Page is loading ...

Field Automation Systems

Loose-leaf version: Part Number D301127X012

Bound version: Contact FAS

FLOBOSS

™

553 FLOW MANAGER

Instruction Manual

Form A6073

June 1999 (2

nd

Edition)

FloBoss 553 Instruction Manual

ii Rev 1/00

Revision Tracking Sheet

June 1999, 2

nd

Edition

This manual may be revised periodically to incorporate new or updated information. The date revision

level of each page is indicated at the bottom of the page opposite the page number. A major change in

the content of the manual also changes the date of the manual which appears on the front cover. Listed

below is the date revision level of each page.

Page Revision

1-20 and 1-21 1/00

2-15 1/00

2-29 1/00

All others 6/99

Note: This 2

nd

Edition adds information about changing the default sleep mode activiation values.

Fisher Controls International, Inc. 1999-2000. All rights reserved.

Printed in the U.S.A.

While this information is presented in good faith and believed to be accurate, Fisher Controls does not guarantee satisfactory results from

reliance upon such information.

Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding the

performance, merchantability, fitness or any other matter with respect to the products

, nor as a recommendation to use any product or

process in conflict with any patent. Fisher Controls reserves the right, without notice, to alter or improve the designs or specifications of the

products described herein.

FloBoss 553 Instruction Manual

Rev 6/99 iii

Table of Contents

SECTION 1 — GENERAL INFORMATION.......................................................... 1-1

1.1 Manual Overview........................................................................................................................ 1-1

1.2 Section Contents.......................................................................................................................... 1-2

1.3 Additional Information................................................................................................................ 1-2

1.4 Product Overview........................................................................................................................ 1-3

1.5 Installation Requirements............................................................................................................ 1-8

1.6 Mounting....................................................................................................................................1-13

1.7 Power Consumption Calculation.................................................................................................1-15

1.8 Startup and Operation.................................................................................................................1-20

SECTION 2 — USING THE FLOBOSS 553............................................................ 2-1

2.1 Scope .......................................................................................................................................... 2-1

2.2 Section Contents.......................................................................................................................... 2-1

2.3 Product Functions........................................................................................................................ 2-3

2.4 Product Electronics...................................................................................................................... 2-9

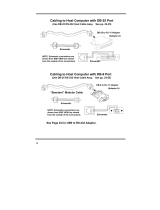

2.5 Connecting the FloBoss to Wiring..............................................................................................2-16

2.6 Calibration .................................................................................................................................2-28

2.7 Troubleshooting and Repair........................................................................................................2-29

2.8 Specifications.............................................................................................................................2-35

SECTION 3 — DUAL-VARIABLE SENSOR.......................................................... 3-1

3.1 Scope .......................................................................................................................................... 3-1

3.2 Section Contents.......................................................................................................................... 3-1

3.3 Description.................................................................................................................................. 3-1

3.4 Process Connections.................................................................................................................... 3-2

3.5 DVS Wiring................................................................................................................................ 3-2

3.6 Configuration.............................................................................................................................. 3-3

3.7 Calibration .................................................................................................................................. 3-5

3.8 Specifications.............................................................................................................................3-13

FloBoss 553 Instruction Manual

Table of Contents (Continued)

iv Rev 6/99

SECTION 4 — COMMUNICATIONS CARDS....................................................... 4-1

4.1 Scope .......................................................................................................................................... 4-1

4.2 Section Contents.......................................................................................................................... 4-1

4.3 Product Descriptions ................................................................................................................... 4-1

4.4 Initial Installation and Setup........................................................................................................ 4-5

4.5 Connecting Communications Cards to Wiring............................................................................. 4-7

4.6 Troubleshooting and Repair......................................................................................................... 4-8

4.7 Communication Cards Specifications .........................................................................................4-10

APPENDIX A — LOOP SCHEMATIC....................................................................A-1

A.1 Scope ..........................................................................................................................................A-1

A.2 Loop Schematic drawings............................................................................................................A-1

GLOSSARY OF TERMS.......................................................................................... G-1

TOPICAL INDEX .......................................................................................................I-1

FloBoss 553 Instruction Manual

Rev 6/99 1-1

SECTION 1 — GENERAL INFORMATION

1.1 MANUAL OVERVIEW

This manual describes the FloBoss 553 Flow Manager, part of the family of FloBoss 500

™

flow

computers manufactured by Fisher Controls. Included in this manual are the following sections:

♦ Table of Contents Table of Contents

♦ Section 1 General Information

♦ Section 2 Using the FloBoss 553

♦ Section 3 Dual-Variable Sensor

♦ Section 4 Communications Cards

♦ Appendix A IS Loop Schematic

♦ Glossary Glossary of Terms

♦ Index Topical Index

Table of Contents lists each section and information contained in that section of the document.

Section 1 describes this manual and mentions related manuals. This section also provides a summary

of the FloBoss hardware, installation requirements, mounting the FloBoss, and power requirements.

Section 2 provides information and specifications concerning the use of the FloBoss. Topics covered

include the Main Electronics Board, wiring, processes, and troubleshooting. The Main Electronics Board

provides the flow sensor input channel, one built-in discrete output channel, a Resistance Temperature

Detector (RTD) input, an operator interface port, and a host communications port.

Section 3 describes the Dual-Variable Sensor (DVS) included with the FloBoss 553 for sensing static (line)

pressure and differential pressure across an orifice.

Section 4 provides information and specifications for the optional communications cards.

Appendix A shows the intrinsic safety Loop Schematic as approved for the FloBoss 553.

Glossary of Terms defines terms used in Fisher Control’s documentation.

Topical Index alphabetically lists the items contained in this manual, including their page numbers.

FloBoss 553 Instruction Manual

1-2 Rev 6/99

1.2 SECTION CONTENTS

This section contains the following information:

Information Section Page Number

Manual Overview 1.1 1-1

Section Contents 1.2 1-2

Additional Information 1.3 1-2

Product Overview 1.4 1-3

Options 1.4.2 1-7

Installation Requirements 1.5 1-8

Environmental Requirements 1.5.1 1-8

Site Requirements 1.5.2 1-9

Compliance with Hazardous Area Standards 1.5.3 1-10

Power Installation Requirements 1.5.4 1-10

Grounding Installation Requirements 1.5.5 1-11

I/O Wiring Requirements 1.5.6 1-12

Mounting 1.6 1-13

Mounting the FloBoss 1.6.1 1-13

Power Consumption Calculation 1.7 1-15

Determining I/O Channel Power Consumption 1.7.1 1-15

Totaling Power Requirements 1.7.2 1-16

Solar Powered Installations 1.7.3 1-17

Batteries 1.7.4 1-19

Startup and Operation 1.8 1-20

Startup 1.8.1 1-20

Operation 1.8.2 1-21

1.3 ADDITIONAL INFORMATION

The following manuals may be used to acquire additional information not found in this manual:

& Type RL101 ROCLINK Configuration Software User Manual – Part Number D301101X012

& Function Sequence Table (FST) User Manual – Part Number D301058X012

& ROC/FloBoss Accessories Instruction Manual – Part Number D301061X012

FloBoss 553 Instruction Manual

Rev 6/99 1-3

1.4 PRODUCT OVERVIEW

The FloBoss 553 is a 32-bit microprocessor-based Electronic Flow Measurement (EFM) computer that

provides functions required for measuring the differential pressure, static pressure, and the temperature

at a single meter run. From these, the FloBoss computes gas flow for both volume and energy. The

FloBoss provides on-site functionality and supports remote monitoring, measurement, data archival,

communications, and control in Class I, Division 1 locations (which may contain continuous

concentrations of flammable gas). The FloBoss design allows you to configure specific applications

including those requiring gas flow calculations, data archival, remote communications, and logic and

sequencing control using a Function Sequence Table (FST).

The FloBoss 553 provides the following standard components and features:

♦ Weather-tight, corrosion-resistant enclosure (NEMA 4X).

♦ Main Electronic Board.

♦ Built-in Liquid Crystal Display (LCD) with two-line alphanumeric viewing.

♦ A 32-bit microprocessor, 512K of flash ROM, and 512K of static memory storage.

♦ Built-in Discrete Output (DO) for sampler or odorizer control.

♦ Built-in Dual-Variable Sensor (DVS) for sensing differential and static pressure.

♦ Built-in Resistance Temperature Detector (RTD) input.

♦ Operator interface (LOI) port (for non-hazardous areas only).

♦ Host communications port for optional communications card.

♦ Applications firmware.

Physically, the FloBoss consists of a printed-circuit Main Electronics Board and a display housed in a

compact, weather-tight case. The FloBoss is packaged in a NEMA 4X windowed enclosure that can

mount on a wall, a pipestand, or directly to the metering pipe. Refer to Figure 1-1.

The plastic enclosure protects the electronics from physical damage and corrosive environments. The

enclosure has a hinged and gasketed door secured by a lockable hasp. The enclosure has mounting

flanges that allow it to be fastened to a wall or panel, or mounted on a pipestand. In addition, it can be

direct-mounted, such as on an integral orifice assembly. The internal structural metal is made from a

low-copper aluminum alloy. All exposed metal is stainless steel.

The enclosure is fabricated from fiberglass-reinforced plastic. Enclosure external dimensions,

including mounting flanges and the Dual-Variable Sensor (DVS), are approximately 16.75 inches high

by 10.38 inches wide by 6.69 inches deep (425 mm by 264 mm by 170 mm). The DVS is factory-

mounted to the bottom of the enclosure. Refer to Figure 1-3 on page 1-14 for further dimensional

details.

FloBoss 553 Instruction Manual

1-4 Rev 6/99

DOC0334P

SCALE IS .5

Figure 1-1. FloBoss 553 Flow Manager

The Main Electronics Board, displayed in Figure 1-2, mounts on a backplate under a black-anodized

aluminum cover. The dimensions of the board are approximately 5 by 7.5 inches. The majority of the

components are surface-mounted, with only the top side of the board used for components. The Main

Electronics Board provides built-in I/O capabilities, an LCD display, and provisions for an optional

communications card. The main electronics board is factory-mounted inside the housing, which

provides protection for the electronics. For more information on the Main Electronics Board, refer to

Section 2.

The built-in Liquid Crystal Display (LCD) provides the ability to look at data and configuration

parameters while on site without using the local operator interface (LOI) and a personal computer. The

LCD display is factory-mounted directly to the Main Electronics Board and visible through the window

on the enclosure door. Through this display, you can view information (defined by configuration)

stored in the FloBoss. Up to 16 items can be defined for display. The display automatically cycles

through the configured list of items, displaying a new value approximately every three seconds.

Mounting Flange

Operato

r

Interfac

e

Port

Coupler

Display

DVS

FloBoss 553 Instruction Manual

Rev 6/99 1-5

A Motorola 32-bit CMOS microprocessor runs at 14.7 MHz and has low-power operating modes,

including inactivity and low battery conditions. The FloBoss comes standard with 512K of built-in,

supercapacitor-backed static random access memory (SRAM) for storing data and history. The FloBoss

also has 512K of programmable read-only memory (flash ROM) for storing operating system firmware,

applications firmware, and configuration parameters.

The built-in inputs and outputs (I/O) consist of a port for a Dual-Variable Sensor (DVS), a 4-wire

Resistance Temperature Detector (RTD) input interface, and a discrete output (DO). Diagnostic inputs

are dedicated to monitoring input voltage and enclosure temperature. Connectors located on the Main

Electronics Board provide terminations for input power, an RTD input, a discrete output (DO), Dual-

Variable Sensor (P/DP), and operator interface (LOI) communications. Refer to Figure 1-2.

The built-in discrete output (DO) is capable of controlling a sampler or odorizer. The DO may be

used as a Timed Duration Output (TDO).

The Dual-Variable Sensor (DVS) measures differential pressure and absolute or gauge (static)

pressure by converting the applied pressure to electrical signals and making the readings available to

the Main Electronics Board. The sensor housing screws into a flanged adapter, which in turn mounts

with four bolts to the bottom of the enclosure. The DVS cable plugs directly into the Main Electronics

Board at the P/DP connector. For more information on the DVS, refer to Section 3.

An RTD temperature probe typically mounts in a thermowell on the metering pipe. RTD wires should

be protected either by a metal sheath or conduit connected to a liquid-tight conduit fitting on the bottom

of the FloBoss enclosure. The RTD wires connect directly to the four-terminal RTD connector on the

Main Electronics Board inside the enclosure.

The operator interface (LOI) port, located on the bottom left-hand side of the enclosure (refer to

Figure 1-1), provides for a local link between the FloBoss and a personal computer through an Operator

Interface Cable. With the personal computer running the ROCLINK Configuration Software, you can

configure the functionality of the FloBoss and monitor its operation. User-level security can be enabled

or disabled for the LOI port.

WARNING

Do not use the LOI port in a hazardous location (Class I, Division 1 or 2). For a

FloBoss 553 in a C1D1 area, you may use the Laptop Computer connectors wired

through an intrinsic safety barrier as shown in the Loop Schematic (Appendix A).

The host communications port (located at COM1) is available for use with an optional communica-

tions card to permit serial communication protocols. User level security can be enabled or disabled for

the host communications port. Refer to Section 4 for details on communication cards.

The I/O parameters, DVS inputs, flow calculations, security, and FST programmability are configured

and accessed using the ROCLINK Configuration Software. Refer to the ROCLINK Configuration

Software User Manual for details concerning software capabilities.

FloBoss 553 Instruction Manual

1-6 Rev 1/00

NORM

RST

J1

60

P3

PT2 PT3

P8

MV1

P10

PT1

P5

U6

U9

CR6

FL1

P11

CR9

U7

CR7

U12

U11

MV2

U8

R1

U2

P1

DOC0331A

C3

Figure 1-2. Main Electronics Board

Reset

Jumper

LCD

Comm Card

Mating

Connector

Super

Capacitor

"Battery"

Board Power

Connector

Built-in I/O

Wiring

Integral Sensor

Connector

Flash

Memory

Chi

p

DOC0380A

FloBoss 553 Instruction Manual

Rev 6/99 1-7

1.4.1 Firmware

The Version 2.x firmware, contained in flash ROM on the electronics board, determines much of the

functionality of the FloBoss, such as:

♦ Memory logging of 240 alarms and 240 events.

♦ Archival of data for up to 15 history points for up to 35 days.

♦ American Gas Association (AGA) flow calculations for a single meter run.

♦ Logic and sequencing control by means of a user-defined Function Sequence Table (FST).

♦ Communications based on either Modbus protocol or ROC protocol.

♦ User-level security.

Refer to Section 2.3 for more information about the functionality provided by the firmware.

1.4.2 Options and Accessories

The FloBoss supports the following options and accessories:

♦ Communications Cards for host communications.

♦ Local Operator Interface (LOI) cable.

Two plug-in communication cards are available for the FloBoss installation. The communication

cards provide an interface for the host communications port. These cards permit serial communication

protocols. One of the following card types can be accommodated:

♦ EIA-232 (RS-232) for asynchronous serial communications.

♦ EIA-485 (RS-485) for asynchronous serial communications.

Stand-offs on the Main Electronics Board allow the optional communications cards to be added easily.

Refer to Section 4 for more information.

The local operator interface (LOI) port, which is approved for use in non-hazardous areas only,

provides for a direct, local link using an Operator Interface Cable between the FloBoss and a personal

computer. With the personal computer running the ROCLINK Configuration Software, you can

configure the functionality of the FloBoss and monitor its operation. The Operator Interface Cable is

available as an accessory from Fisher.

WARNING

Do not use the LOI port in a hazardous location (Class I, Division 1 or 2). For a

FloBoss 553 in a C1D1 area, you may use the Laptop Computer connectors wired

through an intrinsic safety barrier as shown in the Loop Schematic (Appendix A).

FloBoss 553 Instruction Manual

1-8 Rev 6/99

The FloBoss is powered by a 12-volt dc power supply, typically a solar panel and battery combination.

Refer to Section 2, Connecting Power Wiring.

1.5 INSTALLATION REQUIREMENTS

This section provides generalized guidelines for successful installation and operation of the FloBoss.

Planning helps to ensure a smooth installation. Be sure to consider location, ground conditions,

climate, and site accessibility as well as the suitability of the FloBoss application while planning an

installation.

The versatility of the FloBoss allows it to be used in many types of installations. For additional

information concerning a specific installation, contact your Fisher Representative. For detailed wiring

information, refer to Section 2.

The Installation Requirements section includes:

♦ Environmental Requirements

♦ Site Requirements

♦ Compliance with Hazardous Area Standards

♦ Power Installation Requirements

♦ Grounding Installation Requirements

♦ I/O Wiring Requirements

NOTE

The FloBoss has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy. If not installed and used in accordance with this

instruction manual, the FloBoss may cause harmful interference to radio communi-

cations. Operation of the equipment in a residential area is likely to cause harmful

interference, in which case you will be required to correct the interference at your

own expense.

1.5.1 Environmental Requirements

The FloBoss enclosure is classified as a CSA Type 4X (NEMA 4X equivalent) enclosure. This

provides the protection required to keep the units operating under a variety of weather conditions.

FloBoss 553 Instruction Manual

Rev 6/99 1-9

The FloBoss is designed to operate over a -40 to 75°

C (-40 to 167° F) temperature range. The LCD

temperature range is -25 to 70° C (-13 to 158° F). When mounting the unit, be aware of external

devices that could have an effect on the operating temperature. Operation beyond the recommended

temperature range can cause errors and erratic performance. Prolonged operation under extreme

conditions can result in premature failure of the unit. In extreme climates, it may be necessary to

moderate the temperature in which the unit must operate.

Check the installation for mechanical vibration. Ensure that the levels of vibration do not exceed those

specified (see Specifications in Section 2).

1.5.2 Site Requirements

Careful consideration in locating the FloBoss on the site can help prevent future operational problems.

The following items should be considered when choosing a location:

♦ Local, state, and federal codes often place restrictions on monitoring locations and may

dictate site requirements. Examples of these restrictions are fall distance from a meter run,

distance from pipe flanges, and hazardous area classifications.

♦ Locate the FloBoss to minimize the length of signal and power wiring.

♦ When providing solar power to FloBoss units, orient solar panels to face due South (not

magnetic South) in the Northern Hemisphere and due North (not magnetic North) in the

Southern Hemisphere. Make sure nothing blocks the sunlight from 9:00 AM to 4:00 PM.

♦ Antennas equipped for radio communications must be located with an unobstructed signal

path. If possible, locate antennas at the highest point on the site and avoid aiming antennas

into storage tanks, buildings, or other tall structures. Allow sufficient overhead clearance to

raise the antenna.

♦ To minimize interference with radio communications, locate the FloBoss away from

electrical noise sources such as engines, electric motors, and utility line transformers.

♦ Locate the FloBoss away from heavy traffic areas to reduce the risk of being damaged by

vehicles. However, provide adequate vehicle access to aid in monitoring and maintenance.

FloBoss 553 Instruction Manual

1-10 Rev 6/99

1.5.3 Compliance with Hazardous Area Standards

The FloBoss 550 Series typically has hazardous location approval for Class I, Division 1, Groups C and

D exposures. The Class, Division, and Group terms are defined as follows:

Class defines the general nature of the hazardous material in the surrounding atmosphere.

Class I is for locations where flammable gases or vapors may be present in the air in

quantities sufficient to produce explosive or ignitable mixtures.

Division defines the probability of hazardous material being present in an ignitable

concentration in the surrounding atmosphere. Since Division 1 locations are presumed to be

hazardous, all electrical devices must be designed as intrinsically safe, explosion proof, etc.

Group defines the hazardous material in the surrounding atmosphere. Groups C to D are

defined as follows:

♦ Group C - Atmosphere containing ethylene, gases or vapors of equivalent hazards.

♦ Group D - Atmosphere containing propane, gases or vapors of equivalent hazards.

For the FloBoss to be approved for hazardous locations, it must be installed according to the National

Electrical Code (NEC) Article 501.

WARNING

When installing units in a hazardous area, make sure all installation components

selected are labeled for use in such areas. Installation and maintenance must be

performed only when the area is known to be non-hazardous.

1.5.4 Power Installation Requirements

The typical source of primary power for FloBoss installations is solar power. If line power is used, care

must be taken to route it away from hazardous areas, sensitive monitoring devices, and radio

equipment. Local and company codes generally provide guidelines for line power installations.

Adhere rigorously to all local and National Electrical Code (NEC) requirements for line power

installations.

CAUTION

Power to the FloBoss must be connected only to the terminal block labeled INPUT

POWER (the MCU PWR terminals are intended for factory use). For Class I,

Division 1 installations, power must be connected through intrinsic safety barriers

as specified in the Loop Schematic (Appendix A).

FloBoss 553 Instruction Manual

Rev 6/99 1-11

Refer to Section 1.7, Power Consumption Calculation, on page 1-15 to plan for total power

consumption of the FloBoss.

1.5.5 Grounding Installation Requirements

CAUTION

Grounding for the FloBoss in Class I, Division 1 installations must be done in

accordance with the Loop Schematic (Appendix A). Note that the Intrinsic Safety

ground conductors must be connected to a single earth ground.

Ground wiring requirements for line-powered equipment are governed by the National Electrical Code

(NEC). When the equipment uses line power, the grounding system must terminate at the service

disconnect. All equipment grounding conductors must provide an uninterrupted electrical path to the

service disconnect.

The National Electrical Code Article 250-83 (1993), paragraph c, defines the material and

installation requirements for grounding electrodes.

The National Electrical Code Article 250-91 (1993), paragraph a, defines the material

requirements for grounding electrode conductors.

The National Electrical Code Article 250-92 (1993), paragraph a, provides installation

requirements for grounding electrode conductors.

The National Electrical Code Article 250-95 (1993) defines the size requirements for equipment

grounding conductors.

Proper grounding of the FloBoss helps to reduce the effects of electrical noise on the unit’s operation

and protects against voltage transients, such as induced by nearby lightning. Transient protection is

built-in to the FloBoss, providing protection for built-in field wiring inputs and outputs. A surge

protection device installed at the service disconnect on line-powered systems offers lightning and power

surge protection for the installed equipment.

All earth grounds must have an earth to ground rod or grid impedance of 25 ohms or less (1 ohm preferred)

as measured with a ground system tester for computer equipment. The grounding conductor should have a

resistance of 1 ohm or less between the FloBoss case ground lug and the earth ground rod or grid.

The grounding installation method for the FloBoss depends on whether the pipeline has cathodic

protection. On pipelines with cathodic protection, the FloBoss must be electrically isolated from the

pipeline. Electrical isolation can be accomplished by using insulating flanges upstream and downstream

on the meter run. In this case, the FloBoss could be flange mounted or saddle-clamp mounted directly on

the meter run and grounded with a ground rod or grid system.

FloBoss 553 Instruction Manual

1-12 Rev 6/99

On pipelines without cathodic protection, the pipeline itself may provide an adequate earth ground and the

FloBoss could mount directly on the meter run. Using a ground system tester, test to make sure the

pipeline to earth impedance is less than 25 ohms. If an adequate ground is provided by the pipeline, do not

install a separate ground rod or grid system. All grounding should terminate at a single point.

If the pipeline to earth impedance is greater than 25 ohms, the FloBoss installation should be electrically

isolated and a ground rod or grid grounding system installed.

Shields for I/O signal wiring used in the FloBoss should be grounded. A ground bar is provided inside

the FloBoss enclosure for terminating shield wires and other connections that require earth ground.

Note that shields should be grounded at one end only to prevent ground loops.

A lug on the outside of the FloBoss enclosure is provided to connect the enclosure to earth ground.

Note that on the FloBoss 550 series, the ground bar is internally connected to the enclosure ground lug;

no further connection between these points is needed.

1.5.6 I/O Wiring Requirements

I/O wiring requirements are site and application dependent. Local, state, or NEC requirements may

determine I/O wiring installation methods. Direct burial cable, conduit and cable, or overhead cables

are options for I/O wiring installations. Section 2 contains detailed information on connecting I/O

wiring to the FloBoss.

The recommended cable for I/O signal wiring is an insulated, shielded, twisted-pair. The twisted pair

and the shielding minimize signal errors caused by EMI (electromagnetic interference), RFI (radio

frequency interference), and transients. A ground bar is provided inside the enclosure for terminating

shield wires. Note that cable shields should be grounded at one end only.

The I/O wiring for the FloBoss is connected to terminals on the lower edge of the Main Electronics

Board. Refer to Figure 1-2. The terminal designations are printed on the electronics cover.

FloBoss 553 Instruction Manual

Rev 6/99 1-13

1.6 MOUNTING

When choosing an installation site, be sure to check all clearances. For dimensions, refer to Figure 1-3.

Provide adequate clearance for the enclosure door to be opened for wiring and service. The door is

hinged on the left side. The LCD display should be visible and accessible for the on-site operator.

When using a solar panel (must not be located in the Class I, Division 1 area with the FloBoss), there

should be adequate clearance, and view of the sun should not be obstructed. Allow adequate clearance

and an obstructed location for antennas when using radios.

The Dual-Variable Sensor (DVS) is factory-mounted directly to the FloBoss enclosure with four bolts.

This mounting uses a special coupler to join the threads on the sensor to the four-bolt mounting pattern

on the bottom of the FloBoss enclosure. See Section 3 for more information.

1.6.1 Mounting the FloBoss

Mounting of the FloBoss can be accomplished using any of the following methods:

♦ Pipe mounted – The enclosure provides top and bottom mounting flanges with holes for

2-inch pipe clamps (U-bolts and brackets supplied). The 2-inch pipe can be mounted to

another pipe with a pipe saddle, or it can be cemented into the ground deep enough to support

the weight and conform to local building codes.

♦ Wall or panel mounted – Fasten to the wall or panel using the mounting flanges on the

enclosure. Use 5/16-inch bolts through all four holes. Hole spacing dimensions are given in

Figure 1-3.

♦ Integral orifice mounted – Fasten to the pipe using integral orifice mounting equipment and

techniques.

With all mounting methods, the pressure inputs must be piped to the ¼-18 NPT process connections on

the sensor. Refer to Section 3 for more information on piping.

CAUTION

The FloBoss 553 must be mounted vertically with the Dual-Variable Sensor at its base as

shown in Figure 1-3.

FloBoss 553 Instruction Manual

1-14 Rev 6/99

DOC0334A

2X .44

16.88

12.50

10.38

2.81

3.25

6.75

Figure 1-3. Outline and Mounting Dimensions

FloBoss 553 Instruction Manual

Rev 6/99 1-15

1.7 POWER CONSUMPTION CALCULATION

A FloBoss system’s power consumption determines power supply and battery sizing for both line and

solar power. Table 1-1 provides information to assist in determining power requirements. The FloBoss

has low power consumption due to a typical duty cycle of 10 to 20% for its microprocessor; the other

80 to 90% of the time the microprocessor is shut off, with external wake-up signals reactivating it.

The Power Consumption Calculation section includes:

♦ Determining I/O Channel Power Consumption

♦ Totaling Power Requirements

♦ Solar Powered Installations

♦ Batteries

1.7.1 Determining I/O Channel Power Consumption

In estimating total I/O power requirements, the “duty cycle” of each I/O channel must be estimated.

For example, if a discrete output is active for 15 seconds out of every 60 seconds, the duty cycle is:

Duty Cycle = Active time/(Active time + Inactive time) = 15 sec/60 sec = 0.25

To calculate the total power consumed by an I/O channel, use Table 1-1 and read the minimum (P

min

)

and maximum (P

max

) power consumption value from the table for the desired I/O channel. Use the

following equation to calculate the power consumption for a channel with the duty cycle taken into

account:

Power = (P

max

x Duty Cycle) + [P

min

(1 - Duty Cycle)]

Multiply this value by the Quantity of I/O channels with the same Duty Cycle and enter the calculated

value in the Subtotal column. Repeat the procedure for all other I/O channels used.

FloBoss 553 Instruction Manual

1-16 Rev 6/99

Table 1-1. Power Consumption of the FloBoss 553 and Powered Devices

Device Power Consumption

(mW) 12V System

Quantity Duty Cycle Subtotal

(mW)

P

min

P

max

Main Electronics Board; includes

minimum built-in I/O power

consumption, RTD, and integral

sensor.

400 2000 1 N/A

Built-in Discrete Output (load

dependent with a maximum of 5

volts and 25 milliamps).

0125 1

Serial Communications Card 30 N/A

Total

1.7.2 Totaling Power Requirements

To adequately meet the requirements of the FloBoss system, it is important to determine the total power

consumption, size of solar panel, and battery backup requirements accordingly. For total FloBoss

power consumption, add the device values in Table 1-1. Although Table 1-1 takes into account the

power supplied by the FloBoss to its connected devices, be sure to add the power consumption (in mW)

of any other devices used with the FloBoss in the same power system, but not accounted for in the table

(such as intrinsic safety barriers).

Convert the total value (in mW) to Watts by dividing it by 1000.

mW / 1000 = Watts

For selecting an adequate power supply, use a safety factor (SF) of 1.25 to account for losses and other

variables not factored into the power consumption calculations. To incorporate the safety factor,

multiply the total power consumption (P) by 1.25.

P

SF

= P x 1.25 = _____ Watts

To convert P

SF

to current consumption in amps (I

SF

), divide P

SF

by the system voltage (V), which is 12-

volts.

I

SF

= P

SF

/ V = _____ Amps

/