TopWorx GO Switch 10 & 20 Series IOM Owner's manual

- Type

- Owner's manual

This manual is also suitable for

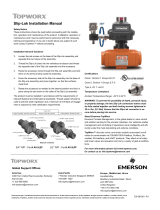

TopWorx GO Switch 10 & 20 Series IOM offers precise sensing and switching solutions for various industrial applications. With its versatile design, it can be mounted in any position and is suitable for both standard and latching switch operations. The switch features adjustable sensing ranges, allowing customization based on specific requirements. It is ideal for detecting ferrous targets or magnets and can be used for limit sensing, over-travel protection, or alarm activation.

TopWorx GO Switch 10 & 20 Series IOM offers precise sensing and switching solutions for various industrial applications. With its versatile design, it can be mounted in any position and is suitable for both standard and latching switch operations. The switch features adjustable sensing ranges, allowing customization based on specific requirements. It is ideal for detecting ferrous targets or magnets and can be used for limit sensing, over-travel protection, or alarm activation.

-

1

1

-

2

2

TopWorx GO Switch 10 & 20 Series IOM Owner's manual

- Type

- Owner's manual

- This manual is also suitable for

TopWorx GO Switch 10 & 20 Series IOM offers precise sensing and switching solutions for various industrial applications. With its versatile design, it can be mounted in any position and is suitable for both standard and latching switch operations. The switch features adjustable sensing ranges, allowing customization based on specific requirements. It is ideal for detecting ferrous targets or magnets and can be used for limit sensing, over-travel protection, or alarm activation.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

TopWorx GO Switch 7J IOM Owner's manual

TopWorx GO Switch 7J IOM Owner's manual

-

TopWorx D-Series Owner's manual

TopWorx D-Series Owner's manual

-

TopWorx GO Switch 70 Series Owner's manual

TopWorx GO Switch 70 Series Owner's manual

-

TopWorx Slip-Lok Flyer Owner's manual

TopWorx Slip-Lok Flyer Owner's manual

-

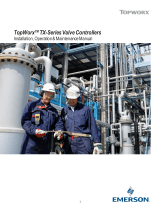

TopWorx TX-Series Valve Controllers Owner's manual

TopWorx TX-Series Valve Controllers Owner's manual

-

Fisher T-Series IOM Owner's manual

-

TopWorx Slip-Lok IOM Owner's manual

TopWorx Slip-Lok IOM Owner's manual

-

TopWorx D Series IOM Owner's manual

TopWorx D Series IOM Owner's manual

-

Fisher Valvetop D-Series D2-FF Foundation Fieldbus IOM (for previous model before 2013) Owner's manual

-

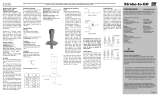

TopWorx GO 7CX & 7DX IOM Stroke-To-GO IOM Owner's manual

TopWorx GO 7CX & 7DX IOM Stroke-To-GO IOM Owner's manual

Other documents

-

VALIN Go Switch User manual

-

Emerson IOM User manual

-

ABB VA Master FAM540 Commissioning Instructions

-

Emerson 70 Series User manual

-

Rosemount 702 Wireless Discrete Transmitter Quick start guide

-

Rosemount 702 Wireless Discrete Transmitter Owner's manual

-

Emerson Rosemount 3300 Series Quick start guide

-

Rosemount 2120 Level Switch Quick start guide

-

Rosemount 2130 Enhanced Vibrating Fork Liquid Level Switch Quick start guide

-

Rosemount 2130 Level Switch Vibrating Fork Owner's manual