location; locate the general area by following the sound.

Most likely, you will have to clear away insulation. Ask your

helper to continue knocking until you locate the area

between wall studs directly above the inlet location.

Next, measure the thickness of the wall. Mark the exact

center of the wall where you will drill the access hole.

Remember that the access hole must be placed exactly in

the center of the wall.

Locating Basement Access Holes

To locate access holes in the basement, remove the toe

molding or baseboard at the base of the inlet wall. Carefully

loosen the molding or baseboard by inserting the blade of a

putty knife behind it. Force another putty knife between the

first knife and the baseboard or wall. Gently hammer a cold

chisel between the two knife blades, prying the loosened

molding away from the baseboard or the baseboard away

from the wall.

Directly below the inlet location, drill a 1/16” reference hole

through the floor into the basement. (If you’re drilling through

carpet, use an awl to slightly open the weave. This will keep

the carpet from wrapping itself around the drill bit.) Insert a

piece of scrap wire or a clothes hanger into the reference

hole so you can easily find the hole in the basement.

Once you’ve found the location in the partition wall, you

must center the access hole in the middle of the wall.

Measure half the thickness of the wall and mark the

center of the wall where you will drill the access hole. If you

cannot see the plate, you can determine this measurement

from upstairs. At the nearest doorway, measure the

thickness of the wall, including the baseboard.

In the basement measure a distance equal to half the

thickness of the wall, using the reference hole as a starting point.

13