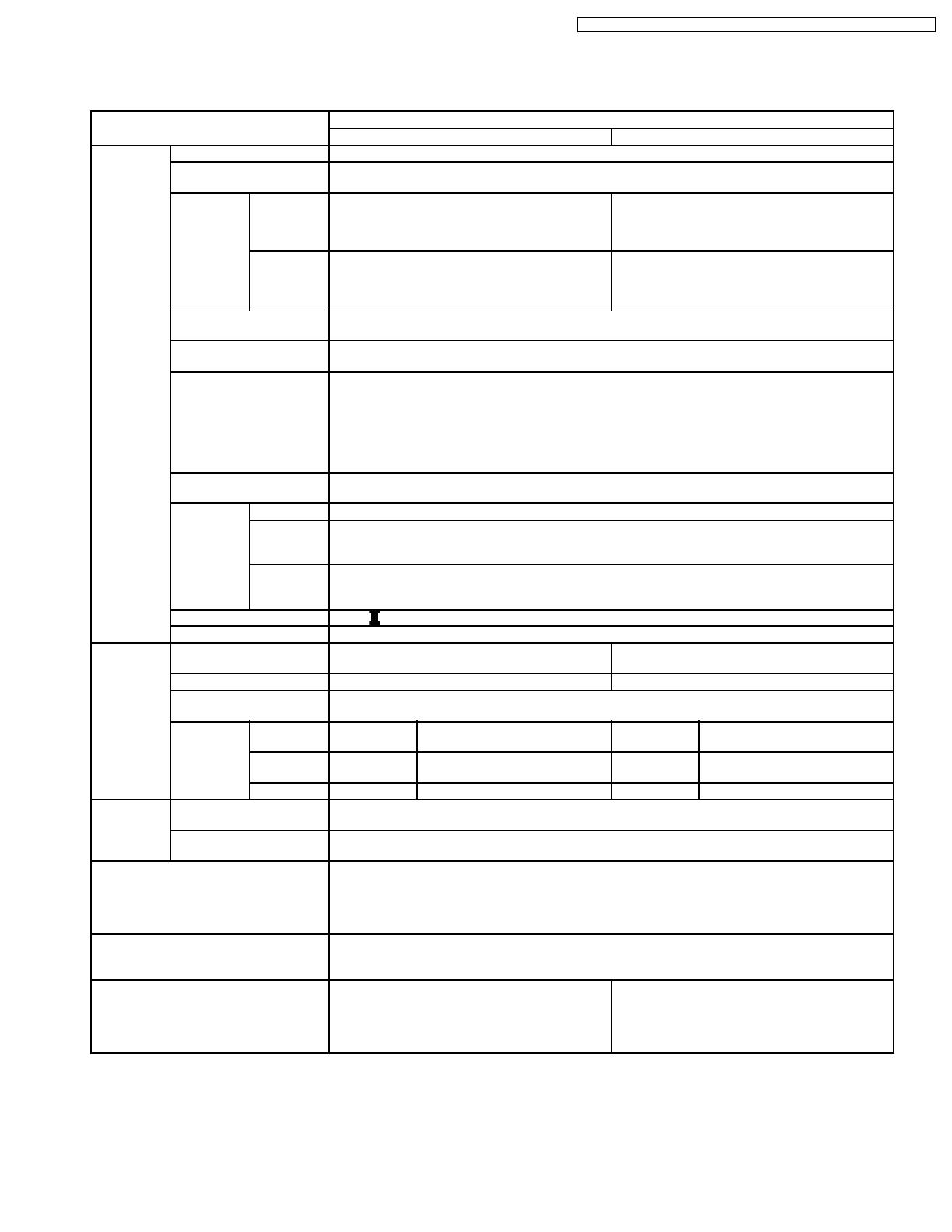

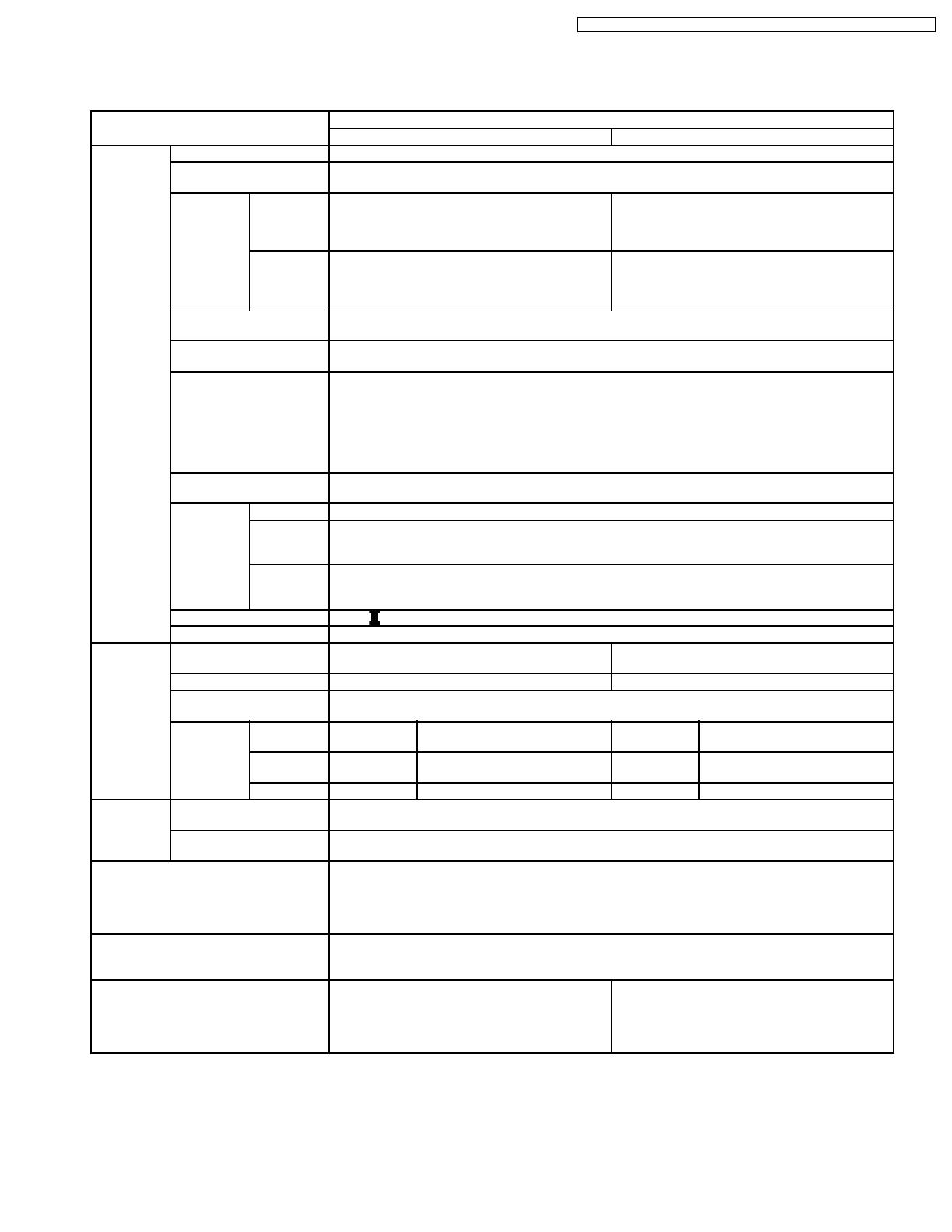

2 SPECIFICATIONS

2.1. KV-S2025C/S2045C Series

Item Model No.

*2 KV-S2025C Series *2 KV-S2045C Series

Scanner Scanning face Duplex

Scanning method CIS (Contact-type color image sensor) for Front & Back sides

Background: Black sensor roller

Readout

Speed *1

Simplex Black & White: 23 ppm

(Letter, Fed portrait, 200dpi)

Color: 10 ppm

(Letter, Fed portrait, 150dpi)

Black & White: 43 ppm

(Letter, Fed portrait, 200dpi)

Color: 19 ppm

(Letter, Fed portrait, 150dpi)

Duplex Black & White: 42 ipm

(Letter, Fed portrait, 200 dpi)

Color: 18 ipm

(Letter, Fed portrait, 150 dpi)

Black & White: 76 ipm

(Letter, Fed portrait, 200 dpi)

Color: 34 ipm

(Letter, Fed portrait, 150 dpi)

Resolution 100 - 600 dpi (10 dpi step)

Optical: 600 dpi (Main and Sub scanning directions)

Tonal gradation Binary mode, Gray scale mode (4 / 8 bit), Dither mode (16 / 256 step), Error diffusion

Note: Dither and Error diffusion are executed by driver or RTIV.

Image control Image emphasis (5step), Dynamic threshold, Automatic separation, Noise reduction, Deskew,

Cropping, Mirror Image, Monochrome Reversing, Gamma correction

Note:

·

Image emphasis: executed by Gate Array

·

Gamma correction for Black & White or Gray-scale: executed by Gate Array

·

Gamma correction for color RGB: executed by driver or RTIV

Other function Patch code detection (Kodak patch 2,3,T)

Note: 1 portion both side each executed only by ISIS driver.

Paper Size 50.8 × 70 mm (2.0 × 2.8 in.) to 216 × 356 mm (8.5 × 14 in.) *3

Thickness Single paper feeding: 0.05 to 0.15 mm (2.0 to 5.9 mils)

Continuous paper feeding: 0.06 to 0.15 mm (2.36 to 5.9 mils)

Note: 1 mil = 1 / 1000 in.

Weight Single paper feeding: 40 to 127g/m

2

(10.7 to 33.9 lbs.)

Continuous paper feeding: 50 to 127g/m

2

(13.3 to 33.9 lbs.)

Note: 1 lbs = 3.75 g/m

2

Interface (Transfer rate) SCSI (20 MB/sec)

Feed tray capacity 120 sheets [64 g/m

2

(17 lbs.)], 100 sheets [75 g/m

2

(20 lbs.)]

Unit External dimensions

(Width × Depth × Height)

343 × 487 × 269 mm (13.5 × 19.2 × 10.6 in.)

Note: When tray is pulled

343 × 487 × 239 mm (13.5 ×19.2 × 9.4 in.)

Note: When tray is installed

Weight 8.4 kg (18.5 lbs.) 9.1kg (20.1 lbs.)

Power requirement AC100 - 120 V, 50 / 60 Hz

AC220 - 240 V, 50 / 60 Hz

Power

consumption

Maximum

(Scanning)

AC100 - 240V 1A AC100 - 240V 1A

Minimum

(Standby)

AC100 - 240V 0.3 A AC100 - 240V 0.35 A

Sleep mode AC100 - 240V 0.1 A (7 W) AC100 - 240V 0.15 A (8 W)

Environment Operating temperature

and Humidity

Temperature: 15 °Cto30°C(59°Fto86°F)

Humidity: 30% to 80%RH

Storage temperature

and Humidity

Temperature: 0 °Cto35°C(32°Fto95°F)

Humidity: 10% to 80%RH

Accessories Power cord, Feed extension tray (Only for KV-S2045C Series), Exit extension tray (Only for KV-

S2045C Series), Roller cleaning paper, CD ROM (Maintenance, Safety and Installation manual,

Operation instructions, RTIV Capture software, ISIS driver, TWAIN driver, PIE manual, RTIV manual,

User utility, User utility manual), CD ROM (Paper Port SE: Only for KV-S2025C/CU), Printed document

(Maintenance, Safety and Installation manual)

PbF (Pb Free) Applied to PCB assemblies for KV-S2025C/S2045C Series KME will manufacture

Note: Distinction of PbF PCB

PCBs (manufactured) using lead free solder will have a PbF stamp on the PCB.

Option White roller kit (KV-SS023)

Roller exchange kit (KV-SS022)

Roller cleaning paper (KV-SS03)

White roller kit (KV-SS023)

Roller exchange kit (KV-SS022)

Roller cleaning paper (KV-SS03)

Imprinter unit (KV-SS020)

Ink cartridge (KV-SS021)

5

KV-S2025C Series / KV-SU225C Series / KV-S2045C Series / KV-SU245C Series