Table of Contents

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

R

EAD THIS MANUAL BEFORE PROCEEDING . . . . . . . . . . . . . . . 1

D

IGITAL AND MANUAL CONTROLS . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

R

ECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS . . . . . . . 1

S

AFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

S

AFE HANDLING OF REFRIGERANTS . . . . . . . . . . . . . . . . . . . . 2

R-410A Q

UICK REFERENCE GUIDE . . . . . . . . . . . . . . . . . . . . 3

SYSTEM INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

U

NPACKING AND INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . 3

H

OW IT WORKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Basic Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

The Importance of Seawater Temperature . . . . . . . . . 4

S

AFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Avoid Harmful Vapors . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Shock Hazard . . . . . . . . . . . . . . . . . . . . . . . . 5

Other Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

T

OOLS REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

P

LACEMENT OF THE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . 6

C

LEARANCES AND ACCESSIBILITY . . . . . . . . . . . . . . . . . . . . . . 7

S

YSTEM SIZING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

M

OUNTING THE CONDENSING UNIT & ELECTRICAL BOX . . . . . . 7

M

OUNTING THE DX AIR HANDLER . . . . . . . . . . . . . . . . . . . . . 7

C

ONDENSATE DRAIN LINES . . . . . . . . . . . . . . . . . . . . . . . . . . 7

C

OPPER LINE SETS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Refrigerant Line Sizing . . . . . . . . . . . . . . . . . . . . . . . . . 9

Refrigerant Connection Sizes . . . . . . . . . . . . . . . . . . . 9

Single-Thickness Flare Procedure . . . . . . . . . . . . . . . . 9

R-410A Replacement Considerations . . . . . . . . . . . . . 9

Routing of Suction Line and Liquid Line . . . . . . . . . . . 9

Filter Dryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Backseating Service Valves . . . . . . . . . . . . . . . . . . . . 10

Pressure Test and Leak Checking . . . . . . . . . . . . . . . 11

Pressure Test . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Leak Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

System Evacuation . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Deep Vacuum Method Procedure . . . . . . . . . . 12

Triple Evacuation Method Procedure . . . . . . . . 13

Insulating the Line Sets . . . . . . . . . . . . . . . . . . . . . . . 14

DUCT & GRILLE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . 14

S

UPPLY & RETURN AIR GRILLES . . . . . . . . . . . . . . . . . . . . . 14

D

UCTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SEAWATER PUMP & PLUMBING INSTALLATION . . . . . . . . 15

S

EAWATER PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

S

EAWATER SPEED SCOOP . . . . . . . . . . . . . . . . . . . . . . . . . . 16

S

EAWATER STRAINER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

I

NSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . 16

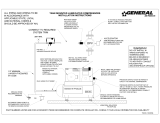

ELECTRICAL CONNECTIONS, GROUNDING AND

BONDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

O

VERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

S

AFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

W

IRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3-P

HASE NOTICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

W

IRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

MANUAL CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . 18

I

NSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

O

PERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

S

LAVE FAN-SPEED CONTROL . . . . . . . . . . . . . . . . . . . . . . . . 19

SYSTEM STARTUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

D

ETERMINING REFRIGERANT CHARGE . . . . . . . . . . . . . . . . . 20

Factory-Charge Settings . . . . . . . . . . . . . . . . . . 20

Determining Charge by Table Method . . . . . . . 20

F

ACTORY-CHARGE RELEASE INTO SYSTEM . . . . . . . . . . . . . . 22

S

YSTEM STARTUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Final Charge Adjustment . . . . . . . . . . . . . . . . . . . . . . 22

Adding/Removing Refrigerant Charge . . . . . . . 22

Verifying System Refrigerant Charge . . . . . . . . 22

Verifying Acceptable Operating Pressures . . . . . . . . 23

F

INAL CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

INSTALLATION CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . 25

QUICK-START OPERATIONS CHECKLIST . . . . . . . . . . . . . . 26

SERVICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

C

OOLING MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

H

EATING MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

S

CHEMATIC DIAGRAM OF REFRIGERANT SYSTEM . . . . . . . . . 26

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

G

ENERAL TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . 28

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

R

ETURN-AIR FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

R

EVERSING VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

S

EAWATER STRAINER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

C

ONDENSER COIL CLEANING . . . . . . . . . . . . . . . . . . . . . . . . 29

W

INTERIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30