1

Contents

Page

Safety 3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operation Practices for Ride-on (riding)

Rotary Lawnmower Machines 3. . . . . . . .

Safe Operating Practices 3. . . . . . . . . . . . . .

Sound Pressure Level 5. . . . . . . . . . . . . . . . .

Sound Power Level 5. . . . . . . . . . . . . . . . . .

Vibration Level 5. . . . . . . . . . . . . . . . . . . . .

Slope Chart 7. . . . . . . . . . . . . . . . . . . . . . . . .

Symbols Glossary

9. . . . . . . . . . . . . . . . . . .

Symbols Glossary

10. . . . . . . . . . . . . . . . . . .

Symbols Glossary

11. . . . . . . . . . . . . . . . . . .

Petrol and Oil 12. . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Petrol 12. . . . . . . . . . . . . . . . .

Using Stabilizer/Conditioner 13. . . . . . . . . . .

Filling the Fuel Tank 13. . . . . . . . . . . . . . . . .

Check Engine Oil Level 13. . . . . . . . . . . . . . .

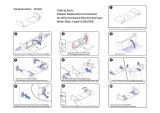

Assembly 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 14. . . . . . . . . . . . . . . . . . . . . . . . .

Install Drive Wheels 15. . . . . . . . . . . . . . . . . .

Tire Pressure 15. . . . . . . . . . . . . . . . . . . . . . . .

Install Seat Retaining Rod 15. . . . . . . . . . . . .

Install Motion Control Levers 16. . . . . . . . . .

Activate the Battery 17. . . . . . . . . . . . . . . . . .

Install Battery 18. . . . . . . . . . . . . . . . . . . . . . .

Hydraulic System 19. . . . . . . . . . . . . . . . . . . .

Greasing the Bearings

20. . . . . . . . . . . . . . . .

Check the Leveling of Mower Deck 20. . . . .

Check Side Dischar

ge Chute

20. . . . . . . . . . .

Check Engine Oil Level 20. . . . . . . . . . . . . . .

Operation 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Think Safety First 21. . . . . . . . . . . . . . . . . . .

Controls 21. . . . . . . . . . . . . . . . . . . . . . . . . . .

Parking Brake 22. . . . . . . . . . . . . . . . . . . . . . .

Installing or Removing Baffles 22. . . . . . . . .

Installing and Removing Blowout Baffles 25.

Starting and Stopping the Engine 27. . . . . . .

Operating the Power Take Off (PTO) 28. . . .

Page

The Safety Interlock System 29. . . . . . . . . . .

Testing the Safety Interlock System 29. . . . . .

Driving Forward or Backward 30. . . . . . . . . .

Stopping the Machine 30. . . . . . . . . . . . . . . .

Instruments 31. . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Tanks 31. . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting Height-of-Cut 32. . . . . . . . . . . . . .

Adjusting Anti-Scalp Rollers 32. . . . . . . . . . .

Positioning the Seat 33. . . . . . . . . . . . . . . . . .

Pushing the Machine by Hand 34. . . . . . . . . .

Side Discharge 34. . . . . . . . . . . . . . . . . . . . . .

T

ransporting Machines

35. . . . . . . . . . . . . . . .

Loading Machines

35. . . . . . . . . . . . . . . . . . .

Tips for Mowing Grass 37. . . . . . . . . . . . . . .

Maintenance 38. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Interval Chart 38. . . . . . . . . . . . . . . .

Cutting Blades

39. . . . . . . . . . . . . . . . . . . . . .

Air Cleaner 42. . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Cooling System 43. . . . . . . . . . .

Engine Oil 44. . . . . . . . . . . . . . . . . . . . . . . . .

Spark Plug 46. . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filter 47. . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Tank 47. . . . . . . . . . . . . . . . . . . . . . . . . .

Greasing and Lubrication 48. . . . . . . . . . . . . .

Greasing the Bearings

49. . . . . . . . . . . . . . . .

Hydraulic System 50. . . . . . . . . . . . . . . . . . . .

Tire Pressure 52. . . . . . . . . . . . . . . . . . . . . . . .

Castor Pivot Bearing Adjustment 52. . . . . . .

Wheel Hub Slotted Nut 53. . . . . . . . . . . . . . .

Mower Leveling 53. . . . . . . . . . . . . . . . . . . . .

Adjusting Push Arms 55. . . . . . . . . . . . . . . . .

Throttle Lever Adjustment 55. . . . . . . . . . . . .

Clean Under Deck 56. . . . . . . . . . . . . . . . . . .

Belt Inspection

56. . . . . . . . . . . . . . . . . . . . . .

Replacing the Deck Belt 57. . . . . . . . . . . . . .

Replacing the Pump Drive Belt 58. . . . . . . . .