Page is loading ...

March

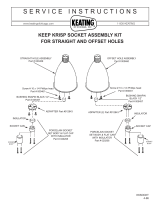

1977

FORM:

OM-853

HLE

COPY

RETURN

TO

FOL1~R

MODEL

RCMP-1

1

STOCK

NO.

000

461

MODEL/STOCK

NO.

SERIAL/STYLE

NO.

DATE

PURCHASED

ADDITIONAL

COPY

PRICE

25

CENTS

OWNERS

MANUAL

MILLER

ELECTRIC

MFG.

CO.

APPLETON,

WISCONSIN,

USA

54911

Ito

I)

S

~

NWSA

CODE

NO.

4579

L~~P

L

~

~

~

~

~

LIMITED

WARRANTY

EFFECTIVE:

NOVEMBER

1,

1976

This

warranty

supersedes

all

previous

MILLER

warranties

and

is

ex

clusive

with

no

other

guarantees

or

warranties

expressed

or

implied.

LIMITED

WAR.RANTYMifler

Electric

Mfg.

Co.,

Apple-

I.

Arc

welders,

power

sources,

and

components

.

..

1

year

ton,

Wisconsin

warrants

to

Customer

that

all

new

and

unused

2.

Original

main

power

rectifiers

3

years

*

Equipment

furnished

by

Miller

is

free

from

defect

in

workman-

(Labor

1

year

only)

ship

and

material

as

of

the

time

and

place

of

delivery

by

Miller.

3.

All

welding

guns

and

feeder/guns

90

days

No

warranty

is

made

by

Miller

with

respect

to

engines,

trade

accessories

or

other

items

manufactured

by

others.

Such

engines,

4.

All

other

Millermatic

Feeders

1

year

trade

accessories

and

other

items

are

sold

subject

to

the

warran-

provided

that

the

user

so

notifies

Miller

in

writing

within

thirty

)

~#

ties

of

their

respective

manufacturers,

if

any.

At

the

present

time,

(30)

days

of

the

date

of

such

failure.

the

manufacturers

warranty

on

the

Mag-Diesel

engine

on

DEL

200

is

limited

to

sj.x

months

and

on

all

other

engines

to

one

year.

5.

Replacement

or

repair

parts

exclusive

of

labor

.

60

days

MILLER

warranty

does

not

apply

to

components

having

ANY

EXPRESS

WARRANTY

NOT

PROVIDED

HEREIN

d

normal

useful

life

of

less

than

one

(1)

year,

such

as

spot

welder

AND

ANY

IMPLIED

WARRANTY,

GUARANTY

OR

REP-

tips,

relay

and

contactor

points,

MILLERMATIC

parts

that

RESENTATION

AS

TO

PERFORMANCE,

AND

ANY

come

in

contact

with

the

welding

wire

including

nozzles

and

REMEDY

FOR

BREACH

OF

CONTRACT

WHICH,

BUT

nozzle

insulators

where

failure

does

not

result

from

defect

in

FOR

THIS

PROVISION,

MIGHT

ARISE

BY

IMPLICA-

~

workmanship

or

material.

TION,

OPERATION

OF

LAW

CUSTOM

OF

TRADE

OR

In

the

case

of

Millers

breach

of

warranty

or

any

other

duty

COURSE

OF

DEALING,

IN~LUDING

ANY

IMPLIED

with

respect

to

the

quality

of

any

goods,

the

exclusive

remedies

WARRANTY

OF

MERCHANTABILITY

OR

OF

FITNESS

therefor

shall

be,

at

Millers

option,

(1)

repair

or

(2)

replace-

FOR

PARTICULAR

PURPOSE,

WITH

RESPECT

TO

ANY

AND

ALL

EQUIPMENT

FURNISHED

BY

MILLER

IS

)

ment

or,

where

authorized

in

writing

by

Miller

in

appropriate

EXCLUDED

AND

DISCLAIMED

BY

MILLER.

cases,

(3)

the

reasonable

cost

of

repair

or

replacement

at

an

authorized

Miller

service

station

or

(4)

payment

of

or

credit

for

EXCEPT

AS

EXPRESSLY

PROVIDED

BY

MILLER

IN

the

purchase

price

(less

reasonable

depreciation

based

upon

WRITING,

MILLER

PRODUCTS

ARE

INTENDED

FOR

actual

use)

upon

return

of

the

goods

at

Customers

risk

and

CX-

ULTIMATE

PURCHASE

BY

COMMERCIAL/INDUS

pense.

Upon

receipt

of

notice

of

apparent

defect

or

failure,

TRIAL

USERS

AND

FOR

OPERATION

BY

PERSONS

Miller

shall

instruct

the

claimant

on

the

warranty

claim

proce-

TRAINED

AND

EXPERIENCED

IN

THE

USE

AND

dures

to

be

followed.

MAINTENANCE

OF

WELDING

EQUIPMENT

AND

NOT

As

a

matter

of

general

policy

only,

Miller

may

honor

an

origi-

FOR

CONSUMERS

OR

CONSUMER

USE.

MILLER

nal

users

warranty

claims

on

warranted

Equipment

in

the

event

WARRANTIES

DO

NOT

EXTEND

TO,

AND

NO

RE-

of

failure

resulting

from

a

defect

within

the

following

periods

SELLER

IS

AUTHORIZED TO

EXTEND

MILLERS

WAR-

from

the

date

of

delivery

of

Equipment

to

the

original

user:

RANTIES

TO,

ANY

CONSUMER.

~b

d~-.

...Jt.

.~

J~,,

.b

,5~b

~

/

SECTION

1

-

INTRODUCTION

1-1.

GENERAL

This

manual

has

been

prepared

especially

for

use

in

familiar

izing

personnel

with

the

design,

installation,

operation,

main

tenance,

and

troubleshooting

of

this

equipment.

All

informa

tion

presented

herein

should

be

given

careful

consideration

to

assure

optimum

performance

of

this

equipment.

1-2.

RECEIVING-HANDLING

Prior

to

installing

this

equipment,

clean

all

packing

material

from

around

the

unit

and

carefully

inspect

for

any

damage

that

may

have

occurred

during

shipment.

Any

claims

for

loss

or

damage

that

may

have

occurred

in

transit

must

be

filed

by

the

purchaser

with

the

carrier.

A

copy

of

the

bill

of

lading

and

freight

bill

will

be

furnished

by

the

carrier

on

request

if

occasion

to

file

claim

arises.

When

requesting

information

concerning

this

equipment,

it

is

essential

that

Model

Description

and/or

Stock

Number

and

Serial

(or

Style)

Numbers

of

the

equipment

be

supplied.

1-3.

DESCRIPTION

This

unit

is

a

multi-purpose

remote

control

which

is

designed

specifically

for

use

with

the

Gas

Metal-Arc

(GMAW)

Welding

process.

This

unit

will

provide

two

welding

conditions

on

one

wire

using

one

control/feeder

and

one

welding

power

source.

~lt

i-pu

rpose

rem

o~

co

ntrol

w

ill

he

reaf

tar

be

referred

to

in

this

manual

as

the

Remote

Control

1-4.

SAFETY

The

following

definitions

apply

to

CAUTION,

IMPORTANT,

and

NOTE

blocks

found

throughout

this

manual:

~(EiUIl1

Under

this

heading,

installation,

operating,

and

main

tenance

procedures

or

practices

will

be

found

that

if

not

carefully

followed

may

create

a

hazard

to

per-

I

sonnel.

I

E~TA~I

1~

Under

this

heading,

installation,

operating,

and

main

tenance

procedures

or

practices

will

be

found

that

if

not

carefully

followed

may

result

in

damage

to

equip

ment.

NOTE

Under

this

heading,

explanatory

statements

will

be

found

that

need

special

emphasis

to

obtain

the

most

efficient

operation

of

the

equipment.

SECTION

2-

INSTALLATION

2-1.

REMOTE

VOLTAGE

CONTROL

CONNECTIONS

(Figure

3-1)

The

Voltage

Control

plug

connects

the

Remote

VOLTAGE

CONTROL

to

the

welding

power

source

voltage

adjustment

circuitry.

Insert

the

three-pole,

twistlock

plug

from

the

Remote

Control

into

the

welding

power

source

Voltage

Control

receptacle

and

rotate

the

plug

clockwise

as

far

as

possible.

ote

Co

nt

rol

of

the

vo

Itage

is

d

esired

,

it

is

essential

that

the

welding

power

source

VOLTAGE

CONTROL

switch

be

placed

in

the

REMOTE

position

2-2.

REMOTE

WIRE

SPEED

CONNECTIONS

(Figure

3-1)

The

Wire

Speed

plug

connects

the

Remote

WIRE

SPEED

control

to

the

control/feeder

wire

speed

circuitry.

Insert

the

six-pin

plug

from

the

Remote

Control

fully

into

the

control/

feeder

Wire

Speed

receptacle.

2-3.

REMOTE

CONDITION

SELECTOR

CONNECTIONS

(Figure

3-1)

The

two-pole

twistlock

plug

originating

at

the

control/feeder

must

be

connected

to

the

Condition

Selector

receptacle

on

the

Remote

Control

to

enable

CONDITION

A

or

B

selection.

Insert

the

plug

into

the

receptacle

and

rotate

it

clockwise

as

far

as

possible.

SECTION

3

-

FUNCTION

OF

CONTROLS

3-1.

CONDITION

A

AND

B

VOLTAGE

CONTROLS

(Figure

3-1)

The

CONDITION

A

and

B

VOLTAGE

CONTROLS

provide

voltage

selection

within

the

welding

power

source

load

voltage

range

being

used.

Either

the

CONDITION

A

or

CONDITION

B

VOLTAGE

CONTROL

will

be

active

depend

ing

on

the

position

of

the

Condition

Selector

switch.

Rotating

the

controls

clockwise

increases

the

load

voltage.

NOTE

The

VOLTAGE

CONTROLS

may

be

adjusted

while

welding.

The

scales

surrounding

the

VOLTAGE

CONTROLS

are

calibrated

in

percentage

and

should

not

be

misconstrued

as

amperage

or

voltage

readings.

It

is

recommended

that

the

meters

be

read

whenever

it

is

necessary

to

know

the

amperage

and

voltage

output.

3-2.

CONDITION

A

AND

B

PILOT

LAMPS

(Figure

3-1)

With

the

welding

power

source

energized

and

with

the

Condition

Selector

in

a

position

corresponding

to

either

Condition

A

or

Condition

B,

the

CONDITION

A

or

CONDITION

B

pilot

lamp,

respectively,

will

be

illuminated.

3-3.

CONDITION

A

AND

B

WIRE

SPEED

CONTROLS

(Figure

3-1)

The

CONDITION

A

and B

WIRE

SPEED

controls

adjust

the

wire

feed

speed.

Either

the

CONDITION

A

or

CONDITION

B

WIRE

SPEED

control

will

be

active

depending

on

the

position

of

the

Condition

Switch.

Rotating

the

controls

clockwise

increases

the

wire

speed.

NOTE

The

WIRE

SPEED

controls

may

be

adjusted

while

1

i

welding.

OM-853

Page

1

The

scales

surrounding

the

WIRE

SPEED

controls

are

calibrated

in

percentage

and

should

not

be

misconstrued

as

amperage

or

voltage

readings.

It

is

recommended

that

the

meters

be

read

whenever

it

is

necessary

to

know

the

amperage

and

voltage

output.

Wire

Speed

Plug

SECTION

4

-

SEQUENCE

OF

OPERATION

TB-009

496

Legend

1

W

Welding

Power

Source

R

Remote

Control

Unit

S

Dual

Schedule

Switch

CF

Control/Feeder

Figure

4-1.

Gas

Metal-Arc

Welding

Connections

Condition

A

Voltage

Control

Condition

A

Pilot

Lamp

Condition

B

Voltage

Control

Ion

A

Wire

Speed

Control

Condition

B

Wire

Speed

Control

Figure

3-1.

Connectors

And

Controls

Condition

Selector

Condition

Selector

Receptacle

&

Plug

Receptacle

&

Plug

CF-RC4

CF-RC3

S

-

PIG1

:eeder/

CF

PLG4/

~Switch

(Mounted

Condition

Selector

_______________

______

On

Gun)

Condition

Selector

Receptacle

&

Plug

R

-

RC1

CF

-

PLG7

Page

2

4-1.

GAS

METAL-ARC

(GMAW)

WELDING

(Figure

4-1)

1.

Make

necessary

electrical

and

mechanical

connections

to

the

welding

power

source,

control/feeder,

and

gun

as

outlined

in

the

welding

power

source

manual,

control/feeder

manual,

and

gun

manual,

respectively.

2.

Make

Remote

VOLTAGE

CONTROL

connections

as

outlined

in

Section

2-1.

3.

Make

Remote

WIRE

SPEED

connections

as

outlined

in

Section

2-2.

4.

Make

Condition

Selector

connections

as

outlined

in

Section

2-3.

5.

Place

the

welding

power

source

LOAD

VOLTAGE

RANGE

switch

in

the

desired

position.

Due

to

the

circuitry

limitations

of

the

Remote

Control,

the

welding

power

source

may

not

be

used

in

the

MEDIUM

range

while

using

the

Remote

Control.

It

will

be

necessary,

therefore,

to

place

the

welding

power

source

LOAD

VOLTAGE

RANGE

switch

in

either

LOW.

HIGH,

or

WIDE

RANGE

when

using

the

Remote

Control.

NOTE

If

the

gun-mounted

Condition

Selector

switch

(option

al

equipment)

is

employed,

both

contactor

and

weld

ing

condition

control

are

provided.

This

switch

has

essentially

three

positions.

1.

In

the

first

switch

position,

to

which

the

switch

automatically

returns

if

no

switch

lever

pressure

is

applied,

the

welding

power

source

contactor

is

not

energized.

2.

In

the

second

switch

position,

which

is

obtained

by

depressing

the

switch

lever

about

half

way

down,

the

welding

power

source

contactor

is

energized

and

the

Remote

Control

is

placed

in

the

CONDI

TION

A

position.

3.

In

the

third

switch

position,

which

is

obtained

by

depressing

the

switch

lever

all

the

way

down,

the

welding

power

source

contactor

is

retained

in

an

energized

state

and

the

Remote

Control

is

placed

in

the

CONDITION

B

position.

Switching

the

Remote

Control

from

CONDITION

A

to

CONDITION

B

(or

from

CONDITION

B

to

CONDITION

A)

can

be

accomplished

by

varying

the

amount

of

pressure

applied

to

the

switch

lever.

4-2.

SHUTTING

DOWN

1.

Break

the

arc.

2.

Allow

the

welding

power

source

to

idle

for

3

minutes

with

no

load

applied.

3.

Place

the

welding

power

source

Power

switch

in

the

OFF

position.

Since

the

Remote

Control

derives

its

operating

power

from

the

welding

power

source,

the

Remote

Control

will

also

be

de-energized

when

the

welding

power

source

is

de-energized.

4.

Place

the

control/feeder

Power

Switch

in

the

OFF

position

if

the

control/feeder

is

provided

with

operating

power

external

to

the

welding

power

source.

5.

Turn

off

the

shielding

gas,

if

used,

at

the

shielding

gas

source.

CAUTION

I

U

If

welding

is

performed

in

a

confined

area,

failure

to

turn

off

the

shielding

gas

supply

could

result

in

a

build

up

of

gas

fumes,

thereby

endangering

personnel

reentering

the

welding

area.

I I

6.

Rotate

the

CONDITION

A

VOLTAGE

CONTROL

and

WIRE

SPEED

control

to

the

desired

setting.

7.

Rotate

the

CONDITION

B

VOLTAGE

CONTROL

and

WIRE

SPEED

control

to

the

desired

setting.

I

Prior

to

welding,

it is

imperative

that

proper

protective

clothing

(welding

coat

and

gloves)

and

eye

protection

(glasses

and/or

welding

helmet)

be

put

on.

Failure

to

comply

may

result

in

serious

and/or

permanent

bodily

damage.

U

I

8.

Turn

on

the

shielding

gas

supply,

if

used.

9.

Energize

the

welding

power

source

and

control/feeder.

Commence

welding.

10.

Welding

Condition

A

or

B

may

be

achieved

by

placing

the

Condition

Selector

in

the

position

corresponding

to

Condition

A

or

Condition

B,

respectively.

NOTE

L

CONDITION

A

and/or

B

VOLTAGE

CONTROL

and/or

WIRE

SPEED

control

may

be

adjusted

while

welding

to

achieve

optimum

welding

conditions.

OM-853

Page

3

~0

0)

Co

cv

AMPHENOL

PLUG

TO

WIRE

FEEDER

REMOTE

CONTROL

RECEPTACLE

GR-GROUND

TO

WELDING

MACHINE

PLG2

REMOTE

CONTROL

RECEPTACLE

C-COPPER

B-BRASS

Circuit

Diagram

No.

CA-DOD

461-lA

27

C

II

Ii

SHI

ELD

~1

1

II

II

~

>E

I

1

A

Figure

4-2.

Circuit

Diagram

March

1977

FORM:

OM-853

MODEL

RCMP-11

STOCK

NO.

000461

MODEL/STOCK

NO.

SERIAL/STYLE

NO.

DATE

PURCHASED

PARTS

LIST

MILLER

ELECTRIC

MFG.

CO.

APPLETON?

WISCONSIN,

USA

54911

NWSA

CODE

NO.

4579

Item

Dia.

Factory

No.

Mkgs.

Part

No.

Figure

A

Complete

Assembly

Description

Quantity

*Recommended

Spare

Parts.

BE

SURE TO

PROVIDE

STOCK,

MODEL,

AND

SERIAL

NUMBERS

WHEN

ORDERING

REPLACEMENT

PARTS.

OM-853

Page

1

1

2

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

PLG2

605797

600

733

010

610

RC1

039855

601

375

Cl

031

608

R7,8

030

653

023

235

019

663

R2,5

030131

034

338

104

045

039

664

CR1

034676

020

528

027

631

PL1,2

*027

638

027 628

019 609

019

627

039

828

057 057

PLG1

039827

CAP,

twistlock

3P3W

20

amp

115

volts

CORD

SET,

115

volts

l6ga

3/c

20

ft

CONNECTOR,

clamp

-

cable

1/2

inch

RECEPTACLE,

twistlock

2P2W

RING,

mounting

-

capacitor

1-3/8x

1-7/16

CAPACITOR,

electrolytic

250

uf

25

volts

ac

RHEOSTAT,WW

l50watt

15

ohm

CASE

SECTION,

base/sides

MOUNT,

neoprene

POTENTIOMETER,

carbon

I

turn

2

watt

50K

ohm

PANEL,

control

BRACKET,

mounting

-

socket

relay

SOCKET,

tube

11

pin

RELAY,

enclosed

24

volts

dc

3PDT

NAMEPLATE

(order

by

stock,

model,

and

serial

numbers)

HANDLE,

control

box

HOUSING,

light

-

indicator

slide

base

125

volts

BULB,

slide

base

48

volts

LENS,

light

-

indicator

red

clear

KNOB,

pointer

KNOB,

pointer

2

4

2

2

2

2

2

2

2

STRAIN

RELIEF,

receptacle/plug

CABLE,

electrical

No.

20

5/c

15

ft

PLUG,

6

pin

MS-3106A-14S-6P

19

18

17

20

21

20

19

18

17

16

Figure

A

-

Complete

Assembly

TD-009

497

I

/