Page is loading ...

Manual

960-130e-02.23

Direct cavity

pressure sensors

Page 1

960-130e-02.23

Cavity pressure measurement oers the greatest poten-

tial for complete process monitoring and process control

in the injection molding process. A correct handling of the

pressure sensors is mandatory to utilize this potential.

This manual provides procedures and guidelines for sen-

sor-compliant handling during the entire application, start-

ing with the mold design, through the mold construction

and up to the machine operator. In addition, this manual

represents a product overview for direct cavity pressure

measurement and the respective accessories.

This manual was generated in cooperation with TE Con-

nectivity Ltd. Company. We are grateful to all participants

of TE Connectivity Ltd. Company for their valuable sug-

gestions and their constructive cooperation during the

creation and enhancement of this manual.

The information in this manual is subject to change at any

time without prior notice. Kistler reserves the right to im-

prove and modify the product in accordance with the tech-

nical progress without the obligation to inform persons

and organizations based on these changes.

© 2015 ... 2023 Kistler Group. All rights reserved.

Kistler Group

Eulachstrasse 22

8408 Winterthur

Switzerland

Phone +41 52 224 11 11

info@kistler.com

www.kistler.com

Foreword

Foreword

Direct cavity pressure sensors

960-130e-02.23

Page 2

Table of Contents

1. General Information ....................................................................................................................5

1.1 Warning Symbols and their Signicance ............................................................................6

1.2 Disposal Instructions for Electronic Devices .......................................................................6

2. Application...................................................................................................................................7

4. Design information .....................................................................................................................9

4.1 Sensor positioning ..............................................................................................................9

4.2 Positioning of contact elements ........................................................................................12

4.3 Sensor dimensions ...........................................................................................................14

4.4 Important points of the bore ..............................................................................................19

4.5 Surface quality of the mounting bore ................................................................................22

4.6 Mounting bore with spacer sleeve ....................................................................................23

4.7 Mounting bore with mounting nut .....................................................................................25

4.8 Mounting bore with conductive spacer sleeve ..................................................................28

4.9 Mounting bore with angled sensor ....................................................................................30

4.10 Mounting bore contact elements ......................................................................................31

4.11 Cable routing ....................................................................................................................33

4.12 Multi-channel connectors ..................................................................................................34

4.13 Sensor installation on tilted mold surfaces .......................................................................35

4.13.1 Sensor axis not at right angles to the mold surface ............................................35

4.13.1.1 Sensor installation with a part feature allowing for a at surface .........36

4.13.1.2 Sensor installation with machinable front ............................................37

4.13.2 Sensor axis right-angled to the mold surface ......................................................37

5. Installation of sensors ..............................................................................................................39

5.1 General .............................................................................................................................39

5.2 Important places of the bore .............................................................................................39

5.3 Installation recommendations ...........................................................................................39

5.3.1 Design of the mounting bore ...............................................................................39

5.3.2 Recommended work process for machining the mounting bore .........................41

5.4 Surface condition of the mounting bore ............................................................................44

5.5 Mounting bore with spacer sleeve ....................................................................................44

5.6 Mounting bore with mounting nut .....................................................................................44

5.7 Mounting bore with conductive spacer sleeve ..................................................................44

5.8 Mounting bore for angled sensors ....................................................................................44

5.9 Mounting bore for contact element ...................................................................................44

Page 3

960-130e-02.23

5.10 Checking the sensor bore .................................................................................................44

5.10.1 Checking and re-lapping of the bore ...................................................................44

5.11 Installation with spacer sleeve ..........................................................................................47

5.12 Machining spacer sleeve ..................................................................................................48

5.13 Installation with mounting nut ...........................................................................................49

5.14 Installation with conductive spacer sleeve ........................................................................50

5.15 Machining conductive spacer sleeve ................................................................................51

5.16 Sensor installation on tilted mold surfaces .......................................................................52

5.16.1 Sensor installation not at right angles to the mold surface ..................................52

5.16.1.1 Sensor installation with a part feature allowing for a at surface .........52

5.16.1.2 Sensor installation with machinable surface ........................................52

5.16.1.3 Information about machining the surface .............................................52

5.16.2 Sensor installation at right angles to the mold surface ........................................54

5.17 Contact element installation .............................................................................................54

5.18 Mounting examples ..........................................................................................................55

6. Cable and connection technology...........................................................................................58

6.1 Single-wire technology .....................................................................................................58

6.1.1 Single-wire repair with repair set 1207 ................................................................59

6.1.2 Exchange single-wire cable.................................................................................62

6.2 Contact elements ..............................................................................................................63

6.2.1 Fastening of the crimp contact at the single-wire cable ......................................64

6.2.2 Contact element with 1 channel for the charge transmission Type 1712 ............65

6.2.3 Contact element with 4 channels for the charge transmission Type 1714 ..........65

6.3 Cable routing ....................................................................................................................66

6.4 Connector installation .......................................................................................................66

6.4.1 Single channel connector Type 1839 ..................................................................67

6.4.2 Multi-channel connector Type 1708 and Type 1710 ............................................70

6.4.2.1 Mold identication ................................................................................74

6.5 Coaxial cable ....................................................................................................................74

6.6 Identication plate .............................................................................................................74

6.7 Installation support devices ..............................................................................................75

6.8 Accessories ......................................................................................................................76

7. Function test before the mold commissioning ......................................................................80

7.1 Handheld tester Type 5495...............................................................................................80

7.1.1 Utilization of the adapters ....................................................................................81

7.1.2 Connection with the sensor .................................................................................82

7.1.3 Sensitivity test .....................................................................................................82

7.1.4 Function test ........................................................................................................84

7.1.5 Insulation test ......................................................................................................85

7.2 Check the jamming of sensors .........................................................................................86

Direct cavity pressure sensors

960-130e-02.23

Page 4

8. FAQ .............................................................................................................................................87

8.1 Sensor provides no signal ................................................................................................87

8.2 Short circuit .......................................................................................................................87

8.3 The sensor shows values that are too low .......................................................................88

8.4 Drift ...................................................................................................................................88

8.5 Interfering signals (noise, leakage current) ......................................................................89

9. Service and repair .....................................................................................................................90

9.1 Handheld tester Type 5495...............................................................................................90

9.1.1 Utilization of the adapters ....................................................................................90

9.1.2 Connection with the sensor .................................................................................90

9.1.3 Sensitivity test .....................................................................................................90

9.1.4 Function test ........................................................................................................90

9.1.5 Insulation test ......................................................................................................90

9.2 Sensor removal ................................................................................................................91

9.2.1 Spacer sleeve......................................................................................................91

9.2.2 Mounting nut........................................................................................................91

9.2.3 Conductive spacer sleeve ...................................................................................91

9.2.4 Angled sensors....................................................................................................92

9.2.5 Auxiliary materials/accessories ...........................................................................92

9.2.6 Calibrating ...........................................................................................................92

9.3 Single wire repair ..............................................................................................................92

9.4 Exchange single wire ........................................................................................................92

9.5 Repairs at Kistler ..............................................................................................................93

9.6 Disposal instructions for electronic devices ......................................................................93

10. Appendix ....................................................................................................................................94

10.1 Checklist for the mold design ...........................................................................................94

10.2 Check-list for the mold shop .............................................................................................96

10.3 Test protocol sensor tester ...............................................................................................98

10.4 Diagrams for cause nding and troubleshooting ..............................................................99

10.4.1 No signal .............................................................................................................99

10.4.2 Short circuit .......................................................................................................104

10.4.3 The sensor shows values that are too low ........................................................108

10.4.4 Drift ....................................................................................................................113

10.4.5 Inuences by the power supply .........................................................................118

11. Supplemental history .............................................................................................................120

Total pages 127

General Information

Page 5

960-130e-02.23

1. General Information

Please take the time to thoroughly read this instruction

manual. It will help you with the installation, maintenance,

and use of this product.

To the extent permitted by law Kistler does not accept any

liability if this instruction manual is not followed or products

other than those listed under Accessories are used.

Kistler oers a wide range of products for use in measur-

ing technology:

Piezoelectric sensors for measuring force, torque,

strain, pressure, acceleration, shock, vibration and

acoustic-emission

Strain gage sensor systems for measuring force and

torque

Piezoresistive pressure sensors and transmitters

Signal conditioners, indicators and calibrators

Electronic control and monitoring systems as well as

software for specic measurement applications

Data transmission modules (telemetry)

Kistler also develops and produces measuring solutions

for the application elds engines, vehicles, manufacturing,

plastics and biomechanics sectors.

Our Sensors and Systems General Catalog (doc. no. 960-112)

provides an overview of our oering. Detailed data sheets

are available for practically all of the products.

The document numbering is based on the following pattern:

960-130d-07.15

960-130 is the internal document number which always

remains identical.

d represents the language of the document (d: German,

e: English, f: French)

07.15 is the creation date of the document and it will be

adapted accordingly with each revision.

If you need additional help beyond what can be found

either on-line or in this manual, please contact Kistler's

extensive support organization.

Direct cavity pressure sensors

960-130e-02.23

Page 6

1.1 Warning Symbols and their Signicance

Noncompliance with the precautionary measures de-

scribed here can lead to malfunctions or to damage to

system components (see table below).

Symbol Noncompliance Can Result In

CAUTION

Indicates a caution or warning notice.

NOTE

Indicates a tip or important information.

1.2 Disposal Instructions for Electronic Devices

Do not discard old electronic instruments in municipal

trash. For disposal at end of life, please return this product

to an authorized local electronic waste disposal service

or contact the nearest Kistler Instrument sales oce for

return instructions.

Application

Page 7

960-130e-02.23

2. Application

This manual exclusively describes direct measuring cav-

ity pressure sensors, which are mainly used in injection

molding tools. The application covers the entire range of

injection molding tools irrespective of whether these are

single or multi cavity systems.

The robust design permits reliable and continuous moni-

toring, analysis and optimization of injection molding pro-

cesses in industrial production.

The sensors described in this manual are not allowed to

be used either for measurements in the screw ante-cham-

ber or in distributors heated from the outside or in the hot

runner. In addition, they are not qualied for the pressure

measurement of gases and liquids.

3. Functional principle

As soon as the plastic melt ows into the mold and reaches

the sensor front, it applies a mechanical load on the sen-

sor. This deforms the quartz element of the sensor and an

electrical charge will be generated. The charge signal will

be routed through a connecting cable to a charge amplier,

which converts it into a voltage of 0 … 10 V. The individual

signals are proportional to each other. This means that the

measured voltage is proportional to the cavity pressure. It

can be acquired by the charge amplier and it can be used

for measurement and monitoring purposes.

The cavity pressure sensors developed by Kistler have

an almost unlimited service life as well as oering high

overload protection.

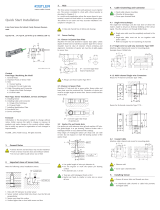

An approx. 0.01 mm wide annular gap separates the sen-

sor case from the wall of the mounting bore, which guar-

antees the free movement of the transmission rate (Fig.

3.1). This is required, because a parallel connection due

to jamming of the sensor results in measurement errors.

Under normal circumstances, the minimum dimensioning

of the annular gap prevents the plastic melt from penetrat-

ing into the gap.

Direct cavity pressure sensors

960-130e-02.23

Page 8

The annular gap for the sensors Type 6182C…, Type

6167A…, 6159A… and 6157B is sealed with a high

temperature resistant O-ring (Viton) to also prevent the

penetration of dirt. The O-ring is also used to center the

sensor (Fig. 3.1).

Fig. 3.1: Functional principle cavity pressure sensor

The material also penetrates the smallest gap openings

when processing very low viscosity molding compounds

(thermo-setting plastics, elastomers and SMC materials).

This can result in measurement errors or in extreme cases

in the destruction of the measuring element. Sensors with

diaphragms, Type 6161…, 6162… or 6163…, which were

especially developed for such materials, are used for the

processing of these molding compounds. The sensors

with diaphragms are not sensitive to the type of installa-

tion. Therefore, the mounting bore can be dimensioned

smaller to ensure that no plastic melt can penetrate the

annular gap during the process.

Single wire

connection cable

Spacer sleeve

Fastening ange

Quartz package

O-ring

Pressure p

Pressure p

Annular gap

Design information

Page 9

960-130e-02.23

4. Design information

It is important for the placement of the sensors to decide

which objectives are pursued with the recording of the

cavity pressure. For example, the optimal sensor position

for process control can be dierent from the optimal posi-

tion for monitoring.

To prevent problems during process monitoring, it is im-

portant to position the sensor in accordance with the re-

quirements of the measuring signal and the monitoring

task. In addition, adherence to the requirements of the

mounting bore is required. This section will provide pro-

cedures about the design of the mounting bore and the

positioning of the sensor.

4.1 Sensor positioning

The selection of the sensor position is of signicant impor-

tance to get meaningful results from the cavity pressure

curve. It must be noted that the optimal position depends

on the requirements or the objectives. If the cavity pres-

sure will be used as a control variable for switching to the

holding pressure, the sensor must be placed near the gate

(Fig. 4.1). This means that the process monitoring already

starts during the injection phase. If the sensor is placed

in the area of the highest wall thickness, the number of

iterations for the complete lling can be reduced signi-

cantly, because this area solidies last and therefore the

pressure signal is maintained longest (Fig. 4.2). The sen-

sor must be positioned at the end of the ow path for the

monitoring of short shots. A ll study or a mold ow analy-

sis can be helpful during the mold trials of a new mold. A

second sensor at the end of the ow path can be sensible

for monitoring certain process-typical errors (Fig. 4.3).

Direct cavity pressure sensors

960-130e-02.23

Page 10

Fig. 4.1: Positioning near the gate

Fig. 4.2: Positioning in the area of the highest

wall thickness

Design information

Page 11

960-130e-02.23

Fig. 4.3: Positioning of a second sensor

For molds with several gates, the sensors must be posi-

tioned at the critical point of the material conuence to be

able to monitor them.

However, the optimal position cannot always be used. In

many cases, geometrical conditions force the user to se-

lect the second or third best installation location. In these

cases, the aspect of the sensor position must always be

included in the interpretation of the measuring results.

As a matter of principle, the sensor must not be positioned

in the sprue or across the gate. The sensor does not de-

liver any process information for the component quality

when placed in the sprue channel (Fig. 4.4). If the sensor

is positioned across the sprue, the impacting plastic melt

distorts the measuring signal. In addition, the sensor front

will be washed out, which signicantly shortens the ser-

vice life (Fig. 4.5).

Direct cavity pressure sensors

960-130e-02.23

Page 12

Fig. 4.4: No positioning of the sensor in the sprue

Fig. 4.5: No positioning of the sensor opposite the gate

4.2 Positioning of contact elements

Contact elements are used for the easy dismounting of

mold inserts for maintenance and repair work. They

should be positioned in such a way that they do not come

into contact with water or with moisture, not even during

service and repair work. In addition, contact elements

should be placed at a distance to the cooling channels as

large as possible.

Design information

Page 13

960-130e-02.23

Contact elements can be designed with 1-channel or

4-channel. Both options are shown in Fig. 4.6 and 4.7.

Fig. 4.6: Contact element with one conductive channel

Fig. 4.7: Contact element with 4 conductive channels

The provided mounting nut is used for the installation or,

if enough space is available, a small steel plate is used.

These small steel plates are not an accessory delivered

by Kistler because they must be created and produced

individually for each installation situation. This is the only

way to maintain the maximal possible exibility. The small

steel plates are shown in Fig. 4.8.

Direct cavity pressure sensors

960-130e-02.23

Page 14

30

ø10,1

±0,1

16

21

9,6 ±0,1

8±0,1 1x45°

R1,5

ø4,2

ø8

90°

2

30

ø10,1

±0,1

16

21

9,6 ±0,1

8±0,1 1x45°

R1,5

ø4,2

ø8

90°

2

Fig. 4.8: Small steel plate for mounting the contact ele-

ment Type 1714…

When using this retaining plate for a 4-channel contact

element, it must be ensured that the retaining plate pre-

vents the rotation of the contact elements.

A mounting example for the contact element, Type 1712…,

is shown in Fig. 4.9.

Fig. 4.9: Mounting example contact element

4.3 Sensor dimensions

The dimensioned sensor drawings are shown in the fol-

lowing sections. The sensors are arranged in descending

type numbers. The angled sensor, Type 6184, is listed at

the end of this section.

Design information

Page 15

960-130e-02.23

11.5 0

-0.05

4 0

-0.05

2.5 g6 -0.002

-0.008

()

1-0.01

-0.02

2.2 0

-0.02

18

23

Fig. 4.10: Dimension sensor Type 6183C… and 6183D...

Fig. 4.11: Dimension sensor Type 6183B.../6183AQ100/

6183DYQ100

Direct cavity pressure sensors

960-130e-02.23

Page 16

10

2kt. SW3,5

0

-

-0,020

0,03

12

2,5 e6

-

21,6

0,014

0,002

0,008

2,5 g6 -

-

0,6

Fig. 4.12: Dimension sensor Type 6182C… and 6183D...

Fig. 4.13: Dimension sensor Type 6159…

O-ring

Type 1100A55

Design information

Page 17

960-130e-02.23

Fig. 4.14: Dimension sensor Type 6157..., 6167..., 6177...

Fig. 4.15: Dimension sensor Type 6152..., 6172...,

6162..., 6163...

O-ring

Type 1100A55

Direct cavity pressure sensors

960-130e-02.23

Page 18

Fig. 4.16: Dimension sensor Type 6184

/