5019 318 33190

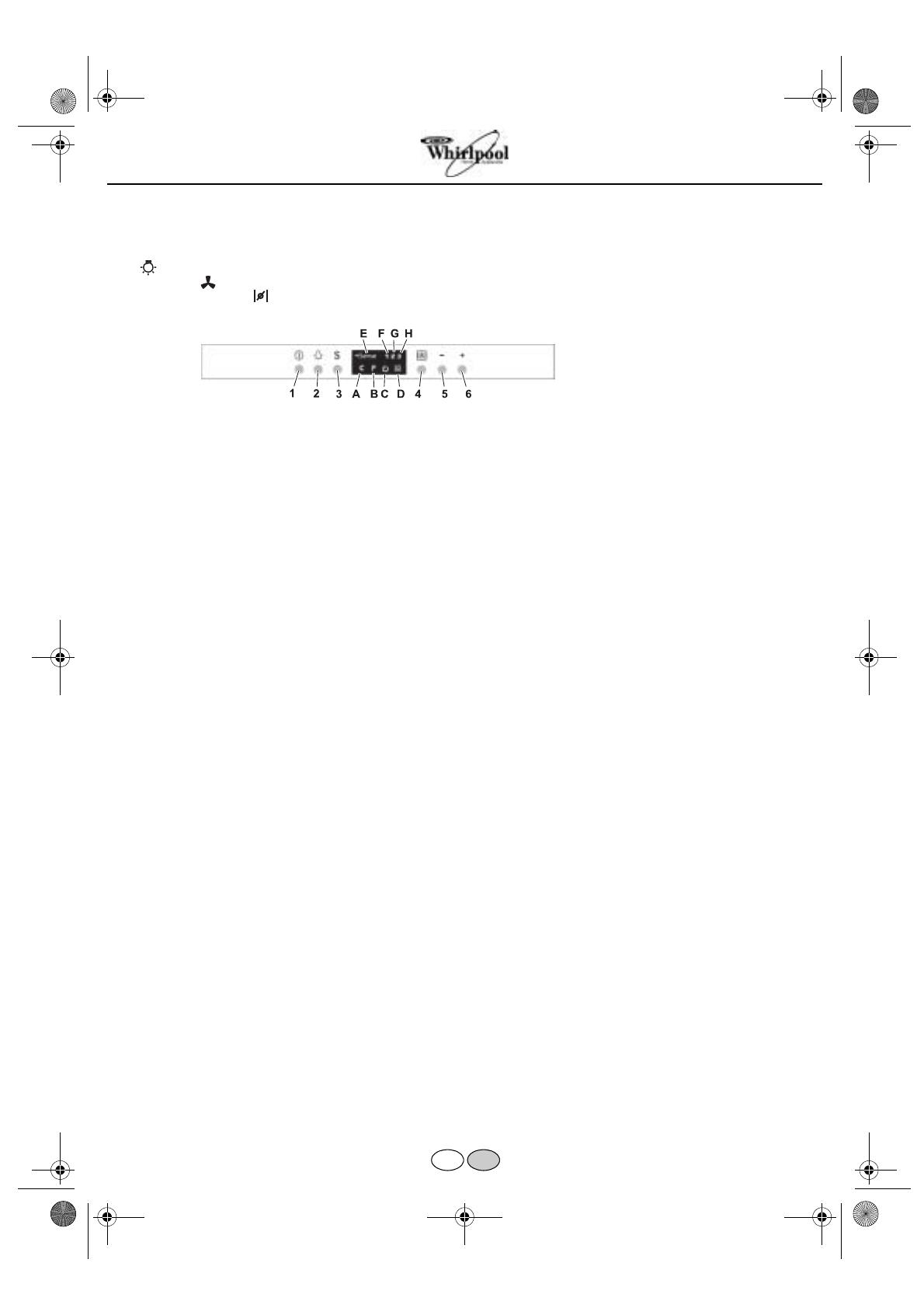

Analogue control panel

Light : move the switch to the right or press the button to switch on.

Extraction speed : Move the switch to the right or press the next button to increase extraction speed

(or open the electric shutter ).

Digital control panel with sensors

The hood is fitted with a series of sensors which enable it to operate in 2 modes:

Automatic

mode

and

Manual mode

.

Automatic mode:

the hood switches on automatically, depending on the ambient temperature (and heat) and variations in this detected by the

hood's sensors. See description of Button 3 function.

Manual mode:

the hood is switched on by the user.

Description of Buttons

1.

OFF/Stand by button:

When the hood is OFF, all the controls are disabled (all LEDs are off).

When on stand-by, the hood is ready to operate in “

Manual mode

”,

LED C

lights up.

2.

Light ON/OFF button: always works, even when the hood is OFF.

3.

ON/OFF button “

Automatic mode

”: press to activate this mode (

LED C

and

E

on) the hood switches on automatically, selecting a suitable

extraction speed in accordance with the ambient temperature (and heat) and any variations in this detected by the hood's sensors. Press

again to revert to

“Manual mode”

:

LED E

switches off,

LED C

remains on (stand by). The hood will continue to run for a few minutes

after you have finished cooking but can be turned off by pressing buttons 1 or 3. The automatic function (

LED

on) stops a few minutes

after the motor has been switched off. The automatic function must be switched on every time you start cooking.

4.

ON/OFF button for controlling intensive extraction speed in “

Manual mode

” (

LED D

switches on): when selected, it operates for 5

minutes, after which time the hood automatically reverts to the previously selected extraction speed.

5.

Buttons for controlling extraction speed

1 - 2 - 3

in “

Manual mode

”.

Description of LEDs

A.

Carbon filter

saturation led indicator

: this led lights up to indicate that the carbon filter needs to be cleaned or replaced.

Important: this indicator must be activated in order for the hood to work:

to activate it, press buttons

4

and

5

at the same time -

LED

B

lights up first, followed by

LED A

to indicate that the led indicator is working.

B.

Grease filter saturation led indicator: this led lights up to indicate that the grease filter needs to be cleaned.

C.

“Stand by” led indicator.

D.

Intensive speed led indicator.

E.

“Automatic mode” led indicator.

F.

Extraction speed 1 led indicator.

G.

Extraction speed 2 led indicator.

H.

Extraction speed 3 led indicator.

Reset filters indicator:

After cleaning or replacing the filters, with the hood on Stand by press Button

1

for more than 3 seconds.

Safety function:

this function is activated ONLY with the hood on stand-by, in the event of any SUDDEN, VIOLENT increase in the

temperature detected by the sensors, upon which the hood switches to “

Automatic mode

” and, if necessary, selects a suitable extraction

speed.

Important - upon initial installation:

Selecting the hob type:

to ensure accurate “reading” by the sensors, the latter must be calibrated to suit the type of hob as follows: with the

hood OFF, press buttons 3 and 4 at the same time until either

LED F

for gas hobs,

LED G

for induction hobs or

LED H

for electric hobs lights

up.

Automatic and manual sensor calibration:

the hood automatically “calibrates” sensor operation, but under certain circumstances (e.g.: in

the event of a prolonged power failure or upon initial installation) calibration can be carried out manually, with the hood OFF, by pressing

buttons

5

and

6

at the same time for more than 3 seconds, otherwise you can wait until the hood carries out calibration automatically.

PRODUCT SHEET

GBTR

31833190GB.fm Page 4 Wednesday, December 21, 2005 3:36 PM