Page is loading ...

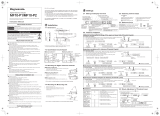

O P E R A T I N G I N S T R U C T I O N S

AOD1

Evaluation unit

Described product

AOD1

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is only

permissible within the limits of the legal determination of Copyright Law. Any modifica‐

tion, abridgment or translation of this document is prohibited without the express writ‐

ten permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2

O P E R A T I N G I N S T R U C T I O N S | AOD1 8020327/2016-09-26 | SICK

Subject to change without notice

Contents

1 About this document........................................................................ 6

1.1 Information on the operating instructions.............................................. 6

1.2 Scope......................................................................................................... 6

1.3 Explanation of symbols............................................................................ 6

1.4 Further information................................................................................... 7

1.5 Customer service...................................................................................... 7

2 Safety information............................................................................ 8

2.1 Intended use............................................................................................. 8

2.2 Incorrect use............................................................................................. 8

2.3 Limitation of liability................................................................................. 8

2.4 Modifications and conversions................................................................ 8

2.5 Requirements for skilled persons and operating personnel................. 8

2.6 Operational safety and particular hazards............................................. 9

3 Product description........................................................................... 10

3.1 Product ID.................................................................................................. 10

3.1.1 Type label................................................................................. 10

3.1.2 Type code................................................................................. 10

3.2 Product characteristics............................................................................. 11

3.2.1 Device view.............................................................................. 11

3.2.2 Product features and functionality......................................... 11

4 Transport and storage....................................................................... 12

4.1 Transport................................................................................................... 12

4.2 Transport inspection................................................................................. 12

4.3 Storage...................................................................................................... 12

5 Mounting............................................................................................. 13

5.1 Scope of delivery...................................................................................... 13

5.2 Mounting instructions.............................................................................. 13

5.3 Mounting the device................................................................................. 13

6 Electrical installation........................................................................ 15

6.1 Notes on the electrical installation.......................................................... 15

6.2 Wiring notes.............................................................................................. 16

6.3 Connecting the device electrically........................................................... 18

6.3.1 Installation with a male connector......................................... 18

6.3.2 Installation with open cable ends (AOD1- xxx7xx)................. 19

6.3.3 Connecting to a compatible sensor........................................ 20

7 Operation............................................................................................ 23

7.1 Operating elements.................................................................................. 23

7.1.1 Pushbuttons............................................................................. 23

7.1.2 Default screen.......................................................................... 23

CONTENTS

8020327/2016-09-26 | SICK O P E R A T I N G I N S T R U C T I O N S | AOD1

3

Subject to change without notice

7.1.3 Switching to the sensor settings menu.................................. 23

7.1.4 Switching to calculation.......................................................... 25

7.1.5 Display shown when no measurements can be taken and

no sensors are connected....................................................... 26

7.1.6 Locking the device’s operating buttons................................. 26

7.2 Device settings.......................................................................................... 27

7.2.1 Menu hierarchy for the settings screen................................. 27

7.2.2 Changing settings.................................................................... 27

7.2.3 Changing the display language............................................... 29

7.2.4 Configuring the I/O polarity..................................................... 29

7.2.5 Resetting the device settings.................................................. 30

7.2.6 APP settings............................................................................. 31

7.2.7 I/O settings............................................................................... 32

7.2.8 Sensor head settings............................................................... 33

7.2.9 AOD1 EXP settings................................................................... 35

7.3 Measurement and calculation settings................................................... 36

7.3.1 Thickness measurement......................................................... 36

7.3.2 Measuring height differences................................................. 42

7.3.3 Calculation settings................................................................. 47

7.3.4 Correction settings................................................................... 50

7.4 Sensor settings......................................................................................... 52

7.4.1 Adjusting settings for a compatible sensor............................ 52

7.4.2 Teach-in.................................................................................... 56

8 Maintenance...................................................................................... 61

8.1 Cleaning..................................................................................................... 61

8.2 Maintenance............................................................................................. 61

9 Troubleshooting................................................................................. 62

9.1 Detecting and displaying errors............................................................... 62

9.2 Repairs...................................................................................................... 62

9.3 Returns...................................................................................................... 62

10 Decommissioning............................................................................. 64

10.1 Dismantling............................................................................................... 64

10.2 Environmental protection......................................................................... 64

10.3 Disposal..................................................................................................... 64

11 Technical data.................................................................................... 65

11.1 Performance............................................................................................. 65

11.2 Interfaces.................................................................................................. 65

11.3 Mechanics/electronics............................................................................. 65

11.4 Ambient data............................................................................................. 65

11.5 Dimensional drawing................................................................................ 66

12 Accessories........................................................................................ 67

12.1 Ordering information for AOD1 evaluation unit...................................... 67

CONTENTS

4

O P E R A T I N G I N S T R U C T I O N S | AOD1 8020327/2016-09-26 | SICK

Subject to change without notice

12.2 Cables........................................................................................................ 67

12.3 Sensor heads............................................................................................ 67

12.4 Gateways................................................................................................... 68

13 Appendix............................................................................................. 69

13.1 Sample calculation................................................................................... 69

13.2 EU declaration of conformity / Certificates............................................. 70

13.3 UL conformity............................................................................................ 70

CONTENTS

8020327/2016-09-26 | SICK O P E R A T I N G I N S T R U C T I O N S | AOD1

5

Subject to change without notice

1 About this document

1.1 Information on the operating instructions

These operating instructions provide important information on how to use devices from

SICK AG. Prerequisites for safe work are:

•

Compliance with all safety notes and handling instructions supplied

•

Compliance with local work safety regulations and general safety regulations for

device applications

The operating instructions are intended to be used by qualified personnel and

electrical specialists.

NOTE

Read these operating instructions carefully before starting any work on the device,

in order to familiarize yourself with the device and its functions.

The instructions constitute an integral part of the product and are to be stored in the

immediate vicinity of the device so they remain accessible to staff at all times. Should

the device be passed on to a third party, these operating instructions should be handed

over with it.

These operating instructions do not provide information on operating the machine in

which the device is integrated. For information about this, refer to the operating instruc‐

tions of the specific machine.

1.2 Scope

These operating instructions serve to incorporate the device into a customer system.

These instructions apply to all available variants of the device. More detailed informa‐

tion for the identification of the device type in question see "Type code", page 10.

Available device variants are listed on the online product page.

b

www.sick.com/OD_mini

Various device variants are used as examples for commissioning, based on the default

parameter settings for the relevant device.

1.3 Explanation of symbols

Warnings in these operating instructions are indicated by symbols. The warnings are

introduced by signal words that indicate the extent of the danger. These warnings must

be observed at all times and care must be taken to avoid accidents, personal injury,

and material damage.

DANGER

… indicates a situation of imminent danger, which will lead to a fatality or serious inju‐

ries if not prevented.

WARNING

… indicates a potentially dangerous situation, which may lead to a fatality or serious

injuries if not prevented.

1 ABOUT THIS DOCUMENT

6

O P E R A T I N G I N S T R U C T I O N S | AOD1 8020327/2016-09-26 | SICK

Subject to change without notice

CAUTION

… indicates a potentially dangerous situation, which may lead to minor/slight injuries if

not prevented.

NOTICE

… indicates a potentially harmful situation, which may lead to material damage if not

prevented.

NOTE

… highlights useful tips and recommendations as well as information for efficient and

trouble-free operation.

1.4 Further information

NOTE

All the documentation available for the device and compatible products can be found

on the online product page at:

b

www.sick.com/OD_Mini

The following information is available for download there:

•

Type-specific online data sheets containing technical data and dimensional draw‐

ings

•

EU declaration of conformity for the product family

•

These operating instructions, available in German and other languages

•

Other publications related to the devices described here

•

Publications dealing with accessories

1.5 Customer service

If you require any technical information, our customer service department will be happy

to help. To find your agency, see the final page of this document.

NOTE

Before calling, make a note of all type label data such as type code, serial number, etc.

to ensure faster processing.

ABOUT THIS DOCUMENT 1

8020327/2016-09-26 | SICK O P E R A T I N G I N S T R U C T I O N S | AOD1

7

Subject to change without notice

2 Safety information

2.1 Intended use

The device is an evaluation unit for displacement measurement sensors and can be

used in conjunction with OD Mini Pro (RS485) displacement measurement sensors.

The evaluation unit can be used to configure and control several measurement sen‐

sors.

SICK AG assumes no liability for losses or damage arising from the use of the product,

either directly or indirectly. This applies in particular to use of the product that does not

conform to its intended purpose and is not described in this documentation.

2.2

Incorrect use

The device does not constitute a safety component according to the EC Machinery

Directive (2006/42/EC). The device must not be used in explosion-hazardous area. Any

other use that is not described as intended use is prohibited. Any use of accessories

not specifically approved by SICK AG is at your own risk.

WARNING

Danger due to improper use!

Any improper use can result in dangerous situations.

Therefore, observe the following information:

■

Use only in accordance with the intended use.

■

All information in these operating instructions must be strictly observed.

2.3 Limitation of liability

Applicable standards and regulations, the latest state of technological development

and many years of knowledge and experience have all been taken into account when

assembling the data and information contained in these operating instructions. The

manufacturer accepts no liability for damage caused by:

■

Failing to observe the operating instructions

■

Incorrect use

■

Use by untrained personnel

■

Unauthorized conversions

■

Technical modifications

■

Use of unauthorized spare parts, consumables and accessories

With special variants, where optional extras have been ordered, or owing to the latest

technical changes, the actual scope of delivery may vary from the features and illustra‐

tions shown here.

2.4 Modifications and conversions

Modifications and conversions to the product and/or the installation may result in

unforeseeable dangers. Before any technical modifications to and expansions of the

product, the prior written approval of the manufacturer must be obtained.

2.5 Requirements for skilled persons and operating personnel

2 SAFETY INFORMATION

8

O P E R A T I N G I N S T R U C T I O N S | AOD1 8020327/2016-09-26 | SICK

Subject to change without notice

WARNING

Risk of injury due to insufficient training.

Improper handling may result in considerable personal injury and material damage.

■

All work must only ever be carried out by the stipulated persons.

These operating instructions list the training requirements for the various fields of activ‐

ity, as follows:

■

Instructed personnel have been given a briefing by the operator about the tasks

assigned to them and about potential dangers arising from improper action.

■

Skilled personnel have the specialist training, skills, and experience, as well as

knowledge of the relevant regulations, to be able to perform tasks delegated to

them and to detect any potential dangers independently.

■

Electricians have the specialist training, skills, and experience, as well as knowl‐

edge of the relevant standards and provisions to be able to carry out work on elec‐

trical systems and to detect any potential dangers independently. In Germany,

electricians must meet the specifications of the BGV A3 Work Safety Regulations

(e. g. Master Electrician). Other relevant regulations applicable in other countries

must be observed.

2.6 Operational safety and particular hazards

Please observe the safety notes and the warnings listed here and in other chapters of

these operating instructions to reduce the possibility of risks to health and avoid dan‐

gerous situations.

SAFETY INFORMATION 2

8020327/2016-09-26 | SICK O P E R A T I N G I N S T R U C T I O N S | AOD1

9

Subject to change without notice

3 Product description

3.1 Product ID

3.1.1 Type label

The type label provides information for identification of the sensor.

MADE IN JAPAN

AOD1-MR27C4

6 058 195

19458 1515F

1

2

3

Figure 1: Type label design for the sensor

1

Device name

2

Part number

3

Serial number

3.1.2 Type code

AOD 1 - M R2 3 Q1

1 2 3 4 5 6

Position Description

1 Product code

AOD: evaluation unit for displacement measurement sensors

2 Product family

1: OD Mini

3 Device type

M: Master

S: Slave

4 Interface (sensor side)

R2: 2x RS485

5 Connection type

4: male connector, M8, 4-pin

5: male connector, M12, 5-pin

7: 2 m cable, 7-pin cable with open cable end

6 Inputs and outputs

Q1: 1x switching output, 1x input

Q2: 2x switching outputs, 1x input

C4: 1x analog output, 3x switching outputs, 1x input

1)

see "Connecting to a compatible sensor", page 20

3 PRODUCT DESCRIPTION

10

O P E R A T I N G I N S T R U C T I O N S | AOD1 8020327/2016-09-26 | SICK

Subject to change without notice

3.2 Product characteristics

3.2.1 Device view

B A

PWR

OUT1

OUT2

OUT3

32

9

6

5

4

8

1

7

1

LED indicators

2

Screen

3

Operating buttons

4

Bus male connector (system bus), only for AOD1 slave

5

Cover

6

Connecting cable

7

Cover for bus connection (system bus)

8

Type label

9

Connections for sensor head 1 and sensor head 2

3.2.2 Product features and functionality

The AOD1 is an evaluation unit that can be used with up to two OD Mini Pro (RS485)

displacement measurement sensors. The evaluation unit can be used to configure the

settings for the displacement measurement sensors. When used in conjunction with

two sensor heads, the evaluation unit is used to measure differences in height or thick‐

nesses.

Adding an extra AOD1 (slave) allows up to four sensor heads to be calculated together,

see "Sample calculation", page 69.

PRODUCT DESCRIPTION 3

8020327/2016-09-26 | SICK O P E R A T I N G I N S T R U C T I O N S | AOD1

11

Subject to change without notice

4 Transport and storage

4.1 Transport

For your own safety, please read and observe the following notes:

NOTE

Damage to the product due to improper transport.

■

Transport should be performed by trained specialist staff only.

■

The utmost care and attention is required at all times during unloading and trans‐

portation on company premises.

■

Note the symbols on the packaging.

■

Do not remove packaging until immediately before you start mounting.

4.2

Transport inspection

Upon receipt, please check the delivery for completeness and for any damage that may

have occurred in transit. In the case of transit damage that is visible externally, proceed

as follows:

■

Do not accept the delivery or only do so conditionally.

■

Note the scope of damage on the transport documents or on the transport compa‐

ny's delivery note.

■

File a complaint.

NOTE

Complaints regarding defects should be filed as soon as these are detected. Damage

claims are only valid before the applicable complaint deadlines.

4.3 Storage

Store the sensor under the following conditions:

■

Do not store outdoors.

■

Store in a dry area that is protected from dust.

■

Do not expose to any aggressive substances.

■

Protect from sunlight.

■

Avoid mechanical shocks.

■

Storage temperature: between –40 and +60 °C, non-freezing

■

Relative humidity: max. 85%, non-condensing

■

For storage periods of longer than 3 months, check the general condition of all

components and packaging on a regular basis.

4 TRANSPORT AND STORAGE

12

O P E R A T I N G I N S T R U C T I O N S | AOD1 8020327/2016-09-26 | SICK

Subject to change without notice

5 Mounting

5.1 Scope of delivery

Included with delivery:

■

AOD1 in the version ordered

■

Caps for the male connectors (type-dependent)

Supplied documentation:

■

Quickstart

NOTE

All available documentation can also be found online at:

b

www.sick.com/OD_mini

5.2 Mounting instructions

To ensure trouble-free operation, observe the following mounting instructions:

■

Observe all technical data.

■

Protect the device from direct sunlight.

■

To prevent condensation, avoid exposing the device to rapid changes in tempera‐

ture.

5.3 Mounting the device

1. Make sure that the device is not connected to a voltage supply.

2. Clamp the device to a mounting rail:

1

2

3. Check that the mounting hooks have engaged properly and that the device is fixed

securely in place.

Master/slave connection (optional)

1. Clamp any downstream devices (e.g., AOD1 slave or WI180C-PB) to the mounting

rail according to their installation instructions, see figure 0.

2. Slide any downstream devices onto the AOD1’s bus male connector in the correct

order (from left to right: 1 x master, n x slave device(s), 1 x bus connection = a

maximum of 9 devices).

MOUNTING 5

8020327/2016-09-26 | SICK O P E R A T I N G I N S T R U C T I O N S | AOD1

13

Subject to change without notice

1

1

Master Slave

3. Check that the devices are connected correctly.

4. Fix the connected devices to the mounting rail without any gaps in between them.

NOTICE

If you are connecting the AOD1 to another device (e.g., AOD1 slave or WI180C-PB) on a

DIN rail, use the bus male connector to connect the devices securely with one another.

If the bus male connector is at an angle or inserted incorrectly, the AOD1 or other con‐

nected devices may be damaged when the power is switched on.

The AOD1 can also be connected to a WLL180T fiber-optic sensor and a field bus

adapter (e.g., WI180C-PB). Please make sure that the layout of the devices is correct:

WLL180T AOD1 WI180C-PB WLL180TAOD1 WI180C-PB

ü

û

5 MOUNTING

14

O P E R A T I N G I N S T R U C T I O N S | AOD1 8020327/2016-09-26 | SICK

Subject to change without notice

6 Electrical installation

6.1 Notes on the electrical installation

NOTICE

Equipment damage due to incorrect supply voltage!

An incorrect supply voltage may result in damage to the equipment.

■

Only operate the device using a protected low voltage and safe electrical insulation

as per protection class III.

NOTICE

Equipment damage or unpredictable operation due to working with live parts.

Working with live parts may result in unpredictable operation.

■

Only carry out wiring work when the power is off.

■

Only connect and disconnect electrical connections when the power is off.

■

The electrical installation must only be performed by electrically qualified person‐

nel.

■

Standard safety requirements must be met when working on electrical systems!

■

Only switch on the supply voltage for the device when the connection tasks have

been completed and the wiring has been thoroughly checked.

■

When using extension cables with open ends, ensure that bare wire ends do not

come into contact with each other (risk of short-circuit when supply voltage is

switched on!). Wires must be appropriately insulated from each other.

■

Wire cross-sections in the supply cable from the customer’s power system must be

selected in accordance with the applicable standards. In Germany, observe the fol‐

lowing standards: DIN VDE 0100 (Part 430) and DIN VDE 0298 (Part 4) and/or

DIN VDE 0891 (Part 1).

■

Circuits connected to the device must be designed as SELV circuits (SELV = Safety

Extra Low Voltage).

NOTE

Layout of data cables

■

Use screened data cables with twisted-pair wires.

■

Implement the screening design correctly and completely.

■

To avoid interference, e.g. from switching power supplies, motors, clocked drives,

and contactors, always use cables and layouts that are suitable for EMC.

■

Do not lay cables over long distances in parallel with power supply cables and

motor cables in cable channels.

The IP protection class for the device is only achieved under the following conditions:

■

The cables plugged into the connections are screwed tight.

■

Any electrical connections that are not being used must be fitted with protective

caps/plugs that are screwed tight (as in the delivery condition).

■

Any other covers must be closed and lie flush on the device.

Failure to observe these points means that the device will not achieve the specified IP

protection class!

ELECTRICAL INSTALLATION 6

8020327/2016-09-26 | SICK O P E R A T I N G I N S T R U C T I O N S | AOD1

15

Subject to change without notice

6.2 Wiring notes

NOTICE

Faults due to incorrect wiring!

Incorrect wiring may result in operational faults.

■

Follow the wiring notes precisely.

NOTE

Preassembled cables can be found online at:

b

www.sick.com/OD_mini

Please observe the following wiring notes:

■

A correct and complete cable shielding design is required for trouble-free data

transmission.

■

The cable shield must be connected at both ends in the control cabinet and at the

sensor. The cable shield of the pre-assembled cables is connected to the knurled

nut and thus also to a large area of the sensor housing.

■

The cable shield in the control cabinet must be connected to a large area of the

signal ground (see figure 5).

■

Appropriate measures must be taken to prevent equipotential bonding currents

flowing through the cable shield.

■

During installation, pay attention to the different cable groups. The cables are

grouped into the following 4 groups according to their sensitivity to interference or

radiated emissions:

°

Group 1: Cables very sensitive to interference, such as analog measuring

cables

°

Group 2: Cables sensitive to interference, such as sensor cables, communi‐

cation signals, bus signals

°

Group 3: Cables which are a source of interference, such as control cables

for inductive loads, motor brakes

°

Group 4: Cables which are powerful sources of interference, such as output

cables from frequency inverters, welding system power supplies, power

cables

w

Cables in groups 1, 2 and 3, 4 must be crossed at right angles (see figure 2).

w

Route the cables in groups 1, 2 and 3, 4 in different cable channels or use

metallic separators (see figure 3 and see figure 4). This applies particularly if

cables of devices with a high level of radiated emission, such as frequency

converters, are laid parallel to sensor cables.

1

2

4

3

1

2

4

3

90

90

Figure 2: Cross cables at right angles

6

ELECTRICAL INSTALLATION

16

O P E R A T I N G I N S T R U C T I O N S | AOD1 8020327/2016-09-26 | SICK

Subject to change without notice

1

2

3

4

Figure 3: Ideal laying – Place cables in different cable channels

1

2

3

4

Figure 4: Alternative laying – Separate cables with metallic separators

Figure 5: Make an extensive and low-impedance ground connection of the cable shield in the

control cabinet

ELECTRICAL INSTALLATION

6

8020327/2016-09-26 | SICK O P E R A T I N G I N S T R U C T I O N S | AOD1

17

Subject to change without notice

Figure 6: Shield connection in plastic housing

NOTE

Prevent equipotential bonding currents via the cable shield with a suitable earthing

method. If necessary, ground currents on the EtherNet/IP cabling can be prevented by

the use of an EtherNet/IP adapter (part number 2044264).

6.3 Connecting the device electrically

NOTE

The connection diagram, and information on inputs and outputs can be found on the

type label on the device.

6.3.1 Installation with a male connector

Connection diagram for M8, 4-pin (AOD1-xxx4xx)

2 4

1

3

L+

In

0V

Q1

1

2

4

wht

blu

brn

blk

3

1 Brown Voltage supply -

2 White Input (sensor head 1 external input) [EXTIN Select] under [AOD1 I/O Set‐

tings]

3 Blue GND -

4 Black Output 1 [OUT 1 Source] under [AOD1 I/O Set‐

tings]

Connection diagram for M12, 5-pin (AOD1-xxx5xx)

1

4 3

5

2

6 ELECTRICAL INSTALLATION

18

O P E R A T I N G I N S T R U C T I O N S | AOD1 8020327/2016-09-26 | SICK

Subject to change without notice

L+

1

brn

0V

3

blu

Q1

4

blk

Q2

2

wht

In

5

gra

1 Brown Voltage supply -

2 White Output 2 [OUT 2 Source] under [AOD1 I/O Set‐

tings]

3 Blue GND -

4 Black Output 1 [OUT 1 Source] under [AOD1 I/O Set‐

tings]

5 Gray Input [EXTIN Select] under [AOD1 I/O Set‐

tings]

1. With the power switched off, connect the connecting cables to the female cable

connector and screw in tightly.

6.3.2 Installation with open cable ends (AOD1- xxx7xx)

1

2

3

4

5

7

6

8

9

L+

0V

Q1

Q3

1

2

blu

blk

pur

brn

3

5

Q2

4

yel

IN1

6

gra

IN2

7

pnk

Analog ground

8

shield

QA

9

wht

Pin Wire

color

Details Adjustment option

1 Brown Voltage supply -

2 Blue GND -

ELECTRICAL INSTALLATION 6

8020327/2016-09-26 | SICK O P E R A T I N G I N S T R U C T I O N S | AOD1

19

Subject to change without notice

Pin Wire

color

Details Adjustment option

3 Black Output 1 [OUT 1 Source] under [AOD1 I/O Set‐

tings]

4 Yellow Output 2 [OUT 2 Source] under [AOD1 I/O Set‐

tings]

5 Violet Output 3 [OUT 3 Source] under [AOD1 I/O Set‐

tings]

6 Gray Input 1 (sensor head 1 external

input)

[EXTIN Select] under [AOD1 I/O Set‐

tings]

7 Pink Input 2 (sensor head 2 external

input)

8 - GND (analog) -

9 White Analog output [Analog Source] under [AOD1 I/O

Settings]

1. Connect the cable ends according to the diagram.

2. Connect the device to the voltage supply.

✓

The display lights up.

6.3.3 Connecting to a compatible sensor

NOTE

If you are connecting several devices together, you will have to connect a voltage supply

to each device using the process described above in order to supply the compatible

sensors with power.

1

2

1. Connect the cable to the sensor.

2. Turn to secure the male connector on the cable end.

6 ELECTRICAL INSTALLATION

20

O P E R A T I N G I N S T R U C T I O N S | AOD1 8020327/2016-09-26 | SICK

Subject to change without notice

/