Page is loading ...

-1-

If you need help with your new item, contact

us at: (360) 734-1540 • FAX: (360) 676-1075

Chucks are heavy! Get assistance when

installing or removing the chuck from the

lathe. Wear heavy duty leather boots for

foot and toe protection, and keep hands and

fingers away from all pinch points. Ignoring

this warning can lead to a severe crushing

injury or finger amputation!

Model SB1314

High Precision 6" Lathe Chuck

Instruction Sheet

Specifications

• OD Clamping Range ...0.32"-6.30" (8-160mm)

• ID Clamping Range ..2.17"-5.90" (55-150mm)

• Outer Diameter ........................6.57" (167mm)

• MaximumChuckKeyTorque .........65 ft/lbs*

• MaximumJawGrippingForce....... 6744 lbs*

• MaximumSpeed .........................4000RPM**

• Two-PieceHardenedSteelJaws ............... Yes

• PlainBackMounting ................................. Yes

• JawMountingCapScrewTorque ......29 ft/lbs

• GreaseFittingLubricated ......................... Yes

• SteelConstruction .....................................Yes

• ChuckWeight ......................................... 22 lbs

• Origin ................................................... Taiwan

*Maximumhandletorqueandgrippingforce

isachievedatfulljawandscrollgearengage-

mentonly.

**ThemaximumspeedaboveisONLYpossible

whenthechuckjawsandtheworkpiecearein

completerotationalsymmetry,andwhenthe

workpieceiswithinsafeweightlimitsforthe

latheandchuck.

Installation

1. DISCONNECTLATHEFROMPOWER!

2. Mountthebackplateonthespindle.

3. Accuratelymeasuretheinsideoftheback

reliefboreonthechuck.Thisdimensionis

criticalandshouldbe±0.001''.

4. Faceandtruethediameterofthebackplate.

Makepassesacrossthefaceuntilitsentire

surfacehasbeencut.

5. Turnashoulderthatis0.015''smallerin

diameterthanthatofthechuckreliefbore.

Theshoulderheightmustalsobetallenough

sowhenthechuckismountedandisbeing

aligned,thechuckalignmentscrewshavea

surfacetojackagainst.

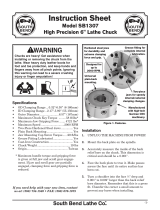

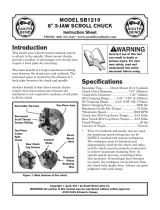

Figure 1. Features.

Four chuck

alignment set

screws

Grease fitting for

complete internal

lubrication

Universal

plain-back

mounting

Hardened steel jaws

for durability and

extreme clamping

force and grip

Two-piece

jaws for speedy

internal/external

clamping changes

Designed for

up to

4000 RPM

6. Removethebackplatefromthelatheand

placeitonaworkbench.

7. Setthechuckonthebackplate,androughly

alignthechuckusingthealignmentset

screws.

8. Useatransferpunchtomarkthebackplate.

Ifatransferpunchisnotavailable,adrill

bitofthesamesizeasthemountingholesin

thechuckcanbeused.Lightlytaponthebit,

rotateit90°andtapitagain.

9. Centerpunchthemarks.Drillandtapthe

holesforM10-1.5threads.

10. Cleanandstoneallmatingsurfacesuntil

theyareperfectlycleanandnoburrsexist.

11. InstallthechuckandsnugtheM10-1.5cap

screwsinanalternatingpatternuntilyou

reachanaltorqueof53.5ft/lbs.Alternating

thetighteningprocessavoidschuckwarpage.

Ifyouareinstallingthechuckbythreading

theM10-1.5hexboltsintothechuckfrom

thebacksideofthemountingplate,repeat

Step 11onthesebolts,andtorquethebolts

to30 ft/lbs.

12. Usinga6mmhexwrench,lightlysnugall

fourchuckalignmentsetscrews.

13. Clampa1"diametertestblankintothe

chuck,installatestindicator.Rotatethe

chuckbyhandandmeasurethechuck

concentricity.

14. Basedonyourreadings,adjustthe

alignmentsetscrewstobringthechuck

intonalalignment.Thetypicalalignment

repeatabilityforthesamediameter

workpiecewhenswappingwillbe0.0005".

Formaximumaccuracy,clampyour

workpieceinthechuckandrealignby

tighteningorlooseningthesetscrews.If

allthesetscrewsaretight,correctionof

alignmentcanalsobedonebylooseningone

ormoresetscrews.

Note: Ifthechuckmustmove0.001"orlessto

bringtheworkpieceintoalignment,itisnot

necessarytoloosenthechuckmountingbolts

beforeusingtheadjustmentsetscrews.

Operation and Safety

• Chuck Key Safety:Achuckkeyleftinthe

chuckcanbecomeadangerousprojectile

whenthespindleisstarted.Alwaysremove

thechuckkeyafterusingit.Developahabit

ofnottakingyourhandoffofachuckkey

unlessitisawayfromthemachine.

•

Disconnect Power: Disconnectthelathe

frompowerbeforeinstallingandremoving

thechuckordoinganymaintenanceor

adjustments.Accidentallathestartupcan

causesevereinjuryordeath.

•

Secure Clamping: Athrownworkpiecemay

causesevereinjuryorevendeath.When

swappingthechuckjawpositions,usea

torquewrenchtore-torquetheM8-1.25

jawmountingcapscrewsto29ft/lbs.When

clampingaworkpiece,maximumgripping

forceisattainedatfulljawandscrollgear

engagement.Ifthejawandscrollgearare

partiallyengaged,clampingforceisreduced.

•

Chuck Speed Rating: Exceedingthe

maximumratedspeedindicatedonthe

chuck,orusingexcessivespindlespeeds

withanunbalancedworkpiece,cancause

theworkpiecetobethrownfromthechuck

causingasevereimpactinjuryorevendeath.

Alwaysusetheappropriatespindlespeedfor

thejob.

•

Large Chucks: Largechucksarevery

heavyanddifficulttograsp,whichcanlead

tocrushedfingersorhandsifmishandled.

Getassistancewheninstallingorremoving

largechuckstoreducethisrisk.Protectyour

handsandtheprecisiongroundwaysby

usingachuckcradleorpieceofplywoodover

thewaysofthelathewhenservicingchucks.

•

Safe Clearances: Oftenchuckjawswill

protrudepastthediameterofthechuckand

cancontactacoolantnozzle,tooling,tool

post,ornearbycomponents.Beforestarting

thespindle,makesuretheworkpieceand

thechuckjawshaveadequateclearanceby

rotatingthespindlethroughitsentirerange

ofmotionbyhand.

-2-

Mfg.Since3/10

ModelSB1314

INSTRUCTIONS

Care & Maintenance

Foroptimumperformancefromyourchuck,

followthemaintenanceschedulebelow,and

neverhammeronthechuck,jaws,oraworkpiece

clampedinthechuck.Neversubjectthechuckto

abrasives,ame,orwater.

Daily:

• Check/correctloosemountingbolts.

• Useavacuum,rag,orbrushtocleanthe

chuckafteruse.Neveruseairpressureto

cleanchipsawayfromachuck.

• Wipethechuckdownwithathincoatofway

oiltopreventsurfacerust.

• Greasethechuckttingwithonetotwo

pumpsofNLGI#2grease.

Ifthechuckeverbecomesstifftooperate,itmay

havebeencontaminatedwithmetalchipsor

abrasivesfromneglectorpoorservicepractices.

Thechuckmustbedissembled,cleaned,andre-

lubricated.

To disassemble the chuck for a full cleaning

and lubrication service:

1. DISCONNECTLATHEFROMPOWER!

2. Markthechuckandthemountingplate

wheretheymatetoensurethatwhen

reassembledbothhalveslineup.Next,

unboltthechuckandseparatebothhalves.

3. Insertandrotatethechuckkey

counterclockwiseuntilthescroll-gearhas

releasedallthreejawsfromthechuck.

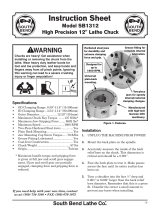

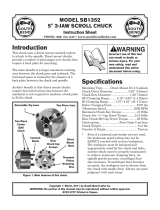

4. Usinga4mmand6mmhexwrench,a#1

standardscrewdriver,andaratchetwitha

7mmsocket,startat#1anddisassemblethe

chuckinthesequenceshowninFigure 2.

Always disconnect

machine from power before

performing maintenance or

serious personal injury may

result.

!

5. Usingmineralspirits,cleananddryall

components.Inspectallbores,teeth,pins,

andmatingsurfacesforwear,burrs,galling,

rust,orcracks.

6. Withoutchangingthedimensionofanypart,

useawirebrush,emerycloth,ordressing

stones,toremoveallrust,burrs,andany

highspotscausedbygalling.

7. CoatallpartswithanyautomotiveNLGI#2

grease,andcarefullyreassemblethechuck

inthereverseordershowninFigure 2.

8. Rotatethechuckkeyclockwiseuntilyou

seethetipofthescroll-gearleadthreadjust

begintoenterjawguide#1.

9. Insertjaw#1intojawguide#1,andholdthe

jawagainstthescroll-gear.

10. Rotatethechuckkeyclockwiseoneturnto

engagethetipofthescroll-gearleadthread

intothejaw.Pullthejaw;itshouldbelocked

intothejawguide.

11. Installtheotherjawsinthesamemanner,

andinstallanewgreasettingifballor

nippleleakgrease.

12. Lineupthetimingmarkonthechuckand

themountingplate,andfastenbothhalves

bytighteningandtorquingthefastenersas

outlinedinStep 11 in Installation.

2

3

6

4

5

1

Figure 2. Chuck sequence of disassembly.

7

Note: Each jaw is marked

1, 2, or 3 to correspond

to its marked slot in the

chuck

Mfg.Since3/10 ModelSB1314

-3-

INSTRUCTIONS

Copyright © March, 2010 By South Bend Lathe Co. Revised February, 2011 (CR)

WARNING: No portion of this manual may be reproduced in any shape or form

without the written approval of South Bend Lathe Co.

#CR12663 Printed in Taiwan.

www.southbendlathe.com

Troubleshooting

Ifyouneedreplacementparts,orifyouareunsurehowtodoanyofthesolutionsgivenhere,feelfree

tocallusat(360)734-1540.

Symptom Possible Cause Possible Solution

Thechuckhas

hardspotsorbinds

completely.

1.

Jawisinwrongposition.

1.

Reinstalljawsincorrectorderandpositiononscroll

gear.

2.

Lackoflubrication,rust,burrs,or

metalshavingsinsideofchuck.

2.

Disassemble,de-burr,clean,andlubricatechuck.

3.

Brokentoothonthepinionorthe

scrollgear.

3.

Disassemble,replacebrokenpartsifpossible,and

reassemblechuck.

Theworkpieceslips

inthejaws.

1.

Incorrectjaworworkpiececlamping

position.

1.

Repositionjawsandworkpieceformaximumscroll

gearandjawengagementisachieved.

2.

Insufcientpinionandscrollgear

torque.

2.

Tightenchuckkeyto65ft/lbs.

3.

Cuttingoverload.

3.

Reducecuttingdepthorfeedrate.

4.

Chuckisbindingbeforefull

clampingisachieved.

4.

Disassembleandservice/rebuildchuck.

Clampingaccuracy

ispoor.

1.

Workpieceisimproperlyclampedor

jawislooseorincorrectlyseated.

1.

Removejaws,clean,de-burr,andre-installwithjaw

mountingcapscrewstorquedto29ft/lbs.

2.

Chuckloose,mountingisoffcenter,

oritisimproperlyseated.

2.

Removechuck,cleanandde-burrmounting,andre-

install,ormachineanewmountingplate.

1

13

10

12

11

6

8

9

7

4

3

5

2

15

14

16

17

REF PART # DESCRIPTION

1 PSB1314001 GREASE FITTING

2 PSB1314002 TOP JAW

3 PCAP33M CAP SCREW M5-.8 X 12

4 PSB1314004 BACK COVER

5 PSB1314005 LOCK PIN

6 PSB1314006 PINION

7 PSB1314007 SCROLL GEAR

8 PSB1314008 CHUCK KEY W/SPRING

9 PSB1314009 COMPRESSION SPRING

10 PCAP171M CAP SCREW M10-1.5 X 80 BLK C12.9

11 PCAP172M CAP SCREW M8-1.25 X 20 BLK C12.9

12 PAW08M HEX WRENCH 8MM

13 PSB1314013 BOTTOM JAW SET OF 3

14 PSB1314014 CHUCK BODY

15 PB174M HEX BOLT M10-1.5 X 35 BLK C12.9

16 PSS108M SET SCREW M12-1.75 X 10

17 PSB1314017 FLANGE PIN

Parts Diagram Parts List

Please Note: We included this breakdown for service purposes only. Since many of the parts shown are machined to each

individual chuck, they are not available as replacement items.

-4-

Mfg.Since3/10

ModelSB1314

INSTRUCTIONS

/