Page is loading ...

FormNo.3426-924RevC

DebrisBlower600

ModelNo.44536—SerialNo.403063082andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)

*3426-924*

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thismachineisa3-pointhitch,tractor-mounted,

debrisblowerwhichisintendedtobeused

byprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedtousewind

powertoquicklyclearlargeareasofunwanteddebris

onwell-maintainedlawnsinparks,sportselds,and

oncommercialgrounds.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.Toro.comforproductandaccessory

information,helpndingadealer,ortoregisteryour

product.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Writethe

numbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure1),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure1

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................3

GeneralSafety...................................................3

SafetyandInstructionalDecals..........................3

Setup........................................................................5

1ApplyingtheEntanglementDecal....................5

2InstallingtheCasterWheels.............................6

3ConnectingtheLowerLinkArms......................7

4ConnectingtheUpperLink...............................7

5AdjustingthePTOShaftLength.......................8

6ConnectingthePTOShaft...............................9

7AdjustingtheSwayLinks.................................9

8Adjustingthe3-Point-LiftStop..........................9

9RemovingtheBlowerfromtheTractor............10

10GreasingtheBlower....................................10

ProductOverview....................................................11

Specications...................................................11

Attachments/Accessories..................................11

BeforeOperation..................................................11

BeforeOperationSafety....................................11

AdjustingtheDischargeDirection.....................12

DuringOperation.................................................12

DuringOperationSafety...................................12

OperatingTips.................................................13

AfterOperation....................................................14

AfterOperationSafety......................................14

Hauling.............................................................14

Maintenance...........................................................15

MaintenanceSafety..........................................15

RecommendedMaintenanceSchedule(s)...........15

Lubrication..........................................................16

GreasingtheMachine.......................................16

BeltMaintenance................................................17

AdjustingtheBlowerBelt..................................17

Storage...................................................................18

Troubleshooting......................................................19

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

2

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Safety

GeneralSafety

Thisproductiscapableofthrowingobjects.Always

followallsafetyinstructionstoavoidseriouspersonal

injury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofboththis

Operator’sManualandtheoperator’smanualof

thetractionunitbeforeusingthismachine.Ensure

thateveryoneusingthisproductknowshowtouse

thismachineandthetractionunitandunderstands

thewarnings.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepchildren,bystanders,andpetsoutofthe

operatingarea.Neverallowchildrentooperate

themachine.

•Alwaysshutoffthetractionunitengine,removethe

key(ifequipped),waitforallmovingpartstostop,

andallowthemachinetocoolbeforeadjusting,

repairing,cleaning,orstoringthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol(

),which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal93-7814

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsandshieldsinplace.

decal98-3110

98-3110

1.Warning—readtheOperator’sManualandreceivetraining.

2.Warning—wearhearingprotection.

3.Thrownobjecthazard—weareyeprotectionandkeep

bystandersawayfromthemachine.

4.Cuttinghazardofhandorfoot—waitformovingpartsto

stop.

3

decal105-0627

105-0627

1.Warning—stoptheengine,removetheignitionkeybefore

leavingthemachineanddisconnectthepowertake–off

(PTO)shaft.

decal105-0628

105-0628

1.Warning—donotoperatethemachinewithpowertake-off

(PTO)atagreateranglethan15degrees.

decal105-0668

105-0668

decal105-0669

105-0669

decal105-0698

105-0698

1.Warning—readtheOperator’sManual.

decal105-0708

105-0708

1.Warning—thrownobjecthazard;keepbystandersaway

frommachine.

decal105-0709

105-0709

1.Entanglementhazard,belt—keepallguardsandshieldsin

place;stayawayfrommovingparts.

decal133-8061

133-8061

decal138-9038

138-9038

1.Entanglementhazard—readtheOperator’sManual;stay

awayfrommovingparts;keepallguardsandshieldsin

place.

4

Setup

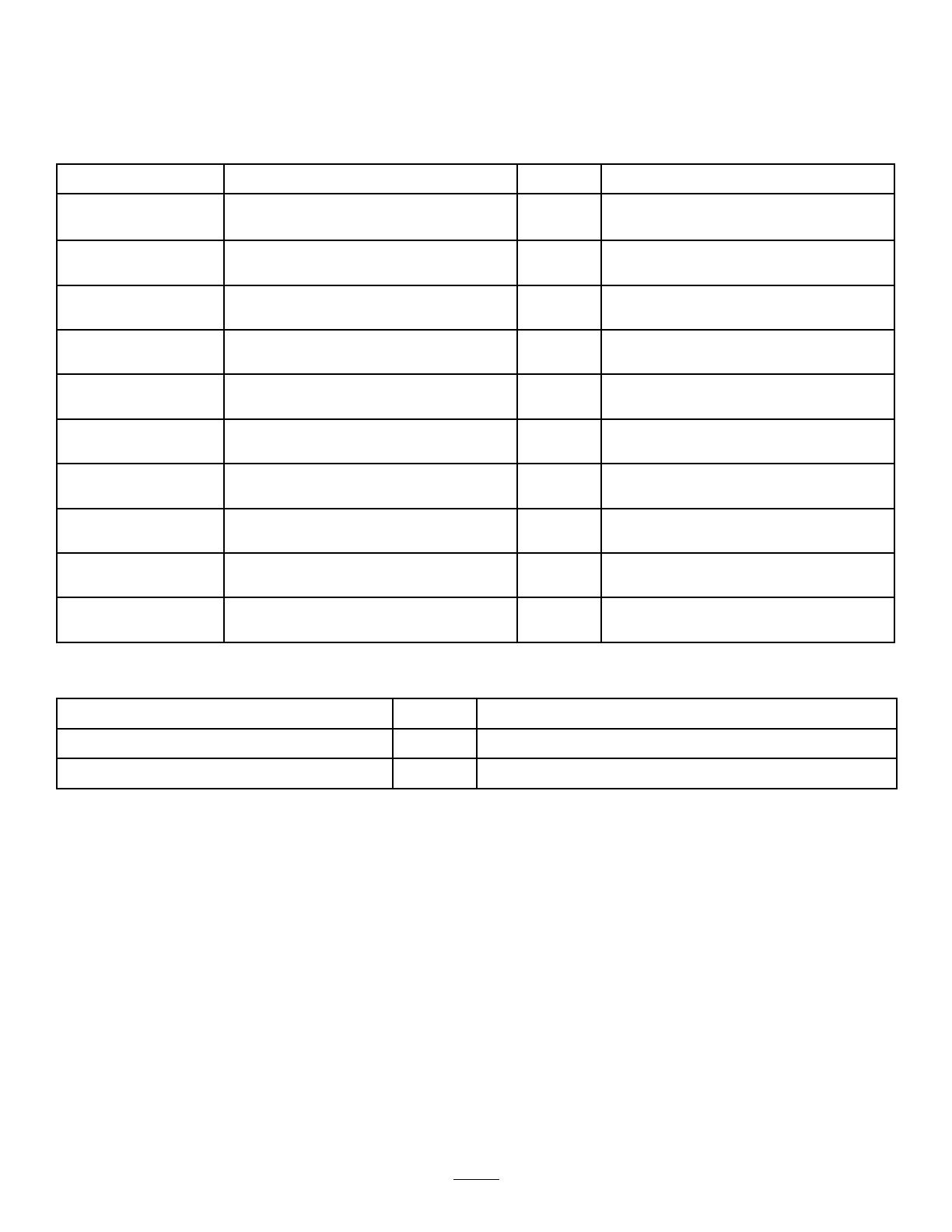

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Qty.

Use

1

CEentanglementdecal

1

Applytheentanglementdecal—CE

mowers

2

Nopartsrequired

–

Installthecasterwheels.

3

Nopartsrequired

–

Connectthelowerlinkarms.

4

Nopartsrequired

–

Connecttheupperlink.

5

Nopartsrequired

–

AdjustthePTOshaftlength.

6

Nopartsrequired

–

ConnectthePTOshaft.

7

Nopartsrequired

–

Adjusttheswaylinks.

8

Nopartsrequired

–

Adjustthe3-point-liftstop.

9

Nopartsrequired

–

Removetheblowerfromthetractor.

10

Nopartsrequired

–

Greasetheblower.

MediaandAdditionalParts

Description

Qty.

Use

Operator'sManual

1

Reviewthemanualbeforeoperatingthemachine.

DeclarationofConformity

1

ForCEcompliance.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

5

1

ApplyingtheEntanglement

Decal

CEMowers

Partsneededforthisprocedure:

1

CEentanglementdecal

Procedure

Important:ThisprocedureisrequiredforallCE

countriesandanywhereEnglishiscommonly

spoken.

1.RotatethePTOshaftguardtoaccessthe

existingentanglementdecal(Figure2).

g262546

Figure2

1.Existingentanglement

decal

2.CEentanglementdecal

2.Cleantheexistingentanglementdecalandthe

guardareasurroundingthedecal.

3.RemovethebackingfromtheCEentanglement

decal.

4.PlacetheCEentanglementdecaloverthe

existingentanglementdecal(Figure2).

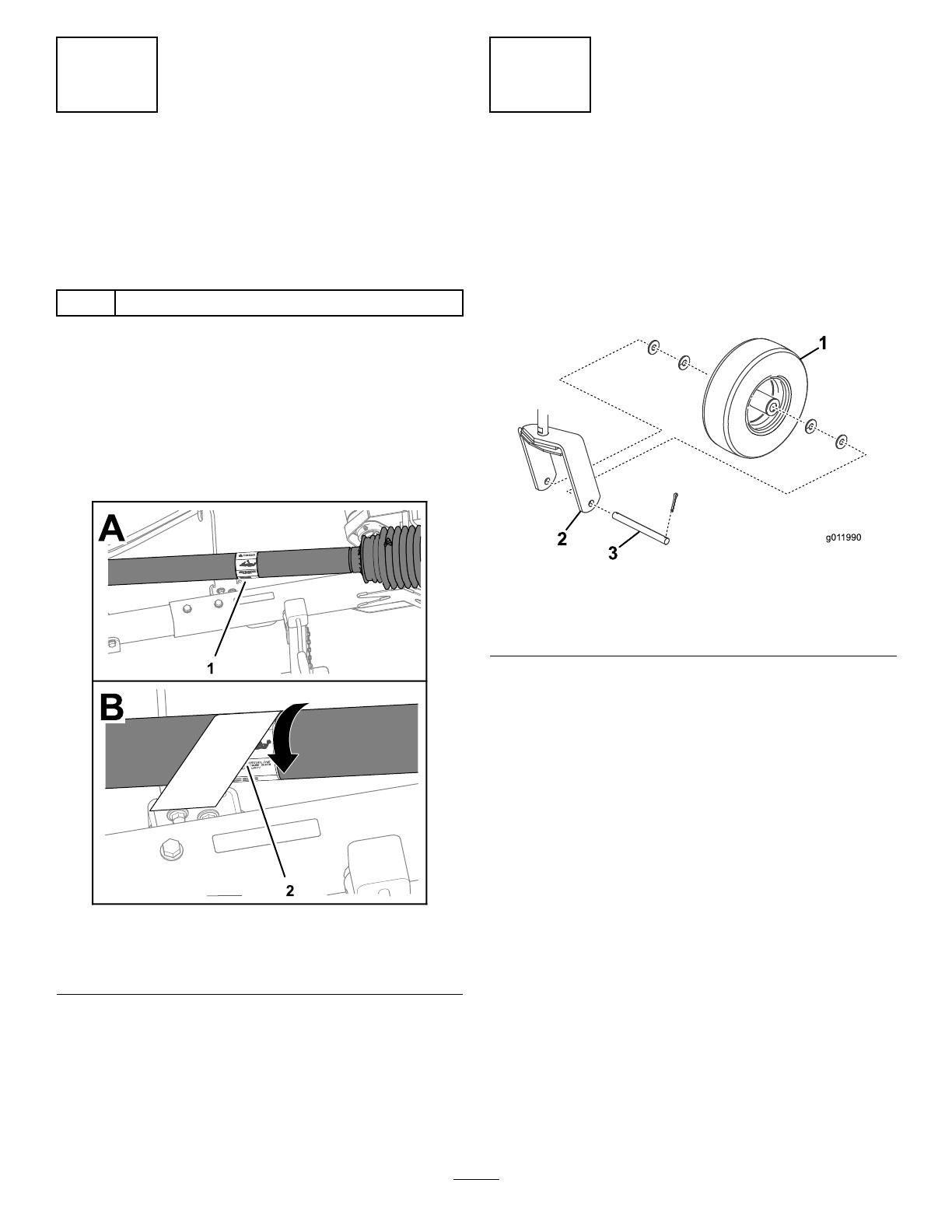

2

InstallingtheCasterWheels

NoPartsRequired

Procedure

Installacasterwheelassemblybetweeneachcaster

forkwith4washers,anaxle,and2cotterpins(Figure

3).

g011990

Figure3

1.Wheelassembly3.Axle

2.Casterfork

6

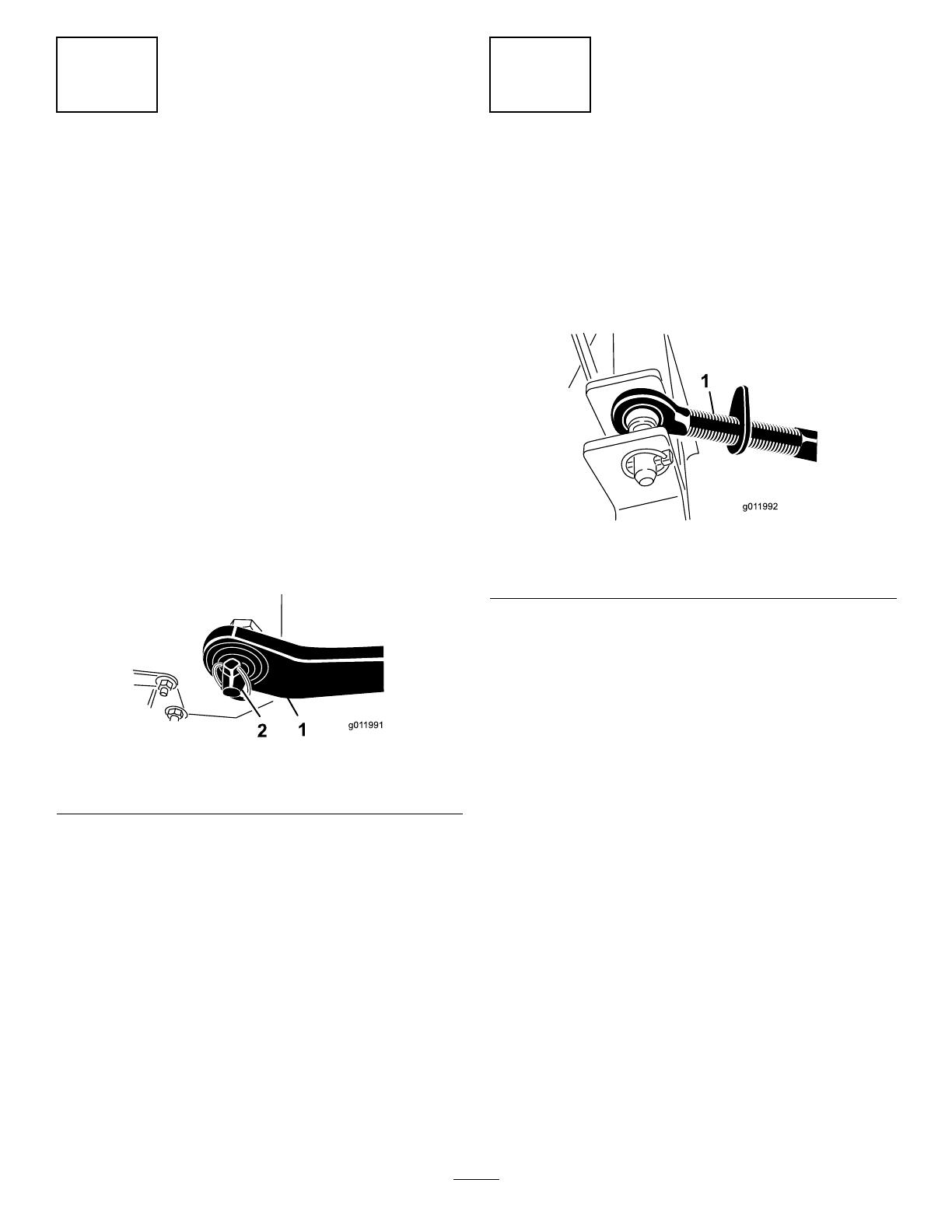

3

ConnectingtheLowerLink

Arms

NoPartsRequired

Procedure

1.Positionthebloweronaat,levelsurfaceand

disengagethePTO.

2.Backthetractorsquarelyuptothebloweruntil

thelowerlinkarmsarealignedwiththehitch

pins.

3.Engagetheparkingbrake,shutoffthetraction

unitengine,andremovethekeyfromthe

ignition.

Note:Waitforthetractionunitengineand

allmovingpartstostopbeforeleavingthe

operator’sseat.

4.Inserttherightandleft,lowerlinkarmsontothe

hitchpins(Figure4).

g011991

Figure4

1.Lowerlink2.Lynchpin

5.Securethelowerlinkarmstothehitchpinswith

thelynchpins(Figure4).

4

ConnectingtheUpperLink

NoPartsRequired

Procedure

1.Connecttheupperlinktotheholesintheblower

bracketandsecureitwithaclevispinandlynch

pin(Figure5).

g011992

Figure5

1.Upperlink

2.Rotatetheadjustinglinktotightenthelink.

Note:Donotovertightentoraisethebackend

oftheblowerofftheground.

3.Tightenthelocknuttosecuretheupperlinkinto

position.

7

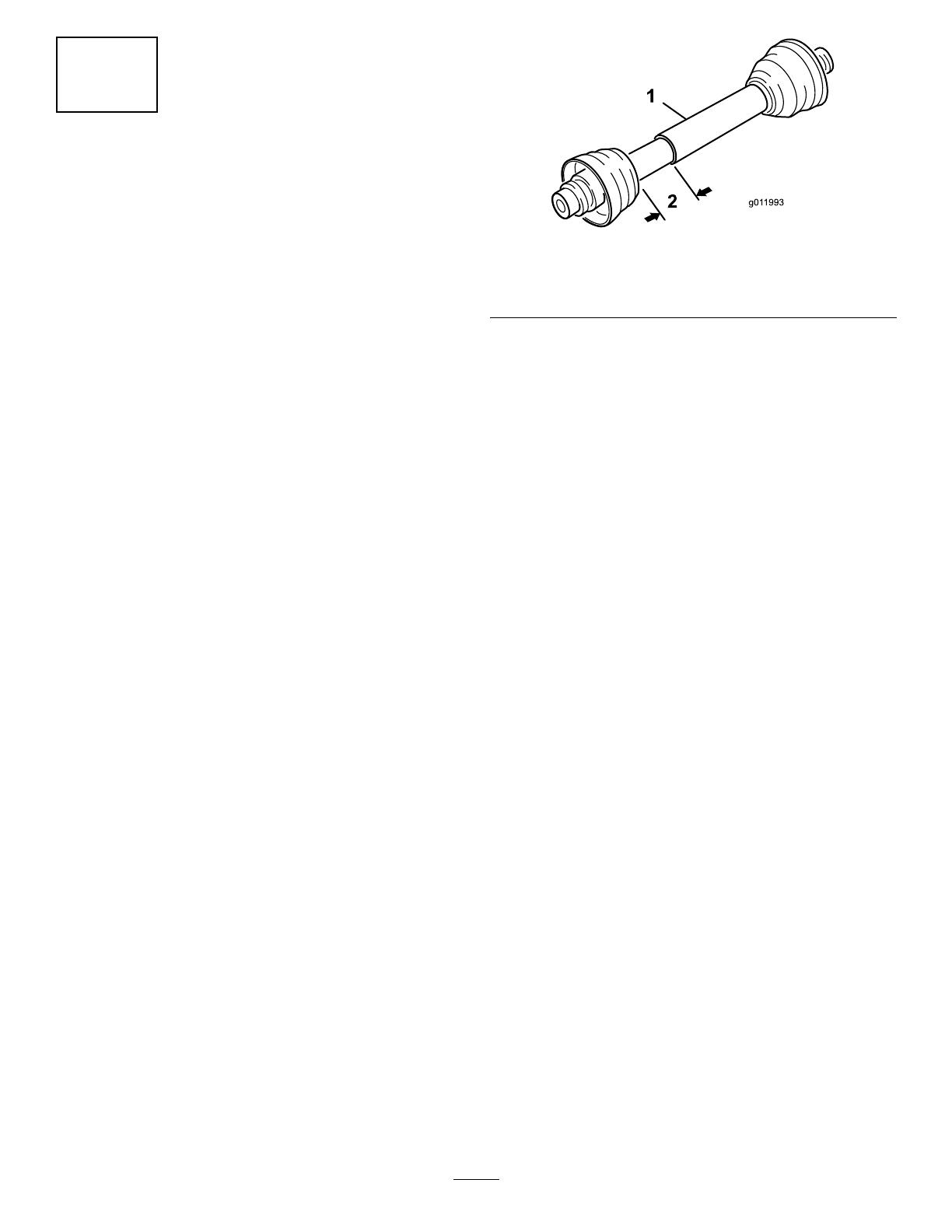

5

AdjustingthePTOShaft

Length

NoPartsRequired

Procedure

Important:AlongPTOshaftissuppliedwiththe

machinetoaccommodatelargevariationsinthe

tractor’sPTOand3-pointlocations.Formost

machines,thisshaftistoolongandmustbecut

tothecorrectlength,ordamagemayresult.

Important:IncorrectPTOshaftlengthcancause

machineand/orattachmentdamageandpersonal

injury.

1.Withthebloweronalevelsurface,lowerthe

bloweruntiltheinputshaftisapproximatelythe

sameheightasthetractorPTOshaft.

Note:Thisistheshortestdistancebetween

the2shafts.

2.Measurethedistancefromthelockgrooveof

thetractorPTOshafttothelockgrooveatthe

blower-inputshaft.

Note:Recordthisdimension.

3.FullycollapsethePTOshaftandmeasurethe

distancebetweenthelockpincollars.

Note:Recordthisdimension.

4.Attheshortestlengthoftheshaft,the2halves

ofthePTOshaftmusthaveatleast37mm

(1-1/2inches)ofadditionalclearancetocollapse

(Figure5).

Note:Ifthedimensioninstep2isnotatleast

37mm(1-1/2inches)greaterthanthedimension

instep3,thePTOshaftistoolong;proceedto

step5.Ifthereisenoughclearancetoallowthe

PTOshafttocollapse,proceedtostep10.

g011993

Figure6

1.PTOshaft2.37mm(1-1/2inches)

dimension

5.Usethefollowingcalculationtoestablish

howmuchshortertheshaftmustbe,when

connected,toensureaclearanceof37mm

(1-1/2inches):

A.Subtractthedimensionrecordedinstep3

fromthedimensionrecordedinstep2.

Note:Recordthisdimension.

B.Subtracttheresultinstep5Afrom37mm

(1-1/2inches).

Note:ThePTOshaftmustbeshortened

bythisamount.

6.Cuttheguardsandthesteeltubesshorterby

thecalculatedlength.

Note:CutbothhalvesofthePTOshaft.

7.Deburrtheendsofthesteeltubesinternallyand

externally.

8.Removealldebrisfromthetubesections.

9.Greasethesteeltubes.

10.AssemblethePTOshaftandsecureittothe

blowerandtractor.

11.Measuretheshaft.

Note:Ifitisnotatleast37mm(1-1/2inches),

repeattheprocedure.

12.Raisetheblowertothehighestposition.

Note:Theremustbeatleast75mm(3inches)

ofoverlapofthehalves.Adjustthe3-point-lift

stop,ifnecessary;referto8Adjustingthe

3-Point-LiftStop(page9).

8

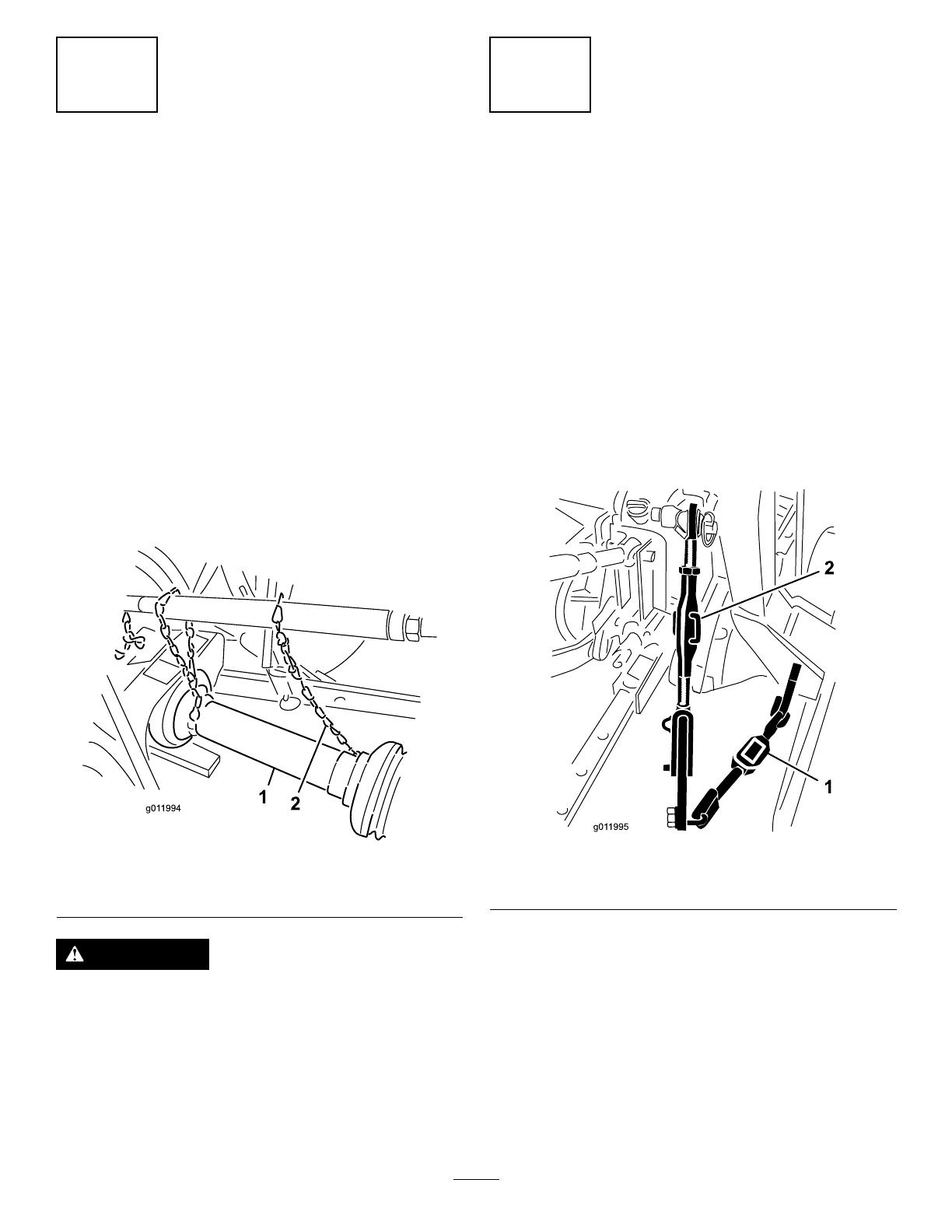

6

ConnectingthePTOShaft

NoPartsRequired

Procedure

1.ConnectthePTOshafttotheblower-inputshaft.

2.ConnectthePTOshafttothereartractorPTO

shaft.

3.SlidethePTOshaftfullyforward.

4.DepressthepintosecurethePTOshaftinplace

andslidethePTOshaftbackandforthtoensure

thatitisproperlylocked.

5.Connecttheguardsafetychainsfromthepower

shaftsectionstotheweldedclipsonthelink

armsortothePTOguards(Figure7).

Note:Ensurethatthechainshaveslackwhen

theblowerisraisedorlowered.

g011994

Figure7

1.PTOguard2.Safetychain

WARNING

Iftheguardchainsarenotconnected,they

couldrotateduringoperationandcause

bodilyinjury.

KeepallPTOguardsinplaceandconnectthe

guardchainstothelinkarmsorPTOguards.

7

AdjustingtheSwayLinks

NoPartsRequired

Procedure

Adjusttheswaylinksonthelowerdraftarmsof

the3-pointhitchtominimizeside-to-sideswaytoa

maximumof25mm(1inch)oneachside.

1.Adjustthelowerlinksinboarduntiltheycontact

theblowermountingplates(Figure8).

Note:Thiswillreducethestressonthepins.

Ifthetractorhasswaychainsinsteadofsway

links,installthewashersbetweenthelowerlink

armandlynchpintoreducetheoverhungload

ontheliftpins.

g011995

Figure8

1.Swaylink

2.Linkbody

2.Turntheadjustable-linkbody(ifprovided)to

raiseorlowerthelinkarmuntilthebloweris

leveledfromsidetoside(Figure8).

Note:Refertothetractoroperator’smanualfor

additionalinstallationandadjustmentprocedures.

9

8

Adjustingthe3-Point-Lift

Stop

NoPartsRequired

Procedure

Adjustandsetthe3-point-liftstoptoprovide

approximately10cm(4inches)groundclearance,

whenintheraisedposition,tominimizethePTOangle

whenraisingtheblower.Fortransportingortrailer

loading/unloading,thefull-liftrangecanbeusedas

longasthePTOtubesdonotslideapart(Figure9).

Important:OperatingthePTOinthefully-raised

positionmaydamagethePTOorother

components

Note:Refertothetractoroperator’smanualfor

adjustmentprocedures.

g011996

Figure9

1.3-point-liftstop

9

RemovingtheBlowerfrom

theTractor

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface,disengage

thePTO,engagetheparkingbrake,shutoffthe

tractionunitengine,andremovethekeyfrom

theignition.

2.Disconnecttheguardsafetychainsfromthe

tractorPTO.

Note:Securetheendofthechaintotheblower

sideofthePTOshafttopreventthePTOshaft

fromcomingapart.

3.Slowlylowerthebloweruntiltherollerand

casterwheelscontacttheground.

4.Removethelynchpinandtoplinkpinsecuring

thecenterlinktothebracket.

5.DisconnectthepowershaftfromthetractorPTO

shaft.

6.Slidethepowershaftrearwardandremoveit

fromthetractor.

7.Removethelynchpinsandslidethelowerlink

armsoffthehitchpins.

10

GreasingtheBlower

NoPartsRequired

Procedure

Beforeoperatingtheblower,lubricatethePTO

drive-shaft;refertoGreasingtheMachine(page16).

Important:Failuretoproperlygreasetheunitwill

resultinprematurefailureofcriticalparts.

10

ProductOverview

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Length

125cm(49inches)

Width

150cm(59inches)

Height

117cm(46inches)

Netweight

227kg(500lbs)

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.T oro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alwaysshutoffthetractionunitengine,remove

thekey,waitforallmovingpartstostop,andallow

themachinetocoolbeforeadjusting,repairing,

cleaning,orstoringthemachine.Knowhowto

stopthemachineandshutofftheenginequickly.

•Keepallguards,safetydevices,anddecalsin

place.Repairorreplaceallsafetydevicesand

replaceallillegibleormissingdecals.Donot

operatethemachineunlesstheyarepresentand

functioningproperly.

•Eachtimeanattachmentorimplementismounted,

checkthe3-point-hitchmovement.Ensurethat

thereisnointerferencewithhosesandattachment

partswhenoperatingthe3–pointhitch.

Important:YoucandamagethePTOshaft

ifyouoperateattachmentsattoohighofan

angle.

•Attachmentscanchangethestabilityandthe

operatingcharacteristicsofthetractionunit.

•Locatethepinchpointareasmarkedonthe

tractionunitandattachmentsandkeepyourhands

andfeetawayfromtheseareas.

•Ensurethatthetractionunitissuitableforusewith

animplementofthisweightbycheckingwiththe

tractionunitsupplierormanufacturer.

•Donotmodifythisequipmentinanymanner.

11

AdjustingtheDischarge

Direction

Thedirectionofthedischargeopeningcanbe

changedfromthesidetothefrontbymovingthe

controlhandle(Figure10).

g011997

Figure10

1.Dischargeopening

2.Controlhandle

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearloosejewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Dischargedairhasconsiderableforceandcould

causeinjuryorlossoffooting.Stayawayfromthe

blowernozzlewhenthemachineisoperating.

•Keepallbystandersaway;shutoffthemachine

whenbystandersenterthearea,donotdirect

dischargetowardthem.

•Donotoperatethemachinewhenitisnot

connectedtoatowingvehicle.

•Donotrunthetractionunitengineinaconned

areawithoutadequateventilation.Engineexhaust

containscarbonmonoxide,anodorlessgasthatis

fatalifinhaled.

•Donotcarrypassengersonthemachineand

keepbystandersandpetsawayfromthemachine

duringoperation.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Neverleavearunningmachineunattended.

•Whentransportingthemachineonpublicroads,

followalltrafcregulationsanduseanyadditional

accessoriesthatmayberequiredbylaw,suchas

lights,turnsignals,slow-movingvehicle(SMV)

signs,andothersasrequired.

•Ifthemachineevervibratesabnormally,stopthe

machineimmediately,shutoffthetractionunit

engine,removethekey,waitforallmovingpartsto

stop,andinspectfordamage.Repairalldamage

tothemachinebeforeresumingoperation.

12

•Reducespeedwhenoperatingonrough,uneven

terrain,andnearcurbs,holes,andothersudden

changesinterrain.

•Toavoidcausingthemachinetotipover,be

carefulwhenturningandavoidunsafemaneuvers.

•ForallPTOshaftsteelparts(tubes,bearings,

joints,etc.)disassemblyorrepairs,itis

highlyadvisabletocontactyourlocalToro

distributor.Removalofcomponentsforrepairs

andreassemblymaydamagesomepartsifnot

performedwithspecialtoolsbytrainedtechnicians.

•ThePTOshaftmustnotbeusedwithoutthe

guardssupplied.

SlopeSafety

•Reviewthetractionunitspecicationstoensure

thatyoudonotexceeditsslopecapabilities.

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Youareresponsibleforsafeslope

operation.Operatingthemachineonanyslope

requiresextracaution.

•Evaluatethesiteconditionstodetermineifthe

slopeissafeformachineoperation,including

surveyingthesite.Alwaysusecommonsense

andgoodjudgmentwhenperformingthissurvey.

•Reviewtheslopeinstructions,listedbelow,for

operatingthemachineonslopes.Beforeyou

operatethemachine,reviewthesiteconditionsto

determinewhetheryoucanoperatethemachine

intheconditionsonthatdayandatthatsite.

Changesintheterraincanresultinachangein

slopeoperationforthemachine.

–Avoidstarting,stopping,orturningthemachine

onslopes.Avoidmakingsuddenchangesin

speedordirection.Maketurnsslowlyand

gradually.

–Donotoperateamachineunderanyconditions

wheretraction,steering,orstabilityisin

question.

–Removeormarkobstructionssuchasditches,

holes,ruts,bumps,rocks,orotherhidden

hazards.Tallgrasscanhideobstructions.

Uneventerraincouldoverturnthemachine.

–Beawarethatoperatingthemachineonwet

grass,acrossslopes,ordownhillmaycause

themachinetolosetraction.

–Useextremecautionwhenoperating

themachineneardrop-offs,ditches,

embankments,waterhazards,orother

hazards.Themachinecouldsuddenlyrollover

ifawheelgoesovertheedgeortheedge

cavesin.Establishasafetyareabetweenthe

machineandanyhazard.

OperatingTips

WARNING

Dischargedairhasconsiderableforceand

couldcauseinjuryorlossoffooting.

•Stayawayfromthedischargeopening

whenthemachineisoperating.

•Keepbystandersawayfromthedischarge

openingwhenthemachineisrunning.

1.Startthetractorandrunitatalowenginespeed.

2.EngagethePTOwhiletheengineisatidle

speed.

3.IncreasethetractorPTOspeedto540rpm.

4.Practiceblowingmaterial.

Note:Blowinthesamedirectionthatthewind

isblowingtopreventmaterialfromblowingback

intotheclearedarea.

13

AfterOperation

AfterOperationSafety

GeneralSafety

•Parkthemachineonarm,levelsurface;shutoff

thetractionunitengine,removethekey,waitfor

allmovingpartstostop,andallowthemachine

tocoolbeforeadjusting,repairing,cleaning,or

storingthemachine.

•Onlydisconnectthemachinefromthetractionunit

whileonalevelsurface.

•Whendisconnectingthemachine,alwayschock

thewheelstopreventmovement.

•Keepallpartsofthemachineingoodworking

conditionandallhardwaretightened.

•Replaceallworn,damaged,ormissingdecals.

Hauling

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usefull-widthrampsforloadingmachineinto

trailerortruck.

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.Directboththefrontand

rearstrapsdownandoutwardfromthemachine.

14

Maintenance

CAUTION

Failuretoproperlymaintainthemachinecouldresultinprematurefailureofmachinesystems

causingpossibleharmtoyouorbystanders.

Keepthemachinewellmaintainedandingoodworkingorderasindicatedintheseinstructions.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

MaintenanceSafety

•Beforecleaning,servicing,oradjustingthe

machine,dothefollowing:

–Parkthemachineonalevelsurface.

–Shutoffthetractionunitengine,removethe

key,andwaitforallmovingpartstostop.

–Chockthewheels.

–Allowmachinecomponentstocoolbefore

performingmaintenance.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededoryouneedassistance,contactan

authorizedT orodistributor.

•Donotrelyonahydraulicsystemtosupportthe

machine;supportthemachinewithblocksorjack

standswhenworkingbeneathit.

•Ensurethatallguardsareinstalledsecurelyafter

maintainingoradjustingthemachine.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Keepallpartsingoodworkingconditionandall

fastenerstightened.Replacealldamagedor

missingdecals.

•Donotinterferewiththeintendedfunctionofa

safetydeviceorreducetheprotectionprovided

byasafetydevice.Checktheirproperoperation

regularly.

•Ifmajorrepairsareevernecessaryorassistance

isrequired,contactanauthorizedTorodistributor.

•Alteringthismachineinanymannermayaffectthe

operationofthemachine,performance,durability,

oritsusemayresultininjuryordeath.Suchuse

couldvoidtheproductwarrantyofTheT oro®

Company.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Every20hours

•Checkand/oradjusttheblower-belttension.

Every100hours

•Greasethefanshaftbearings.

•Greasethecasterwheelttings.

•Greasethe2drive-shaftttings.

15

Lubrication

GreasingtheMachine

Themachinehasgreasettingsthatyoumust

lubricateregularlywithNo.2lithiumgrease.

Fan-ShaftBearings

ServiceInterval:Every100hours

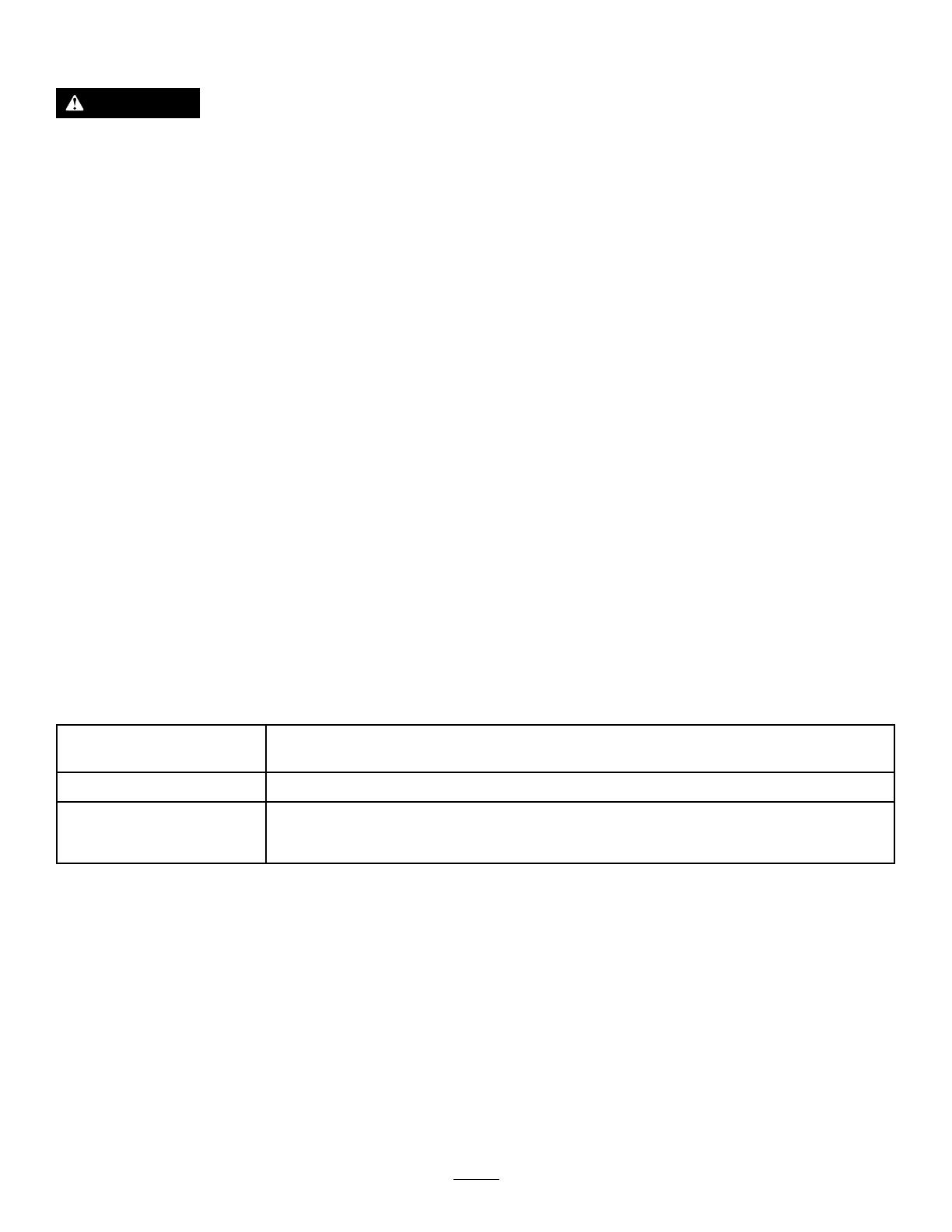

Greasethe2fanshaftbearings(Figure11).

Note:Removebeltcovertoaccessreartting.

g011998

Figure11

CasterWheels

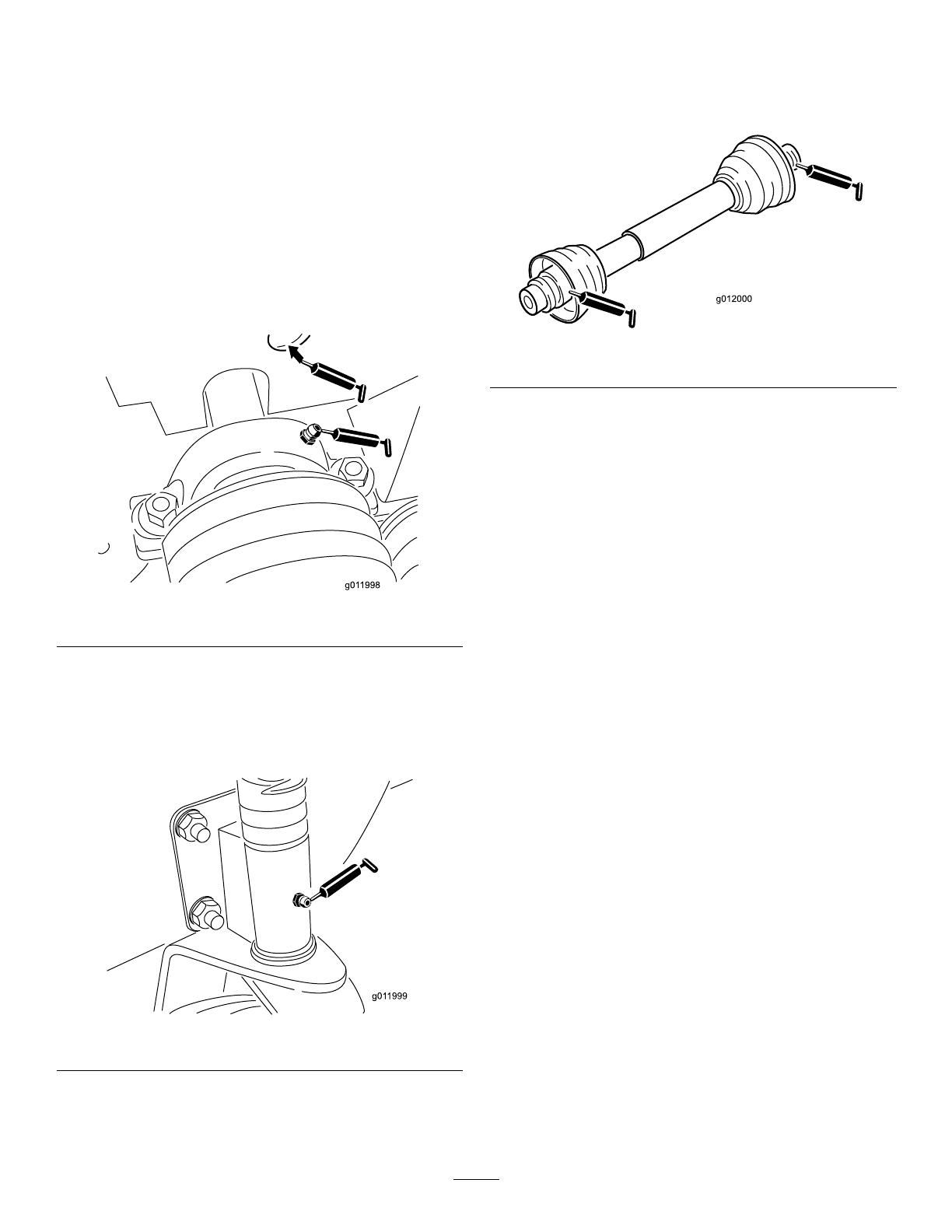

ServiceInterval:Every100hours

Greasethe2casterwheelttings(Figure12).

g011999

Figure12

DriveShaft

ServiceInterval:Every100hours

Greasethe2drive-shaftttings(Figure13).

g012000

Figure13

16

BeltMaintenance

AdjustingtheBlowerBelt

ServiceInterval:Every20hours

Ensurethatthebeltisproperlytensionedtoensure

properoperationofthemachineandunnecessary

wear.Checkthebeltfrequently.

Important:Thefastenersonthecoversofthis

machinearedesignedtoremainonthecover

afterremoval.Loosenallofthefastenerson

eachcoverafewturnssothatthecoverisloose

butstillattached,thengobackandloosenthem

untilthecovercomesfree.Thispreventsyou

fromaccidentallystrippingtheboltsfreeofthe

retainers.

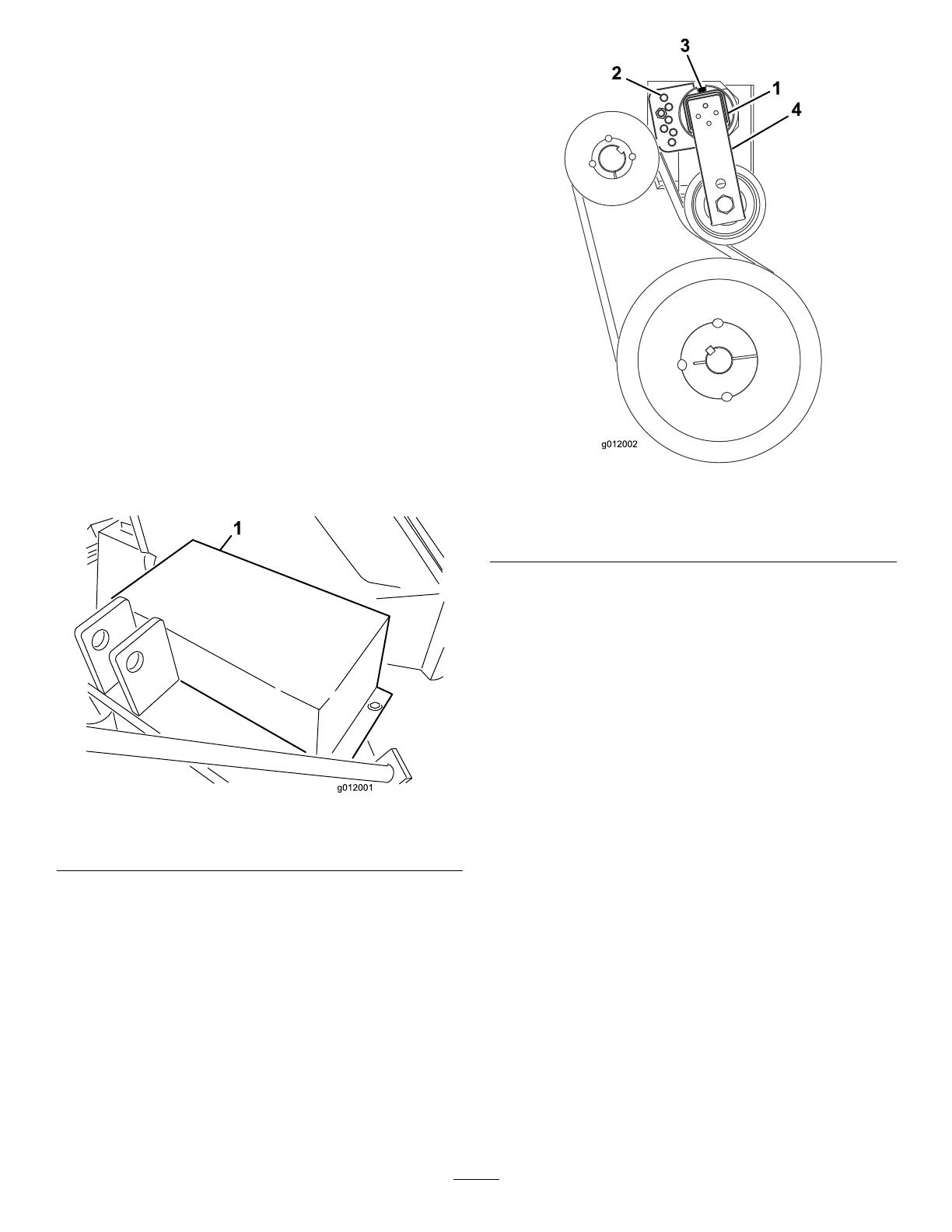

1.Removethecapscrews,washers,andnuts

securingthebeltguardtotheblowerhousing

(Figure14).

Note:Thedriveshaftdoesnothavetobe

disconnectedtoadjustthebelt.

g012001

Figure14

1.Beltguard

2.Removethebeltguard(Figure14).

3.Removecapscrewandnutsecuringthe

tensionerguidetotheblowerframe(Figure15).

Note:Thebelttensionreleaseswhenthe

capscrewisremoved.

g012002

Figure15

1.Belt-tensionertube

3.Capscrew

2.Tensionerguide4.Idlerarm

4.Ontherearoftheframe,loosenthecapscrew

securingthebelttensionertoframe(Figure15).

5.Positionalargewrenchonthetensionerand

rotatethetensionerclockwiseuntilthedecalis

aligned15ºonthetensionertube.

6.Insertthecapscrewintothealignedguideholes

andsecureitwiththenut(Figure15).

Note:Ifholesarenotexactlyaligned,rotatethe

guidetothenexthigherholeuntilitisaligned.

7.Tightenthecapscrewontherearoftheframeto

lockthetensioner.

8.Installthebeltguardtotheblowerhousingwith

thecapscrews,washers,andnuts.

17

Storage

1.Thoroughlycleantheblower.

Note:Thefanhousingshouldbefreeofdirt,

leaves,anddebris.

2.Lubricateallgreasettings.Wipeoffanyexcess

lubricant.

3.Placealightcoatofgreaseonthesplinesofthe

PTOshaft.

4.Tightenallfasteners.

18

Troubleshooting

Problem

PossibleCauseCorrectiveAction

1.Thebearing(s)onthefanshaftis

damaged.

1.Replacethebearings.

2.Materialisbuiltuponthefanblades.2.Cleanoutanybuildupontheinside

ofthehousing.

Thereisexcessivevibration.

3.TheenginespeedofthePTOshaftis

toofast.

3.ReducethePTOspeedto540rpm.

1.Theairslotsarecloggedwithdebris.

1.Cleanoutanydebrisfromtheslots.

2.Theenginespeedonthetractoristoo

slow.

2.IncreasethePTOspeedto540rpm.

Thereislackofadequateairow.

3.Thethrottleonthetractorengineistoo

slow.

3.Makeanynecessaryrepairstobring

thetractorspeeduptonormal.

19

Notes:

/