Bunn TCD - 1/2 User manual

- Category

- Water dispensers

- Type

- User manual

This manual is also suitable for

Bunn TCD - 1/2 is a commercial iced tea dispenser designed to mix liquid tea concentrate with water to produce iced tea by the glass or pitcher. It can be connected to a cold water system with operating pressure between 30 and 90 psi from a ½" or larger supply line and has a 1/4" flare water inlet fitting. The dispenser allows for strength adjustment of the tea by turning the adjustment screw clockwise or counterclockwise. It can be used with concentrate stored inside the dispenser or outside with a hose connection.

Bunn TCD - 1/2 is a commercial iced tea dispenser designed to mix liquid tea concentrate with water to produce iced tea by the glass or pitcher. It can be connected to a cold water system with operating pressure between 30 and 90 psi from a ½" or larger supply line and has a 1/4" flare water inlet fitting. The dispenser allows for strength adjustment of the tea by turning the adjustment screw clockwise or counterclockwise. It can be used with concentrate stored inside the dispenser or outside with a hose connection.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

Bunn TCD - 1/2 User manual

- Category

- Water dispensers

- Type

- User manual

- This manual is also suitable for

Bunn TCD - 1/2 is a commercial iced tea dispenser designed to mix liquid tea concentrate with water to produce iced tea by the glass or pitcher. It can be connected to a cold water system with operating pressure between 30 and 90 psi from a ½" or larger supply line and has a 1/4" flare water inlet fitting. The dispenser allows for strength adjustment of the tea by turning the adjustment screw clockwise or counterclockwise. It can be used with concentrate stored inside the dispenser or outside with a hose connection.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Bunn TCD-2 Operating instructions

-

Bunn tcd-1/2 User manual

-

Bunn ThermoFresh Operating instructions

-

Bunn TDO-N-4.0 User manual

-

Bunn TDO-N-4.0LP User manual

-

Bunn TDO-4 User guide

-

Bunn TCD-2 w/2 Nozzles & Solid Lid Installation guide

-

Bunn TDR-3 User manual

-

Bunn TDO-4T User guide

-

Bunn TDO-4T Operating instructions

Other documents

-

Valley View Industries 90-CC Installation guide

Valley View Industries 90-CC Installation guide

-

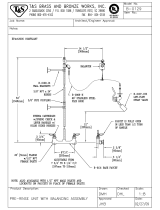

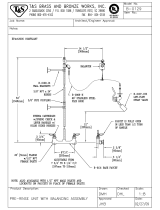

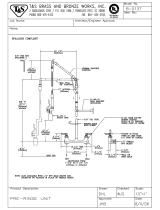

T & S Brass & Bronze Works B-0129 Datasheet

T & S Brass & Bronze Works B-0129 Datasheet

-

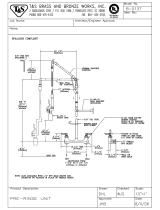

T & S Brass & Bronze Works B-0137 Datasheet

T & S Brass & Bronze Works B-0137 Datasheet

-

Nedis SEC-CABLE10 Datasheet

-

Bunn-O-Matic ThermoFresh Operating instructions

-

Bunn-O-Matic Titan Server Operating instructions

-

Bunn-O-Matic TD4T Operating instructions

-

Bunn-O-Matic JDF-2 Operating instructions

-

Colston B424325 User manual

Colston B424325 User manual

-

Bunn-O-Matic JDF-4 Operating instructions