Page is loading ...

INSTALLATION GUIDE FOR THE MULE™ 3000 OPERATOR ENCLOSURE

1

INSTALLATION OF THE OPERATOR

E

NCLOSURE FOR THE MULE™ 3000

J

ULY ‘07

www.essexmfg.com PO Box 92864 Southlake, TX 76092 Ph:888-643-7739

INSTALLATION GUIDE FOR THE MULE™ 3000 OPERATOR ENCLOSURE

2

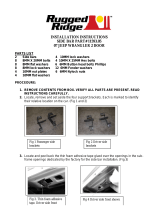

PREPARATION

The passenger side grab handle and mounting brackets-

must be removed for the cab to install. They can be

sawed or ground off.

Loosen the roll cage for cab installation by loosening the

three frame bolts on each side of the rear rollbar at the floor-

boards and loosen the 5 bolts on each bedrail. Position the

bed-sides as far back as they will adjust and retighten. This

will allow you to maximize the clearance between the cab

and the bed.

[Fig 2] Replace the hex head bolt on the front of the bed with

a pan head carriage bolt provided in the bolt kit. Note: DO

NOT TIGHTEN THE ROLL CAGE UNTIL ENTIRE CAB IN-

STALLATION IS COMPLETE!

The enclosure is shipped with all trim and doors preassembled. All hardware is included. The fasteners for the body

panel are 10mm serrated flange nuts and 6mm bolts. Use the black washers provided under the heads of the exter-

nal bolts. The front Quarter panels are fastened with self-tapping Tek screws on each side. 5/16” carriage bolts se-

cure the floorboards. You will need the following tools to complete the installation:

• Metric Sockets, 10, 12 & 14mm, SAE 3/8, 7/16, 1/2 & 9/16

• #3 Phillips Screwdriver / 5/16” Drill Bit / Hacksaw / Angle Grinder

NOTE: Use portions of these instructions for partial cab installation.

1 USE THE LONG 8MM BOLTS and NUTS PROVIDED.

2 Remove the rear screen and seat back. Install the

8mm long bolts provided and reattach the seat back.

3 Fit the lower closeout panel into position over the four

8mm lower screen bolt. Adjust the positition for best fit

and cut out the marked sections at the bottom to fit the

gas or diesel oil details at the frame rail. Use zipties to

secure the panel to the lower and upper cross tubes of

the Mule as shown. There are pairs of holes in the

panel; start the ziptie through the top hole from inside

the cab and feed it back thru the lower hole. Do not

tighten the ties until all of them are started and the

panel has been adjusted for best fit.

REAR FABRIC PANEL

FLOORBOARDS & MOUNTING BRACKETS

Position the left and right treadplate floorboards. The notch

should be located around the front wheel well member. Re-

move the bolt from the rubber boot and use it to secure the

floorboard. Drill two 5/16” holes thru the square holes in the

boards into the floor for the left & right sides. Install carriage

bolts and tighten. If planned, install the heavy duty battery at

this time before the rear quarter panels are installed.

[Fig 2] Loosen the 19mm rollbar bolts to provide a gap for

the front quarter panel brace and the lower windshield brace

to fit alongside the frame.

[Fig 3] Remove the two screws on each front wheel well and

install the left & right side mounting brackets.

Fig. 1.

Fig. 2.

Fig. 3.

INSTALLATION GUIDE FOR THE MULE™ 3000 OPERATOR ENCLOSURE

3

REAR QUARTER PANELS

1 Install the 1x2" angle brackets on the floorboard us-

ing 6mm bolts. Don’t tighten until later. Repeat for

the other side

2 [Fig 2] Set the rear qtr panel on the floorboard and

against the rear cage. Use an 8mm bolt from the

rear screen to fasten the door post tab to the floor-

board on each side. Fasten the panel to the angle

bracket with a 6mm bolt.

3 [Fig 3] Line up the holes in the rear quarter panels

and roof and loosely

install 6mm bolts.

4 Leave the nuts loose until adjustments are made for

the door opening

STEEL HARDTOP

1 [Fig 1] Attach the visor to the roof using six 6mm

bolts. Install the top bolts on each side first, then ro-

tate to a 45 degree position for the others. Use the

black washers under the outside bolt heads.

2 Place the rectangular black gasket over the air intake

before you install the roof. Set the roof in place in-

side the rear window panel Locate the roof as far for-

ward as it will fit. Tighten the rear screen first and

then the seat back.

REAR WINDOW

1 The rear window fits on the outside of the roof

and on the outside of the rear quarter panels.

Foam gasket is preinstalled on the top and

sides of the window.

2 Install the window panel against the bolt tabs

and secure each 8mm bolt with a washer and

two 8mm nuts provided. Adjust the first nut so

that the sliding window operates smoothly and

’lock it with the 2nd nut.

3 [Fig 4] Install the rear screen guard and secure

it with the original 8mm nuts.

Fig. 1.

Fig. 3.

Fig. 2.

Fig. 4.

INSTALLATION GUIDE FOR THE MULE™ 3000 OPERATOR ENCLOSURE

4

WINDSHIELD AND FRONT PANELS

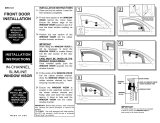

Inside Latch Handle Swell Latch Parts Outside Latch view

Install the "swell" latches into the aligned holes of the windshield and

lower closeout panel. [Fig 4] The pivot handle is on the inside; washer,

rubber sleeve and nut to the outside. [Fig 3] Position the lower windshield

assembly on the hood so that it fits on the rubber sleeves of the upper

corner latches and lies flush against the hood as shown.

ADJUST IT AND CENTER THE LOWER WINDSHIELD PANEL BE-

FORE DRILLING THE MOUNTING HOLES.

Drill 1/4" holes for the mounting bolts on the front side of the lower win-

dow assembly.

[Fig 5] Raise the hood and fasten it with M6 bolts and the inside squeeze

plate as shown. Drill the two rear 1/4" holes from the inside and install

M6 bolts. [Fig 6] Pull the gasket tight and fold it around the lower edge of

the hood. [Fig 7] Install the plastic clip to secure it as shown.

Adjust the swell latches for smooth closure by tightening, or loosening

the nut on the front side. Once adjusted for proper closure, we suggest

that you secure the nut with LocTite or teflon tape to keep it from coming

loose.

Slide the upper windshield assembly with flip-up glass across the front of

the Mule behind the roll cage. [Fig 1] Once it is in position, push the top

forward against the top roll bar frame and start the 6mm bolts in the top

of the windshield to attach it to the nuts welded in the roof. Leave them

loose until the quarter panels and doors are adjusted

[Fig 2] Assemble the quarter panels to the frame by aligning the side

holes with the mounting bracket and with the hole in the side of the roof.

Install the lower closeout bracket in the rollbar bolt slot and the flange

into the seam of the corner beam.

Slide the upper windshield panel into position aligning it with the nuts in

the roof beam. Start M6 bolts to hold it in place. Seat the tongue of the

windshield panel fully into the side seams in the corner beams. Install the M6

bolts to secure the windshield to the corner beams.

Install the T handles for the upper window and adjust the nylock nuts for smooth

operation. The inside tongue fits in the track of frame.

LOWERWINDSHIELD PANEL

Fig. 1

Fig. 7

Fig. 3

Fig. 2

Fig. 6

Fig. 5

Fig. 4

INSTALLATION GUIDE FOR THE MULE™ 3000 OPERATOR ENCLOSURE

5

SETTING THE DOORS

• Check and tighten all fasteners and bolts including the roll cage.

• [Fig 3] Install roll cage gaskets, oval shaped holes, at the top of the windshield

on the inside.

• Install the windshield wiper (Refer to page 6)

• See page 6 for additional accessory installation.

Note: LEAVE the cab bolts LOOSE to permit adjustment of the margins for the doors.

1 [Fig 1] Install the door headers and fit the gasket to them.

2 Install the hinges on each side and leave them finger tight to permit adjustment of

the gap on the edges of the doors.

3 Install the latches in the doors and secure with the Torx head screws provided.

Leave the latch loose enough to adjust and fit to the strike.

4 [Fig 2] Set the doors on the hinges to check for height and clearance. There should

be 1/8” clearance around the door. A paint stick works well as a spacer during ad-

justment.

5 Adjust the hinges and rear post as needed. The hinge plates have adjustment range

in each direction. Adjust the rear post and tighten the bolt to the floorboard. The door

strike can also be adjusted by bending it open to meet the latch.

6 Once the door is aligned in the frame, tighten the hinge plates.

Note: If you still have trouble setting the doors, simply loosen up the bolts on the quarter

panels and roof and move them until the door sets up.

Fig. 1

FINISHING THE INSTALLATION

Fig. 3

Fig. 2

INSTALLATION GUIDE FOR THE MULE™ 3000 OPERATOR ENCLOSURE

6

3000FCP: Floorpan and Close Out Panel

The floor pan bolts to the underside of the frame. Use these in-

structions for it and for the full 2500FCP. The Insulated Close

Out Panel installs behind the seat with the soft gray sound ab-

sorbing foam to the engine side and are bolted to the bolt tabs on

the seat frame cross tube.

CLOSE OUT PANEL

1. The panel is diecut to fit the opening behind the seat and is

cut to fit around all of the hoses, lines and harness. Start on the

passenger side, it has the most detail to fit.

2. The top corner by the fuse box is a tight fit. Bend the fuse box mount-

ing bracket up slightly to create clearance; slide the panel into position

over the tab on the back rail. Bend the bracket back to its horizontal posi-

tion.

FLOORPAN

1. Stuff the three pieces of front cross member insulators in the air gaps

between the front cross channel of the frame and the passenger com-

partment floor.

2. Position the Floor Pan with the foam side up, by locating the front notch

on the bolt in the edge of the front cross member under the floor panel.

Align the panel evenly with the frame members and check the fit of the

panel with the back side of the cross member.

3

. Using the guide holes in the floorpan, install TEK screws provided into

the frame working from front to rear. Use a drive gun.

CAB ACCESSORY PACKAGE

The following section includes installation instructions for accessories that may have been included in your Cab

enclosure package.

ACCESSORY HARNESS

The roof has a wiring harness preinstalled at the factory.

Together with the fuse panel this will save time in installa-

tion and servicing of powered accessories.

• Connect the 4-way female connector to the male con-

nector in the headliner. Route the loom down the left

rear post into the compartment under the seat. Secure

with cable ties.

• Mount the fuse block to the side panel, near the other

fuses holders, with the Tek screws provided. Insert the

male bullet connector to the brown wired female bul-

let. , This +12v is keyed to the ignition switch. Attach

the ring terminal to + battery terminal for constant

power.sources

WINDSHIELD WIPER

• Install the windshield wiper through the hole provided

in the windshield for the shaft and with the #10 screw and

bolt. The small bolt makes the ground for the motor; be

sure it is tightened to make contact. Attach the roof har-

ness spade connector to the motor.

• Operate the motor and turn it off in the left most posi-

tion of travel.

• With the shaft in the left most position, set the arm

along the top left edge of the window.

• The arm is adjustable in length. Pivot the lever under

the joint in the arm and to set the arm length to best cover the windshield. The

wiper s set for 120 degree sweep.

• To permit the windshield to open without wiper interference, stop the motor when the arm is at the full left

sweep position. The arm will then be out of the way when the lift windshield is opened

INSTALLATION GUIDE FOR THE MULE™ 3000 OPERATOR ENCLOSURE

7

COOLING DEFROST FAN

Mount the fan to the top passen-

ger windshield. Ground the ring

terminal to the cab and connect

the +12v lead to the roof har-

ness. Alternatively, the fan can

be mounted on top of the dash

on either the driver or passen-

ger side.

CAB ACCESSORY

The following section includes installation instructions for accessories that may have been included in your Cab

enclosure package.

REARVIEW MIRROR

The heavy duty wide angle mirror can be bolted to the channel

inside the roof with the self tapping Tek screws provided;

Or, it can be mounted to the windshield frame above the

Driver’s side using the No.10 machine screws provided.

BREAKAWAY EXTERIOR MIRRORS

Using the mounting template, Drill two 1/4” holes in front

of the hinge on the driver’s quarterpanel and fasten the

arm with the M6 bolts. DO NOT OVERTIGHTEN.

Mount the right mirror arm on the door as shown. Drill two

1/4” holes with the template and fasten to the door.

Install the mirrors on the arms & adjust for best view.

DOMELIGHT & POWERPORTS

Face the Powerports down on the inside of the rollbar

air intake & ‘Tek’ screw them with the ground lead as

shown. Connect to the accessory harness. The

domelight should be preinstalled at the factory and

A

VAILABLE

MULE

ACCESSORIES

Essex “SureFoot”

runflat tires

Essex Lift Kits

provide increased

clearance, better ride

and superior handling

and come

standard with

tire kits.

Winch Bumper

& Grille guard

BED SEATS

BED SEATS

P.O. Box 92864 Southlake, TX 76092

SEE THE REST OF OUR PRODUCT LINE AT ESSEXMFG.COM

OR CALL US AT 1-888-64-ESSEX

THANK YOU FOR YOUR BUSINESS!

INSTALLATION GUIDE FOR THE MULE™ 3000 OPERATOR ENCLOSURE

8

CAB CARTON #1 HARDTOP & WLT

FRONT QTR PANELS, LEFT & RIGHT

FRONT QTR MOUNTING BRACKETS, L & R

HARDTOP WITH DOME LIGHT

FRONT VISOR

LOWER WINDSHIELD ASSEMBLY

LOWER WINDSHIELD CLOSEOUT BRACKETS

LIFT WINDSHIELD PANEL W/GAS PROPS

3000S1/2CAB SMALL PARTS BAG #1

⇒ HARDTOP/ WLT BOLT KIT

21 - 6MM X 12MM HEX SERRATED BOLTS

12 - 6

MM HEX FLANGE NUTS

21

M6 FLAT WASHERS FOR USE ON OUTSIDE BOLTS.

F

OUR 6 X 25 MM CAP HEAD BOLTS FOR THE FRONT

M

OUNTING BRACKETS

2 "S

WELL" CAM LATCHES FOR SECURING THE

LOWER WINDSHIELDPANEL TO THE UPPER FRAME

2 P

LASTIC “U” CLIPS FOR SECURING THE ENDS OF

THE LOWER HOOD GASKET

⇒ A

CCESSORY HARNESS & 4 FUSE BLOCK

⇒ 2

ADHESIVE GASKETS (OVAL) FOR WINDSHIELD TO

ROLL CAGE CLOSEOUT

⇒ S

PARE PARTS KIT, FASTENERS AND FUSES

⇒ H

ANDLES FOR THE SAFARI LIFT WINDSHIELD

CAB CARTON #2 CABUPGD

REAR QTR PANELS, LEFT & RIGHT

DOOR HEADER PANELS, L & R

FLOORBOARDS, L & R

LOWER REAR CLOSEOUT PANEL BLACK

REAR SLIDING GLASS WINDOW

3000 CABUPGD SMALL PARTS BAG #2

⇒ W

INDSHIELD WIPER KIT{MOTOR, ARM, BLADE & FASTENE R

AIR CLEANER CLOSEOUT GASKET

♦ REAR WINDOW BOLT BOX: SIX 8MM BOLTS, 12 NUTS &

10

WASHERS FOR THE USE THE 8MM BOLTS/NUTS FROM

THE REAR SCREEN FOR THE DOOR POSTS.

♦ 4 - 5/16”

CARRIAGE BOLTS & NUTS FOR FLOOR

BOARDS

♦ 2 - M6 C

ARRIAGE BOLTS FOR THE FRONT OF THE BED

AND ON THE REAR QTR PANELS.

♦ 8 - 11" C

ABLE TIES FOR REAR CLOSEOUT PANEL INSTAL-

LATION

♦ 2

ANGLE CLIPS FOR REAR QTR TO FLOOR ATTACHMENT

♦ T

EN 6MM NUTS, BOLTS & WASHERS FOR DOOR HEADERS

AND QTR PANELS

OPTIONAL ACCESSORIES

DOORS, L & R W/ 2 KEYS AND HINGES

⇒ STEEL DOORS W/SLIDER WINDOW

⇒ M

ARINE VINYL COVERED DOORS W/ZIPPERED WINDOW

CAB PACKAGE:

♦ DEFROSTER FAN

♦ F

LOOR PAN AND ENGINE CLOSEOUT PANEL

♦ F

LOORMAT

♦ E

XTERNAL MIRRORS, LEFT - RIGHT

♦ R

EAR VIEW MIRROR

ROOF MOUNT DIGITAL RADIO, CASSETTE OR CD,

SPEAKERS

BODY ARMOR: ENGINE SKID PLATE & CV GUARDS

17,500 BTU CAB HEATER W/ 2 SPEED FAN

GAUGE PKG - OIL & VOLTMETER

BACK-UP ALARM

TURN SIGNALS – 2 & 4 WAY

GUN RACKS

STROBE LIGHT, 70 FPM BEACON

55 AMP ALTERNATOR, 110V POWER AND WELDING

P O B 92864 S thl k TX 76092

CAB INSTALLATION TIPS:

⇒ LOOSEN THE 3 BOLTS THAT SECURE THE REAR

ROLL CAGE TO THE FLOOR. [12MM SOCKET]

⇒ LOOSEN THE BED SIDE BOLTS AND SLIDE THE BED

RAILS BACK AS FAR AS THEY WILL ADJUST

W

ITH THE BACK OF THE CAB INSTALLED BUT NOT

TIGHTENED, WEDGE 1/2" OR SO OF FOAM MATERIAL

BETWEEN THE CAB AND BED. LOWER AND LATCH THE

BED AND TIGHTEN THE BED RAILS AND THE LOWER

ROLL CAGE BOLTS. THIS WILL GENERATE CLEARANCE

BETWEEN THE BED AND THE REAR OF THE CAB.

SEE THE REST OF OUR PRODUCT LINE AT ESSEXMFG.COM

OR CALL US AT 888-64-ESSEX

THANK YOU FOR YOUR BUSINESS!

/