Page is loading ...

INSTALLATION, OPERATION & MAINTENANCE MANUAL

PORTABLE BASKETBALL BACKSTOP

No. 1235

INST 00257 127

© 1997 PORTER ATHLETIC EQUIPMENT COMPANY. ALL RIGHTS RESERVED. 12-1-1997

INSTALLER NOTE:

Upon completion of the installation/assembly of this portable backstop,

make sure this instruction manual is in the possession of the owner or

facility manager, to save for future reference.

2

Dear Customer:

Congratulations on purchasing the Porter No. 1235 Competition Portable Basketball

Backstop. This quality built backstop features the unique Porter Center-Strut® design for

maximum player and equipment safety while providing many features for the ultimate in

competition play. Your athletes and spectators should enjoy thousands of hours of

practice and competition on Porter equipment.

This booklet is intended to be used for the initial set-up of your No. 1235 backstop, and

as a guide for the safe use and maintenance of the unit. PLEASE READ THESE

INSTRUCTIONS CAREFULLY AND COMPLETELY BEFORE BEGINNING

THE SET-UP WORK, OR MAINTENANCE, OF THIS UNIT.

If after reviewing this manual you have any questions, please feel free to consult our

factory.

THE OWNER OF THIS EQUIPMENT MUST SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE

Porter Athletic Equipment Company

2500 South 25th Avenue, Broadview, IL U.S.A., 60155

Toll Free: (800) 947-6783 • Phone: (708) 338-2000 • Fax: (708) 338-2060

www.porter-ath.com

3

GENERAL OPERATING INFORMATION

Electrical Supply

Connect control panel to 120 volt AC, 60HZ, 20AMP circuit, with a maximum length to power source of 50 feet. If additional cord

beyond 50 feet is required, a minimum power cable of #10awg is required to prevent power loss and possible damage to controls and

motor assembly.

Backstop Operation

Before attempting assembly of this unit check operation by doing the following:

1. To raise backstop to playing position rotate key switch to the up position. CAUTION - If backstop is already up on its casters the

unit will lower itself to the floor before boom will start to extend. Hold key until fully extended. WARNING - Release key

switch when unit is fully extended to avoid undue strain on frame and hydraulic system.

2. To lower mast make sure safety T-handle (see Illustration D) is disengaged and secured to backside of mast with lock pin. To

lower mast, rotate key switch to the down position and hold until fully lowered. Unit will start to raise up on casters at this point

for transport. WARNING - Make sure any floor anchoring system is disengaged before unit is raised onto its casters.

Glass Backboard Handling

During assembly of this backstop, it is of extreme importance that the glass backboard is not dropped, attachment bolts are not

improperly torqued (bolts tightened before plumbing all attachment points) or allowing the glass section to contact or strike metal

parts as the backboard warranty does not cover breakage during installation.

CAUTIONS

DO NOT stand or sit in front of the unit when being raised or lowered.

DO NOT attempt to lower unit with safety T-handle lock engaged.

DO NOT have hand or feet under unit when being raised or lowered.

DO NOT continue to pump unit after cycle (up or down) has been completed.

DO NOT operate key switch intermittently.

DO NOT move or roll the backstop with the mast in the up or extended position.

REMOVE top base pads and rear upright support pads before folding unit to the down position.

DISENGAGE floor anchor system before lowering unit to the transport position.

DO NOT allow untrained or unauthorized individuals to operate this backstop.

4

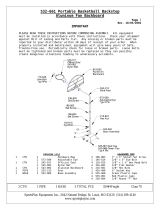

No. 1235 PORTABLE BASKETBALL BACKSTOP

ASSEMBLY, ADJUSTMENT, OPERATION and MAINTENANCE INSTRUCTIONS

WARNING

READ THESE ASSEMBLY AND OPERATING INSTRUCTIONS IN THEIR ENTIRETY, BEFORE ATTEMPTING TO

UNPACK, ASSEMBLE, OR OPERATE THIS PORTABLE BACKSTOP, TO AVOID POSSIBLE INJURIES, OR

DAMAGE TO THE EQUIPMENT.

PARTS LIST

ITEM Qty. PART NUMBER DESCRIPTION

1 1 FRME 00015 003 BACKSTOP FRAME ASSEMBLY (8' EXTENSION ONLY)

1 FRME 00165 003 BACKSTOP FRAME ASSEMBLY (10'-8" EXTENSION ONLY)

2 1 EXTN 00064 003 BANK YOKE FRAME

3 2 HING 00064 003 HINGE WELDMENT

4 1 PLTE 00048 003 YOKE CLAMP PLATE

5 2 CLMP 00007 003 2-3/8" HALF CLAMP

6 2 HDWE 01164 0P0 1/2" x 2-1/2" HEX HEAD CAP SCREW (Grade 5)

7 4 HDWE 01225 0P0 3/8" x 5-1/2" HEX HEAD CAP SCREW (Grade 5)

8 4 HDWE 02073 0P0 3/8" x 1-1/4" CARRIAGE BOLT (Grade 5)

9 8 HDWE 03002 0E0 3/8" HEX NUT

10 2 HDWE 03003 0E0 1/2" HEX NUT

11 8 HDWE 04002 0E0 3/8" LOCKWASHER

12 2 HDWE 04003 0E0 1/2" LOCKWASHER

13 8 HDWE 05005 0E0 1/2" FLATWASHER

14 15 HDWE 06020 0E0 1/4" x 4" HEX HEAD LAG SCREW

15 19 HDWE 06019 0E0 #12 x 1" PHILLIPS PAN HEAD MACHINE SCREW

BACKBOARD

16 1 00208-000 GLASS BACKBOARD

GOAL WITH NET AND HARDWARE

17 1 (PER ORDER) GOAL WITH NET (AS SPECIFIED ON ORDER)

18 4 HDWE _____ 0E0 3/8" x 3-1/2" BOLT

19 4 HDWE 03002 0E0 3/8" HEX NUT

20 4 PCAP 00040 002 THREAD COVER

21 4 HDWE 04002 0E0 3/8" LOCKWASHER

22 4 HDWE 05004 0E0 3/8" FLATWASHER

BACKBOARD PAD

23 1 00326-000 GLASS BACKBOARD PAD

BASE / UPRIGHT PADDING

No. 01235-914 No. 01235-108

(8′-0″ UNIT) (10′-8″ UNIT)

24 1 ZMAT 11234 300 FRONT BASE PAD ZMAT 11234 300

25 2 ZMAT 11234 200 SIDE BASE PAD ZMAT 11234 200

26 1 ZMAT 11234 410 REAR BASE PAD ZMAT 11234 410

27 1 ZMAT 11234 100 FRONT MAST PAD ZMAT 11234 180

28 1 ZMAT 11234 500 TOP BASE PAD ZMAT 11234 510

29 1 ZMAT 11234 505 TOP BASE PAD ZMAT 11234 520

30 2 ZMAT 11234 723 REAR MAST PAD ZMAT 11234 723

5

6

No. 1235 PORTABLE BACKSTOP

ASSEMBLY INSTRUCTIONS

1. Unpack and identify all parts (refer to packing list) on page 4.

2. Position the unpacked glass backboard (#16) on its cardboard packing carton in front of portable backstop frame (#1). Remove

(2) 3/8" x 1" hex head cap screws from back of glass bank.

3. Assemble 3/8" x 3-1/2" bolt (#18) with 3/8" flatwasher (#22) in the upper two goal mount holes on the backboard. Note - This

hardware is packed with goal. Carefully lift backboard (#16) and position so that upper goal mounting bolts are in alignment with

the corresponding holes on the backstop mounting plate. See Illustration “A”. Three men are required to safely perform this

assembly. (Do not mount the goal at this time.)

4. While holding backboard in this position, secure in place on the backstop mounting plate (#1) with 3/8" hex nut (#19), 3/8"

lockwasher (#21) and 3/8" flatwasher (#22), finger tighten only.

5. Carefully shift backboard (pick one end up or down) to align slots shown in Illustration “A” with the two (2) tapped holes in the

backside of the backboard frame and secure with the two 3/8" x 1" long hex head cap screws (from No. 16) and 3/8" lockwashers

that were removed from the backboard in Step #2. Do not overtighten.

3/8" x 1-1/4" Lg. MACHINE BOLT, FLATWASHER,

LOCKWASHER AND HEX NUT SHIPPED

ASSEMBLED TO BACKBOARD

ILLUSTRATION "A"

7

6. Attach the two (2) hinge weldments (#3) into the slots in the upper corners of the glass backboard using four (4) 3/8" x 1-1/4"

long carriage bolts (#8), 3/8" hex nuts (#9), and 3/8" lockwashers (#11). Finger tighten only. See Illustration “B”.

7. The remaining assembly requires only to men. Lay bank yoke frame (#2) on the top side of the backstop horizontal extension

assembly positioning upper ends of the yoke into the hinges in the upper corner of the backboard assembled in Step #6. Secure in

place with two (2) 1/2" x 2-1/2" lg. hex head cap screws (#6), 1/2" hex nuts (#10), and 1/2" lockwashers (#12). Use 1/2"

flatwashers (#13) as spacers on either side of bank yoke frame stud (#2) (see Illustration “B”). Center the two hinge weldments

(#3) on the frame of the backboard and tighten all bolts securely.

8. Attach lower end of bank yoke frame (#2) to the top tube of the horizontal extension assembly (see Illustration “C”) using two (2)

half clamps (#5), mounting plate (#4), and four (4) 3/8" x 5-1/2" hex head cap screws (#7), 3/8" hex nuts (#9), and 3/8"

lockwashers (#11). Snug bolts only at this time.

MUST BE CENTERED LEFT-TO-RIGHT

BACKBOARD YOKE FRAME/HINGE WELDMENTS

12 10 6

11 9

3

8

ILLUSTRATION "B"

16

13

2

STUDS MUST BE EXTENDED EQUALLY.

ON GLASS BACKBOARD FRAME.

8

9. Remove the two goal mounting bolts (#18, #19, #21, #22) assembled in Steps 3 & 4.

10. You are now ready to mount the goal. Carefully hold the goal (#17) against the face plate of the backboard (#16) and insert the

two bolts (#18) through the goal, backboard and the backstop mounting plate (refer back to Illustration “A”). Note - Flatwashers

are not required at this point. Backboard may have to be shifted slightly for proper alignment. Secure with two (2) 3/8" hex nuts

(#19), 3/8" flatwashers (#22), and two (2) 3/8" lockwashers (#21) on backside of mounting plate. Assemble two 3/8" plastic caps

(#20) on end of bolts.

11. Repeat Step 10 by inserting bolts through the bottom two goal mounting holes. Snug bolts only at this time.

12. With the backstop in the down or folded position, roll the unit into the playing position, from end of court toward center court, so

that the two front swivel casters are facing the rear of the unit.

13. Raise the unit to the playing position and align the face of the backboard parallel to and 4′-0″ in from the inside edge of the 2"

wide court line.

14. Marking the floor with tape, etc. will ensure proper alignment on future set-ups. Check anchor locations per anchor instructions.

15. Check Goal Height – Using a stepladder set goal height at 10' by adjusting the safety arm T-handle (see Illustration “D”). Lay

level across bottom of backboard while making this adjustment to insure that the backboard is level when the goal is at the 10'-0"

dimension. Note that it may be necessary to loosen the six (6) bolts in the backboard mounting plate very slightly to shift and

level the backboard. Re-tighten securely after final adjustments are complete. Goal height with shot clock installed (per shot

clock instructions), and T-handle disengaged, should be at 9′ 11-1/2". T-handle will raise goal height and place rear mast in

tension for maximum rigidity. NOTE – Unit will have to be checked again if the additional weight of a shot clock is added.

16. Lay a level vertically on the face of the glass backboard. Shift the clamp assembly on the rear of the bank yoke frame assembly

(see Illustration “C”) to properly plumb backboard. Tighten clamp bolts securely to hold backboard in position.

1

11

FRONT-TO-BACK TO PLUMB

ADJUST BACKBOARD YOKE FRAME

ILLUSTRATION "C"

FACE OF BACKBOARD

94

7 5

2

9

ASSEMBLE PADDING AND ENCLOSURE PANELS TO FRAME AS FOLLOWS

17. Position base pads around base so that front pad (#24) extends over edges of long side pads (#25). Side pads (#25) will extend

over edges of rear pad (#26). Assemble front pad (#24) to front of base (#1) using 1/4" x 4" lg. hex head lag screw (#14). Next

attach side pads (#25) to base (#1) using #12 x 1" lg. phillips pan head S.M.S. (#15). Rear pad (#26) will be attached to base (#1)

using either #12 x 1" lg. phillips pan head S.M.S. (#15), or Velcro peel and stick, depending on base (#1) weight configuration.

18. Front mast pad (#27) is positioned on top of front base pad and attached with 1/4" x 4" lg. hex head lag screws (#14).

19. Place top base pads (#28-#29) in position. Also check fit of rear wrap around brace pads (#30). Note - Both top base pads and

rear brace pads need to be removed when lowering unit so damage does not occur.

20. Attach glass backboard padding (#23) per instructions with pads.

21. Touch up any scratches that may have occurred during shipping or assembly with white touch up paint.

ILLUSTRATION "D"

10

IMPORTANT - UPON FINAL SET UP OF THIS UNIT, SHOW THE INDIVIDUAL WHO WILL OPERATE THIS UNIT HOW

TO PROPERLY OPERATE THIS UNIT AND READ THE WARNING LABELS TO HIM/HER EXPLAINING THE NECESSITY

TO FOLLOW SAFE OPERATING PROCEDURES. THESE INSTRUCTIONS MUST BE GIVEN TO AN OFFICIAL IN

CHARGE OF THE FACILITY TO KEEP FOR FUTURE REFERENCE.

THIS BACKSTOP MUST BE OPERATED ONLY BY AUTHORIZED PERSONNEL FAMILIAR WITH THE SAFE OPERATING

INSTRUCTIONS AND PROCEDURES. THIS EQUIPMENT SHOULD BE INSPECTED BEFORE EACH USE FOR WEAR,

LOOSE FITTINGS, DAMAGE, AND PROPER STABILITY. CONSULT A TRAINED SERVICE TECHNICIAN OR THE

FACTORY WHEN IN DOUBT.

WARNING

DANGER / WARNING ON MISUSE OF PORTABLE BACKSTOPS

(Published in Compliance with NCAA Comments on the Rules of Basketball)

A high degree of injury potential and severe liability problems exist when players or spectators are allowed to hang, sit or stand on the

goal, backboard or support structure.

This equipment is not designed for adding weight to the goal or backboard. Please do not climb on the goal, backboard or support

structure.

Administrators are cautioned that this practice be eliminated and that portable units are lowered immediately after the completion of

each game. There is a high risk of severe injury or even death if these instructions are not strictly followed.

The use of a floor anchor system for all competition games is mandatory and is the responsibility of game management and the

personnel responsible for the facility.

THIS UNIT MUST BE OPERATED ONLY BY AUTHORIZED PERSONNEL FAMILIAR WITH THE SAFE OPERATING

INSTRUCTIONS AND PROCEDURES AS DESCRIBED IN THE OPERATING MANUAL. READ AND REFER TO ALL

OPERATING INSTRUCTIONS BEFORE ATTEMPTING TO OPERATE THIS UNIT.

CAUTION - The following steps must be observed to provide the safe operation of this unit.

- Do not move this unit in the “up” position.

- When raising or lowering this unit, stand to one side and keep all individuals clear from beneath unit (front and back). Keep

hands and feet away from all pinch and crush points.

- Inspect this equipment for wear, loose fittings, damage and proper stability before each use. Consult a trained service technician

or the factory when in doubt.

11

1235 MAINTENANCE CHECK LIST

1. Check key switch, electrical connections for proper operation, tightness and integrity.

2. Operate unit, check operation, up cycle, and down cycle.

3. Check hydraulic system for leaks, check hoses, cylinders, seals, and motor. Check level of hydraulic fluid. (Use hydraulic fluid,

available at most auto part stores, if necessary). CAUTION - Do not overfill.

4. Check structural integrity, look for broken welds or bent metal parts or fittings. Check casters.

5. Inspect rubber pad on bottom of backstop base, backboard pad and padding on unit.

6. Inspect safety/adjustment “T” handle and brace tube for metal fatigue. IMPORTANT – T-handle and threads must be lubricated

with grease at all times.

7. Inspect floor attachment system including floor anchors, move unit onto playing floor, check attachments. With unit in playing

position check backboard for level and plumb, goal for level 90° from face of goal and at parallel position. Check distance from

free throw line to face of backboard.

Make corrections to units as needed. Repair or replace components as necessary.

If it is necessary to add hydraulic fluid, use an anti-wear fluid with a

viscosity grade of VG46. Use of one of the following is recommended:

Amoco AW 46

Chevron HYD 46

Mobil DTE 25

Or An Equivalent

12

1235 ELECTRIC TROUBLE SHOOTING GUIDE

PROBLEM #1 Rotate key switch to up or down and motor does not run.

POSSIBLE CAUSE: No main power. Break in extension cord.

SOLUTION: Check receptacle and extension cord with voltage meter for 120V 60Hz.

POSSIBLE CAUSE: Lack of voltage and amperage.

SOLUTION: Check with amperage gauge for excessive current draw and low voltage. Extension cord should not exceed

50 ft. in length to power source. If additional cord is required, an extension cord of heavy gauge wire will

be required: 12/3 up to 50 ft, 10/3 up to 100 ft., 8/3 up to 200 ft., amperage and voltage reading must not

exceed motor amperage rating. Lack of voltage and amperage will cause the motor to cut-out on thermal

overload. Repeat operation will cause switch and motor damage.

POSSIBLE CAUSE: Key switch defective.

SOLUTION: Check electrical connections for loose termination on key switch and wire connectors.

POSSIBLE CAUSE: Motor burned out.

SOLUTION: Remove and replace.

PROBLEM #2 Rotate key switch to up or down and motor runs but does not raise or lower.

POSSIBLE CAUSE: Hydraulic pump pressure adjustment.

SOLUTION: To adjust pump pressure, remove cap nut and loosen locknut at base of pump. Using a flat blade screw

driver, turn slotted bolt fully clockwise until snug. Tighten locknut and install cap nut securely.

POSSIBLE CAUSE: Low hydraulic oil level.

SOLUTION: To check hydraulic oil level, do so with mast fully lowered. Remove breather cap located on top of pump

reservoir, oil level should be about 1-1/2 in. from top of reservoir. Use a high-grade hydraulic jack oil

(available at auto supply store).

POSSIBLE CAUSE: Sticking hydraulic valve assembly.

SOLUTION: The electric hydraulic valve assembly has a manual over by-pass, at each end of the valve (center). With

power off, use a small screw driver and push pin on each side in several times. This will free any

contaminant that might have accumulated in valve assembly.

POSSIBLE CAUSE: Loose wire termination on Electro-Hydraulic valve.

SOLUTION: Remove electrical power. Remove cover on electric hydraulic valve and tighten all wire connections.

POSSIBLE CAUSE: Loose wire termination in key switch.

SOLUTION: Remove Electrical Power. Remove access cover plate on key switch electrical box. Remove key switch

assembly by turning knurled nut on top of electrical panel counter clockwise. Tighten all terminals, tighten

all wire connections.

POSSIBLE CAUSE: Burned out electric solenoid coils.

SOLUTION: Remove cover on electric hydraulic valve assembly, remove all electrical connectors to coils. Use Ohm

meter on 1K scale. Take reading across each coil, good coil separately. Zero reading indicates open coil,

good coil will read approximately 1K Ohm.

POSSIBLE CAUSE: Defective hydraulic pump.

SOLUTION: Replace or repair only by an authorized hydraulic pump dealer.

13

1235 HYDRAULIC TROUBLE SHOOTING GUIDE

PROBLEM #1 Unit comes down to fast when key is turned to down cycle.

SOLUTION: Turn in slightly knob on flow control valve located at back end of large mast cylinder.

PROBLEM #2 Unit goes up on casters as unit is coming down.

SOLUTION: An adjustment balance between the flow control and needle valves. Located at the rear of each cylinder.

Readjust each valve slightly until operation is obtained. (Caster cylinder will start to extend on down cycle

until casters do put some pressure on the floor but should not lift entire base off the floor until mast is all

the way down.)

PROBLEM #3 A) Unit will not come down off casters.

B) Unit will not go up on casters.

C) Boom and mast will not come down.

D) Boom and mast will not go up.

SOLUTION: Check to see if someone has turned in the knob on either or both of the control valves. Open slowly.

Readjust per Problem #2.

PROBLEM #4 A) When unit is up on casters but starts to lower itself.

B) When front mast and boom are up but starts to come down. (Also, when T-handle is loosened, mast

comes back.)

SOLUTION: Check and tighten any loose fittings. If no loose fitting are found it maybe an internal leak in a valve or

cylinder. Call a hydraulic serviceman.

IMPORTANT

FILE THIS ASSEMBLY, ADJUSTMENT, OPERATION AND MAINTENANCE BOOKLET IN A SAFE LOCATION FOR

FUTURE REFERENCE, TO AVOID INJURIES OR PRODUCT DAMAGE WHEN REPLACING A BACKBOARD, OR

PERFORMING OTHER NECESSARY MAINTENANCE.

14

15

BACKBOARD (8'-0" EXTENSION)

PORTABLE BACKSTOP WITH 3'-6" x 6'-0"

(106.7cm x 182.9cm) RECTANGULAR GLASS

01235-914

BACKSTOP WITH 8'-0" EXTENSION

PORTABLE HYDRAULIC FIELD-HOUSE

TRANSPORT/STORAGE POSITION

BACKSTOP SHOWN IN

SEE B-1236-8 FOR FLOOR ANCHOR SYSTEM

SEE B-1237 FOR SHOT CLOCK

SEE B-1237 FOR GOAL LIGHT

16

(106.7cm x 182.9cm) RECTANGULAR GLASS

PORTABLE BACKSTOP WITH 3'-6" x 6'-0"

BACKBOARD (10'-8" EXTENSION)

01235-108

BACKSTOP WITH 10'-8" EXTENSION

PORTABLE HYDRAULIC FIELD-HOUSE

BACKSTOP SHOWN IN

TRANSPORT/STORAGE POSITION

MEETS FIBA REQUIREMENTS FOR COMPETITION

SEE B-1237 FOR GOAL LIGHT

SEE B-1237 FOR SHOT CLOCK

SEE B-1236-10 FOR FLOOR ANCHOR SYSTEM

17

DETAIL "B"

01236-300

No. 01235-914 PORTABLE BACKSTOPS

FLOOR ANCHOR SYSTEM FOR PAIR OF

"A"

"A"

SECTION "A-A"

PLAN VIEW

18

FLOOR ANCHORS REQUIRED (2)

FOR USE WITH TIE-DOWN

DETAIL "B"

TIE-DOWN SYSTEM

No. 01235-108 PORTABLE BACKSTOP

FLOOR ANCHOR SYSTEM SUPPLIED WITH

"A"

"A"

SECTION "A-A"

PLAN VIEW

19

AND CONTROL, WITH GOAL LIGHT

SHOT CLOCK WITH SUPPORT ASSEMBLY

AND CONTROL, WITHOUT GOAL LIGHT

SHOT CLOCK WITH SUPPORT ASSEMBLY

01237-100 and 01237-300

FOR No. 1235 PORTABLE BACKSTOPS

SHOT CLOCK WITH SUPPORT ASSEMBLY

20

Porter Athletic Equipment Company

2500 South 25th Avenue, Broadview, IL U.S.A., 60155

Toll Free: (800) 947-6783 • Phone: (708) 338-2000 • Fax: (708) 338-2060

www.porter-ath.com

SAVE THESE INSTRUCTIONS FOR FUTURE USE

WARNING: This product can expose you to Urethane, which

is known to the State of California to cause cancer and birth

defects or other reproductive harm. For more information go to

www.p65warnings.ca.gov.

A

/