Page 6 IM-800

LOCATION

If unit is to be located under an overhang, there should be a

minimum of 36” clearance and provisions made to deflect the

water discharge air out from the overhang. If the outdoor unit

is mounted above the air handler, the maximum lift should not

exceed 70’ (suction line). If the air handler is mounted above

condensing unit, the lift should not exceed 50’ (liquid line.).

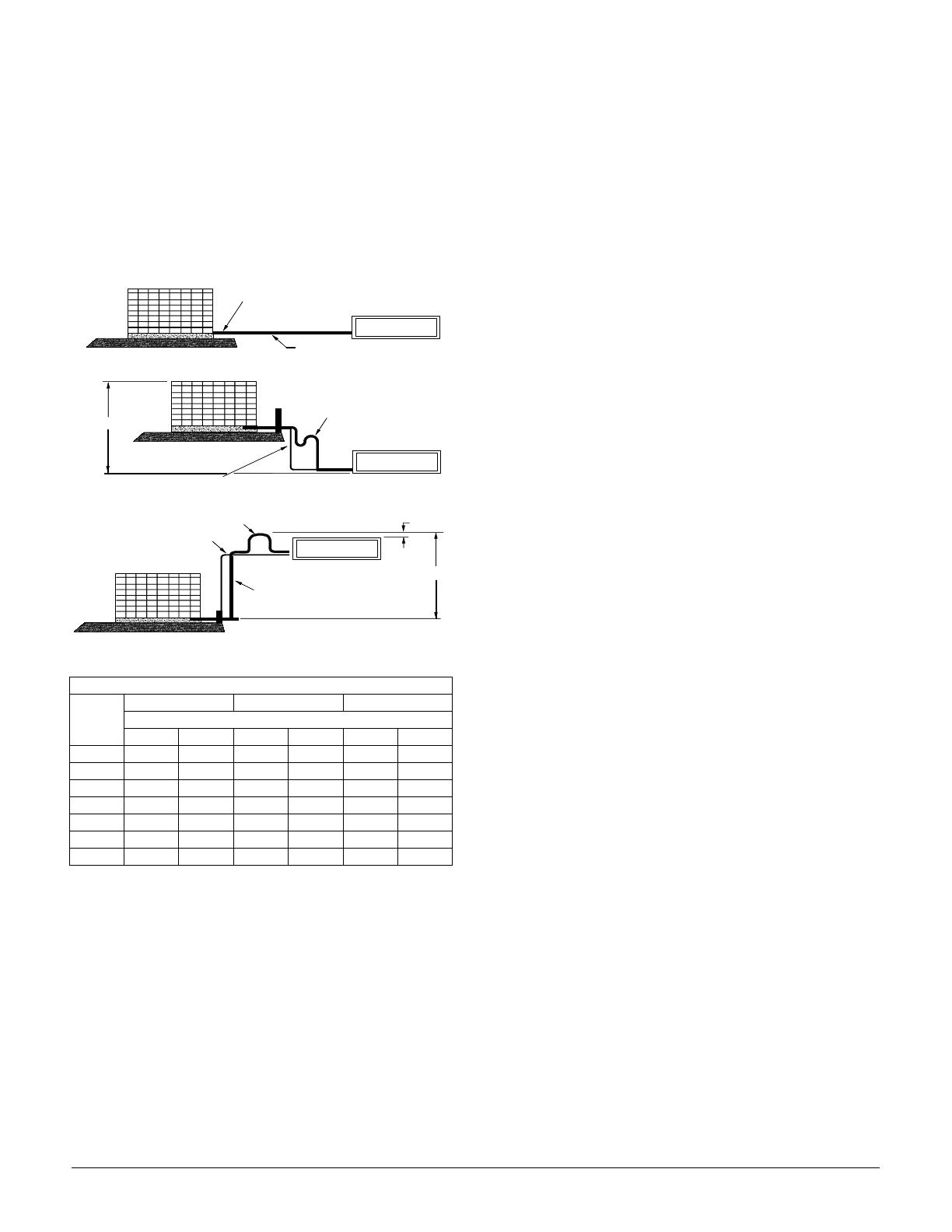

Refer to Figure 3 and Table 2 for maximum refrigerant line

lenghts.

Figure 3. Maximum Refrigerant Line Lengths

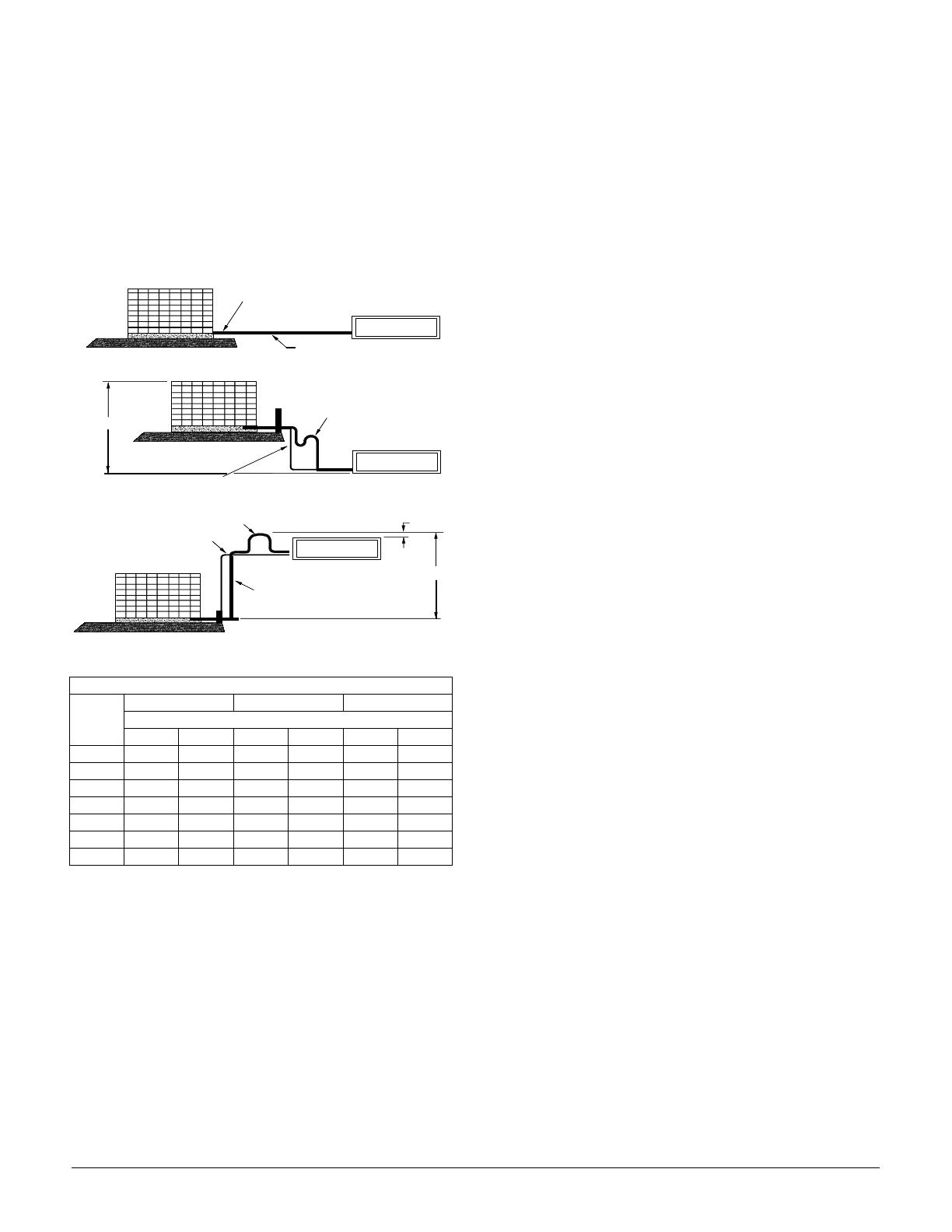

Table 2: Maximum Refrigerant Line Lengths

* 7/8" required for full ratings

** 1 1/8" required for full ratings

The condensing unit must be mounted on a solid, level founda-

tion (i.e. pre-formed concrete slab or other suitable base). For

rooftop application, verify that the building construction can

support the weight and that proper consideration is given to the

weather-tight integrity of the roof. The condensing unit con-

tains moving components and can vibrate. Therefore, sound is

also a consideration in rooftop application. Since this unit dis-

charges warm condenser air from the top with cooler air being

drawn in three sides, plantings can be made in relatively close

proximity to the unit. However, debris on the fan coil surface

reduces product efficiency. Avoid lawn mower discharge

toward the unit.

ELECTRICAL

Electrical installation will consist of power supply wiring to

the condensing unit, as well as control wiring between thermo-

stat, indoor unit and the condensing unit as shown on wiring

diagram. All wiring must be in accordance with National

Electrical Code and/or local codes that may apply.

The condensing unit rating plate lists pertinent electrical data

necessary for the selection of proper size electrical service and

over-current protection. The installer should make the owner

familiar with the location of the over-current protection, the

proper size for this application, and the proper procedure for

disconnecting power service to the unit.

The condensing unit control wiring requires a 24 Volt mini-

mum 25 VA service from the indoor transformer as shown on

the wiring diagram.

REFRIGERANT TUBING

Use only refrigerant grade (dehydrated and sealed) copper tub-

ing of the size indicated in Table 1 to interconnect the condens-

ing unit with the indoor evaporator. Take extreme care to keep

the refrigerant tubing clean and dry prior to and during instal-

lation.

Do not remove plugs from ends of tubing until connection is

ready to be made. Suction line insulation is necessary to pre-

vent condensation from forming on and dropping from suc-

tion line. Generally 3/8" wall thickness of Armflex or

equivalent is satisfactory. In severe applications (hot, high

humidity areas) greater thickness may be required. Apply suc-

tion line insulation by sliding it on the sealed tubing before

cutting and making connections.

EVAPORATOR COIL

Suction and liquid lines are under pressure. Point lines away

from persons and obects that can be damaged. Use extreme

care when removing caps. Use fittings on the liquid line to

remove pressure.

Do not remove caps until installation is complete and final

connections are to be made.

Field Connection to the Valve and Valve Opening

1. Cut tubing square. Make sure it is round and free of burrs

at the connecting ends. Clean the tubing to prevent con-

taminants from entering the system.

2. Wrap a wet rag around the copper valve stub before braz-

ing.

3. Braze or silver solder the joint.

4. After brazing, quench with a wet rag to cool the joint.

Evacuate and charge the connecting lines as outlined in this

manual.

5. Remove the valve top cap. It is important to keep the cap

in a clean area to provide proper sealing once replaced.

6. Using a standard L shaped Allen wrench, break open the

valve body. To expedite opening the valve body after it is

broken, use a ratchet wrench with a short Allen stub.

Please note that it is normal to see oil on the valve stem

body once the cap is removed.

7. Replace the valve cap and tighten with a wrench, making

sure that the the cap is sealed.

REFRIGERANT LINE LENGTH (Ft)

Cond

Unit

Tons

0-24 25-49 50-74***

Line Diameter (In. OD)

Suct Liq Suct Liq Suct Liq

1 1/2 5/8 1/4 3/4 3/8 3/4 3/8

2 5/8 1/4 3/4* 3/8 3/4 3/8

2 1/2 3/4 3/8 3/4** 3/8 7/8 3/8

3 3/4 3/8 3/4** 3/8 7/8 3/8

3 1/2 3/4 3/8 7/8** 3/8 1 1/8 3/8

4 7/8 3/8 1 1/8 3/8 1 1/8 3/8

5 7/8 3/8 1 1/8 3/8 1 1/8 3/8

CONDENSING UNIT

PITCH SUCTION LINE TOWARD OUTDOOR

UNIT 1/2" FOR EVERY 10' OF LINE

EVAPORATOR BLOWER

LIQUID LINE

CONDENSING UNIT

EVAPORATOR BLOWER

70' MAX

ADDITIONAL SUCTION LINE OIL

TRAP FOR EACH 20' RISE OF PIPE

LIQUID LINE

SUCTION LINE OIL TRAPS WHEN INDOOR UNIT

IS 4 FEET OR MORE BELOW OUTDOOR UNIT

CONDENSING UNIT

EVAPORATOR BLOWER

LIQUID LINE

SUCTION LINE

INVERTED LOOP

50' MAX

8'