Page is loading ...

Instruction

Manual

6909_002-173e-02.22

Pressure Pulse

Generator

Type 6909

Page 1

6909_002-173e-02.22

Thank you for choosing a Kistler quality product

characterized by technical innovation, precision and long

life.

Information in this document is subject to change without

notice. Kistler reserves the right to change or improve its

products and make changes in the content without

obligation to notify any person or organization of such

changes or improvements.

© 2021 ... 2022 Kistler Group. Kistler Group products are

protected by various intellectual property rights. For more

details visit www.kistler.com. The Kistler Group includes

Kistler Holding AG and all its subsidiaries in Europe, Asia,

the Americas and Australia.

Kistler Group

Eulachstrasse 22

8408 Winterthur

Switzerland

Tel. +41 52 224 11 11

info@kistler.com

www.kistler.com

Foreword

Foreword

Pressure Pulse Generator

6909_002-173e-02.22Page 2

Contents

1. Introduction .................................................................................................................................3

2. Hints on the use of these Operating Instructions ....................................................................4

3. General description of the equipment ......................................................................................5

4. Operation .....................................................................................................................................7

4.1 General information ............................................................................................................7

4.2 Start-up ...............................................................................................................................7

4.3 Location ..............................................................................................................................8

4.4 Performing drop tests .........................................................................................................8

4.5 Exchanging the adapter ......................................................................................................8

4.6 Supporting the drop weight .................................................................................................9

4.7 Limiting the drop height ......................................................................................................9

5. Operating faults, notes .............................................................................................................10

5.1 Air inclusions ....................................................................................................................10

5.2 Defective seal ...................................................................................................................10

6. Equipment supplied ..................................................................................................................12

6.1 Accessories available .......................................................................................................12

7. Technical data ...........................................................................................................................13

Total pages 13

Introduction

Page 3

6909_002-173e-02.22

1. Introduction

Thank you for choosing a quality product from Kistler.

Please read through this manual thoroughly to enable you

to fully exploit the various features of your product.

To the extent permitted by law Kistler accepts no liability

if this instruction manual is not followed or products other

than those listed under Accessories are used.

Kistler oers a wide range of measurement products

through to turnkey solutions:

Piezoelectric sensors for measuring pressure, force,

torque, strain, acceleration, shock and vibration

Strain gage sensor systems for measuring force and

torque

Piezoelectric pressure sensors and transmitters with

matching measuring ampliers

Matching measuring ampliers (charge ampliers,

piezoresistive ampliers, etc.), displays and charge

calibrators

Electronic control, monitoring and evaluation units as

well as software for specic measurement applications

Data transmission modules (telemetry)

Kistler also develops and produces measuring solutions

for the application elds engines, vehicles, manufacturing,

plastics and biomechanics sectors.

Our product and application brochures will provide you

with an overview of our product range. Detailed data

sheets are available for almost all products.

If you need additional help beyond what can be found

either on-line or in this manual, please contact Kistler‘s

extensive support organization.

Pressure Pulse Generator

6909_002-173e-02.22Page 4

2. Hints on the use of these Operating Instructions

These instructions describe the pressure pulse generator

Type 6909.

Please keep these operating instructions in a safe place

where you can retrieve them at any time.

The current version of this document may be downloaded

from Kistler.com

Details and information in these instructions are subject to

change at any time without prior notice.

General description of the equipment

Page 5

6909_002-173e-02.22

3. General description of the equipment

Equipment for the generation of pressure pulses from

about 25 to 5 000 bar. The pressure pulse generator can

be used to test pressure sensors dynamically without

complication. Compared with static calibration, the

sensors are exposed only briey to a high pressure.

Pressure is generated by means of a dropping weight

which drops onto the piston of an oil-lled pressure

chamber. The pressure pulse thereby produced acts

on the sensors screwed into the pressure chamber

(adapter).

The dropping weight is inserted into a tube and, by

means of a lifting device with a scale, is raised by hand to

the desired dropping height and allowed to drop.

The pressure chamber consists of a piston-cylinder unit

and an interchangeable adapter with 2 mounting holes for

Kistler pressure sensors.

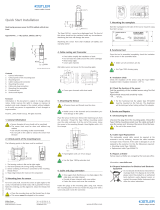

Fig. 1: Pressure pulse generator

Pressure Pulse Generator

6909_002-173e-02.22Page 6

Fig. 2: Main dimensions

Main parts:

1 Base plate 218 x 190 x 28

2 Spacer D65 x 30

3 Adapter 6931A...

4 Piston-cylinder unit

5 Drop tube base D85 x 20

6 Drop weight

7 Drop tube D85/80 x 460

8 Handle D28, black

28

58

572

25

40

86

218

/190

27

8

6

7

2

1

5

4

3

Operation

Page 7

6909_002-173e-02.22

4. Operation

4.1 General information

For pressure pulses up to about 500 bar, only the

aluminum rod is used as drop weight (Kistler Material

65013682).

For pressure pulses > 500 bar, the drop weight of 5,4 kg

is used (Kistler Material 65013680).

NOTE

For sensors with a pressure range < 500 bar, the drop weight

of 5,4 kg must not be used, otherwise there is a risk that the

sensor will be overloaded or even damaged beyond repair!

4.2 Start-up

Tilt the generator horizontal so that the mounting holes

of the adapter point upwards.

Screw in reference sensor with prescribed torque into

adapter Type 6931A...

Turn the generator 180° through its axis so that the

opposite mounting hole is on top.

Check that the piston is pressed fully downwards. If

not, slide the piston with the drop weight downwards.

Fill oil (Type 1053) into the hole with a pipette until the

thread is completely covered.

Gradually screw the test sensor by hand completely

into the adapter Type 6931A. The pressure produced

automatically slides the piston upwards into the correct

position. Remove excess oil.

Unscrew the test sensor and ll once more with oil

until about 1/3 of the thread is covered.

Gradually screw in the test sensor to vent the

remaining air and tighten to the prescribed torque.

Bring the generator into the vertical operating position.

Unscrew the drop tube cover and insert the drop

weight into the drop tube.

- For pressure pulses up to about 500 bar, t the

insert with the aluminum rod into the drop tube.

- For pressure pulses > 500 bar, screw the drop

weight onto the thread of the lifting device (steel

bar) and insert the drop weight into the drop tube.

Connect measuring chain.

Pressure Pulse Generator

6909_002-173e-02.22Page 8

4.3 Location

To obtain ideal operation, i.e. max. pressures, shortest

pulse duration and good recoil of the drop weight, the

pressure pulse generator must be set up on a at and

hard base (e.g. steel plate, concrete oor).

Good recoil allows the weight to be caught again with the

hand after the initial impact on the piston.

4.4 Performing drop tests

The pressure generated is not proportional to the drop height,

i.e. even very low drop heights produce high pressure, and

the pressure rises only slightly with increasing drop height.

It is therefore advisable to begin testing with very low drop

heights and gradually to increase the drop height.

WARNING

If pressure sensors with a pressure range of < 5 000 bar are

used, there is a danger when using the drop weight (5,4 kg)

that the permissible pressure range will be exceeded and the

sensors damaged beyond repair.

Pressure sensors with a pressure range of < 500 bar must not be

tested with the drop weight 5,4 kg but only with the aluminum rod.

With pressure sensors with a pressure range of up to 250 bar,

testing must be started with a drop height of not more than 5 cm.

4.5 Exchanging the adapter

Unscrew the 4 hexagonal slot screws M4 at the base

of the drop tube.

Remove drop tube and drop weight.

Unscrew the 4 hexagonal slot screws M8.

Remove the drop tube base

Withdraw the piston-cylinder unit from the adapter.

Fit new seal Type 1101B in the adapter and push

together with the piston-cylinder unit. It is advisable

to apply a light lm of grease to the tting surface to

increase adhesion between the parts.

Slide the piston up to the limit stop in the adapter.

Then t the adapter and piston-cylinder unit onto the

intermediate adapter.

Place the drop tube base in position, screw in the

4 x M8 hexagonal slot screws by hand and then

tighten them with the wrench in stages by tightening

opposite pairs of screws in turn until all screws are

fully tightened.

Fit the drop tube and screw in position.

Operation

Page 9

6909_002-173e-02.22

4.6 Supporting the drop weight

Insertion of the support ring (Kistler Material 65000013)

between handle and drop tube cover ensures that the

drop weight does not rest on the piston and cause oil to

be squeezed out of the pressure chamber.

4.7 Limiting the drop height

In order to protect the sensors against overload, the

drop height of the 5,4 kg drop weight can be limited by

clamping a circlip (Kistler Material 65013337) as a limit

stop on the piston rod.

Unscrew the 4 hexagon screws M4 in the drop tube

cover

Remove the drop tube cover and piston rod

Ax the circlip in the corresponding notch in the piston

rod.

Mount the drop tube and screw in position.

Pressure Pulse Generator

6909_002-173e-02.22Page 10

5. Operating faults, notes

5.1 Air inclusions

Air inclusions in the pressure chamber cause pressure

uctuations during the pressure rise.

Remedy:

Dismantle the test sensor, top up with oil and screw the

sensor back in as described in paragraph 4.2.

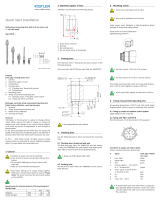

Fig. 3: Pressure curve with air inclusion

5.2 Defective seal

If the drop weight strikes without producing pressure after

only a few strikes (5 ... 10), then the seal Type 1101B of

the piston-cylinder unit or that of the sensor is damaged.

A leaking system can also be recognized by a pressure

curve which is not sinusoidal.

Remedy:

Exchange defective seal.

Operating faults, notes

Page 11

6909_002-173e-02.22

Fig. 4: Pressure curve with leaking seal Type 1101B

In order to obtain max. pressure pulses, the drop weight

must slide smoothly in the tube. If there is a noticeable

resistance in the movement of the drop weight, the piston

must be lubricated with oil.

Continuous loading of the piston by the drop weight will

cause oil loss. The drop weight should therefore not be

allowed to remain resting on the pressure piston for a

lengthy period.

Pressure Pulse Generator

6909_002-173e-02.22Page 12

6. Equipment supplied

High pressure oil Type 1053

Klüber grease Type 1063

10 seals Type 1101B

Seeger circlip pliers 65007815

Support ring 65000013

Pipette 65007816

Wrench SW3 65007763

Wrench SW8 65007817

Drop weight up to 5 000 bar 65013680

Drop weight up to 500 bar 65013682

5 x circlips 65013337

6.1 Accessories available

Working standard Type 6213B

Adapter M12x1/M10x1 shoulder seal 6931A1/18006807

Adapter M12x1/M10x1 front seal 6931A2/18006808

Adapter M12x1/M12x1 6931A3/18006809

Adapter M14x1.25/M14x1,25 6931A4/18006810

Adapter M14x1.25/M10x1 6931A5/18006811

Adapter M10x1/M10x1 6931A6/18006812

Adapter M7x0.75 (4pc.) 6931A7/18033741

Adapter M12x1/M10x1 6931A8/18036713

Adapter M12x1/3/8-24UNF 6931A9/18036714

Technical data

Page 13

6909_002-173e-02.22

7. Technical data

Range bar 25 ... 5 000

Pulse width ms 5 ... 10*

Drop weight 25 ... 500 bar

500 ... 5 000 bar

g

g

130

5 400

Oil volume cm30,5

Pressure transmission

(by hydraulic oil)

Type 1053

Weight kg 14,6/19

Total height mm ≈ 600

Width mm ≈ 218

Drop tube diameter mm 86

Drop height mm ≤ 320

* Pulse width is dependent on the adapter

8. Warranty

Regarding the warranty reference is made to the

agreement between the respective contracting parties.

/