SERVICE MANUAL

Sony Corporation

Connect Business Division

Published by Sony Techno Create Corporation

US Model

Canadian Model

ICD-SX46

AEP Model

UK Model

E Model

ICD-SX46/SX56

Chinese Model

Korean Model

ICD-SX46/SX56/SX66

Tourist Model

ICD-SX56

IC RECORDER

9-879-953-04

2006F16-1

© 2006.06

Ver. 1.3 2006.06

SPECIFICATIONS

ICD-SX46/SX56/SX66

Maximum recording time

The maximum recording time of all

the folders is as follows. You can

record messages for the maximum

recording time in a single folder.

Recording modes

ICD-SX46

ST 5 hr. 50 min.

STLP 11 hr. 15 min.

SP 17 hr. 50 min.

LP 47 hr. 35 min.

ICD-SX56

ST 11 hr. 45 min.

STLP 22 hr. 40 min.

SP 35 hr. 55 min.

LP 95 hr. 50 min.

ICD-SX66

ST 23 hr. 40 min.

STLP 45 hr. 30 min.

SP 72 hr. 5 min.

LP 192 hr. 20 min.

(hr.: hours/min.: minutes)

ST: Standard play stereo recording

mode

STLP: Long play stereo recording

mode

SP: Standard play monaural

recording mode

LP: Long play monaural recording

mode

Recording media

Built-in flash memory 128 MB (ICD-SX46) /

256 MB (ICD-SX56) / 512 MB (ICD-SX66),

Stereo/Monaural recording

Recording time

Frequency range

• ST: 60 Hz - 13,500 Hz

• STLP: 60 Hz - 6,900 Hz

• SP: 60 Hz - 7,000 Hz

• LP: 80 Hz - 3,500 Hz

Speaker Approx. 16 mm (

21

/

32

in.) dia.

Power output

150 mW

Input/Output

• Microphone jack (minijack, stereo)

– input for plug in power, minimum input

level: 0.6 mV, 3 kilohms or lower

impedance microphone

• Headphones jack (minijack, stereo)

– output for 8 - 300 ohms headphones

• USB connector

• DC IN 3V jack (

For Korean and the People’s

Republic of China models, this jack does not

exist.)

Playback speed control

+100% to –50% (DPC)

Power requirements

Two LR03 (size AAA) alkaline batteries: 3 V DC

Dimensions (w/h/d) (not incl. projecting parts and

controls)

28.0 × 120.0 × 13.8 mm (1

1

/

8

× 4

3

/

4

×

9

/

16

in.)

Mass (incl. batteries)

64 g (2.26 oz)

Supplied accessories

Stereo headphones × 1

USB connecting cable × 1

Application Software (CD-ROM) × 1

LR03 (size AAA) alkaline batteries x 2

Carrying pouch x 1

Your dealer may not handle some of the above listed

optional accessories. Please ask the dealer for detailed

information.

Design and specifications are subject to change without

notice.

Photo: ICD-SX56

2

ICD-SX46/SX56/SX66

TABLE OF CONTENTS

1. GENERAL ................................................................... 3

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 5

2-2. Cover (Jack)..................................................................... 5

2-3. Case Block Assy .............................................................. 6

2-4. AUDIO Board, Microphone Unit (Mic2/3)..................... 6

2-5. Ornament Belt Assy, SW Board ...................................... 7

2-6. Cover (Chassis) Block Assy ............................................ 7

2-7. MAIN Board, Liquid Crystal Display Panel ................... 8

3. TEST MODE ............................................................... 9

4. DIAGRAMS

4-1. Block Diagram – MAIN Section-1 – ............................. 13

4-2. Block Diagram – MAIN Section-2 – ............................. 14

4-3. Block Diagram – PANEL Section – ............................... 15

4-4. Printed Wiring Board – AUDIO Board (Side A) – ......... 16

4-5. Schematic Diagram – AUDIO Board (Side B) –............ 17

4-6. Schematic Diagram – AUDIO Board (1/2) – ................. 18

4-7. Schematic Diagram – AUDIO Board (2/2) – ................. 19

4-8. Printed Wiring Board – MAIN Board (Side A) –........... 20

4-9. Printed Wiring Board – MAIN Board (Side B) –........... 21

4-10. Schematic Diagram – MAIN Board (1/2) – ................... 22

4-11. Schematic Diagram – MAIN Board (2/2) – ................... 23

4-12. Printed Wiring Board – SW Board – .............................. 24

4-13. Schematic Diagram – SW Board –................................. 25

5. EXPLODED VIEWS

5-1. Case Block Assy .............................................................. 33

5-2. Chassis Block Assy ......................................................... 34

6. ELECTRICAL PARTS LIST .................................. 35

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

*

Replacement of IC6001 and IC7003 used in this set requires

a special tool.

•The voltage and waveform of CSP (chip size package) cannot

be measured, because its lead layout is different from that of

conventional IC.

• Lead layouts

surface

Lead layout of

conventional IC

CSP (chip size package)

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the lead-

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder. Operating instructiondd

Using on house current (excluding the Korean and the

People’s Republic of China models)

Connect the AC power adaptor AC-E30HG (not

supplied) to the DC IN 3V jack of the unit and to the

wall outlet. Do not use any other AC power

adaptor.

Polarity of the plug

3

ICD-SX46/SX56/SX66

SECTION 1

GENERAL

This section is extracted

from instruction manual.

Identifying the front and rear panels of the unit

1 i (headphones) jack

2 Built-in microphone

3 DIRECTNL (directional) switch

4 VOICE UP (Digital Voice Up) switch

5 DPC ON/OFF switch

6 Display window

7 ERASE button

8 DIVIDE/

(bookmark) button

9 A-B

(repeat)/PRIORITY button

0 OPR (operation) indicator

qa zREC (record) /REC PAUSE button

qs xSTOP button

qd Jog lever

FOLDER/MENU/.(review/fast backward)/

> (cue/fast forward)/x• B (play/stop•enter)

qf VOL (volume) +/– buttons

qg Base

qh HOLD switch

qj Speaker

qk Battery compartment

ql Clip*

w; m (microphone) jack

wa USB connector

ws DC IN 3V jack

(For Korean and the People’s Republic of China

models, this jack does not exist.)

wd Slit for a handstrap

*Notes

• To prevent the clip from breaking, avoid hooking it on thick

fabric, such as a pocket of a heavy coat.

•When bending down or running with the unit clipped on

your pocket, be careful not to drop the unit.

Using the display window

1 Folder indication

Displays the current folder (A, B, C, D or E).

2 Recording mode indication

Displays the current recording mode:

•ST: Standard play stereo recording mode

•STLP: Long play stereo recording mode

•SP: Standard play monaural recording mode

• LP: Long play monaural recording mode

3 REC (Recording) indicator

4 Remaining battery indicator

When the AC power adaptor (not supplied) is

connected, the indicator does not appear (excluding

the Korean and the People’s Republic of China

models).

5 Remaining memory indicator

6 Priority marks

7 Selected message number /Total message

number in the folder

8 Alarm indicator

Appears when the alarm is set for a message.

9 Repeat play indicator

Appears while a message or a specific portion (A-B)

of the message is played back repeatedly.

0 Bookmark indicator

Appears when the bookmark is set for a message.

qa Counter /Remaining time indication /

Recording date and time indication /Current

time indication

The display selected with the DISP in the menu

appears.

qs SENS (microphone sensitivity) indication

Displays the current microphone sensitivity:

•H (high): To record at a meeting or in a quiet/

spacious place.

•L (low): To record for dictation or in a noisy place.

4

ICD-SX46/SX56/SX66

Step 2: Setting the Clock

You need to set the clock to use the alarm function or record the date and time.

Clock setting display appears when you insert batteries for the first time, or

when you insert batteries after the unit has been without batteries for a certain

period of time. In this case, proceed from step 4.

Jog lever

Press the center

(x•B).

Press up (>).

Press down (.).

Turn toward MENU.

Note on setting the clock

Set the clock while the unit is in the

stop mode.

1 Turn the jog lever toward MENU.

The menu mode will be displayed in

the display window

2 Press the jog lever up or down

(>/.) to select “SET DATE”.

3 Press the jog lever (x•B).

The date and time setting window is

displayed. The year digits will flash.

4 Set the date.

1 Press the jog lever up or down

(>/.) to select the digits of

the year.

2 Press the jog lever (x•B).

The month digits will flash.

3 Set the month and day in sequence,

then press the jog lever (x•B).

The hour digits will flash.

v

5 Set the time.

1 Press the jog lever up or down

(>/.) to select the digits of

the hour.

2 Press the jog lever (x•B).

The minute digits will flash.

3 Set the minute.

4 Press the jog lever (x•B).

The menu mode will be displayed

again.

Note

If you do not press the jog lever (x•B) for more than one minute, the clock

setting mode is cancelled and the window will return to normal display.

6 Turn the jog lever toward MENU.

The window will return to normal

display.

1 If the unit is left unused for more than 3

seconds in the stop mode after the clock

is set, the display will show the current

time.

5

ICD-SX46/SX56/SX66

Note: Follow the disassembly procedure in the numerical order given.

2-2. COVER (JACK)

SECTION 2

DISASSEMBLY

2-1. DISASSEMBLY FLOW

Note: Disassemble the unit in the order as shown below.

2-3.CASE BLOCK ASSY

(Page 6)

2-4.AUDIO BOARD,

MICROPHONE UNIT(MIC2/3)

(Page 6)

2-5.ORNAMENT BELT ASSY,

SW BOARD

(Page 7)

2-6.COVER (CHASSIS)

BLOCK ASSY

(Page 7)

2-7.MAIN BOARD,

LIQUID CRYSTAL DISPLAY

PANEL (Page 8)

2-2.COVER (JACK)

(Page 5)

SET

4

screw

6

screw

5

cover (jack)

3

lid (connecter)

2

screw (M1.4)

1

battery lid

6

ICD-SX46/SX56/SX66

2-3. CASE BLOCK ASSY

2-4. AUDIO BOARD, MICROPHONE UNIT (MIC2/3)

Pass the flexible board through

the hole during assembling.

3

Slide the chassis from the case completely and remove it.

1

Slide the chassis from the case until the connector becomes visible.

2

connector

11pin (CN7005)

9

Remove the microphone unit (MIC2/3)

from the groove.

8

cushion

6

Remove soldering at two positions of the speaker cable.

2

1

connector

40pin (CN7003)

4

LCD holder

5

liquid crystal

display panel

3

three claws

7

connector

4pin (CN3001)

q;

AUDIO board

7

ICD-SX46/SX56/SX66

2-5. ORNAMENT BELT ASSY, SW BOARD

2-6. COVER (CHASSIS) BLOCK ASSY

6

SW board

2

knob (HOLD)

1

peel off the three

adherent areas

3

ornamental belt assy

4

six claws

6

ornamental

belt

5

three sheets

(ornamental belt

)

1

claw

1

claw

1

claw

1

claw

2

cover (CHASSIS

)

3

speaker (1.6cm)

SP3001

chassis block assy

8

ICD-SX46/SX56/SX66

2-7. MAIN BOARD, LIQUID CRYSTAL DISPLAY PANEL

2

1

Remove the two battery terminals

from the groove of the chassis.

chassis block assy

8

MAIN board

5

battery (–) terminal

4

battery (+) terminal

3

Remove soldering from the two points.

7

liquid crystal

display panel

6

sheet, insulating

9

ICD-SX46/SX56/SX66

SECTION 3

TEST MODE

[Setting Method of the Test Mode]

To enter the test mode, turn on the HOLD . switch while press-

ing the x key and VOL+ key at the same time with the power on.

[Exiting Method of the Test Mode]

Exit the test mode by turning off the power.

[Initial Status of the Test Mode]

When the test mode is set, the LCD display appears as shown below.

LCD display (Example)

[Flow Chart of the Test Mode]

START

>

.

.

.

>

>

.

Initial status of test mode

Model code, LPEC ST,

F/W version display

TEST MODE

END

TEST MODE

Turn off the power

(Extract the batteries or DC jack)

>

USB

KEY COUNT

RESET MENU

LED

B A T TKEY

LCD

AUDIO

SLEEP

BEEP

RTC

>

>

>

>

.

.

.

.

>

>

>

>

.

.

.

.

[Operation in the Test Mode]

After entering the test mode, you can move within the test menu by

pressing the . / > key. You can move to the submenu by

pressing the x•B key. Then each test mode can be executed.

1. LCD test

• LCD is tested of all light-on and all light-off.

2. Audio test

Perform the through-playback and sine wave output.

• Contents of the submenu

DSP ST: DSP STEREO through mode

DSP MO: DSP MONO through mode

SIN: 1 kHz sine wave output mode

• Select the microphone sensitivity with the A-B switch.

HtMtLtHtMt ...

•The VOR detection operation can be checked by the LED.

Sound : The red LED is turned on. No sound: The red LED

is turned off.

• MUTE can be set to “ON” or “OFF” with the ERASE key.

•The sound volume can be adjusted with the VOL+ key or VOL–

key during the audio test except the MUTE mode.

• In the directional microphone selection, ON/OFF of the DI-

RECTNL switch is performed with the DIVIDE key.

DIRECTNL switch ON : The green LED is turned on.

OFF : The green LED is turned off.

• In the audio test mode the operation is performed according to

JACK detection.

•The microphone sensitivity, sound volume and MUTE (on/off)

are displayed on the LCD.

•The microphone sensitivity selection and the VOR test are ef-

fective in the through-playback mode.

•The directional microphone selection is effective in the DSP

MONO through mode.

6d

01

b110

-56

6d

01 b110-56

Iris(DSP) version : 6d

LPEC ST version : 01

SakuraR(CPU) version : 1.10

(In α version or β version, A or B is displayed)

Model code : SX56

x•B

.

>

LCD OFF

LCD CHK

LCD ALL

:

:

LCD ALL

CHK START

CHK END

LCD

x

x

x x

BA DC E

REC

STLP

SP

LH

YH

88

8888

888888

MM DS

m

(LCD off)

.

>

(select), (set)

x•B

x•B

:

:

DSP MONO

SIN WAVE

DSP ST

AUDIO DSP ST

oFDSP ST12 oFSIN WAV06

x x x

H

m

oFDSP M 23

L

m

DSP STEREO through mode / MIC : M / MUTE : ON / VOL-LEVEL : 12

t "M / on / 12 / DSP ST"

DSP MONO through mode / MIC : H / MUTE : OFF / VOL-LEVEL : 23

t "H / oF / 23 / DSP MO"

1k sine wave output mode / MUTE : ON / VOL-LEVEL : 06 t "on / 06 / SIN"

.

>

(select), (set)

x•B

10

ICD-SX46/SX56/SX66

3. Sleep test

•Pressing the x•B key causes the set to enter the sleep state.

•When the HOLD . switch is ON, the LCD is turned off.

When OFF, the LCD is turned on.

•Press any keys to exit the sleep state.

4. Beep test

• Beep sound of 1.3 kHz or 2 kHz is output.

5. RTC test

•Perform the function test of the RTC and EEPROM.

(1) RTC EEPROM test

Confirmation of writing, reading (verifying) and erasing of

arbitrary data with the specified registers.

(2) RTC clock function test

Confirmation that RTC updates the time to the microcomputer

at one second interval.

• OK, NG judgement is performed to the test result.

When NG, it is displayed which device RTC or EEPROM

becomes NG.

(All OK : “RTC OK” / RTC NG : “RTC BAD” / EEPROM NG

: “EEP BAD”)

6. Key entry test

•When the any key is pressed, the entry key and the A/D con-

verted value (hexadecimal) of the two channel keys are dis-

played.

•When the x key is pressed, the A/D value of the key is dis-

played while the key is depressed. When the key is released, the

screen returns to the test menu.

7. Battery remaining power and DC IN test

•The detected A/D value (hexadecimal) of the battery remaining

power is displayed. When DC jack is inserted, the battery mark

on the LCD is turned off.

any keys any keys

(LCD OFF)

(with HOLD .

OFF status)

x•B

(with HOLD .

ON status)

x•B

SLEEP SOON

SLEEP IN

SLEEP

x•B

RTC RTC OK

x

bATT FF bATT C2

x•B

DC jack

is inserted

DC jack

is extracted

B A T T

bATT FF

x

x•B

KEY oFFiFFKEY

x

8. LED test

• LEDs (OPR: red and green) are all turned on.

9. USB test

• When the menu starts the USB self-check, either presence or

absence of the Vbus is judged.

(Vbus is present: “ON VBUS”, Vbus is absent: “OFF VBUS”)

•The USB driver always works regardless of presence or ab-

sence of the USB signal only when Vbus is available during the

USB test. At this time, turning on HOLD . causes the set

to move to the suspend state. Turning off the Vbus causes the

set to return to the test menu.

• In the menumode if the Vbus is supplied, any key will not work.

Therefore the Vbus will be supplied after surely pressing the

x•B key.

10. Key durable test

•Pressing the x•B key makes the count to “------” and sets test

standby status.

Once more pressing the x•B key makes the count to “000000”

and sets the key durable test.

In this mode any key input and slide switch operation are counted

and the number is displayed.

Turn off the power to exit this mode.

11. Menu reset

•Pressing the x•B key causes the set to enter the menu initial-

ization standby state.

•When the following keys are all entered, the EEPROM initial-

ization (returning setting in the menu and user name to default

value) and formatting process (deleting all message files in the

flash memory) are executed. At the same time, the WakeUp

signal is checked, too.

Check keys: VOL– , VOL+ , A-B

, ERASE ,

DIVIDE , DPC ON, DPC OFF, . ,

x•B , > , FOLDER , MENU , x ,

z REC , HOLD

.

ON, HOLD

.

OFF,

DIRECTNL ON

, and DIRECTNL OFF,

VOICE UP ON

, and

VOICE UP

OFF

x•B

LED ONLED

x

LED ON (orange)LED OFF

x•B

ON

cut Vbus

Vbus

on

cut Vbus

Suspend

mode

HOLD .

SUSPENDVBUS ONVBUS OFFUSB

x

x•B x•B

any keys or slide

switches operation

KEY 000001KEY 000000KEY-----KEY COUNT

x

Key durable

test

x•B

BEEP 2.0K

BEEP 1.3K

:

:

BEEP1.3K

BEEP1.3K BEEP 2.0K

BEEP

x

x

x

.

>

(select), (set)

x•B

11

ICD-SX46/SX56/SX66

x•B

In the case that

the initialization

and reset operation

end correctly.

(0.5 sec. blinking)

All keys

are entered

ALL OK INITKEY PUSH RESET MENU

x

• If all tests end in success, “ALL OK” is displayed. If initializa-

tion in the EEPROM is NG, “INIT. NG” appears.

•Turn off the power to exit the test mode.

12

ICD-SX46/SX56/SX66

SECTION 4

DIAGRAMS

•Waveform

Note on Schematic Diagrams:

• All capacitors are in µF unless otherwise noted. (p: pF) 50 WV or

less are not indicated except for electrolytics and tantalums.

• All resistors are in Ω and

1

/

4

W or less unless otherwise specified.

• f : internal tolerance.

• C : panel designation.

• A : B+ Line.

•Power voltage is dc 3V and fed with regulated dc power supply

from DC IN jack (J5001).

•Voltages and waveforms are dc with respect to ground under no-

signal (detuned) conditions.

no mark : PLAY

[ ] : REC

∗ : Impossible to measure

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production toler-

ances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production toler-

ances.

• Circled numbers refer to waveforms.

• Signal path.

F : PB

L : REC

* Replacement of IC6001 and IC7003 used in this set requires a

special tool.

• The voltage and waveform of CSP (chip size package) cannot be

measured, because its lead layout is different from that of conven-

tional IC.

Note on Printed Wiring Boards:

• Y : parts extracted from the conductor side.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

* Replacement of IC6001 and IC7003 used in this set requires a

special tool.

• Lead layouts

Lead layout of

conventional IC

CSP (chip size package)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

surface

1 IC7003 <z/, (XTAL)

1 V/DIV, 100 ns/DIV

3.2 Vp-p

244 ns

1313

ICD-SX46/SX56/SX66

ICD-SX46/SX56/SX66

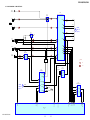

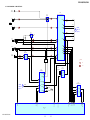

4-1. BLOCK DIAGRAM – MAIN SECTION-1 –

+2.5V

REG

Signal path

: REC

: PB

10112116

46

25

26

14

15

9

8

7

5

4

3

2

6

15

11

2

3

9

8

6

12

5

IC7001

SI/PO DRIVER

DATA

CLK

HPMUTE

XADAPDN

SPAMP

10

EXTMIC

XREDLED

IDSPRST

XBATTEN

XGRLED

XBATTEN

D7001

RED(REC)

GREEN(PB)

1

4

IC6003

CLOCK GEN.

IC7003 (1/3)

CPU

XCONT

FOUT

Q3003

MUTE

J3002

(SPEAKER)

3

9

7

8

10

IC7004

REAL TIME CLOCK

CLK

DI

DO

CE

XIRQ

5

FOUT

14

MONOIN

IC3004

ADC, DAC, HEADPHONE AMP

AINR2

AINL2

HPR

HPL

17

MOUT

1

PDN

28

27

AINL1

AINR1

STDO

STDO

MAIN-2

SECTION

(Page 14)

BICK

LRCK

SDTI

CDTI

CCLK

CSN

18

MIN

MCLK

BCLK

LRCK

SO

XRST

MCLK

HPJACK

SPICLK

115

SPIDATA

45

MICJACK

DSPSYSCLK

RTCCS

111

XRTCINTR

98

AUSIN

13

X0A32K

99

AUSOT

100

AUSCK

102

XADACS

18

BEEP

SP3001

B

A

MIC301

MIC2

MIC3

R

IC3003

POWER AMP

VO1

AVDD

VO2

-IN

XSHUT-

DOWN

5

8

4

1

J3001

5

3

XT

XXT

X6001

11.2896MHz

L

STEREO

1

4

6

3

IC3005

SELECTOR

A

1

3

5

IC3001

PANEL

SECTION

(Page 15)

MIC

(DIRECTNL)

OPR

1414

ICD-SX46/SX56/SX66

ICD-SX46/SX56/SX66

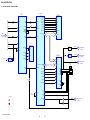

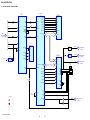

4-2. BLOCK DIAGRAM – MAIN SECTION-2 –

Signal path

: REC

: PB

40,

17-22

31

109

XUSBCS

USBADR0 - USBADR6

XINTUSB

29-32,

41-44

DATA0-DATA7

34

XUSBLWR

32

XUSBRD

IC6002

FLASH MEMORY

45

35

47

40

138

150

46

48

52

159

49

160

157

50

55

158

11

12

5

2

6

3

1

119

120

1

118

104

107

108

I/O1-I/O8

1923

WPXFLMWP

1035

NC_XCE2XFLMCS1

IC7002

FLASH MEMORY

IC6001

DSP

ADASI

BCLK

LRCLK

SO

XRST

MCLK

TSO

TSCK

TSOEN

TSIEN

TSIOEN

TSI

REQ

CLKIN

FMSDIO

FMSCK

DSPCVDD

XFMWP

XFMCS

SDI

SDO

SCK

XWP

XCS

DSPSIN

DSPSCK

DSPSIOEN

DSPSOT

DSPIFREQ

XTALIN

XTAL

X7001

4.096MHz

14

13

XIN

5

VBUS

3

D-

4

D+

6

TRON

XOUT

X8001

12MHz

E

A

IC7003 (2/3)

CPU

D8002

Q7002

SWITCH

45

42

44

43

23-30

24-30

3-10

CS

33

XUSBRST

95

RX

96

TX

87

MOD2

103

WAKEUP

46

RST

INT0

110

XUSBVBUS

11

INT1

LWR

RD

D0 - D7

A0 - A6

1

2

3

VBUS

D-

D+

4IN

IC8001

USB CONTROLLER

CN7001

(USB)

VBUS

D

F

DDCOUT

WAKEUP

STDO

BCLK

LRCK

MAIN-1

SECTION

(Page 13)

SO

XRST

MCLK

R/B

7

FLMRB

22

CLE

16

FLMCLE

2

17

ALE

XFLMALE

21

9

XCE

XFLMCS0

11

8

RE

XFLMRE

20

18

WEXFLMWE

19

12

IC5005

IC6004

Q7005

Q7003

Q7004

VOLTAGE

DETECT

2

4

23

IC8003

+3.5V

REG

C

KEYINH

PANEL SECTION

(Page 15)

PANEL SECTION

(Page 15)

PANEL SECTION

(Page 15)

PANEL SECTION

(Page 15)

1515

ICD-SX46/SX56/SX66

ICD-SX46/SX56/SX66

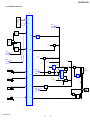

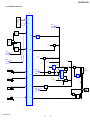

4-3. BLOCK DIAGRAM – PANEL SECTION –

40

41

112

90

97

39

DDCOUT

DDCOUT

(3.1V)

XBATTEN

Q5001

SWITCH

Q5010, 5011

SWITCH

SEG0 - SEG31

COM0 - COM3

KEYIN0

KEYIN1

HOLDSW

44

XDPCSW

IC7003(3/3)

CPU

D

F

C

WAKEUP

MAIN-2

SECTION

(Page 14)

MAIN-2

SECTION

(Page 14)

S7001

1

3

Q5002

SWITCH

Q5003

SWITCH

Q5012

SWITCH

Q5005

DC DET

VBUS

E

B

L5001

L5002

D5003

D5004

IC5003

DC/DC CONV.

31

IC5002

D5005

Q5009

VOLTAGE

DETECT

FLMVCC

(IC7002)

RESET

32

IC7005

15

IC5001

+2.9V

REG

AVDD(2.9V)

DDCOUT(3.1V)

FB1

EXT1

108

FB2

4

PWM1

6

EN2

EXT2

DSPCVDD(1.6V)

DRY BATTERY

SIZE "AAA"

(IEC DESIGNATION LR03)

2PCS. 3V

4

B+

SWITCH

Q5006,5007

B+

SWITCH

Q7001

B+

SWITCH

Q5013

DSPEVDD

(IC6001, 6002, 6003)

VBATT

IC3003 VDD

LIQUID

CRYSTAL

DISPLAY

MODULE

S901,902,

7002,7004

FUNCTION

KEY

S903,904

7003

FUNCTION

KEY

S905

SEESAW

KEY

XCPURST

XFLMPWR

BATT

117

DSPPWR

113

XDCINDET

S907

S908

DPC

KEYINH

J5001

DC IN 3V

42

MICSEL

S906

43

VUPSW

83-86

49-74,

77-82

MAIN-2

SECTION

(Page 14)

MAIN-1

SECTION

(Page 13)

ON

OFF

VOICE UP

HOLD

MAIN-2

SECTION

(Page 14)

DIRECTNL

ON

OFF

ON

OFF

ON

OFF

1616

ICD-SX46/SX56/SX66

ICD-SX46/SX56/SX66

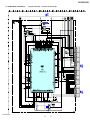

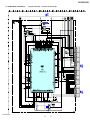

4-4. PRINTED WIRING BOARD – AUDIO BOARD (SIDE A) –

• :Uses unleaded solder.

• Semiconductor

Location

Ref. No.

Location

IC3001 F-11

IC3003 F-13

IC3004 C-12

IC3005 D-14

IC6001 C-3

IC6003 C-6

IC6004 D-6

Q3003 E-13

IC6001

IC6003

IC6004

IC3001

IC3004

IC3003

IC3005

AUDIO BOARD (SIDE A)

3

3

1

1

34

5

1

6

5

4

4

39 1

40 2

4

6

3

1

1-867-746-

(11)

11

MIC

PLUG IN POWER

J3001

A

MAIN BOARD

CN7004

(Page 21)

MIC301

CSP (Chip size package)

*

1818

ICD-SX46/SX56/SX66

ICD-SX46/SX56/SX66

4-6. SCHEMATIC DIAGRAM – AUDIO BOARD (1/2) –

IC3001

R3002

R3004

R3032

R3022

R1001

R1015

R2001

R3031

R3003

R3023

R2015

R2007

R1007

R1013

R2013

R3001

R1008R2008

R3025

R2014

R1014

R2011 R1011

R1009

R2009 R1012

R2012

R1010

R2010

R3013

R3015 R3027

R3014

R3030

R3029

R3026

R3011

R3016

R3017

R3020

R3018

MIC3

MIC2

MIC301

(DIRECTNL)

TP3005

TP3003

TP1001

TP2001

TP3004

TP3002

TP3001

R3021

Q3003

IC3003

IC3004

IC3005

C3008

C3004

C3002

C3005

C1004

C2004

C1003

C1001

C2003

C2001

C2007

C1007

C3001C1008

C2008

C3009

C1009 C2009

C3010

FB3001

FB1001

FB2001

C2011 C1011

FB1002

FB2002

FB3002

FB3006

C1012

C2012

FB3005

FB3004

C3011

C3015

C3013

C3016

C3014

C3021

C3022

C3023

C3024

C3025

C3026

C2010

C1010

C3017

C3018

C3020

C3019

SP3001

J3002

J3001

PLUG IN POWER

CN3001

C3027

C3028

XC6204B252MR

0

100

100

0

100

0

100

0

100k

470k

0

100

100

2.2k

2.2k

2.2k

4.7k4.7k

4.7k

0

0

2.2 2.2

1k

1k 1k

1k

4.7

4.7

150k

22k 10k

100k

100k

47k

2.2k

100k

220

100k

10

100k

220k

NTHD4508NTIG

MM3111AWLE

AK4569VN-L

TC7PA53FU(TE85L

0

1

0.1

10

6.3V

10

6.3V

10

6.3V

1

0.1

1

0.1

0

0

11

1

0.01

0.01 0.01

nm

0.22 0.22

47

6.3V

47 6.3V

0H

0H

0.1

0.47

220p

0.022

0.022

0.1

0.1

0.01

0.1

0.1

1000p

0.1

0.1

0.1

2.2

6.3V

10

6.3V

0.1

(SPEAKER)

HP JACK

MIC JACK

FPC MIC 4P

nFm18pS105

nFm18pS105

• See page 26 for IC Block Diagrams.

1919

ICD-SX46/SX56/SX66

ICD-SX46/SX56/SX66

4-7. SCHEMATIC DIAGRAM – AUDIO BOARD (2/2) –

IC6004

R6004

R6009

R6026 R6027

R6025

R6022

R6023

R6013 R6014

R

6

01

7

R

60

1

6

R6018

R6019

R6015

R6021

R6020

R7051

R7052

R

60

1

2

R6011R6010R6008

R6002

R3028

R6001

R6007

R6005

R6006

R7002

OPR

R7003

S7002

ERASE

DIVIDE/PRIORITY

S7004 S7003

TP6013

TP6012

TP6011

TP6001

T

P

6

002

TP6003 TP6004 TP6005 TP6006

TP6007

TP6008

TP6009

TP6010

IC6002

IC6003

CN7003

CN7005

R

60

03

C6003

C6006

C6007

C6010

C6014

C6002

C6001

D

70

0

1

X

6

00

1

RB6001

RB6002

IC6001

TC7S04FU(TE85R)

470k

100k

100k 100k

0

47

47

100k 100k

10

0k

100

k

100k

100k

100k

100k

100k

4.7k

0.5%

3.3k

0.5%

47

0

k

470k470k470k

470k

220

470k

100k

100k

100k

470

2.2k

M25P10-AVMN6TP

NJU6366AF1(TE1)

B TO B

FPC SW 11P

470

k

0.1

0.1

1000p

100p

0.1

1

1

L

C

-3

75

H

R

1

Y

G

-D

-T

S

11

.2

89

6

M

H

z

100k

100k

-DA2

• See page 26 for IC Block Diagrams. • See page 19 for IC Pin Function Description.

2020

ICD-SX46/SX56/SX66

ICD-SX46/SX56/SX66

4-8. PRINTED WIRING BOARD – MAIN BOARD (SIDE A) –

• :Uses unleaded solder.

• Semiconductor

Location

Ref. No.

Location

D5002 A-4

D5003 C-8

D5004 D-7

D5005 D-5

D5007 D-3

D5009 C-3

IC5001 D-10

IC5002 E-6

IC5003 D-9

IC5005 F-11

IC7001 B-16

IC7003 C-13

IC7005 E-15

Q5002 D-8

Q5003 E-8

Q5006 C-11

Q5007 B-11

Q5009 D-4

Q5012 E-7

IC7001

IC7003

IC5001

IC5005

IC5003

IC5002

IC7005

MAIN BOARD (SIDE A)

1

45

8

1

4

5

8

J5001

3

3

1

1

2

4

4

5

1

2

1-867-745-

(11)

11

HOLD.

ON

40

1

DC IN 3V

DRY BATTERY

SIZE "AAA"

(IEC DEESINATION LR03)

2PCS 3V

LCD MODULE

CSP (Chip size package)

*

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

Sony ICD-SX66 - Ic Recorder User manual

- Type

- User manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Sony ICD-SX46 Digital Voice Editor 2 User manual

-

Sony ICD-MX20 Owner's manual

-

Sony ICD-ST20 Operating instructions

-

Sony ICD-SX20 User manual

-

Sony ICD-S7 Operating instructions

-

Sony ICD-S7 Operating instructions

-

Sony ICD-ST25 User manual

-

Sony ICD-ST25 Operating instructions

-

Sony ICD-MX20 Operating instructions

-

Sony ICD-MX20 Operating instructions

Other documents

-

Mircom LT-974 RB-MD-953 Installation guide

-

APC SUDP001 Datasheet

-

Onyx C8002 User manual

-

Audio Authority 922 Diagram

Audio Authority 922 Diagram

-

BLADEZ R500I Owner's manual

-

Master Appliance MICROPRO BT-30 User manual

-

Applied Energy Products NACpoint User manual

Applied Energy Products NACpoint User manual

-

Mojotone TMB User manual

Mojotone TMB User manual

-

Roland BOSS AD-2 Service Notes

-

Simrad R2009/R3016 Operating instructions