Page is loading ...

mn

m MB

mm

RIC

ELECTRIC

AIRCRAFT

SPECIFICATIONS

S ^ 7L

USER'S

GUIDE

$M

^

SR

BS

i

•TTT^

GW/B2-EDF55-150

(W/EDF55-150

Duct

Fanset x2 )

GW/B2-EDF55-300H

(W/EDF55-300H

Duct

Fanset X2 ) •N

GW/B2-EDF55-150/G8

(W/EDF55-150

Duct

Fanset x2 )

GRAY

1x6

GW/B2-EDF55-3Q0H/C

(W/EDF55-300H DuctFan set x 2 )

GRAY

RS

Length

(^«)

430mm (16.9

InDlf)

Length

(^R)

430 mm (16.9 in)

Wing

Span

(H^)

882mm

(34.7

in) Wing

Span

(«g)

882 mm (34.7 in)

Wing

Area

(SH®a)

18.4dm2(285.2sq in) Wing

Area

(iHBW)

18.4dm2

(2B5.2sqin)

Flying

Weight

(£iMU)

420~480g

(14.8-16.9

oz) Flying Weight

{^(•••)

420-500

g

(14.8-17.6

oz)

Wing

Loading

(MBfiB)

30.1-34.4 g/dm^(9.9-11.3 oz/sq.ft) Wing Loading

(HHilB)

30.1-35.8 g/dm^(9.9-11.7 oz/sq.ft)

Power

System

(ISTJJSSi)

EDF55-150X2

Power

System

(ll)73?ftiii)

EDF55-300Hx2

Propeller

(SiSSiS)

EDF2245X6

Propeller

(llJIig)

EDF2245x6

BatteryRequired (SitjlSItS)

7N-8N730AAAmAh

BatteryRequired (BitfiStS)

7N~8N730AAAmAh

Servo

(islSBS)

PICO

/

NARO

Servo

(fBjflBg)

PICO

/

NARO

Receiver

(gUXffi)

R4Pli/R6Nil

Receiver

(gUSS)

R4Pli/R6Nii

Speed

controller

(5?®jSil)

iCS-300

above

litJl

Speed

controller

(B^SiliS)

iCS-400

above

ULJl

Radio

Required

(iiSI^B)

4 channel radio

(4l!)('F^Jl)iS^)

Radio

Required

(iiSIIB)

4 channel radio

(4BfFls/JljSJ§^)

Other

V

(Hffl^B)

1 V-Taii

MixerSSS

Other

(Sffii^B)

1 V-Taii

MixerilSgg

2

01. B-2

Fuselage

02. B-2 Main Wing (R)

03. B-2 Main Wing (L)

04. B-2 Stabilized (Giay)

05. B-2 Hatch (Giay)

06. B-2 Plasticarticuiated (Giay)

07. Ultra-Light Wheel rim (1 1/2") Black

08. Cowling

Seat

(1 x 8 x 8mm) x4

01. B-2

IS

02. B-2 (R)

03. B-2

iaiii

(L)

04. B-2 (R)

05. B-2 (K)

06. B-2

iJSSgR

(M)

07.

ffi^3i'ttii38mm

(1

1/2")1

08. S;yft3il:®>^ABS

(1

X8 X8mm)x4

CONTENTS

OF

KIT(PARTS

LIST)

x1

x1

x1

x2

x1

x2

x3

x3

x1

x1

x1

x2

x1

x2

x3

x3

09.

1.4mm

(Nose

Gear)

10.

*1

1.4mm

(Main Landing Gear-L)

11. 1.4mm (Main Landing Gear-R)

12.

Si

1mm (Aileron Linkage Wire)

13.

1mm

(Linkage)

14. Cowling Fixing

Screw

M1.4 x

9mm

TPA

15. Hinge (10x18mm) x

15pcs.

16.

Plastic

Parts

Frame"A"

17.

Plastic

Parts

Frame"C"

1^

^

09. 1.4mm (I^HS?)

10. M .4mm

(i^S-L)

11.

12.

13.

14.

15.

16.

17.

mwMrc"

Si

1.4mm (±fftS§-R)

1mm

(iiSai)#)

Si

1mm

(J^^iS®#)

Ml.4

X

9mm

TPA

10*18gH)^ (15^1)

"A"

WWW.9WS.G0m.IW

Xl

18.

GWS

Glue

xl

Xl

19. Battery Hatch

xl

xl

20.

EDF-55

xl

x2

21.

"Y"

Cord

x2

xl

22. Clay

xl

x20

23.

B-2

instruction

Manual

xl

xl

24.

GWS

Decal

xl

xl

25.

B-2

Decal

xl

xl

26. Servo Tape

x4

xl

18.

GWS

xl

xl

19.

xl

xl

20.

EDF55-150

6il(EP2245)$i^

xl

x2

21.

W22/YSiif/^I,l/l6.5cm

x2

xl

22. 30g

xl

x20

23.

B-2i!^0JB

xl

xl

24.

GWS

xl

xl

25.

B-2i?gififfi

xl

xl

26.

iSgfflaP

x4

www.giNs.com.iw

PYPOP-1055

B-2

Deca

WWW.gWS.COm.tW

www.gw^s:corirtw

-1

-

PYPOP-1003

GWS

Decal

PYINS-1075

B-2

^ ^

Instruction

Manual

X1

pee.

I

GW/B2-FAS1

•

PHFUS-1021-W-

GW/B2-FAS4

PHTYRP1004-D2-

®a®14^38mm(1

1/2")^

Ultra-light

Wheei

Rim

38mm

dia. (1 1/2") x 3

pcs.

PHFL)S-1021-W-R-

Main Wing(Right

Side)

PHFUS-1021-W-L-

Main

Wlng(Left

Side)

B2ffl*£(i(a)

PYCRD-1001—-

10x18^^MJn

Hinge

(15

in-'|||

GW/B2-FAS6

Jk_

?

iA

fH

PMSPC-1008—1-

MiCROWEfr(C)

Plastic

Parts

Frame

"C"x1

set

GW/B2-FAS7

FB]

b:

5c=ir

PMSPC-1001-

PICO

STICK

I

Plastic

Parts

Frame

"A"x1

set

PMSTD-1007

n,mm

ABattery

Seat

X1

pee.

PTMEW-1020-L~M-

PTMEW-1020-R-M-

.4mm

(Main Landing

Gear

& R) x

Ipce.

PMSPC-1002—^

mmm

i

abs(i

xsxamm)

cowling

Seat

x 12 pcs.

PMSPC-1020--B-

B2®^®M(M)

X1pee. B-2Hatch

(Giay)

PTMEW-1026-—N-

^#^Si1mm(*^iiiSl#) x

1pce.

ptmEW-TO0^---1

SI

.4mm(l^^^)

X1pee.

. •

PXTPAF-4J-1490R-

Slmm(l!|JliiS!l^) x

2pcs.

M1.4-9mm

TPA

PTMEW-1026--

PQHOSS13602

"Y"Cord W22 /

YMB

/

Em

16.5cm x 1pee.

GW/FAS9B

8ADHP1003"

GWS

Glue

X1

pee.

Cowing Fixing

Screw

x

20

pcs.

I

PTWEG-i

001

30g Clay x 1pce.

8STOL-1002

A^®¥x2PCS.

PTCUS-1016—

i@1SS®0

4(1

Servo

Tape

x 4

pcs.

PMSPC-1020-~-A-

B2i|||^^>n

(H) X2pcsL

B-2 Stabilized (Glay)

GW/EDF55-150x2

I AASEDF55 C-

EDF,55:,140J,^_BLADE,(E[^^^^

TOOLS

AND

ITEMS

To

assemble

this

airplane

you

will

need

to

prepare

some

tools.

III11

Cutter

Knife

Pliers

mxn

nn

Triangle

A

Screwedriver

Nippers

mam

r

Drill

Paper

Tape

Alcotiol

mxm-'

Clamp

515?

Spray

Paint

IDlii

CA

Glue

5^

- 2 -

PVPEF-1060

B2SiJMiiS)n (H) X2pcs.

B-2

Plasticarticulated

(Glay)

Scissors

m73

Epoxy

^ABiP(5minfB'ii)

Channel

Transmitter

7.2~9.6V

"AAA"500~750mAh

(Ni-MH

m

7.2~8.4V2/3

"AA"270~400m,

or

"AA" eOOmAh (Ni-Cd

m

m M

FUSELAGE

ASSEMBLY

USER'S

GUIDE

fM

Si

Bff

i

k.

RADIO

CONTROL

SYSTEM

t: . i

Electronic

Speed

Controller

ICS-100

orlGS-400

Charger

GWS

PICO,

NARO

MICRO

or

MINI

Series

Servos

GWS

R4N

or

R6N

,

R8M

FM

Receiver

I

Servo

Extension

Wire

5EMili

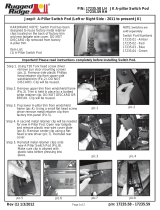

Cut the aiieron apart from the main wing (both right &left)with a knife

as

per the groove.(Pic.2,3)

Poiish both

side

of

the

rudder

with a

sandpaper

as

the

picture shown.(Pic.4)

Cut two slits for hinges installation on the rudder. Insert the two hinge and glue them in place.(Pic.5,6,7,8)

Mark the location of the aileron hingers on the wing and cut slits for the hinges.(Pic.5,6,7,8)

Apply glue on all hinges and aileron linkages and insert them to the wing securely.(Pic.9)

Insert the elevator control horn into the slot and

fix

itwith CAglue.(Pic.10,11)

(H2,3)

°

(H5,6,7,8)

tbiitSMiiZB

' "

(•5,6,7,8)

o

(Hio,ll)

3 -

m m

IB

FUSELAGE

ASSEMBLY

Cutthe aileron apart

from

the

main

wing

(both

right

&

left)

with

a

knife

as per the groove.(Pic.12,13)

Polish both side of the rudder with a

sandpaper

as

the picture shown.(Pic.14,15)

Mark

the location ofthe aileron hingers on the

wing

and cut slitsforthe hinges.(Pic.16,17,18,19)

Apply

glue

on

all

hinges

and

aileron

linkages

and

insert

them

tothe

wing

securely.(Pic.20,21)

Apply

A,B

glue am

all

plasticarticulated and insertthem to the aileron. (Pic.22,23,24)

Plasticarticulated

(Pic.25-1)

Glue the linkage plastic of aileron and elevator

with

epoxy. (Pic.25-2,25-3)

°(112,13) -

MUf

;2^i5gy^K-t

°(814,15) °(822,23,24)

°SMIOm/mS5iti373fflZI>^ti]A;^9m/m

(•16,17,18,19)

jiBliin

°

(•25-1,25-2,25-3)

a£fflAB|pifi^i!

mmm

tm

STABILIZED

FIN

AND

CABIN

HATCH

INSTALLATION

Apply

epoxy

glueonthe

stabilized

fin

and

cabin

hatch

tothefuselage. (Pic.26,27,28,29)

°(•26,27,28,29)

- 4 -

(•20,21)

iMRnmrn

im

MAIN

WHEEL

INSTALLATION

USER'S

auioE

2mm

Plastic

Tube

Z"

Shape

72mm

'

ln4M

i

r"--"

1

iSl

.4SliTl

9,(T

43.

Insert

the

nose

gear

into

the

plastic

part

"C8",

the

"V"

shape

mast

match

the

slot

of

the

"C8".

(Pic.30,31)

Then thought 2mm plastic tube

and

the

nose

gear

mount"C7". (Pic.32)

Press

the

retainer C9 to the

end

of

the

nose

gear,

then drop little amount of CA glue to hole of

the

"C9".

Make

sure

there

is no glue between

nose

gear

and

"C7". (Pic.33.34)

Make

sure

all

the

parts

are

on

the

correct station. (Pic.35)

Clean the outer shell of servo, receiver and

speed

controller with paper towel and alcohol. (Pic.36)

Apply

the

double

side

foam

tape

to the

servos

as

picture. (Pic.37)

Nose

steering

servo

sits

15mm

to

the

hatch. (Pic.38)

Glue

the

nose

gear

set

in place. (Pic.39.40)

Then attach this servo inside of the fuselage, Slide the nose steering push rod over the hole of the retainer.

Install nose wheel

(ct>

38 mm) to the nose

gear

and

fix

with

A1

retainer (Plc.41)

^ 1mm

Steeling

Z ROD (Pic.42)

Trim the

nose

gear

in neutral position. (Pic.43,44)

Pff"C8"ggiJ«liO^Ji'

»(Bso.si)

°

(^32)

afiJE"C9"EAglJP^± ' >ii:^fli7j(;S^;figlJ"C7" »

(•33.34.35)

"(•36)

°

(^37)

l^flim}iHS01]fiZM

'S§iHilIlulil5mni ° (B38)

°(•39,40)

<5(1

mm

li#,||(#.|miiil)ff)

(H41)

Z?0g-M5i)glJ"C8"Jl01]/J\5L °

(^42)

°(143,44)

- 5 -

fm 7

iB

WHEEL

INSTALLATION

msm'

Slidethe

tail

dragger

into

the wireas the

picture

shown.(Pic.45)

Fix

the

retainer to

the

axie. (Pic.46)

install

the

landing

gear tothe plasticpart

"C"4

as the picture shown.(Pic. 47,48)

Apply

the epoxyglue to

fix

the plasticpart

"C"4

on the slot. (Pic.49)

SJlfllMligA

'

^JilratiA;^^0iiB{4(B45,46)

"(•47,48)

°

(149)

ssmm

(mmss)

RADIO

GEAR

INSTALLATION

WIRING

AND

CONNECTION

(GWS/JR/SANWA)

RADIO

SYSTEM

jif'SrSIIC

•Ch1. Throttle

_____

(Electronic

speed

controller

Bll

Ch2.

Aileron

eaU^

Ch3. Elevator IS

Ch4. Rudder TdI^JIS

(Nose

Steering

=|fflii|q)

(Futaba

IHitec )

RADIO

SYSTEM

'Ch1. Aileron

SOS

•Ch2. Elevator54-P$lb

•Ch3.Throttle)ffiP5

(Electronic

speed

controller

•Ch4.

Rudder

(Nose

Steering

wilffllira)

Electric

Accessories

Wire

Installation

Diagram

TITTiTII

RECEIVER

1

RECEIVER

{•cwA'A/?o

ry/'s

"Y

Power

Cord

"Y"

Electronic

Speed

Controller

lCS-300

or

ICS-480

•Crystal installation.

*^tl3

9.6V730mAh

(Ni-MH)

GWS Nl-cad Battery

(Pic.84.85)

184.85)

(GWS PICO, NARO

Series

Servos)

(GWS

PICO,

NARO

fBjSgffi^JiJ)

Receiver

GW/R-6N

Operation

Voltage:

4.8V~6V(typical •(•tS4.8V)

i[]

g

RUDDER

(GWS PICO, NARO

Series

Servos)

(GWS PICO, NARO

•AILERON

mm

ELEVATOR

(GWS PICO, NARO

Series

Servos)

(GWS

PICO,

NARO

(Bl)

fA

MMsm

(mm^)

RADIO

GEAR

INSTALLATION

WIRING

AND

CONNECTION

USER'S

CUIDE

i

A'

CAUTION:

Please

read

the

instruction

careful

before

installation.

Please

follow

the

scheme

showing

wiring

diagram

to

connect

the

wire

and

be

sure

the

servo

are

in

neutral

position.

When

you

are

testing

the

servo,

please

do

not

connect

the

motor

wire

and

be

sure

to

turn

on

the

transmitter

first.

^ •

It;

V

Mounting the receiver and

speed

controller with double-side

adhesive tapes. (Pic.50-55) , EDF-55x2 (Pic.56)

Applyenough glue to the grooves , then place the wire over

the

hole. (Pic.57.58)

Ative 5 min Epoxy glue fixed. (Pic.59,6G)

Remove two

excess

plastic parts of the battery hatch, than

Slidethe speed controllerconnecter to the

hollow

for battery

connecting. (Pic.61,62,63,64,65)

Gluethe battery hatch

with

GWSglue or

EPOXY

ifnecessary.

(Pic.61~65)

Ailleron push rod (Pic.66)

Hook the push rod (Z

shape)

to the servo horn and fixthe horn

with

screw.

(Pic.67)

_ ^

I

w

SQli/m

=(•50-55)

ffiaiMMEDF-55

(^56)

°(H57-6O)

iij«;1i3lis

' - fflABlPififfi »

(•61-63)

(^64)

Jtatf

$§ (•65)

°(B66,67)

Spray

Paint

Bm

}m

im

PAINTING

1. Ifyou

choose

un-painted version,

please

refer

these

steps

to paint your P-51D.

2. (1)

Choose

emulsion

paint

suitable

for

the

polystyrene.

(2) Before painting, wipe all

surfaces

of the

fuselage,

wing, stabilizer

and

fin with

medical

alcohol

and

remove

any

oil,

dust,

dirt

etc.

(3) For

best

results,

holding

the

can

about

20cm

away

from

the

surface.

Remember,

to

use

as

little

paint

as

possible

to

complete

coverage,

because

extra

paint

Is

extra

weight.

WARNING:

(1) Always

test

the paint for compatibility on a small

area

before

proceeding

to

paint

the

entire

surface.

(2) Always

paint

In a weil-ventilated

area.

1

- 8

ivj

HI

II—

1.

2. (1) °

(2)

Rif

-

(3)

l«i®KHII«llBif»®»(!iB5nHFJSi20cm

w,mm

• •

sStaisBiiS-ig*

esii

•

sas-te

•

(2)

iii!sa§aans$«ijfta«iiff

•

iMtsSoBOsStE

RADIO

SETTING

USERS

CUIDE

i

CONTROLLER

FUNCTION

AND

RADIO

SET-UP

MODE

2

•The right side stick of

the

transmitter (elevator

and

aileron)

•

The

left

side

stick of

the

transmitter (throttle

and

nose

steering)

ELEVATOR

TEST

• Pull

the

stick

backward

then

the

elevator

should

flip up ( pull-up).

•

Push

the

stick forward

then

the

elevator

should flip down (pushing down).

•

When

the

stick

is in

neutral

,

the

elevator

should

return

to

neutral

position.

AILERON

TEST

•

Moving

the stick to right, then the right side aileron should

flip

up and the left side

aileron

should

flip

down.

•Moving the stick to left, then the right side aileron should

flip

down and the left side

aileron

should

flip up.

•

When

the

stick

is in

neutral

,

the

two

ailerons

should

return

to

neutral

position.

THROTTLE

TEST

• Pull

the

stick all

the

way

backward

and

the

trimmer

at

the 1/3 position ,then wait for 2

seconds.

• Slowly

push

the

stick forward

and

the

power

system

starts

to run. Now

push

the

throttle all

the

way

forward

and

the

motor

should

run athigh

speed.

• Pull

the

stick all

the

way

backward

and

the

motor

should

stop.

NOSE

STEERING

TEST

• Moving

the

stick to

right,

the

nose

steering

should

turn to

the

right.

• Moving

the

stick to

left,

the

nose

steering

should

turn to

the

left.

•

When

the

stick is in

neutral

,

the

nose

steering

should

return to

neutral

position.

MODE

1

•

The

right

side

stick of

the

transmitter

(throttle

and

aileron)

•

The

left

side

stick of

the

transmitter

(elevator

and

nose

steering)

• If

the

control fin

or

throttle is not on

the

correct

movement,

please

switch

the

reverse

on

the

transmitter.

(SUGGEST

CONTROL

THROW

SETTING)

Down

(1)Elevator (2)Aileron

- 9 -

(3)Nose

Steering

8-1

Omm

8-1

Omm

PrefUght

Checking

List

USER'S

GUIDE

M

&§

bR

Bff

i

1. It is

best

for

you

to fly

your

plane

in a

large

open

place.

2. Do

not

fly

around

some

restricted location like airports, military

bases,

etc.

3. You

will

need

to

range

check

the

transmitter to be

sure

you

are

not experiencing any interference. (Ifyou

are

flying with other RC modeler at a field, do not turn on your transmitter until you

are

certain that no

one

else

is

using

your

channel.)

4. Always turn on

the

receiver

last after turning on

the

transmitter

and

shut

off

the

receiver

first before turning off

the

transmitter.

5. Ifyou

are

only a beginner to the radio control model

flying,

do not attempt to fly your model without any

assistance

or

advice

from

advanced

expert

fliers.

6.

Please

refer to

the

instruction guide carefully

and

thoroughly before assembling equipment kits. Different

power units

and

servos

combination

will

lead to its various flight performance.

Remember

the

lighter

the

better.

7.Watch

the

wind

direction.

Hill

Wind

Direction

TAKE

OFF

1. Apply full throttle to

speed

up

the

airplane

against

the

wind.

2. Keep

the

tracking straight using

the

tail

steering

during

the

take-off

process.

3. Apply

just

a

touch

of

up-elevator

when

the

model

reaches

sufficient

takeoff

speed

and

the

model

lifts

smoothly

into

the

air.

4. Make

the

turn

when

the

model

is

at

a high altitude.

Then

the

trim all control

surfaces

to

achieve

the

level flight.

\r

nil

Wind

Direction

LANDING

1. Gradually reduce the throttle during the

final

pattern for speed down the airplane.

2. Slightly touch up-elevator to maintain a smooth ratio ofthe descendent process.

Do not apply too much up-elevator otherwise the plane may go into a stall.

3. Make a

final

turn against the windand heading to the runway.

4.When the altitude approximately 30cm from the ground, pulla

little

more

up-elevator

and

let

the

airplane nose-up

and

touch- down.

•11-

HurnJimmm

Preflight

Checking

List

m

^ il

tssij

r^'^^-faa

Uf:

J^:

P•1 G0S

ft

J-

/<iii

SRS

^

'-vi

Please

Note:

Below

photos

show

stick position using a

Mode

1transmitter.

Mode

2

transmitters

used

in

the

U

.S.

market

will

have

throttle

control on

the

left

and

aileron/elevator

control on

the

right. ^

•

Turn

on

your

transmitter.

•

Place

the

battery

in to

the

battery

compartment

of

fuselage.

•

Connect

power

wires

and

turn

on

the

receiver.

• Puil

down

the

throttle to

the

lowest

position

and

also

the

micro

adjustment

to

the

minimum.

The

motor

should

in

neutral

position

and

no

operation.

•

Push

up

the

throttle stick slowly

and

watch

the

reaction

of

the

motor.

The

motor

should

run from low to full throttle

as

you

adjust

the

stick

upward.

•

Stick

move

to left,

the

left

side

aileron

on

the

airplane

will

move

up,

and

right

side

aileron

move

down.

Stick

location on

the

transmitter

varies

by

mode.

• Aileron stick

move

to right.

The

right

side

aileron on

the

airplane

will

move

up

and

left

aileron

move

down.

•Stick in neutral position. All aileron on

the

airplane

should

return to neutral.

If

the

movement

of aileron

are

working in

opposite

direction,

please

switching

the

aileron

reverse

switch

on

the

transmitter.

•Moving

the

stick

to

the

left

should

move

the

rudder

to

the

left.

• Moving the stick to the right should move the rudder to the right.

• Moving

the

stick down should move

the

elevator

up.

•Moving

the

stick

up

should

move

the

elevator

down.

•

When

the

stick

is in

neutrai,

the

elevator

should

return

to

neutral.

-13-

USER'S

CU/DE

mS§SRBHi

GWS

ft

-GWS-jSl-^#

,

H.-3

••

ih»fi..^.*

W - #

ilit

°

•

[liiJIEfilBt'

iiJKHIllS

ff'

siysiiji^i"

iM'F"

•

[s]gyiEfii0f'

mmmm

%•

SLOPE

GLIDER

(H1-28)

"

(180)

(•51-55,81)

Hf

(B82)

mmwm

(B83) °(•84,85)

gija)ti3iis'

>

mmAm^

•>

(•86,8?)

Please see page three and

four

stabilized

fin

and

cabin

hatch

instaiiation.

(Pic.

1-28)

Apply

epoxy

glue

onthe

cabin

hatch

tothefuselage.

(Pic.80)

Remove twoexcess plastic parts ofthe battery hatch, than

Slide

the

speed

controlier

connecter

to

the

hollow

for

battery

connecting.

(Page.7,

Ailleron

push

rod

(Pic.82,83)

Pic.5i-

Hook

the

push

rod

(Z

shape)tothe

servo

horn

and

fix

the

horn

with screw. (Pic.84,85)

Glue

the

battery

hatch

with

GWS

glue

or

instant

glue

if

necessary.

(Pic.86,87)

PHFUS-1021--W-:~

Fuselage

:

• .

PMSPC-1020—C-

B2ffiaMS(K) X1poe.

» . B-2 Hatch (Glay)

•

•••••

•

.....

,

..,.

PMSPC-1020—A-

B2

x2p'

Glay)

PHFUS-1021--W-R

Main

Wing(Rlght

Side)

B2MHS^(0)

PHFUS-1021-W-L

Main

Wlng{Left

Side)B2^^^M(S.)^

Pic.51-55,

81)

PYCRD-1001

10x18?gM>n

Hinge (15 in1)

PMSPC-1002

gas®

Sin

ABS(1x8x8mm)

cowling

Seat

x 12 pcs.

PTMEW-1026

slmm(iiJM®liw) x2pcs

PVPEF-1060

B2iJP)igi^(H)

X2pcs.

B-2

Plasticarticulated

(Glay)

PXTPAF-4J-1490R

•V-

M^4ife^M1.4*9mmTPA

-14-

PMSTD-1007—

Battery

Seat

XI

pee

I

jVj

^

b'

PMSPC-1001—

PICO STICK

E^II(A)

Plastic

Parts

Frame

"A"x1

set

8ADHP1003—-

GWS

Glue

X 1

pee

wngp

n

PTCUS-1016

411

Double-sided

Foam

^5

V 4

n^c

' V"

Tape

X4

pcs

/