Page is loading ...

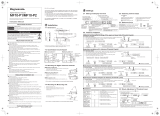

Contents Technical Manual TNC 426 B, TNC 430

Update Informations No. 4 - 1

Update information for your TNC.

Introduction

Technical data and general information on software and ID numbers.

Mounting and Electrical Installation

Mounting restrictions, power supply, pin layouts of the units and cables.

Machine Integration

Detailed description of machine functions with the respective machine parameters, markers, words and

PLC modules.

PLC Programming

General information on the PLC, TRACE functions, complete set of PLC commands.

Data interfaces

Detailed description of the data interfaces.

Original Equipment Manufacturer’s (OEM) Cycles

Important on the OEM cycles.

Error Messages

List of the PLC and DSP error messages.

Machine Parameters

Machine parameter input and output, complete list of the machine parameters.

Modules, Markers and Words

Complete list of the modules, markers and words. 5

4

10

9

8

7

6

3

1

2

April 2000 2 – 1

2 Introduction

2.1 General.............................................................................................. 2 – 2

2.2 Overview of Components ............................................................... 2 – 4

2.3 Brief Description ............................................................................ 2 – 15

2.4 Hardware ........................................................................................ 2 – 21

2.4.1 Designation of the Logic Unit .................................................. 2 – 21

2.5 Software ......................................................................................... 2 – 22

2.5.1 Designation of the Software ................................................... 2 – 22

2.5.2 Software Option ...................................................................... 2 – 23

2.5.3 PLC Software .......................................................................... 2 – 23

2.5.4 Software Exchange ................................................................. 2 – 24

2.5.5 Data Backup ............................................................................ 2 – 27

2.6 Software Releases ......................................................................... 2 – 28

2.6.1 NC Software 280 470-xx and 280 471-xx ................................ 2 – 28

2.6.2 NC Software 280 472-xx and 280 473-xx ................................ 2 – 30

2.6.3 NC Software 280 474-xx and 280 475-xx ................................ 2 – 35

2.6.4 NC Software 280 476-xx and 280 477-xx ................................ 2 – 42

2 – 2 HEIDENHAIN Technical Manual TNC 426, TNC 430

2 Introduction

2.1 General

HEIDENHAIN contouring controls are designed for use with milling, drilling

and boring machines as well as machining centers.

The TNC 426 PB/M, TNC 430 PA/M features integral digital drive control and

controls the power stages via PWM signals.

Integration of the drive controllers in the TNC 426 PB/M, TNC 430 PA/M

offers the following advantages:

nAll of the software is contained centrally in the NC; this means that the

individual components of the NC such as feed axes, spindle, NC or PLC are

optimally matched

nHigh control quality, because the position control, speed control and current

control are combined into one unit.

nFor commissioning, optimization and diagnosis, the same functions are

available both for the feed drive and the main spindle.

The TNC 426 PB offers digital control for machines with up to 5 axes and

spindle speeds up to 12 000 rpm (option: 24 000 rpm).

The TNC 430 PA supports up to 6 digitally controlled NC axis, 3 analog

controlled secondary axes, and digitally controlled spindle speeds up to

24 000 rpm.

April 2000 General 2 – 3

The TNC 426 M offers digital control for up to 5 axes and spindle speeds up

to 12 000 rpm (option: 24 000 rpm).

The TNC 430 M offers digital control for up to six or nine axis and spindle

speeds up to 24 000 rpm.

The TNC 426 M, TNC 430 M is designed for connection of a compact or

modular inverter system. Thus, together with HEIDENHAIN motors, a

complete control package including servo drive can be offered (see Technical

Manual "Inverter Systems and Motors").

The TNC 426 CB is the version of the TNC 426 that is equipped with analog

speed command interface and can control machines with up to five axes plus

spindle.

The TNC 430 CA also has analog speed command interface for machines with

up to eight axes plus spindle. A ninth axis can be controlled with an additional

PCB.

2 – 4 HEIDENHAIN Technical Manual TNC 426, TNC 430

2.2 Overview of Components

Logic unit LE 426 CB, LE 430 CA

Logic unit Signal inputs ID numbers of LE for

BC 120 display unit

ID numbers of LE for

BF 120 display unit

LE 426 CB

5 position inputs

1 spindle position

1 VPP (350 kHz)

1V

PP (350 kHz)

312 001-xx 313 524-xx

5 position inputs

1 spindle position

1 VPP (50 kHz)

1V

PP (350 kHz)

326 415-xx 326 419-xx

5 position inputs

1 spindle position

11 µAPP (50 kHz)

1V

PP (350 kHz)

312 002-xx 313 525-xx

LE 430 CA

8 position inputs

1 spindle position

1 VPP (350 kHz)

1V

PP (350 kHz)

311 050-xx 313 523-xx

5 position inputs

3 position inputs

1 spindle position

1 VPP (50 kHz)

1V

PP (350 kHz)

1V

PP (350 kHz)

326 418-xx 326 424-xx

April 2000 Overview of Components 2 – 5

Logic unit LE 426 PB, LE 430 PA

Logic unit Signal inputs ID numbers of LE for

BC 120 display unit

ID numbers of LE for

BF 120 display unit

LE 426 PB

5 position inputs

1 spindle position

6 motor encoder inputs

1 VPP (350 kHz)

1V

PP (350 kHz)

1V

PP

Spindle up to 9000 rpm 312 000-xx 313 527-xx

Spindle up to 15 000 rpm 315 475-xx 318 178-xx

5 position inputs

1 spindle position

6 motor encoder inputs

1 VPP (50 kHz)

1V

PP (350 kHz)

1V

PP

Spindle up to 9000 rpm 326 414-xx 326 421-xx

Spindle up to 15 000 rpm 326 416-xx 326 420-xx

5 position inputs

1 spindle position

6 motor encoder inputs

11 µAPP (50 kHz)

1V

PP (350 kHz)

1V

PP

Spindle up to 9000 rpm 311 999-xx 313 526-xx

Spindle up to 15 000 rpm 317 349-xx 318 177-xx

2 – 6 HEIDENHAIN Technical Manual TNC 426, TNC 430

LE 430 PA

5 position inputs

1 spindle position

7 motor encoder inputs

1 VPP (350 kHz)

1V

PP (350 kHz)

1V

PP

311 049-xx 313 521-xx

5 position inputs

1 spindle position

7 motor encoder inputs

1 VPP (50 kHz)

1V

PP (350 kHz)

1V

PP

326 417-xx 325 716-xx

Logic unit Signal inputs ID numbers of LE for

BC 120 display unit

ID numbers of LE for

BF 120 display unit

April 2000 Overview of Components 2 – 7

Logic unit LE 426 M, LE 430 M

Logic unit Signal inputs ID numbers of LE for

BC 120 display unit

ID numbers of LE for

BF 120 display unit

LE 426 M

6 position inputs

6 motor encoder inputs

11 µAPP /1 VPP

switchable

1 VPP

Spindle to 12 000 rpm 324 990-xx 324 991-xx

Spindle to 24 000 rpm 324 994-xx 324 995-xx

LE 430 M

6 position inputs

7 motor encoder inputs

11 µAPP /1 VPP

switchable 1 VPP

324 992-xx 324 993-xx

10 position inputs

10 motor encoder inputs

11 µAPP /1 VPP

switchable

1 VPP

324 996-xx 324 997-xx

2 – 8 HEIDENHAIN Technical Manual TNC 426, TNC 430

Operating panel TE 420

Id. Nr. 313 038-01

Horizontal rows to match the design of the flat-

panel display

Id. Nr. 316 343-01

Visual display unit BC 120

15-inch color screen (640 x 480 pixels)

Id. Nr. 313 037-01

Visual display unit BF 120

10.4-inch color flat-panel display

(640 x 480 pixels)

Id. Nr. 313 506-01

April 2000 Overview of Components 2 – 9

Screen-keyboard switching unit BTS 1x0

With the BTS 1x0, it is possible to connect two

monitors and two operating panels to a LE.

Id. Nr. 317 292-01 BTS 110 (2 x BC 120)

(see figure at right)

Id. Nr. 329 965-01 BTS 120 (2 x BF 120)

Machine operating panel MB 420

The MB 420 machine operating panel features

(standard assignment):

n5 axis keys

nNC start, NC stop

nSpindle start, spindle stop

nCoolant

nRapid traverse

nEmergency stop

n5 freely definable keys (via PLC)

Id. Nr. 293 757-13 Standard

Id. Nr. 293 757-23 Keys not placed,

Assortment of keys

supplied to be placed

by user

PLC input/output unit PL 410 B

For the expansion of PLC inputs and outputs

Id. Nr. 263 371-12 64 inputs

31 outputs

Id. Nr. 263 371-02 64 inputs

31 outputs

4 analog inputs ± 10 V

4 inputs for

Pt 100 thermistors

PLC input/output unit PL 405 B

Id. Nr. 263 371-22 32 inputs

15 outputs

2 – 10 HEIDENHAIN Technical Manual TNC 426, TNC 430

HR 410 handwheel

Portable handwheel with:

nKeys for selection of 5 axes

nKeys for traverse direction

nKeys for preset feeds

nKey for actual value position capture

nThree keys for machine functions

(definable via PLC)

nTwo permissive buttons

nEmergency stop

nMagnetic holding pads

Id. Nr. 296 469-xx HR 410 handwheel

Id. Nr. 312 879-01 Connecting cable to

cable adapter

(spiral cable 3m)

Id. Nr.296 467-xx Connecting cable to cable

adapter (normal cable)

Id. Nr.296 687-xx Connecting cable to

cable adapter (with metal

armor tubing)

Id. Nr. 296 466-xx Adapter cable to LE

Id. Nr. 281 429-xx Extension to adapter cable

Id. Nr.271 958-03 Dummy plug for

EMERGENCY STOP circuit

HR 130 handwheel

Panel-mounted handwheel

Id. Nr. 254 040-05 with ergon. control knob

Radial cable outlet

(see figure at right)

April 2000 Overview of Components 2 – 11

Handwheel adapter HRA 110

The handwheel adapter can be used to connect

up to three HR 150 to the TNC.

The axes and the subdivision factor are selected

via step switch.

Id. Nr. 261 097-01 HRA 110

Id. Nr. 257 061-08 HR 150 cable outlet axial

Id. Nr. 270 908-01 Step switch

2 – 12 HEIDENHAIN Technical Manual TNC 426, TNC 430

TS 220 Touch Probe

Touch-trigger probe with cable connection for

workpiece setup, measurement during

machining and digitizing

Id. Nr. 293 488-xx TS 220

Id. Nr. 274 543-xx Adapter cable for

connection to LE:

TS 632 touch probe

Touch-trigger probe with infrared transmission,

for workpiece setup and measurement during

machining

Id. Nr. 331 397-xx TS 632

Id. Nr. 262 904-01 Receiver unit EA 550

Id. Nr. 339 317-xx Receiver unit EA 552

Id. Nr. 275 759-xx Interface electronics

APE 511 for connecting

two EA 552 to the LE

Id. Nr. 310 197-xx Adapter cable for

connecting the EA 550 or

the APE 511 to the LE:

April 2000 Overview of Components 2 – 13

TT 130 tool touch probe

Touch-trigger probe for measuring tools.

Id. Nr. 296 537-xx TT 130

Id. Nr. 335 332-xx Adapter cable for

connection to LE:

Further components ID Numbers

Options for TNC 426 CB/PB, TNC 430 CA/PA

Additional position input for a 6th or 9th axis

(350 kHz)

311 537-51

Position input for 3 additional axes with nominal

speed command interface (350 kHz)

294 130-51

Ethernet interface 293 890-xx

Digitizing with triggering 3-D touch probe 286 405-01

Digitizing with a measuring 3-D touch probe

(SP 2/1)

311 647-51

Options for TNC 426 M, TNC 430 M

Ethernet interface 293 890-xx

Digitizing with triggering 3-D touch probe 286 405-01

Digitizing with a measuring 3-D touch probe

(SP 2/1)

325 818-51

Adapter for encoder signals

TTL (HEIDENHAIN layout)/1 VPP 317 505-01

TTL (SIEMENS layout)/1 VPP 317 505-02

11 µAPP /1 VPP 313 119-01

2 – 14 HEIDENHAIN Technical Manual TNC 426, TNC 430

Documentation Items supplied with the control include:

n1 User's Manual for conversational programming

n1 User's Manual for ISO programming

n1 Pilot (brief user's programming guide)

The components required for operating the TNC 426 and TNC 430 with non-

HEIENHAIN inverter systems are described in the "Technical Information for

Operation of SIMODRIVE and POWER DRIVE inverter systems"

The HEIDENHAIN inverters and motors for the TNC 426 M and the TNC 430

M are described in the Technical Manual "Inverter Systems and Motors."

You will receive a set of supplementary pages every time changes are made

to this manual.

April 2000 Brief Description 2 – 15

2.3 Brief Description

Technical Data TNC 426 TNC 430

Basic version with integrated motor control

TNC 426 PB, TNC 430 PA:

All position and motor encoder inputs 1 VPP

TNC 426 M, TNC 430 M:

All pos. inputs switchable between 1 VPP and 11 µAPP

All motor encoder inputs 1 VPP

TNC 426 PB:

n5 axes plus spindle with

position and motor enco-

der inputs

TNC 426 M:

n5 axes plus spindle (up to

12 000 rpm ) with position

and motor encoder inputs

n5 axes plus spindle (up to

24 000 rpm ) with position

and motor encoder inputs

TNC 430 PA:

n5 axes plus spindle with

position and motor enco-

der inputs

n6th axis with motor enco-

der input

TNC 430 M:

n6 axes plus spindle with

position and motor enco-

der inputs

n9 axes plus spindle with

position and motor enco-

der inputs

Basic version with analog speed command interface

Position inputs 1 VPP

TNC 426 CB:

n5 axes plus spindle

TNC 430 CA

n8 axes plus spindle

Options

TNC 426 CB/PB:

Position inputs for the axes:

11 µAPP

TNC 430 CA:

nPosition input for the 9th

axis:

TNC 430 PA:

nPosition inputs for

3 additional axes with

analog speed interface

nPosition input for the

6 axis:

nDigitizing with triggering touch probe

nDigitizing with measuring touch probe

nEthernet interface

Display

n15-inch CRT color screen

n10.4-inch TFT color flat-panel display

Program memory

Hard disk with 2.1 gigabytes

Input resolution and display step

Up to 0.1 µm for linear axes

Up to 0.000 1° for angular axes

2 – 16 HEIDENHAIN Technical Manual TNC 426, TNC 430

Interpolation

Straight lines 5 of 5 axes 5 of 9 axes

Circle n2 of 5 axes

n3 of 5 axes with tilted

working plane

n5 of 9 axes

n3 of 9 axes with tilted

working plane

Helices Superimposition of circular and linear paths

Interpolation

Spline Cubical splines can be executed

Block processing time

From the hard disk: 4 ms

Machine integration TNC 426 TNC 430

Feedback control

Integral drive control TNC 426 PB, TNC 430 M TNC 430 PA, TNC 430 M

Analog speed command interface TNC 426 CB TNC 430 CA

Position loop resolution

Cycle time for path interpolation TNC 426 CB/PB, TNC 430 CA/PA: 3 ms

TNC 426 M, TNC 430 M: can be set between 3 ms and

6ms

Cycle time for speed TNC 426 PB/M, TNC 430 PA/M: 0.6 ms

Feed rate TNC 426 PB/M, TNC 430 PA/M:

TNC 426 PB/M, TNC 430 PA/M:

nUp to 60 m/min for encoders with 20 µm grating period

nUp to 300 m/min for encoders with 100 µm grating

period

Speed TNC 426 PB (standard),

TNC 426 M/12 000 rpm:

TNC 426 PB (option)

TNC 426 M/24 000 rpm :

TNC 430 PA,

TNC 430 M:

TNC 426 CB: TNC 430 CA:

Technical Data TNC 426 TNC 430

Signal period

1024

-----------------------------------------

18000

No. of pole pairs

---------------------------------------------------- Scrow pitch min 1–

⋅⋅

24000

No. of pole pairs

---------------------------------------------------- min 1–

⋅

48000

No. of pole pairs

---------------------------------------------------- min 1–

⋅48000

No. of pole pairs

---------------------------------------------------- min 1–

⋅

100000 min 1–100000 min 1–

April 2000 Brief Description 2 – 17

Error compensation

nLinear and nonlinear axis error

nBacklash

nReversal spikes during circular movements

nOffset

nThermal expansion

nStiction

nSliding friction

Integral PLC

PLC memory Hard disk

Main memory (RAM) 512 KB

PLC cycle time TNC 426 CB/PB, TNC 430 CA/PA: 21 ms

TNC 426 M, TNC 430 M: can be set between 21 ms and

120 ms

PLC inputs 24 Vdc 56 (additional inputs as option)

PLC outputs 24 Vdc 31 (additional outputs as option)

Analog inputs ±10 V 3 (additional analog inputs as option)

Analog outputs ±10 V TNC 426 PB/M: 13 TNC 430 PA/M: 13

TNC 430 CA: 3 with 9 NC

axes plus spindle

TNC 430 CB: 7 with 5 NC

axes plus spindle

Inputs for thermistors 3 (additional inputs as option)

Commissioning aids

nOscilloscope

nTrace function

nTable function

nLogic diagram

nLog

Data interfaces

nOne each RS-232-C/V.24 and RS-422/V.11 with max.

115 kilobaud

nExpanded data interface with LSV2 protocol for external

operation of the TNC

nOption: Ethernet interface approx. 200 kilobaud to

1 megabaud

Machine integration TNC 426 TNC 430

2 – 18 HEIDENHAIN Technical Manual TNC 426, TNC 430

User Functions TNC 426 and TNC 430

Program entry HEIDENHAIN conversational and ISO

Position data nNominal positions for straight lines and circles in Cartesian or

polar coordinates

nAbsolute or incremental dimensional data

nDisplay and input in mm or inches

nDisplay of handwheel path during machining with handwheel

superpositioning

Contour approach and departure nVia straight line: tangential or perpendicular (APPR/DEP),

nVia circular arc (APPR/DEP)

nVia rounding radius (RND)

Tool compensation nTool radius in the working plane, tool length

nRadius compensated contour look ahead for up to 99 blocks

(M120)

Cutting data table For automatic calculation of speed and feed rate from various

definable combinations of tool and workpiece materials

Constant contour speed nWith respect to the path of the tool center

nWith respect to the tool cutting edge (M109, M110, M111)

3-D machining nInsertion of rounding radius between two straight line segments

(M112, M113, M124)

nReduced feed rate during plunging (M103)

n3-D tool compensation through surface normal vectors

nAutomatic compensation of machine geometry when working

with tilted axes (M114, M115, M128, M130)

nChanging the position of the swivel head with the electronic

handwheel during program run. The position of the tool tip does

not change.

nJerk reduction

nSpline

nTool perpendicular to contour

nTool radius compensation perpendicular to traversing and tool

direction

Machining with rotary tables nProgramming a contour on a cylindrical surface as if on a plane

nFeed rate in mm/min (M116)

FK free contour programming FK free contour programming in HEIDENHAIN conversational

format with graphic support for workpiece drawings not

dimensioned for NC

Subprogramming Program section repeats, subprograms, program calls

Background programming Creating or editing a program while another program is being run

— also with graphical support

Fixed cycles nPeck drilling, tapping with or without a floating tap holder, rea-

ming, boring, hole patterns, slot milling, rectangular and circular

pocket milling, facing milling of plane surfaces

nOEM cycles (special cycles developed by the machine tool buil-

der) can also be integrated

nContour pockets — also contour parallel

nContour train

/