Page is loading ...

Products Solutions Services

Operating Instructions

SS2100i-2 TDLAS Gas Analyzer

ATEX/IECEx: Zone 1

BA02197C/66/EN/0

2.23

70210290

Operating Instructions SS2100i-2 TDLAS Gas Analyzer

2 Endress+Hauser

SS2100i-2 TDLAS Gas Analyzer Operating Instructions

Endress+Hauser 3

Table of Contents

1 About this document ............................ 4

1.1 Warnings .................................................................. 4

1.2 Symbols on the device............................................. 4

1.3 U.S. export compliance ........................................... 4

1.4 Standard documentation ........................................ 4

2 Introduction .......................................... 6

2.1 How to use this manual .......................................... 6

2.2 General warnings and cautions ............................. 6

2.3 Manufacturer address ............................................ 8

2.4 About the gas analyzers ......................................... 9

2.5 Getting familiar with the analyzer ...................... 12

3 Safety ................................................... 24

3.1 Potential risks affecting personnel ..................... 24

3.2 Explosion hazard ................................................... 24

4 Installation .......................................... 25

4.1 What should be included in the shipping box .... 25

4.2 Lifting/carrying the analyzer ............................... 25

4.3 Inspecting the analyzer ........................................ 25

4.4 Hardware and tools for installation .................... 26

4.5 Mounting the analyzer ......................................... 26

4.6 Protective chassis ground connections ............... 26

4.7 Opening the analyzer enclosure covers .............. 27

4.8 Cable installation .................................................. 27

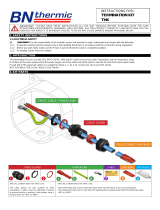

4.9 Cable glands ........................................................... 27

4.10 Connecting the solenoid valves ........................... 28

4.11 Application of gland lubricant ............................. 31

4.12 Connecting the signals and alarms ..................... 32

4.13 Configuring the RS-232/RS-485 converter........ 34

4.14 Connecting electrical power to the analyzer ...... 34

4.15 Connecting the gas lines ...................................... 36

4.16 Changing the 4-20 mA current loop mode ........ 37

5 Specifications ...................................... 39

5.1 Exd accessory conditions of use .......................... 40

6 Maintenance and troubleshooting ... 42

6.1 Gas leaks ................................................................ 42

6.2 Excessive sampling gas temperatures and

pressures ................................................................ 42

6.3 Electrical noise ...................................................... 42

6.4 Contamination ...................................................... 42

6.5 Cleaning the mirrors ............................................. 43

6.6 Replacing the pressure sensor ............................. 47

6.7 Flame arrestor replacement and safety ............. 56

6.8 Peak tracking reset procedure ............................. 59

6.9 Instrument issues .................................................. 59

6.10 Service .................................................................... 61

6.11 Service repair order ............................................... 61

6.12 Packing, shipping, and storage ........................... 61

6.13 Storage ................................................................... 62

6.14 Disclaimers ............................................................ 62

6.15 Warranty ................................................................ 62

7 Analyzer parts .................................... 63

8 Wiring diagrams ................................. 72

Operating Instructions SS2100i-2 TDLAS Gas Analyzer

4 Endress+Hauser

1 About this document

1.1 Warnings

Structure of Information Meaning

WARNING

Causes (/consequences)

If necessary, consequences of non-compliance

(if applicable)

‣ Corrective action

This symbol alerts you to a dangerous situation. Failure to avoid the dangerous

situation can result in a fatal or serious injury.

CAUTION

Causes (/consequences)

If necessary, consequences of non-compliance

(if applicable)

‣ Corrective action

This symbol alerts you to a dangerous situation. Failure to avoid this situation

can result in minor or more serious injuries.

NOTICE

Cause/situation

If necessary, consequences of non-compliance

(if applicable)

‣ Action/note

This symbol alerts you to situations which may result in damage to property.

Table 1. Warnings

1.2 Symbols on the device

Symbol

Description

The Laser Radiation symbol is used to alert the user to the danger of exposure to hazardous visible laser radiation

when using the Raman Rxn2 system.

The High Voltage symbol that alerts people to the presence of electric potential large enough to cause injury or

damage. In certain industries, high voltage refers to voltage above a certain threshold. Equipment and conductors that

carry high voltage warrant special safety requirements and procedures.

The ETL Listed Mark provides proof of product compliance with North American safety standards. Authorities Having

Jurisdiction (AHJ) and code officials across the US and Canada accept the ETL Listed Mark as proof of product

compliance to published industry standards.

The WEEE symbol indicates that the product should not be discarded as unsorted waste but must be sent to separate

collection facilities for recovery and recycling.

The CE Marking indicates conformity with health, safety, and environmental protection standards for products sold

within the European economic area (EEA).

Table 2. Symbols

1.3 U.S. export compliance

The policy of Endress+Hauser is strict compliance with U.S. export control laws as detailed on the website of the

Bureau of Industry and Security at the U.S. Department of Commerce.

1.4 Standard documentation

All documentation is available:

• On the USB provided with the analyzer

• Endress+Hauser’s website: www.endress.com

Each analyzer shipped from the factory is packaged with documents specific to the model that was purchased. This

document is an integral part of the complete document package, which also includes:

SS2100i-2 TDLAS Gas Analyzer Operating Instructions

Endress+Hauser 5

Part Number

Document Type

Description

TI01670C

SS2100i-2 Technical

Information

Planning aid for your device. This document contains information for the analyzer

including system design with sample conditioning components and inlet/outlet

points, certificates and approvals, and product technical data.

XA02694C SS2100i-2 Safety

Instructions

Requirements for installing or operating the SS2100i-2 TDLAS Gas Analyzer

related to personnel or equipment safety.

GP01180C

Description of Device

Parameters (NS 5.14)

Provides the user with an overview of the NS 5.14 firmware functionality.

For additional instruction manuals, please refer to the following:

• For custom orders, go to the Endress+Hauser website for the list of local sales channels who can provide the

requested order-specific documentation:

https://endress.com/contact

or

https://addresses.endress.com/

• For standard orders, go to the Endress+Hauser website to download the published documentation:

www.endress.com

Operating Instructions SS2100i-2 TDLAS Gas Analyzer

6 Endress+Hauser

2 Introduction

Endress+Hauser SS2100i-2 products use SpectraSensors TDLAS technology and are high-speed, diode-laser based

extractive analyzers designed for extremely reliable monitoring of very low (trace) to standard concentrations of

specific components in various background gases. To ensure that the analyzer performs as specified, it is important

to closely review the sections of this manual. This manual contains a comprehensive overview of the SS2100i-2

analyzer and step-by-step instructions for:

• Inspecting the analyzer

• Mounting and installing the analyzer

• Troubleshooting the system

2.1 How to use this manual

Take a moment to familiarize yourself with this Operating Instruction by reading the "Table of Contents".

Some options and accessories are available for the SS2100i-2 analyzers. This manual addresses the most common

options and accessories.

Images, tables, and charts are included to provide a visual understanding of the analyzer and its functions. Special

symbols are used to provide the user with key information regarding the system configuration and/or operation. Pay

close attention to this information.

2.1.1 Who should read this manual

This manual should be read and referenced by anyone installing, operating, or having direct contact with the

analyzer.

2.1.2 Conventions used in this manual

In addition to the symbols and instructional information, this manual is created with “hot links” to enable the user to

quickly navigate between different sections within the manual. These links include table, figure and section

references and are identified by a pointing finger cursor when rolling over the text. Simply click on the link to

navigate to the associated reference.

2.2 General warnings and cautions

Instructional icons are provided in this manual and on the SS2100i-2 unit to alert the user of potential hazards,

important information and valuable tips. Following are the symbols and associated warning and caution types to

observe when servicing the analyzer. Some of these symbols are provided for instructional purposes only and are not

labeled on the system.

2.2.1 Safety warning label

The warning label shown below will be affixed to the front side of all analyzer enclosures that contain sample gas.

SS2100i-2 TDLAS Gas Analyzer Operating Instructions

Endress+Hauser 7

Hazards may vary by stream composition. One or more of the following conditions may apply.

Symbol

Description

Flammable. Gases used in the processing of this analyzer may be extremely flammable. Any work in a hazardous

area must be carefully controlled to avoid creating any possible ignition sources (e.g., heat, arcing, sparking, etc.).

Toxins

. Endress+Hauser analyzers measure a variety of gases, including high-level H2S. Follow all safety protocols

governing toxic gases and potential leaks.

Inhalation

. Inhaling toxic gases or fumes may cause physical damage or death.

CAUTION

Technicians are expected to follow all safety protocols established by the customer that are necessary for

servicing or operating the analyzer. This may include, but is not limited to, lockout/tagout procedures, toxic gas

monitoring protocols, personal protective equipment (PPE) requirements, hot work permits and other

precautions that address safety concerns related to performing service or operation on process equipment

located in hazardous areas.

2.2.2 Equipment labels

Symbol

Description

Warning statement for

hazardous voltage

. Contact may cause electric shock or burn. Turn off and lock out system

before servicing.

Failure to follow all directions may result in damage or malfunction of the analyzer.

Maximum voltage and current specifications for the fuse closest to label.

PROTECTIVE EARTH GROUND

— Symbol indicates the connection point of the ground wire from the main power

source.

FUNCTIONAL EARTH GROUND

— Symbol indicates grounding points intended primarily for troubleshooting.

2.2.3 Instructional symbols

Symbol

Description

General notes and important information concerning the installation and operation of the analyzer.

Failure to follow all directions may result in fire.

INVISIBLE LASER RADIATION — Avoid exposure to beam. Class 3b Radiation Product. Refer servicing to the

manufacturer-qualified personnel.

Failure to follow all directions may result in damage or malfunction of the analyzer.

Maximum voltage and current specifications for fuses.

Operating Instructions SS2100i-2 TDLAS Gas Analyzer

8 Endress+Hauser

2.2.4 Special safety symbols used on the equipment

Special safety symbols and labeling are used on the equipment to alert the user to potential hazards and important

information associated with the analyzer. Every symbol and label has significant meaning that should be heeded.

Symbol

Description

ENERGIZED FUSE WARNING

— Do not remove or replace fuse when energized.

INVISIBLE LASER RADIATION — Avoid exposure to beam. Class 3b Radiation Product. Refer

servicing to the manufacturer or qualified personnel.

DO NOT REMOVE — Removal of the seal and/or disassembly of pieces traversed by label voids

the warranty.

CLASS 1 LASER PRODUCT — Invisible laser radiation when open. Avoid direct exposure to the

beam.

CLASS 3B LASER PRODUCT — Invisible laser radiation. Avoid direct exposure to beam. Class 3b

laser product.

CLASS 3B LASER WARNING

— Class 3B invisible laser radiation when open. Avoid direct

exposure to the beam.

2.3 Manufacturer address

Endress+Hauser

11027 Arrow Route

Rancho Cucamonga, CA 91730

United States

www.endress.com

SS2100i-2 TDLAS Gas Analyzer Operating Instructions

Endress+Hauser 9

2.4 About the gas analyzers

Endress+Hauser SS2100i-2 analyzers employ SpectraSensors tunable diode laser absorption spectroscopy (TDLAS) to

measure the concentration of single compounds in gas mixtures. The tunable diode laser (TDL) absorption

spectrometers in the SS2100i-2 operate in the near- to short-wavelength infrared. Each compact sensor consists of a

TDL laser light source, sample cell, and detector configured for high sensitivity measurement of a particular

component within the gas-phase constituents in the stream. The sensor is controlled by microprocessor-based

electronics with embedded software that incorporates advanced operational and data processing algorithms.

In its simplest form, a diode laser absorption spectrometer typically consists of a sample cell with a mirror at one end,

and a mirror or window at the opposite end, through which the laser beam can pass, as shown in the figure below.

The laser beam enters the cell and reflects off the mirror(s) making one or more trips through the sample gas and

eventually exiting the cell where the remaining beam intensity is measured by a detector. With the SS2100i-2

analyzers, sample gas flows continuously through the sample cell ensuring that the sample is always representative

of the flow in the main pipe.

0.8 m cell 8 or 28 m cell

Figure 1. Schematic of a typical tunable diode laser absorption spectrometer

1. Laser 5. Detector

2. Pressure sensor 6. Window/near mirror

3. Outlet 7. Inlet

4. Optical head 8. Far mirror

Due to their inherent structure, the molecules in the sample gas each have characteristic natural frequencies (or

resonances). When the output of the laser is tuned to one of those natural frequencies, the molecules with that

resonance will absorb energy from the incident beam. That is, as the beam of incident intensity, I0(λ), passes through

the sample, attenuation occurs via absorption by the trace gas with absorption cross section σ(λ). According to the

Beer-Lambert absorption law, the intensity remaining, I(λ), as measured by the detector at the end of the beam path

of length / (cell length x number of passes), is given by

()=()exp [()]

where N represents the species concentration. Thus, the ratio of the absorption measured when the laser is tuned on-

resonance versus off-resonance is directly proportional to the number of molecules of that species in the beam path,

or

4

1 5

6

7

2

8 3

4

1 5

6

7

2

3 8

Operating Instructions SS2100i-2 TDLAS Gas Analyzer

10 Endress+Hauser

N =

()()

()

Figure 3 below shows the typical raw data from a laser absorption spectrometer scan including the incident laser

intensity, I0(λ), and the transmitted intensity, I(l), for a clean system and one with contaminated mirrors (shown to

illustrate the system’s relative intensity to mirror contamination).

Fig 2. Typical raw signal from a laser diode absorption spectrometer with and without mirror contamination

A. Resonance absorption Blue line: raw signal, I (l)

B. Red line: incident energy I0(l) Green line: raw signal, I (l) (contaminated mirrors)

The positive slope of raw data results from ramping the current to tune the laser, which not only increases the

wavelength with current, but also causes the corresponding output power to increase. By normalizing the signal by

the incident intensity, any laser output fluctuations are canceled, and a typical, yet more pronounced, absorption

profile results, as shown in figure 4 below.

Fig 3. Typical normalized signal from a laser diode absorption spectrometer

Contamination of the mirrors results solely in lower overall signal. However, by tuning the laser off-resonance as

well as on-resonance and normalizing the data, the technique self-calibrates every scan resulting in measurements

that are unaffected by mirror contamination.

Wavelength [a.u.]

Wavelength [a.u.]

1.0

0.99

0.98

0.97

0.96

0.95

Wavelength [a.u.]

Signal [a.u.]

3.0

2.5

2.0

1.5

1.0

0.5

0.0

A

SS2100i-2 TDLAS Gas Analyzer Operating Instructions

Endress+Hauser 11

2.4.1 Differential TDLAS

SpectraSensors differential TDLAS technology involves subtracting two spectrums from one another. A “dry”

spectrum, a response from the sample when the analyte of interest has been completely removed, is subtracted from

the “wet” spectrum, a response from the sample when the analyte is present. The remainder is a spectrum of the

pure analyte. This technology is used for very low or trace measurements and is also useful when the background

matrix changes over time.

2.4.2 Wavelength modulation spectroscopy (WMS) signal detection

Endress+Hauser takes the fundamental absorption spectroscopy concept a step further by using a sophisticated

signal detection technique called wavelength modulation spectroscopy (WMS). When employing WMS, the laser

drive current is modulated with a kHz sine wave as the laser is rapidly tuned. A lock-in amplifier is then used to

detect the harmonic component of the signal that is at twice the modulation frequency (2f). Refer to the figure

below, which is shown in arbitrary units (a.u.). This phase-sensitive detection enables the filtering of low-frequency

noise caused by turbulence in the sample gas, temperature and/or pressure fluctuations, low-frequency noise in the

laser beam or thermal noise in the detector.

Fig 4. Typical normalized 2f signal showing species concentration proportional to height.

A. 2f peak height

B. Normalized 2f signal

With the resulting low-noise signal and use of fast post-processing algorithms, reliable parts per million (ppm) or

parts per billion (ppb) detection levels are possible (depending on target and background species) at real-time

response rates.

All Endress+Hauser TDLAS gas analyzers employ the same design and hardware platform. Measuring different trace

gases in various mixed hydrocarbon background streams is accomplished by selecting a different optimum diode

laser wavelength between 700-3000 nm, which provides the least amount of sensitivity to background stream

variations.

2.4.3 Sample conditioning system

The analyzer may be integrated with a sample conditioning system (SCS) designed to meet the sample condition

requirements for the analyzer while preserving sample integrity and minimizing lag time. Refer to the SCS Operating

Instruction for more information.

2.4.4 Determining firmware version

When the analyzer is powered on for the first time, the firmware version will display on the system LCD display for

approximately seven seconds. Refer to Powering Up the Analyzer in the Description of Device Parameters → for this

Wavelength [a.u.]

Signal [a.u.]

B

A

Operating Instructions SS2100i-2 TDLAS Gas Analyzer

12 Endress+Hauser

analyzer for operational instructions. The firmware version for each analyzer is also listed on the analyzer calibration

certificate.

2.5 Getting familiar with the analyzer

The SS2100i-2 analyzer consists of two connected enclosures in a standard cable-coupled configuration, as shown in

the figure below.

Fig 5. Cable-coupled analyzer configuration

The left enclosure (electronics enclosure) contains the control electronics and input/output electrical connections, as

shown below. The right enclosure (sample cell enclosure) contains the sample cell and heater, as shown in Figure 8

→ (8/28 m sample cell) , Figure 9 → (0.8 m sample cell), or Figure 10 → (0.1 m sample cell). The keypad and

LCD display on the cover of the electronics enclosure are the user interface to the analyzer. Power and signal

connections are made via access ports on the bottom of the electronics enclosure. Tube fittings on the right side of

the sample cell enclosure are for sample supply and return connections. Both enclosures are mounted on a Unistrut®

frame.

Cable & Gland Kit

1100002143

SS2100i-2 TDLAS Gas Analyzer Operating Instructions

Endress+Hauser 13

Fig 6

. Dimensions and Mounting for Electronics and sample cell enclosures (cable

-coupled configuration)

Front view

Back view Bottom view

1.

Electronics enclosure

1. 8x mounting feet 1. M25 4-20 mA output board

2.

LCD display

A. 1036.83 mm (40.82 in) 2. M25 digital input/output port

3.

Keypad window

B. 439.93 mm (17.32 in) 3. M25 solenoid valve port

4.

Chassis ground

C. 500.13 mm (19.69 in) 4. M20 power input port

5.

24x cover screws

5. Breather

6.

Measurement cell enclosure

6. M25 serial com port

7.

Chassis ground

A. 247.90 mm (9.76 in)

8. Gas in

9. Gas out

A 1066.8 mm

(42.0 in)

B.

469.9 mm

(18.5 in)

C.

670 mm

(26.38 in)

A

B B

C

A

A

B B

C

Front View Back View

Bottom View

1

2

3

4

5

6

1

6

7

2

8

3

9

4

5

1

Operating Instructions SS2100i-2 TDLAS Gas Analyzer

14 Endress+Hauser

Fig 7. Components in SS2100i-2 electronics enclosure

1. 4-20mA AI board 11. Relay control board

2. Fuse (F3) 12. Temperature control board

3. High temperature limit thermostat 13. ARM9 control electronics

4. Analyzer power supply 14. RS-232 to RS-422/485 converter

5. Relays 15. Solid-state relay

6. AC line filter 16. Temperature controller

7. Fuses (F4-F10) 17. Auxiliary power supply

8. Main circuit breaker 18. AC terminal block for sample cell heater

9. Ground bus bar 19. Ground terminal blocks

10. 4-20mA AO board 20. Terminal blocks

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

SS2100i-2 TDLAS Gas Analyzer Operating Instructions

Endress+Hauser 15

Fig 8. Components on an 8 or 28 m sample cell panel enclosure

1. Heater 6. Transition plate thermistor

2. High temp. limit thermostat set at 70 °C 7. Sample temperature thermistor

3. AC terminal block for heater 8. Measurement cell

4. Terminal blocks 9. Pressure sensor

5. Fan

1

2

3

4

5

6

7

8

9

Operating Instructions SS2100i-2 TDLAS Gas Analyzer

16 Endress+Hauser

Fig 9. Components on a 0.8 m sample cell panel assembly

1. Heater 6. Transition plate thermistor

2. High temp. limit thermostat set at 70 °C 7. Pressure sensor

3. AC terminal block for heater 8. Measurement cell

4. Terminal blocks 9. Sample temperature thermistor

5. Fan

1

2

3

4

5

6

7

8

9

SS2100i-2 TDLAS Gas Analyzer Operating Instructions

Endress+Hauser 17

Fig 10. Components on a 0.1 sample cell panel enclosure

1. Heater 6. Transition plate thermistor

2. High temp. limit thermostat set at 70 °C 7. Measurement cell

3. AC terminal block for heater 8. Pressure sensor

4. Terminal blocks 9. Sample temperature thermistor

5. Fan

In the electronics enclosure, the analyzer power supply provides power to the analyzer control electronics and relays

controlling valves. The analyzer control electronics drive the laser, collect the signal and analyze the spectra.

Powered relays control valves while unpowered relays serve as alarm contacts. An AC line filter is used to condition

the input power.

The auxiliary switch-mode power supply provides power to the heater temperature controller and the RS-232/RS-

485 converter. The power supply is rated for 1.3 A at 24VDC output at ambient temperatures Ta ≤ 60 °C. The

operational state is indicated by LEDs on the front face, where green means the output voltage is on and within

specification, and red means the output voltage is on but below specification.

The thermostat prevents the temperature inside the enclosure from getting too hot. The thermostat is preset at the

factory to open the power circuit if the temperature inside the analyzer enclosure exceeds 70 ± 4 °C. The power

1

2

3

4

5

6

7

8

9

Operating Instructions SS2100i-2 TDLAS Gas Analyzer

18 Endress+Hauser

circuit will remain open until the manual reset button (located between the two wire terminals) on the thermostat is

pressed or the temperature drops approximately 30% below the set-point.

A DIN rail near the bottom holds fuse terminal blocks, the main breaker, and terminal blocks for all external

connections. The temperature controller controls the heater in the sample cell enclosure via the solid-state relay.

NOTICE

See Figure 7→ for locating fuses. If you need to replace a fuse, use only the same type and rating of fuse as the

original as listed in the tables below.

In the sample cell enclosure, the sample cell is the actual TDLAS spectrometer through which the gas sample flows.

The sample cell is equipped with a pressure sensor and thermistor to monitor the thermodynamic conditions of the

sample. The heater maintains the inside of the analyzer enclosure at a constant temperature with air circulated by

the fan.

Drawing Reference

Description

Rating

F3

Miniature Fuse, 5 x 20 mm, Time Delay

250 VAC 1.6 A

F41 Miniature Fuse, 5 x 20 mm, Time Delay 250 VAC 0.5 A

F5141, F61, F71, F81

Miniature Fuse, 5 x 20 mm, Time Delay

250 VAC 0.1 A

F91 Miniature Fuse, 5 x 20 mm, Time Delay 250 VAC 1 .0A

F101 Miniature Fuse, 5 x 20 mm, Time Delay 250 VAC 1.2 A

Fuse specifications for 240 VAC systems

Drawing Reference Description Rating

F3

Miniature Fuse, 5 x 20 mm, Time Delay

250 VAC 1.6 A

F41 Miniature Fuse, 5 x 20 mm, Time Delay 250 VAC 0.5 A

F5

141

, F6

1

, F7

1

, F8

1

Miniature Fuse, 5 x 20 mm, Time Delay

250 VAC 0.1 A

F91 Miniature Fuse, 5 x 20 mm, Time Delay 250 VAC 1.0 A

F101

Miniature Fuse, 5 x 20 mm, Time Delay

250 VAC 2.0 A

Fuse specifications for 120 VAC systems

1 Housed in fuse terminal blocks. Illuminated LED indicates blown fuse.

SS2100i-2 TDLAS Gas Analyzer Operating Instructions

Endress+Hauser 19

Fig 11. Label placement on exterior of enclosures

1. Chassis ground label 4. Chassis ground label

2. Manufacturer label 5. Port label

3. Class 1 laser product label

1

2

3

4

5

5

Operating Instructions SS2100i-2 TDLAS Gas Analyzer

20 Endress+Hauser

Fig 12. Label placement on electronics panel assembly

1. Electric shock warning label 6. Functional ground earth label

2. Energized fuse warning label 7-8. General warning label

3. General warning label 9. Electric shock warning label

4. Electric shock warning label 10. Functional earth ground label

5. Fuse rating label 11. Protective earth ground label

1

2

3

4

5

6

7

8

9

10

11

/